Patents

Literature

42 results about "Sodium Glycollate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium glycolate is the sodium salt of carboxymethyl ether. Starch glycolates are from potato, rice, wheat or corn origin. Sodium glycolate is a white to off-white, tasteless, odorless, relatively free flowing powder.

Coal washing and desulfurizing agent composition and preparation method thereof

The invention relates to an adjuvant for coal washing and desulfurizing. The adjuvant is prepared from the following raw materials in parts by weight: 20-25 parts of sodium hypochlorite NaClO, 12-15 parts of ammonium persulfate (NH4)S2O8, 8-12 parts of sodium glycollate HOCH2COONa, 6-10 parts of sodium acetate CH3COONa, 7-12 parts of potassium citrate K3C6H5O7H2O, 5-9 parts of sodium gluconate, 5-9 parts of edetic acid, 7-12 parts of potassium permanganate KMnO4, 25-32 parts of methanol CH3OH, 22-30 parts of triethanolamine (HOCH2CH2)3N, 12-16 parts of sodium dichromate Na2Cr2O7, 3-5 parts of polyaluminum ferric chloride PAFC,1-2 parts of urea CON2H4, 1-2 parts of polyacrylamide PAM, 0.5-0.8 part of sodium dodecyl benzene sulfonate C18H29NaO3S, 0.2-0.4 part of dispersing agent JFC and 100-120 parts of water. The adjuvant disclosed by the invention is simple to use, stable in performance and free of large investment and transformation equipment; the removal rate of inorganic sulfur and organic sulfur is more than 70 percent; and the removal rate of nitric oxides is more than 70 percent.

Owner:LANZHOU XINXING NEUTRAL CLEANING TECH

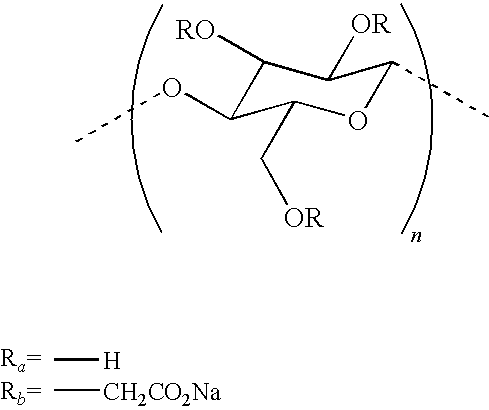

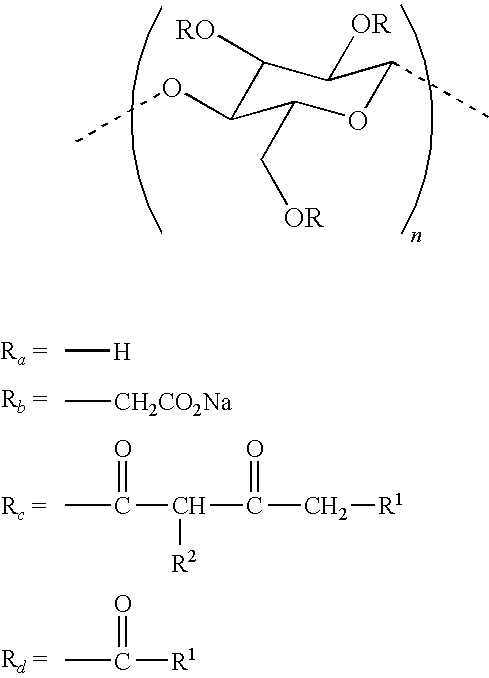

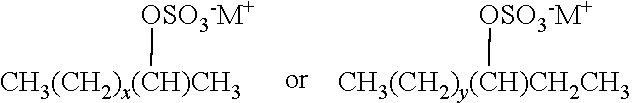

Laundry Detergent Composition Comprising a Highly Water-Soluble Carboxymethyl Cellulose Particle

ActiveUS20110034365A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCarboxymethyl celluloseWater soluble

A solid laundry detergent composition having: (a) detersive surfactant; and (b) from 0.05 wt % to 20 wt % carboxymethyl cellulose particle, wherein the carboxymethyl cellulose particle: (i) from 70 wt % to 98 wt % carboxymethyl cellulose having an average degree of carboxymethyl substitution of from 0.6 to 0.9; (ii) from 2 wt % to 12 wt % water; (iii) optionally from 0 wt % to 4 wt % sodium glycolate; and (iv) optionally from 0 wt % to 4 wt % sodium chloride.

Owner:THE PROCTER & GAMBLE COMPANY

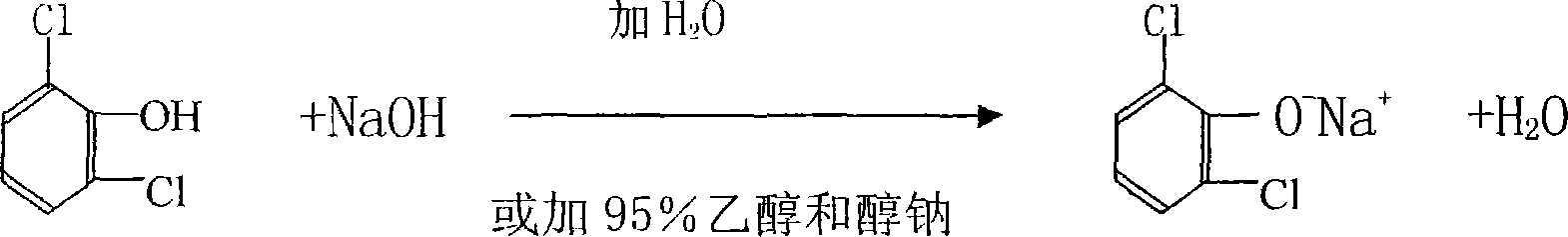

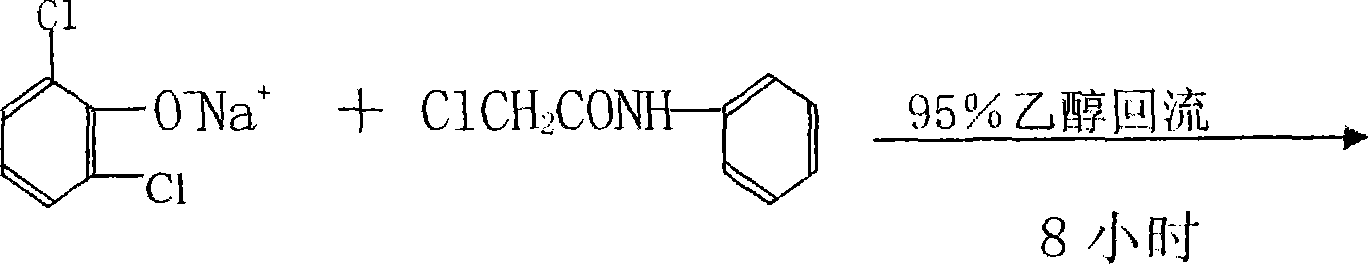

Novel technique for producing 2,6-dichloro diphenylamine

ActiveCN101230007ARelieve pressureSave moneyPreparation by rearrangement reactionsWastewaterAcetylation

The invention relates to a new process for producing 2, 6-dichloro diphenylamine, which includes a chloroacetylization step, an etherification step, rearrangement and post-processing steps; wherein, the reaction formula of the final product, 2, 6-dichloro diphenylamine, is shown as the right: The process of the invention causes no effluent, and the biproducts such as the sodium glycollate, the sodium chloride, etc during the reaction are recycled and transferred into reused resources. Moreover, the production technology is clean and environmentally friendly with no wastes and reduced total cost, and no catalyst and sodium carbonate are needed.

