Novel technique for producing 2,6-dichloro diphenylamine

A technology of dichlorodiphenylamine and a new process, applied in rearrangement reaction preparation, organic chemistry, etc., can solve the problems of large amount of wastewater, environmental impact, no wastewater treatment, etc., achieve clean production process, lower total cost, and simple method effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

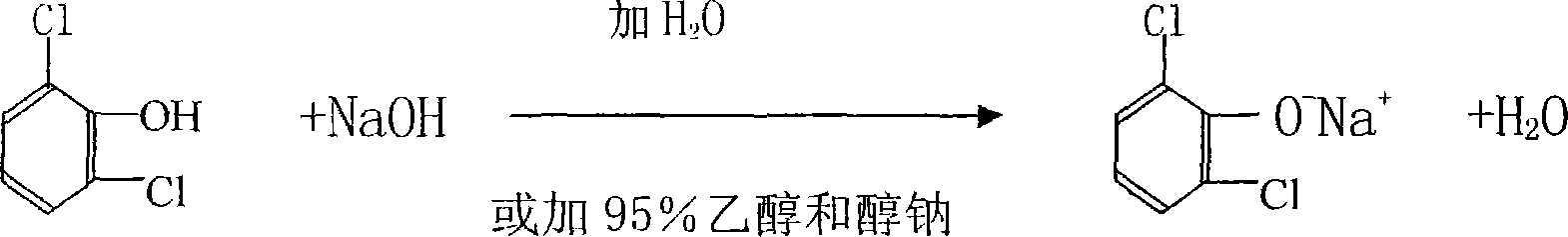

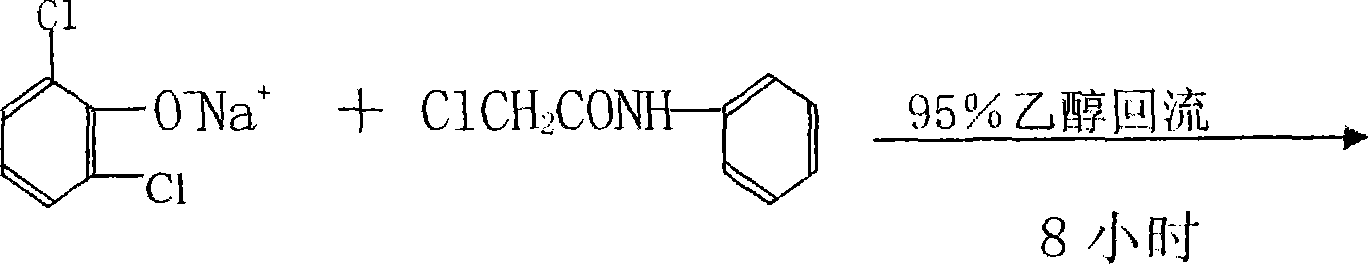

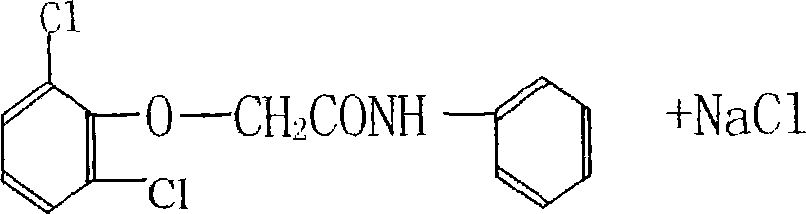

Method used

Image

Examples

Embodiment 1

[0033] Chloroacetylation step: Add 30ml of industrial toluene (leave 10ml of aniline measuring cylinder for washing) and 10g of industrial aniline (10g÷93=0.1075M) into a 250ml three-necked flask equipped with a stirring reflux condenser and a thermometer, stir, and add with a dropper 12.8g (9ml) chloroacetyl chloride (12.8÷1.42=9ml, 12.8÷113=0.113M), when adding about 1ml of the first part, there will be white smoke, and the temperature will rise at the same time, block the mouth of the thermometer with a thermometer, when the white smoke After dissipating, add about 1-2ml of the second part, depending on the reading of the thermometer, do not exceed 60°C, and operate in this way until the addition is completed. When about half of the amount is added, because the temperature rise stops, it can be added directly. The process of adding chloroacetyl chloride, time No limit, as long as the temperature is less than 60°C and there is no white mist, gradually increase the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com