Granular starch lipid compound with low glycemic index, and preparation method thereof

A low-glycemic index and lipid complex technology, which is applied in food science, the function of food ingredients, food ultrasonic treatment, etc., can solve the problem of reducing the digestion rate of starch-lipid complex and unfavorable wide application of starch-lipid complex , Low product yield and other issues, to achieve the effect of easy cleaning and purification, high efficiency of production equipment, and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

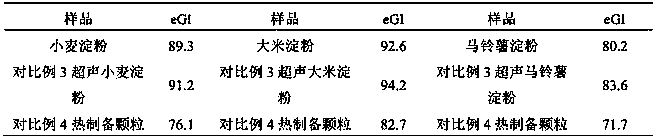

Embodiment 1

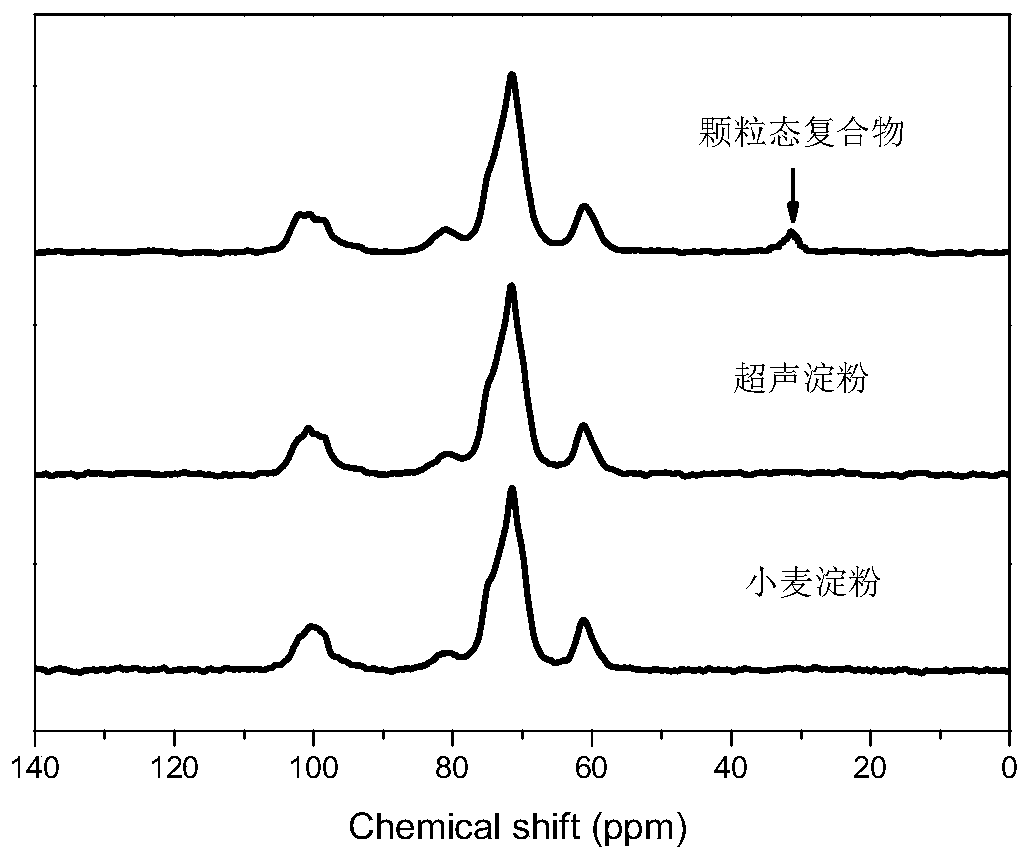

[0049] This embodiment relates to a method for ultrasonic treatment to prepare granular starch-lipid complexes with low glycemic index, comprising the following steps:

[0050] (1) take by weighing 100g dry base wheat starch, fully mix with distilled water, obtain the wheat starch suspension that mass fraction is 5%;

[0051] (2) Take 6g of oleic acid, disperse and dissolve it with 2 times the volume of dehydrated alcohol, add it to the wheat starch suspension, mix the wheat starch and oleic acid evenly, and obtain the wheat starch lipid mixture;

[0052] (3) Wheat starch lipid mixture is placed in constant temperature ultrasonic treatment equipment and carries out ultrasonic treatment, under the condition of 40kHz, 240W ultrasonic treatment 20min, keep composite reaction system temperature at (T o -5) at about ℃, stirring constantly to obtain the ultrasonically treated wheat starch lipid mixture;

[0053] (4) Cool the ultrasonically treated wheat starch lipid mixture to room...