Owner:HENAN DONGTAI PHARM

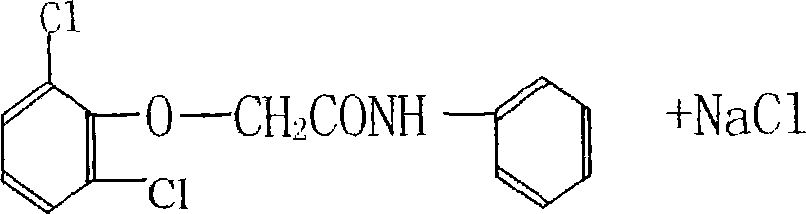

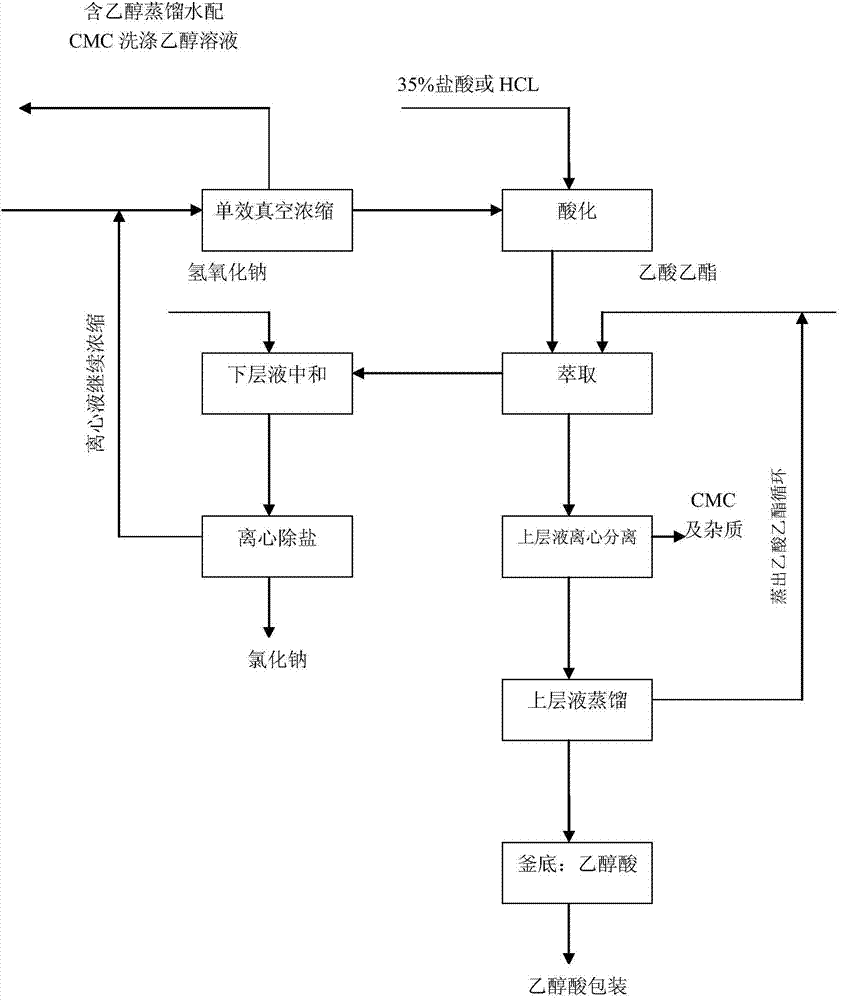

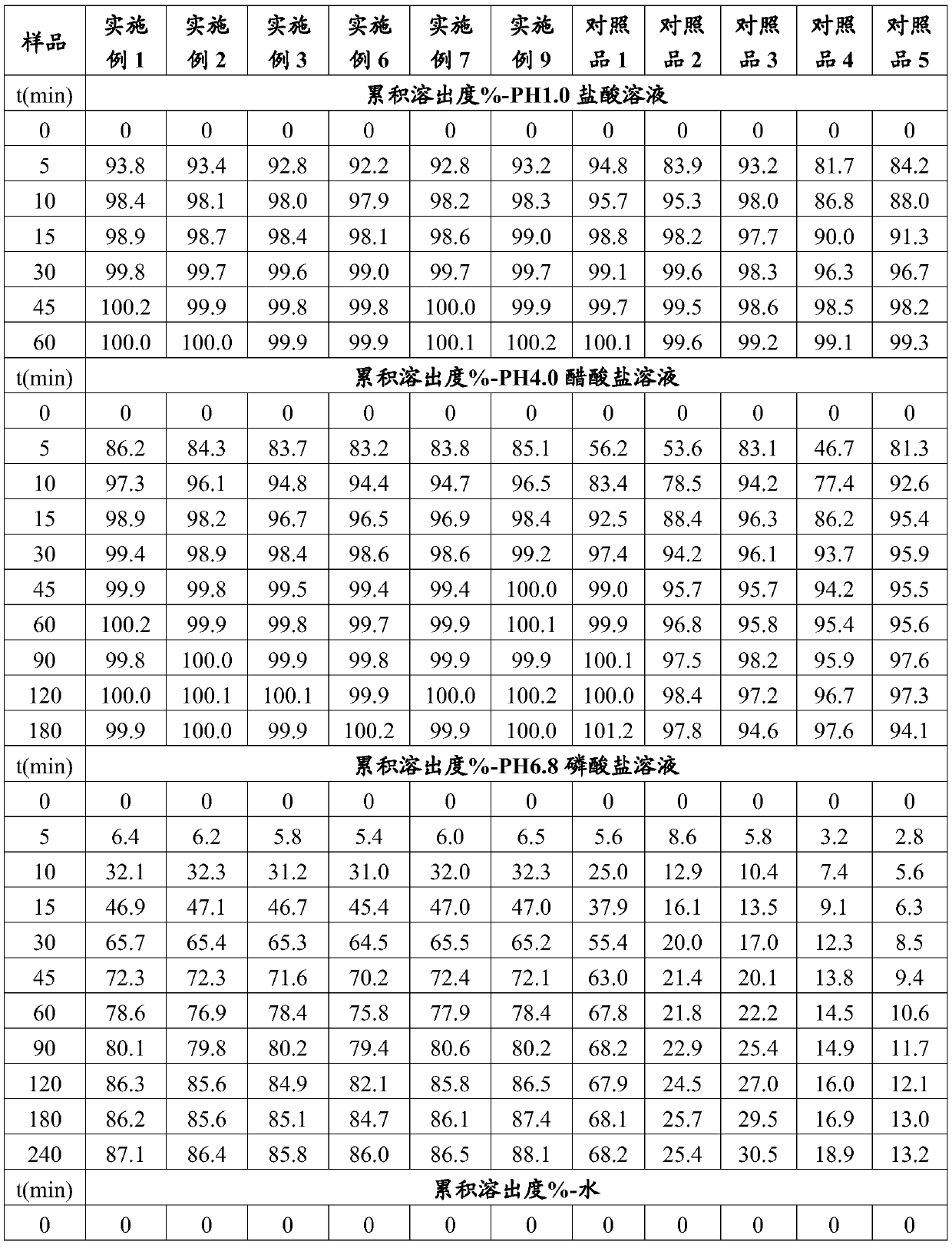

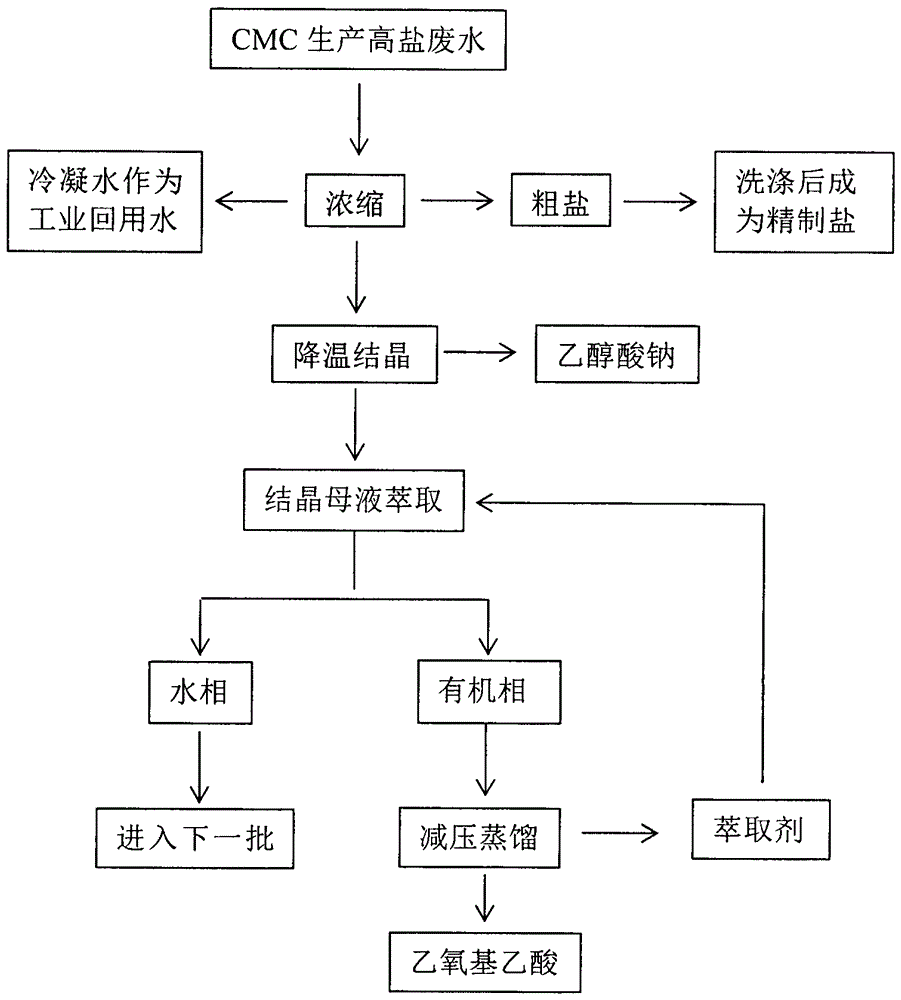

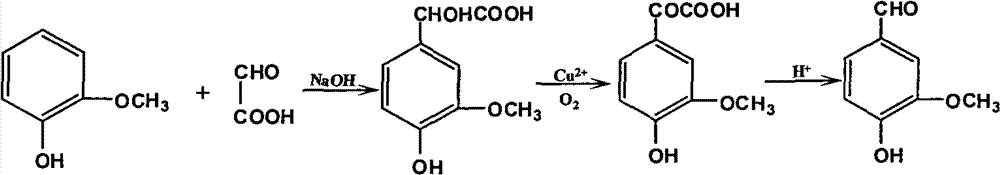

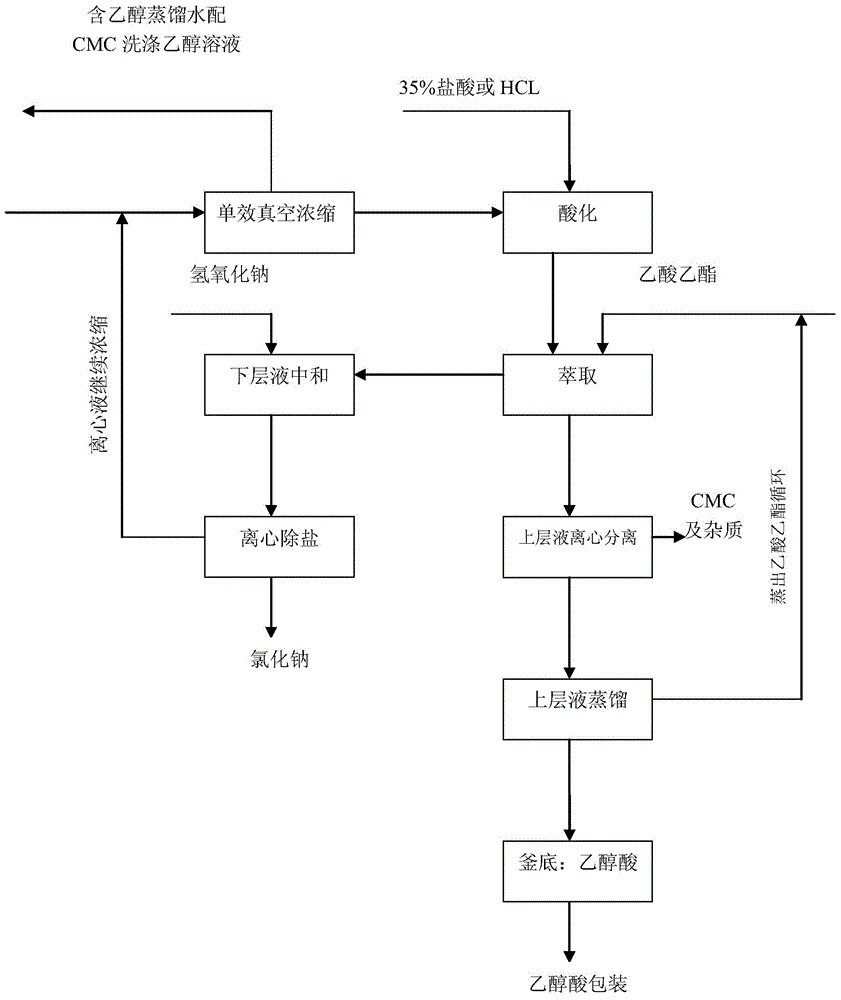

Recycling processing technology for high-salt wastewater during carboxymethyl cellulose production

ActiveCN104370312AAvoid mutual interferenceHigh purityMultistage water/sewage treatmentNature of treatment waterEvaporationEthoxyacetic acid

The invention discloses a recycling processing technology for high-salt wastewater during carboxymethyl cellulose production. The processing technology combines extraction and graded crystallization technologies. In the graded crystalization process, through multi-effect (or mechanical recompression) evaporation crystallization, crude salt is recovered from wastewater and condensate water is evaporated, the condensate water reaches the industrial reuse water standard, and refined salt is prepared from crude salt through washing; and then through cooling crystallization, sodium glycollate crystal is separated out, the crystallization mother liquid is used for a next crystallization process, so that closed cycle is realized. In the above graded crystallization process, ethoxyacetic acid is obtained by performing extraction separation on a concentrated liquid, and the viscosity is reduced. The method is simple in operation, low in cost and high in separation recovery rate. The whole processing technology employs closed cycle, has no pollutants, and is easy for industrialization. The technology helps to solve the high-salt wastewater processing problem in the carboxymethyl cellulose production process, also helps to realize the recycling processing purposes of turning harm into good and changing wastes into valuables, and has substantial economic, social and environment benefit.

Owner:JIANGNAN UNIV

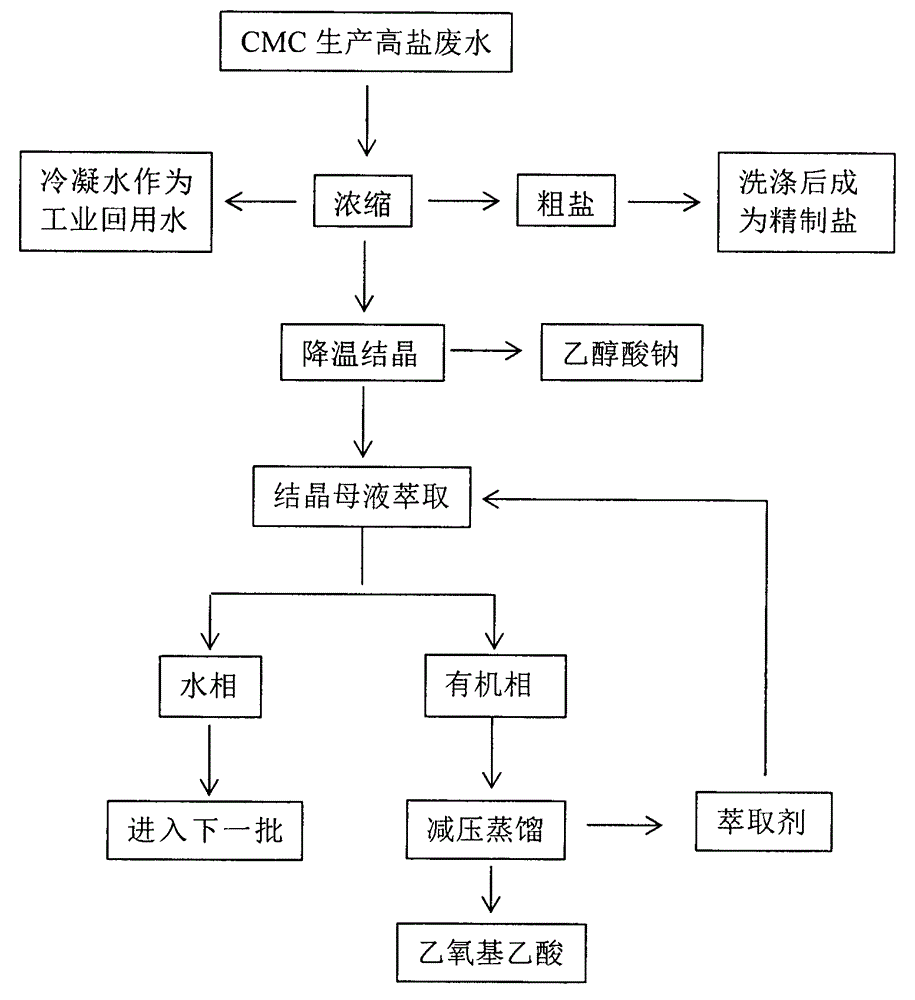

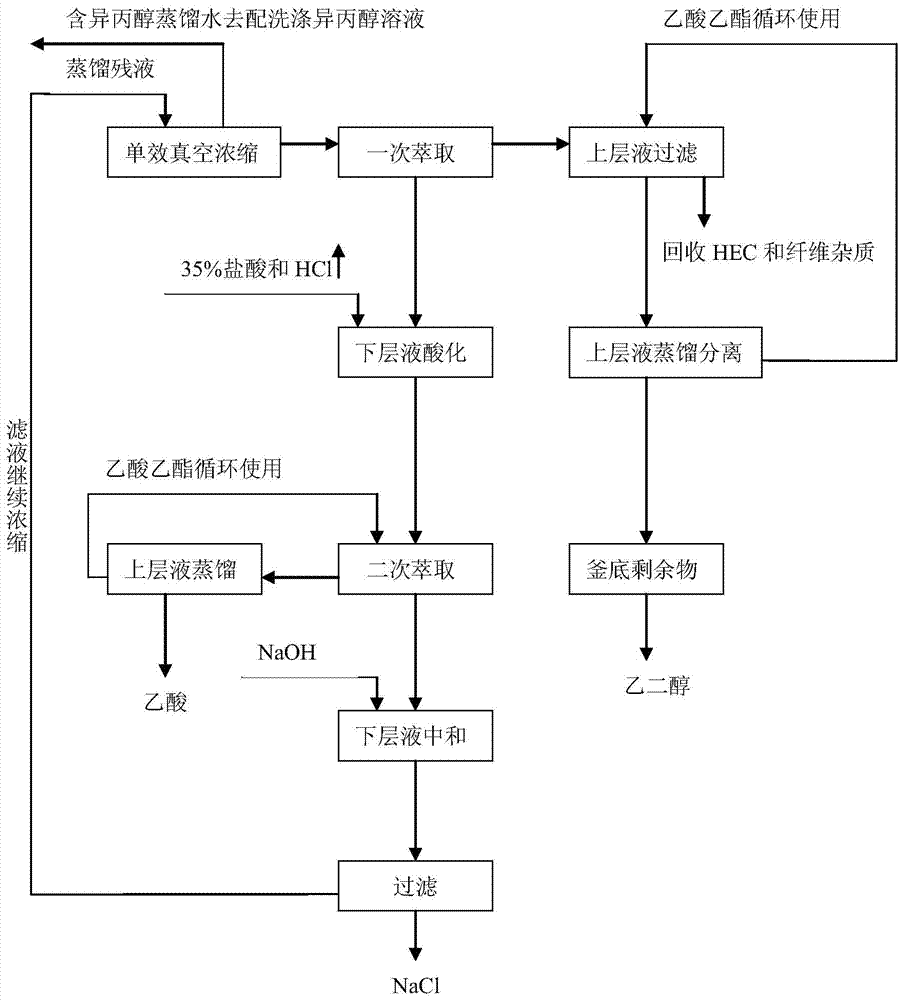

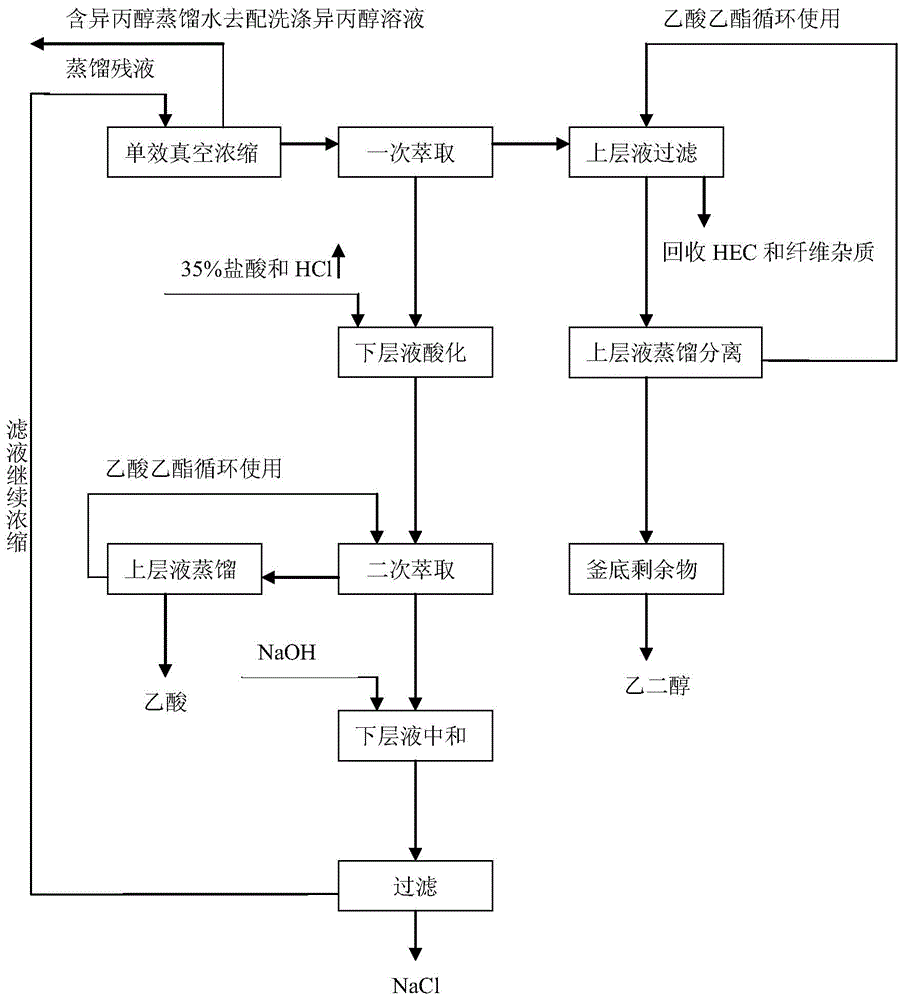

Treatment method adopting cellulose ether solvent to recycle vinasse

The invention discloses a treatment method adopting cellulose ether solvent to recycle vinasse, which comprises the following steps: during the production process of cellulose ether, an organic solvent medium is adopted to distill the vinasse generated during the recycling process to a supersaturated solution or until the moisture is completely evaporated to dryness, ethyl acetate is adopted to perform first extraction so as to filter and separate lost cellulose ether, the ethyl acetate is distilled for recycling, and the leftover after distillation is a secondary product of etherifying agent; first extraction is performed on the subnatant, quantitative hydrogen chloride is added for acidification, then ethyl acetate is added for secondary extraction so as to recycle acetic acid or glycollic acid, the ethyl acetate is distilled and recycled for recycling, the leftover after distillation is acetic acid or sodium glycollate, secondary extraction is performed on the subnatant, alkali is adopted for neutralization, concentration is performed continuously, and sodium chloride is filtered and recycled. According to the invention, as less organic solvent in the concentrated solution is evaporated, and the organic solvent can be used together with a washing solution in the production technology of cellulose ether, zero emission of the three wastes during the production process of the cellulose ether is realized, waste material is changed into things of value, and higher economic benefit is obtained.