Embodiment 2

[0057] A method for ultrasonic treatment to prepare low-glycemic index granular state-starch-lipid complex, comprising the steps:

[0058] (1) take by weighing 100g dry basis potato starch, fully mix with distilled water, obtain the potato starch suspension that massfraction is 6%;

[0059] (2) take 10g oleic acid, after dispersing and dissolving with dehydrated alcohol of 2 times volume, add in the potato starch suspension, potato starch and oleic acid are mixed uniformly, obtain the potato starch lipid mixture;

[0060] (3) the potato starch lipid mixture is placed in constant temperature ultrasonic treatment equipment and carries out ultrasonic treatment, under the condition of 40kHz, 400W ultrasonic treatment 30min, keep composite reaction system temperature at (T o -10) ℃ or so, constantly stirring, obtain the ultrasonic treatment potato starch lipid mixture;

[0061] (4) Cool the ultrasonically treated potato starch lipid mixture to room temperature, centrifuge at 3000r...

Embodiment 3

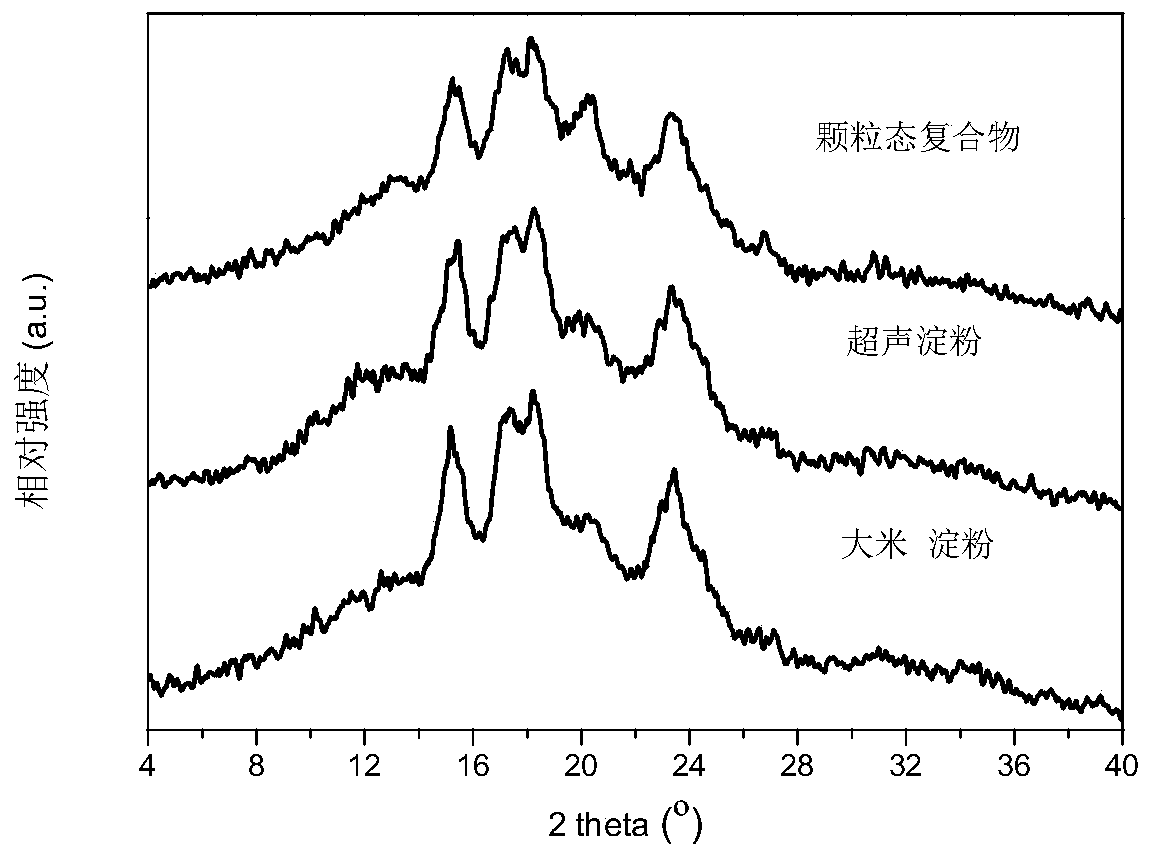

[0065] A method for preparing low-glycemic index granular starch-lipid complexes by ultrasonic treatment, comprising the steps of:

[0066] (1) take by weighing 100g dry base rice starch, fully mix with distilled water, obtain the rice starch suspension that mass fraction is 10%;

[0067] (2) Take by weighing 15g oleic acid, after dispersing and dissolving with dehydrated alcohol of 3 times volume, add in the rice starch suspension, rice starch and oleic acid are mixed evenly, obtain the rice starch lipid mixture;

[0068] (3) The rice starch lipid mixture is placed in a constant temperature ultrasonic treatment device for ultrasonic treatment, and ultrasonic treatment is performed for 50min under 20kHz, 500W conditions, and the temperature of the composite reaction system is kept at (T o -3) at about ℃, stirring constantly to obtain a mixture of ultrasonically treated rice starch and lipid;

[0069] (4) Cool the ultrasonically treated rice starch lipid mixture to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com