Owner:湖北博斐逊生物新材料有限公司

Desulfurization assistant

InactiveCN103343028ATo achieve the purpose of coal washing and desulfurizationSettling fastSolid fuelsBenzoic acidSodium acetate

The invention discloses a desulfurization assistant. The desulfurization assistant is prepared from the following components in parts by weight: 10-20 parts of sodium hypochlorite, 5-10 parts of potassium hypochlorite, 10-12 parts of ammonium persulfate, 2-6 parts of sodium glycollate, 5-8 parts of potassium acetate, 5-8 parts of sodium citrate, 3-10 parts of ethylenediamine tetraacetic acid, 2-6 parts of potassium permanganate, 2-5 parts of formic acid, 5-10 parts of sodium carboxymethyl cellulose, 5-10 parts of benzoic acid, 2-5 parts of potassium dichromate, 3-5 parts of urea, 2-5 parts of polyacrylamide, 2-5 parts of alcohol, 0.1-0.5 part of sodium dodecyl benzene sulfonate, 0.2-0.8 part of Twain 20 and 150-200 parts of water. The desulfurization assistant disclosed by the invention has the advantages of being good in desulfurization effect and free of environment pollution.

Owner:WUXI JINSHENG AUX FACTORY

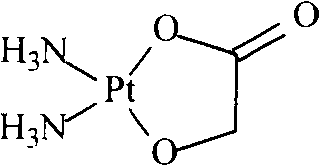

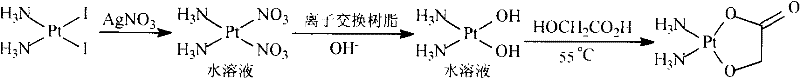

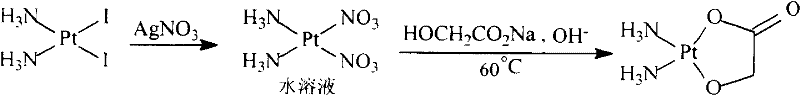

Preparation method of nedaplatin with extremely low silver content

InactiveCN102417522AGood process reproducibilityEase of industrial productionPhotography auxillary processesGroup 8/9/10/18 element organic compoundsSilver ionPt element

The invention relates to a preparation method of nedaplatin with an extremely low silver content. The preparation method comprises the following steps: allowing cis-diiododiammine platinum to react with silver nitrate at 10-90 DEG C for 0.5-8 hours, filtering, adding the filtrate in an electrolytic cell composed of an anode (a graphite rod) and a cathode (stainless steel), adjusting the electrolytic voltage and current to allow residual silver ions in the solution to be reduced and precipitated, filtering, adding sodium glycollate into the filtrate, adjusting the pH to become neutral, reacting at 40-70 DEG C for 3-10 hours, performing reduced-pressure concentration and crystallization, filtering, washing the filter cake, drying to obtain the nedaplatin with an extremely low silver content. The reaction molar ratio of cis-diiododiammine platinum and silver nitrate is 1:2, and the reaction molar ratio of cis-diiododiammine platinum and sodium glycollate is 1:1. The electrolytic voltage is 0.6-3.0 V, and the current is 5-200 mA. The nedaplatin prepared by the method of the invention has a silver content of less than 1.0 ppm; the content of nedaplatin in the product is more than 99.00%, and the content of related substances is less than 1.00%; the product quality is stable.

Owner:NANJING UNIV OF TECH

Method for extracting sodium glycollate from CMC wastewater

InactiveCN106008201AEfficient removalHigh economic valueOrganic compound preparationWater contaminantsChemical treatmentChemical products

The invention relates to a method for extracting sodium glycollate from CMC wastewater. The method specifically comprises the following steps of extracting a mother solution, evaporating CMC salt-containing wastewater by utilization of an MVR evaporator, and removing 80 percent of inorganic salt to obtain organic matters with 10 to 15 percent of salt and 35 to 55 percent of moisture, thus obtaining the mother solution, wherein for 35 to 50 percent of the organic matters in the mother solution, 90 percent of the organic matters is sodium glycollate; adjusting the PH value of the mother solution to 10 by utilization of sodium hydroxide, filtering at a temperature about 60 DEG C while the mother solution is hot, and extracting from the solution by utilization of an ethanol solvent so as to obtain a crude sodium glycollate solid product; acidizing by utilization of sulfuric acid, taking the sulfuric acid as a catalyst, performing esterification by utilization of methanol so as to obtain methyl glycolate, and finally hydrolyzing and converting the methyl glycolate into a glycolic acid solution with a purity of 70 percent. The method disclosed by the invention has the advantages that the design is complete, the use is convenient, salt contents are effectively removed and a part of recycled water reaching industrial reuse water standards is produced after the CMC wastewater is treated, and residual concentrated wastewater is prepared into chemical products with a higher economic value through further chemical treatment.

Owner:JIANGSU TAILIDA NEW MATERIAL CO LTD

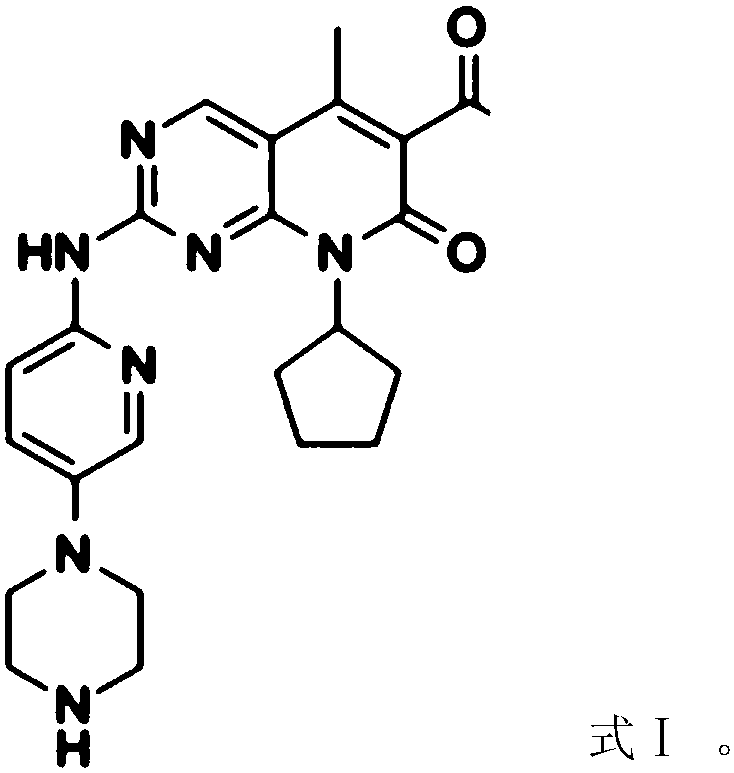

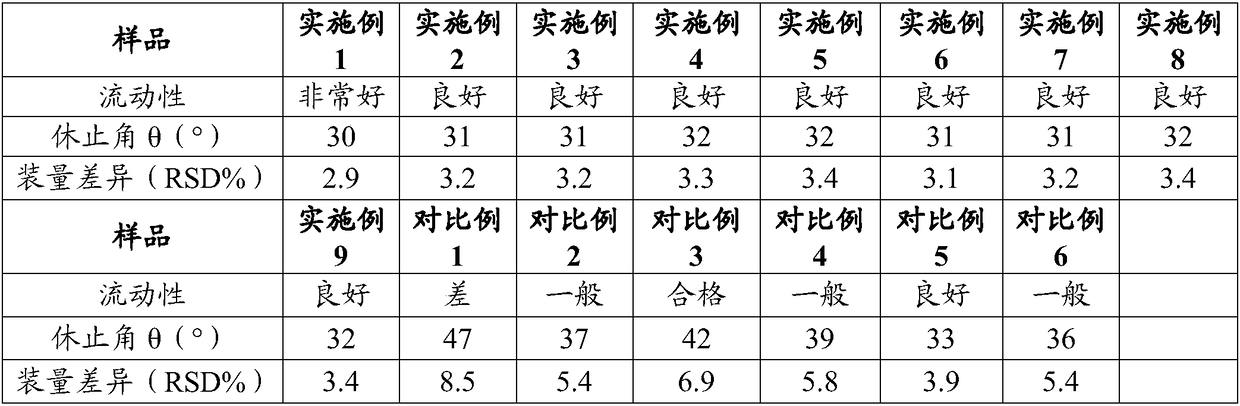

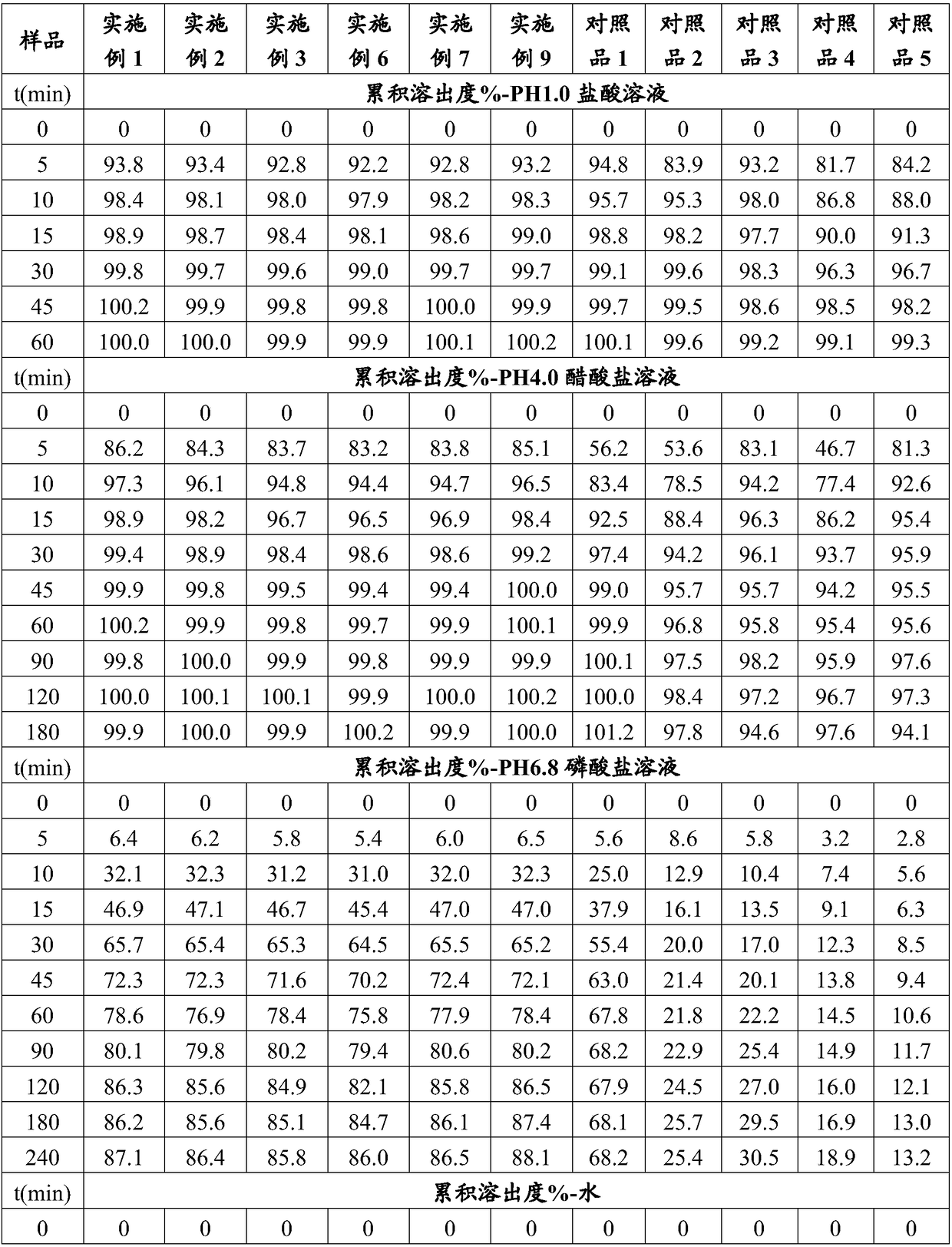

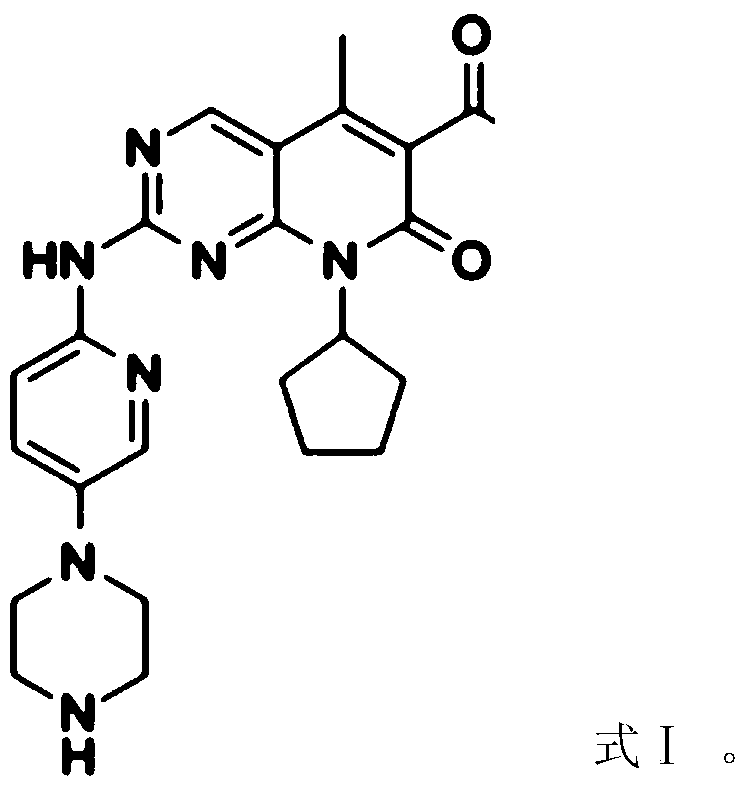

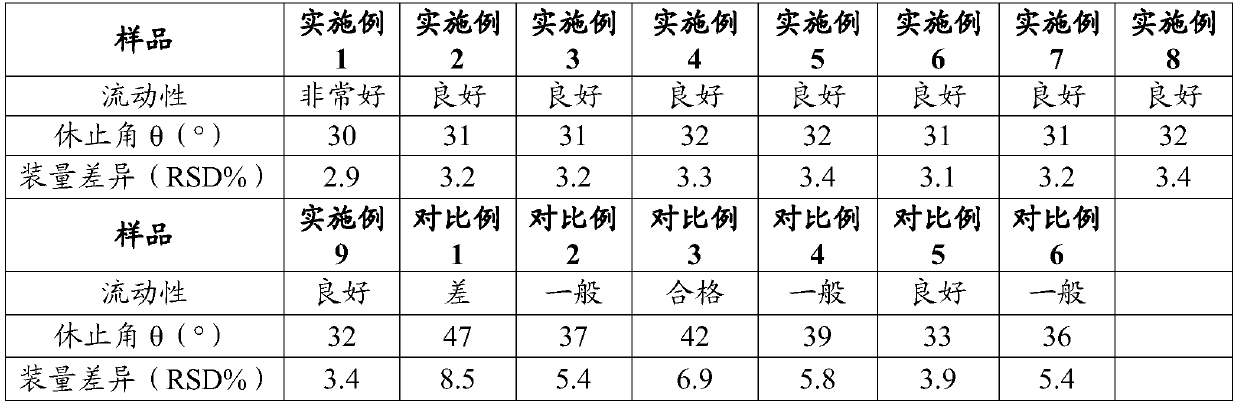

Palbociclib pharmaceutical composition and method for preparing same

ActiveCN108066312AReduce solubilityHigh dissolution rateOrganic active ingredientsCapsule deliveryPalbociclibCitric acid

The invention relates to the field of pharmaceutical preparations, and particularly discloses a palbociclib pharmaceutical composition and a method for preparing the same. The palbociclib pharmaceutical composition comprises, by weight, 20%-30% of palbociclib, 30%-40% of pregelatinized starch, 20%-30% of lactitol, 3%-5% of starch sodium glycollate, 4%-6% of hydroxyethyl methyl celluloses, 3%-5% ofhydroxyethyl celluloses and 1%-3% of citric acid fatty glyceride. The palbociclib pharmaceutical composition and the method have the advantages that excellent dissolution effects can be realized by the palbociclib pharmaceutical composition, the contents of related substances can be obviously reduced, the stability can be obviously enhanced, and clinical medicines can be advantageously safely used and can be advantageously stored for a long term; the particle sizes of raw auxiliary materials are controlled, accordingly, the palbociclib pharmaceutical composition is good in mixing property andflowability as discovered via experiments, and capsules can be directly filled with the palbociclib pharmaceutical composition by means of mixing.

Owner:SHANDONG YUXIN PHARMA CO LTD

Cleaning agent

InactiveCN102994268ARaw materials are easy to getLow priceAnionic-cationic-non-ionic surface-active compoundsGlycerolPotassium hydroxide

A cleaning agent is formed by mixing the following standby raw materials by weight percent: 50-80 of disodium of 1-hydroxy ethylidene-1, 1-diphosphonic acid, 17-26 of bentonite, 2-5 of lauric acid, 1-3 of fatty alcohol-polyoxyethylene ether, 2-6 of sodium glycollate, 4-7 of coconut fatty acid diethanol amide, 1-3 of sodium oxalate, 3-5 of sodium gluconate, 4-9 of potassium hydroxide, 25-30 of magnesium stearate or zinc stearate, 15-20 of glycerol, 2-6 of sodium bichromate, 1-10 of ethylene glycol and 35-40 of water. The cleaning agent is prepared from easily obtained raw materials, is low in price and has a good cleaning effect.

Owner:WUHAN SPACEFLIGHT SCI & TECH PETROCHEM CO LTD

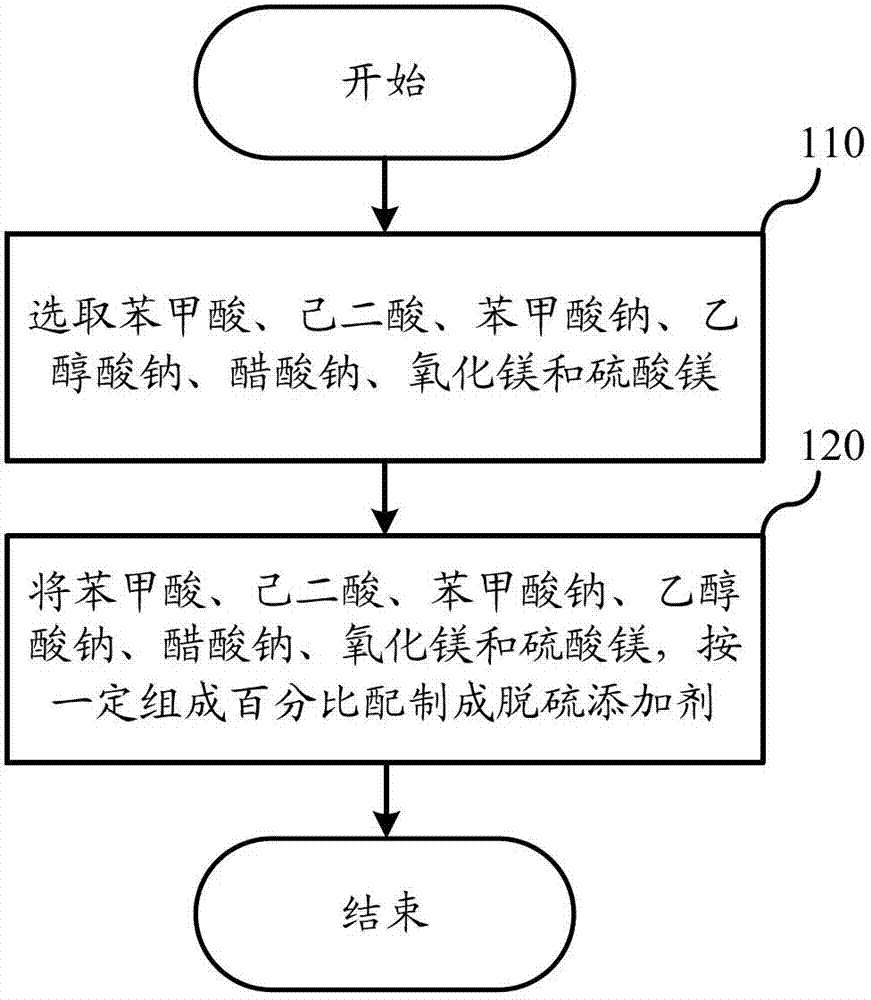

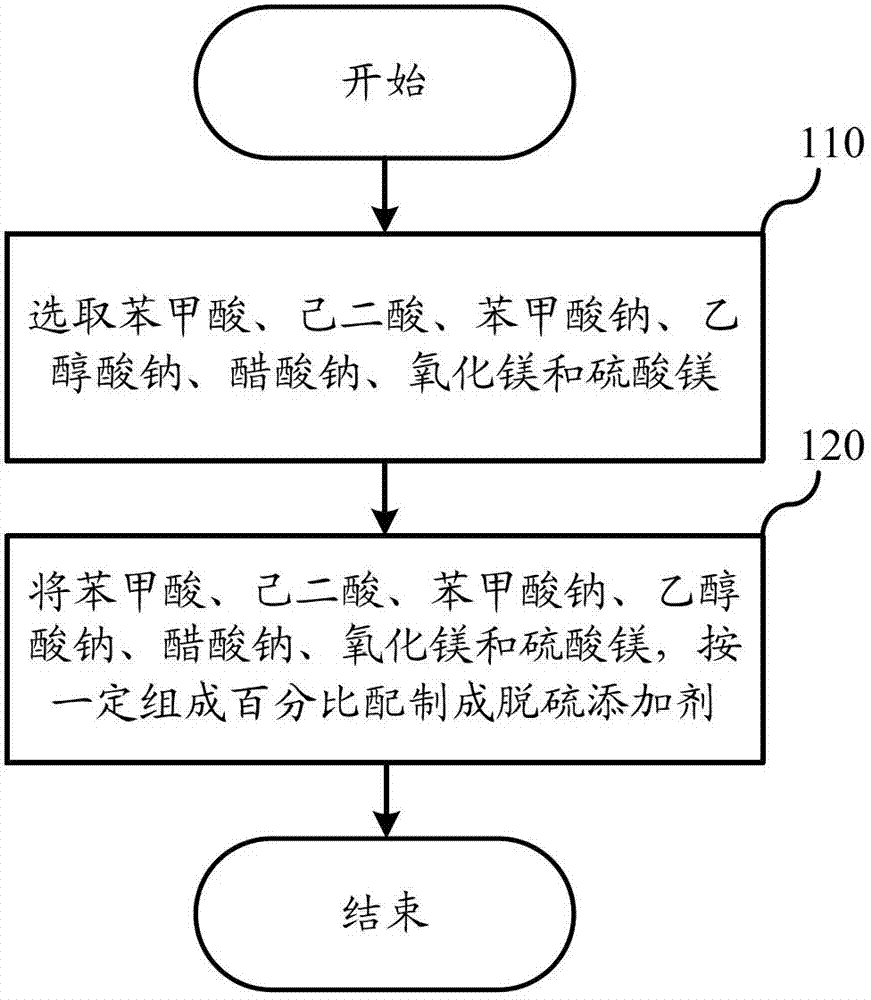

Desulfuration additive and manufacturing method thereof

ActiveCN103157370ALow viscosityReduce sedimentation velocityDispersed particle separationSodium acetateBenzoic acid

The invention relates to the field of chemical engineering and discloses a desulfuration additive and a manufacturing method thereof. The desulfuration additive comprises, by weight, 15% of benzoic acid, 20 to 30% of adipic acid, 10% of sodium benzoate, 10 to 20% of sodium glycollate, 5 to 10% of sodium acetate, 10 to 15% of magnesium oxide, and 15 to 20% of magnesium sulfate. The desulfuration additive greatly improves desulfuration efficiency, appropriately reduces energy consumption and improves by-product gypsum quality under the premise of no reconstruction of the existing device. The desulfuration additive provides a novel choice for the power plant.

Owner:上海申欣环保实业有限公司

Liquid-solid combined fermentation process for Bacteroides fragilis

InactiveCN105274019ARich in nutrientsImprove biological activityBacteriaMicroorganism based processesBiotechnologyGlucose-cysteine

The invention provides a liquid-solid combined fermentation process for Bacteroides fragilis. The process comprises a first step of preparing a liquid nutrient solution from, by weight, 0.5 to 2.5% of peptone, 0.2 to 0.5% of glucose, 0.001 to 0.5% of cysteine, 0.2 to 0.5% of NaCl, 0.1 to 0.3% of NaHPO4, 0.02 to 0.1% of sodium thioglycolate, 30 to 60% of liquid ox liver extract, 30 to 60% of liquid beef extract and 0.1 to 0.8% of yeast extract. The process provided by the invention employs liquid-solid combined fermentation, and a great amount of Bacteroides fragilis can be obtained in a short period of time by using the process; and the process has the advantages of easiness, small investment, easy controllability in operation, small possibility of infection with competitors due to implementation of all the operations under vacuum and aseptic conditions and high concentration of bacterial strains.

Owner:王军

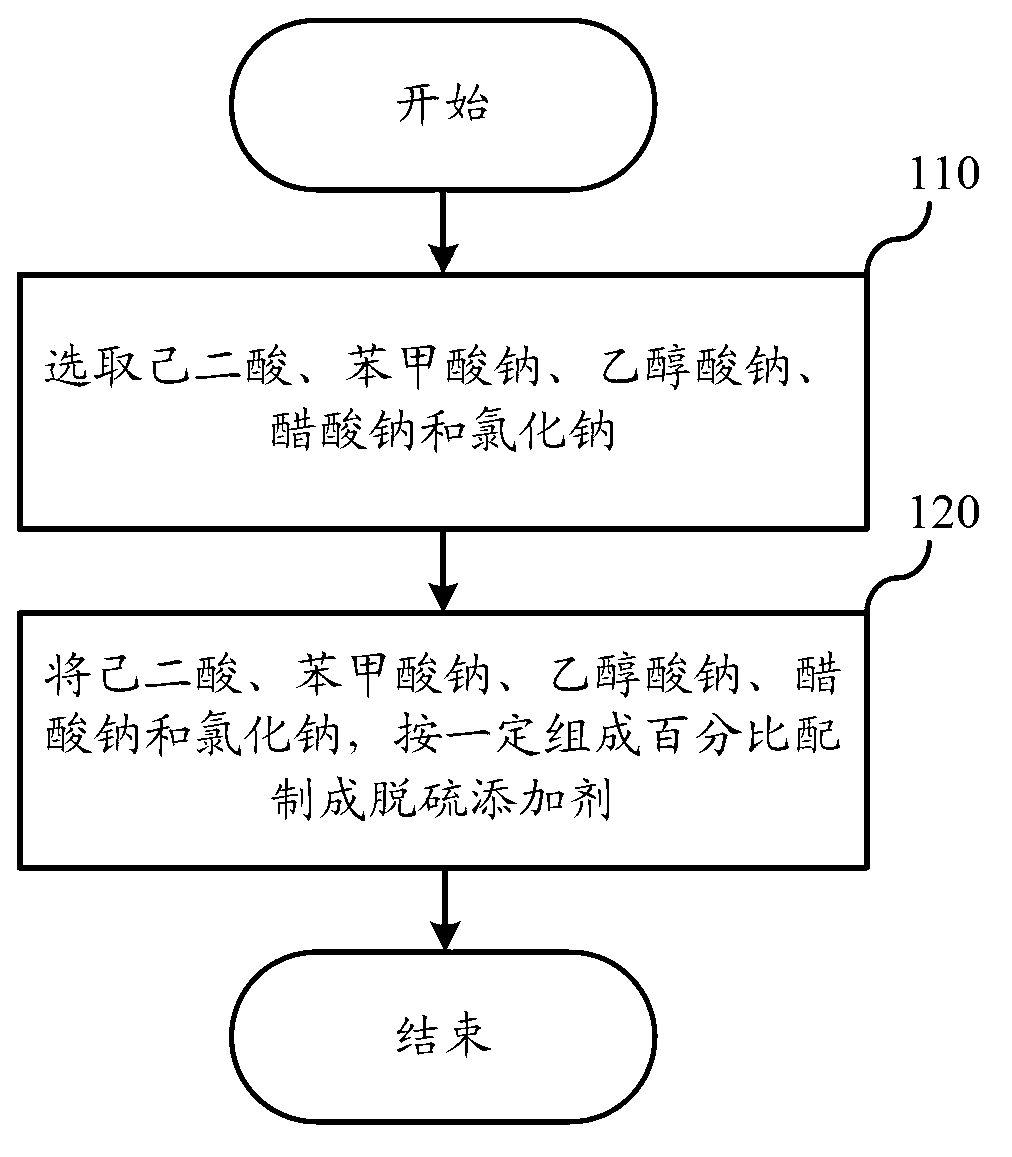

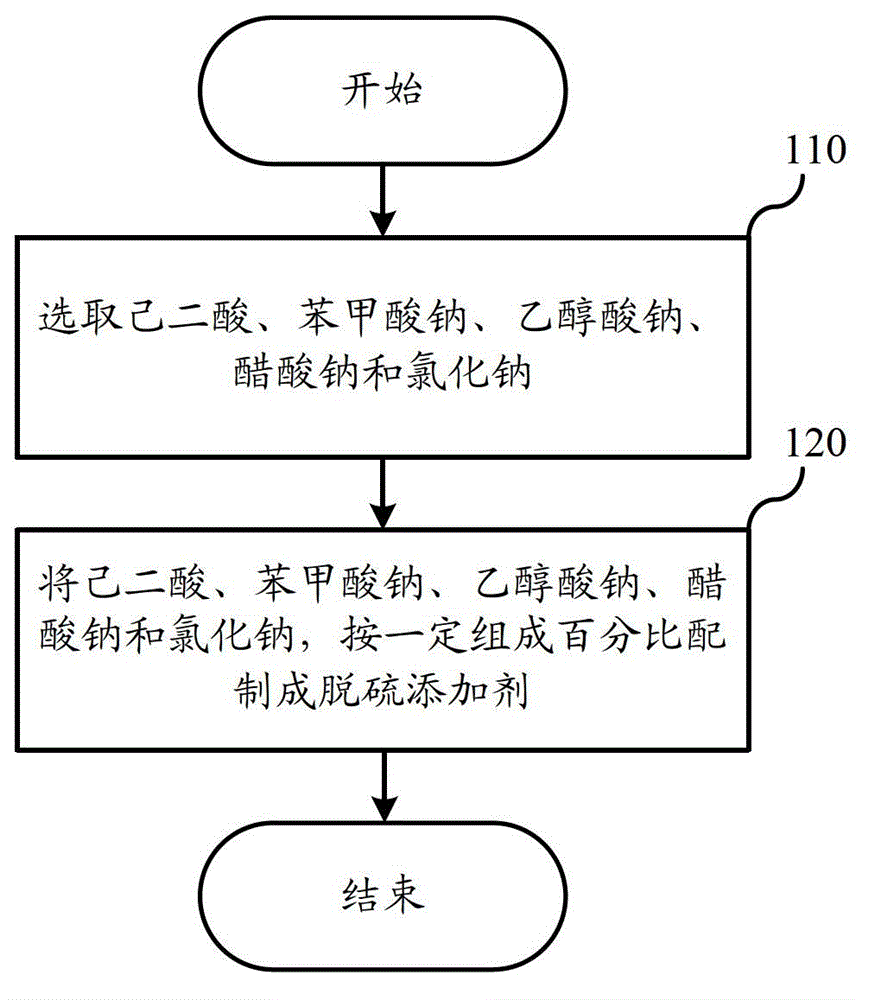

Devulcanizing additive and preparation method thereof

ActiveCN103055690AReduced pH bufferingImprove desulfurization efficiencyDispersed particle separationSodium GlycollateGypsum

The invention relates to the field of chemistry and discloses a devulcanizing additive as well as a preparation method thereof. The devulcanizing additive is prepared from the following components in parts by weight: 30-40% of adipic acid, 15-25% of sodium benzoate, 15-25% of sodium glycollate, 15-25% of sodium acetate and 10-15% of sodium chloride. Under the premise that the existing device is not randomly changed, the desulphurization efficiency can be greatly improved, the energy consumption can be reduced to a certain degree, and the quality of gypsum as a byproduct is improved, so that a new choice is provided for a power plant.

Owner:上海申欣环保实业有限公司

Zinc-nickel alloy electroplating liquid and electroplating method

InactiveCN111876804AGood deep plating abilityImprove wear resistanceSodium GlycollateZinc Acetate Dihydrate

The invention provides zinc-nickel alloy electroplating liquid. The zinc-nickel alloy electroplating liquid comprises 30-50 g / L of zinc chloride, 10-20 g / L of zinc acetate, 30-40 g / L of nickel sulfate, 100-150 g / L of sodium hydroxide, 20-40 g / L of a complexing agent, 5-10 g / L of a brightener and water. The brightener comprises sodium glycolate, sodium sulfamate, toluenesulfonamide and propargyl alcohol in a ratio of (1-2): (1-2): (3-5): (3-5); and the complexing agent comprises sodium citrate, ethylenediamine and triethanolamine in a mass ratio of (1-2): (3-5): (3-5). According to the electroplating liquid, zinc chloride, zinc acetate and nickel sulfate are used as main salt, and the brightener and the complexing agent with specific compositions are matched, so that a plating layer obtained by electroplating not only has good deep plating capability, but also has good wear resistance, high brightness and good neutral salt mist resistance.

Owner:霸州市青朗环保科技有限公司

Detergent auxiliary agent

InactiveCN104862097AImprove washing effectNon-ionic surface-active compoundsDetergent compounding agentsSodium acetateHexamethylenetetramine

The invention relates to a detergent auxiliary agent which is characterized in that the detergent auxiliary agent is prepared from the raw materials of, by weight, 8-14 parts of sodium glycollate, 3-4 parts of formic acid, 2-4 parts of sodium dodecylbenzenesulfonate, 5-14 parts of fatty alcohol polyoxyethylene ether, 4-10 parts of peregal, 3-5 parts of sodium tripolyphosphate, 10-16 parts of glucose, 2-6 parts of urotropin, 4-7 parts of ethylene acrylate carbon monoxide, 3-6 parts of sodium alkylbenzene sulfonate, 1-4 parts of silica, 2-5 parts of alcohol sulfate, 3-7 parts of sodium tripolyphosphate, 10-16 parts of sodium citrate, and 20-25 parts of deionized water.

Owner:QINGDAO GUOHANG XIANGYU TECH SERVICE

Preservation culture solution of bacterial strain for efficiently degrading lignocellulose and preparation method of thereof

InactiveCN102703372AImprove performanceAdaptableChemical cell growth stimulationCelluloseCulture fluid

The invention relates to a preservation culture solution of bacterial strain for efficiently degrading lignocellulose and a preparation method of the culture solution, belonging to the field of biotechnology. The culturing solution provided by the invention is characterized in that each 1L of deionized water contains the following materials: magnesium sulfate, ferric sulfate, ammonium nitrate, glutamine, sodium molybdate, cobalt chloride, potassium iodide, monopotassium phosphate, yeast powder, glucose, sulfuretted sodium glycollate, citric acid, starch, beef extract, asparagine and peach gum. The culturing solution is added with multiple nutrient elements which can promote the bacterial strain for degrading lignocellulose to rapidly and stably grow; the culturing solution is simple in preparation method, low in equipment investment, low in material cost and can accurately, stably and efficiently cultivate excellent bacterial strains with good adaptability; and the lignocellulose degrading activity of the obtained bacterial strain is higher than that of the bacterial strain naturally grown in natural world.

Owner:ZHEJIANG FORESTRY UNIVERSITY

A kind of palbociclib pharmaceutical composition and preparation method thereof

ActiveCN108066312BHigh dissolution rateLow impurity contentOrganic active ingredientsGranular deliveryFatty acid glycerol estersBiology

The invention relates to the field of pharmaceutical preparations, and particularly discloses a palbociclib pharmaceutical composition and a method for preparing the same. The palbociclib pharmaceutical composition comprises, by weight, 20%-30% of palbociclib, 30%-40% of pregelatinized starch, 20%-30% of lactitol, 3%-5% of starch sodium glycollate, 4%-6% of hydroxyethyl methyl celluloses, 3%-5% ofhydroxyethyl celluloses and 1%-3% of citric acid fatty glyceride. The palbociclib pharmaceutical composition and the method have the advantages that excellent dissolution effects can be realized by the palbociclib pharmaceutical composition, the contents of related substances can be obviously reduced, the stability can be obviously enhanced, and clinical medicines can be advantageously safely used and can be advantageously stored for a long term; the particle sizes of raw auxiliary materials are controlled, accordingly, the palbociclib pharmaceutical composition is good in mixing property andflowability as discovered via experiments, and capsules can be directly filled with the palbociclib pharmaceutical composition by means of mixing.

Owner:SHANDONG YUXIN PHARMA CO LTD

Resource treatment process of high-salt wastewater in carboxymethyl cellulose production

ActiveCN104370312BHigh viscosityAffect crystallizationMultistage water/sewage treatmentNature of treatment waterEvaporationEthoxyacetic acid

The invention discloses a recycling processing technology for high-salt wastewater during carboxymethyl cellulose production. The processing technology combines extraction and graded crystallization technologies. In the graded crystalization process, through multi-effect (or mechanical recompression) evaporation crystallization, crude salt is recovered from wastewater and condensate water is evaporated, the condensate water reaches the industrial reuse water standard, and refined salt is prepared from crude salt through washing; and then through cooling crystallization, sodium glycollate crystal is separated out, the crystallization mother liquid is used for a next crystallization process, so that closed cycle is realized. In the above graded crystallization process, ethoxyacetic acid is obtained by performing extraction separation on a concentrated liquid, and the viscosity is reduced. The method is simple in operation, low in cost and high in separation recovery rate. The whole processing technology employs closed cycle, has no pollutants, and is easy for industrialization. The technology helps to solve the high-salt wastewater processing problem in the carboxymethyl cellulose production process, also helps to realize the recycling processing purposes of turning harm into good and changing wastes into valuables, and has substantial economic, social and environment benefit.

Owner:JIANGNAN UNIV

Moderate rust-proof cleaning agent

The invention discloses a moderate rust-proof cleaning agent which is prepared from the following raw materials in parts by weight: 2.5-4.3 parts of n-propyl bromide, 2.3-3.5 parts of an antirust agent, 4.5-6.6 parts of aminobenzene sulfonamide, 7.1-8.3 parts of sodium diethylenetriamine pentamethylene phosphonate, 2.3-4.5 parts of ethydiaminedhephen acetic-Na, 5.6-7.4 parts of sodium glycollate, 5.3-7.2 parts of water and 0.9-1.5 parts of organic phosphoric acid. The moderate rust-proof cleaning agent has the following benefits: the cleaning efficiency is high, the dirt-removing ability is high, the safety performance is excellent, the environment is not polluted, the energy is saved, the cleaning cost is low, the metal equipment is free from damage during the cleaning process, the metal equipment is not corroded after being washed, the cleaning difficulty is reduced after adding the ethydiaminedhephen acetic-Na, the ferrous metal parts are not corroded, the dirt-removing ability is high and the cleaning speed is high.

Owner:QINGDAO CHENXUTONG COMMERCE & TRADE

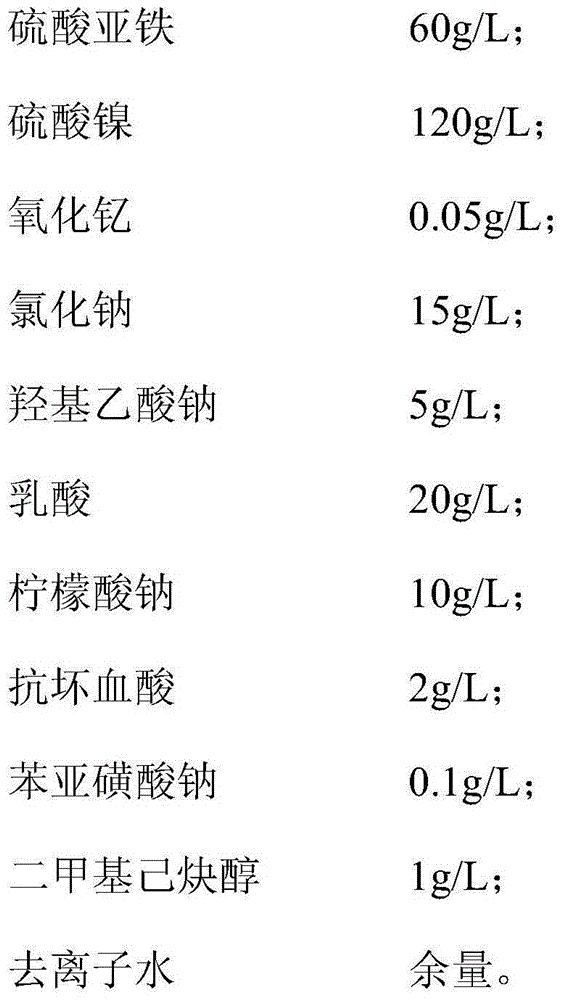

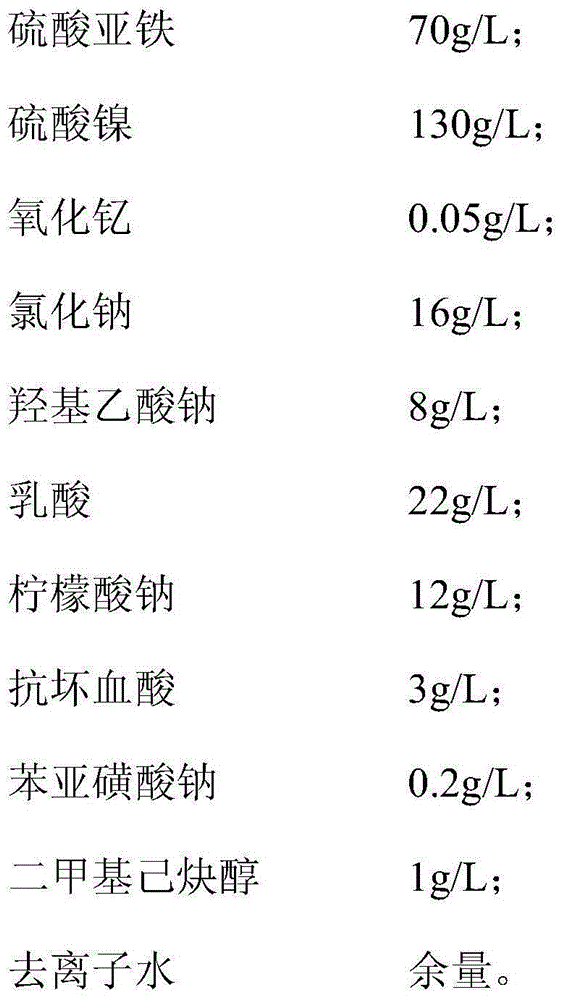

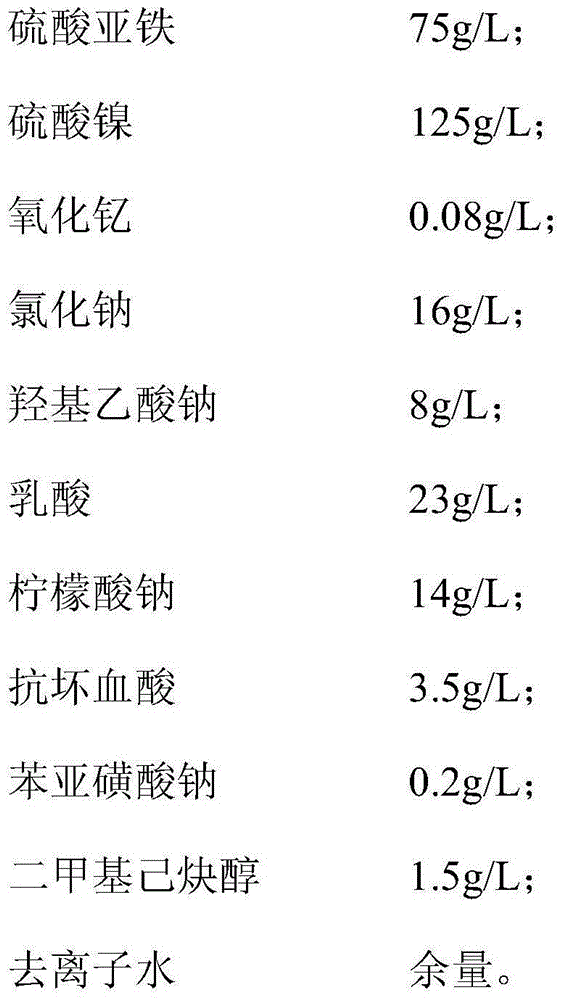

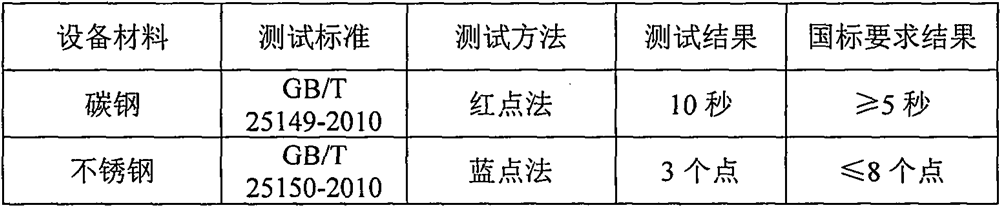

Yttrium-nickel-iron alloy electroplate liquid and electroplating method thereof

The invention discloses yttrium-nickel-iron alloy electroplate liquid and an electroplating method thereof. The yttrium-nickel-iron alloy electroplate liquid comprises 100 g / L-180 g / L of ferrous sulfate, 120 g / L-200 g / L of nickel sulfate, 15 g / L-30 g / L of sodium chloride, 10 g / L-20 g / L of sodium glycollate, 10 g / L-25 g / L of lactic acid, 30 g / L-45 g / L of complexing agents, 2 g / L-5 g / L of stabilizer, 0.1 g / L-0.3 g / L of primary brightener, 3 g / L-8 g / L of brightener and the balance deionized water. Rare earth metal yttrium is added to the yttrium-nickel-iron alloy electroplate liquid, so that the electroplate liquid is good in stability, high in electroplating efficiency, low in cost, safe and environmentally friendly. A plated layer obtained through electroplating is attractive in color and luster, good in smoothness and good in density and flexibility.

Owner:WUXI QIAOYANG MACHINERY MFG

Desulfurization additive and its preparation method

ActiveCN103055690BReduced pH bufferingImprove desulfurization efficiencyDispersed particle separationSodium acetateAdipic acid

The invention relates to the field of chemistry and discloses a devulcanizing additive as well as a preparation method thereof. The devulcanizing additive is prepared from the following components in parts by weight: 30-40% of adipic acid, 15-25% of sodium benzoate, 15-25% of sodium glycollate, 15-25% of sodium acetate and 10-15% of sodium chloride. Under the premise that the existing device is not randomly changed, the desulphurization efficiency can be greatly improved, the energy consumption can be reduced to a certain degree, and the quality of gypsum as a byproduct is improved, so that a new choice is provided for a power plant.

Owner:上海申欣环保实业有限公司

Improved derusting degreasing cleaning fluid

The invention discloses an improved derusting degreasing cleaning fluid comprising the following parts by weight of raw materials: 2.5-4.3 parts of triethanolamine oleate, 2.3-3.5 parts of a thickening agent, 4.5-6.6 parts of alkyl benzyl ammonium oxide, 7.1-8.3 parts of a penetrating agent, 2.3-4.5 parts of di poly ethylene glycol monoethyl ether, 5.6-7.4 parts of sodium glycollate, 5.3-7.2 parts of ethyl acrylate and 0.9-1.5 parts of butyl acetate. The improved derusting degreasing cleaning fluid comprises the alkyl benzyl ammonium oxide, the penetrating agent, the di poly ethylene glycol monoethyl ether, the sodium glycollate and the like, and the cleaning agent is easy in raw material, simple in process, excellent in performance and wide in the use range, and can also form a protective film on the surface of metal items during metal surface item cleaning, so that the improved derusting degreasing cleaning fluid facilitates moisture and rust proofing.

Owner:王璐

Desulfuration additive and manufacturing method thereof

ActiveCN103157370BLow viscosityReduce sedimentation velocityDispersed particle separationSodium acetateBenzoic acid

Owner:上海申欣环保实业有限公司

Environment-friendly neutral oil and rust removal passivation cleaning agent

The invention discloses an environment-friendly neutral oil and rust removal passivation cleaning agent which is suitable for the field of industrial cleaning. The cleaning agent comprises the following components in percentage by mass: 1%-15% of sodium glycollate; 1%-20% of disodium succinate; 20%-70% of a chelating agent; 5%-30% of organic weak acid; 0.1% to 10% of a surfactant; and 0.1%-10% of a fluorine-containing inorganic compound. The preparation method thereof comprises the following steps: grinding the powdery or granular components to be not less than 30 meshes according to the mass ratio of the components of the cleaning agent, and stirring for 2-3 hours by using a three-dimensional stirrer of which the rotating speed of a main shaft is not less than 20 revolutions per minute to obtain the cleaning agent disclosed by the invention. The cleaning agent has the advantages of no strong acid, no strong alkali, neutral aqueous solution and wastewater, environment friendliness, no toxicity, easiness in decomposition, convenience in transportation, small amount of generated wastewater, small harm to human bodies and metal bodies, no need of heating during use and good passivating effect.

Owner:巨伯清洗技术(上海)有限公司

A strain preservation culture solution for efficiently degrading lignocellulose and its preparation method

InactiveCN102703372BImprove performanceAdaptableChemical cell growth stimulationCelluloseCulture fluid

The invention relates to a preservation culture solution of bacterial strain for efficiently degrading lignocellulose and a preparation method of the culture solution, belonging to the field of biotechnology. The culturing solution provided by the invention is characterized in that each 1L of deionized water contains the following materials: magnesium sulfate, ferric sulfate, ammonium nitrate, glutamine, sodium molybdate, cobalt chloride, potassium iodide, monopotassium phosphate, yeast powder, glucose, sulfuretted sodium glycollate, citric acid, starch, beef extract, asparagine and peach gum. The culturing solution is added with multiple nutrient elements which can promote the bacterial strain for degrading lignocellulose to rapidly and stably grow; the culturing solution is simple in preparation method, low in equipment investment, low in material cost and can accurately, stably and efficiently cultivate excellent bacterial strains with good adaptability; and the lignocellulose degrading activity of the obtained bacterial strain is higher than that of the bacterial strain naturally grown in natural world.

Owner:ZHEJIANG FORESTRY UNIVERSITY

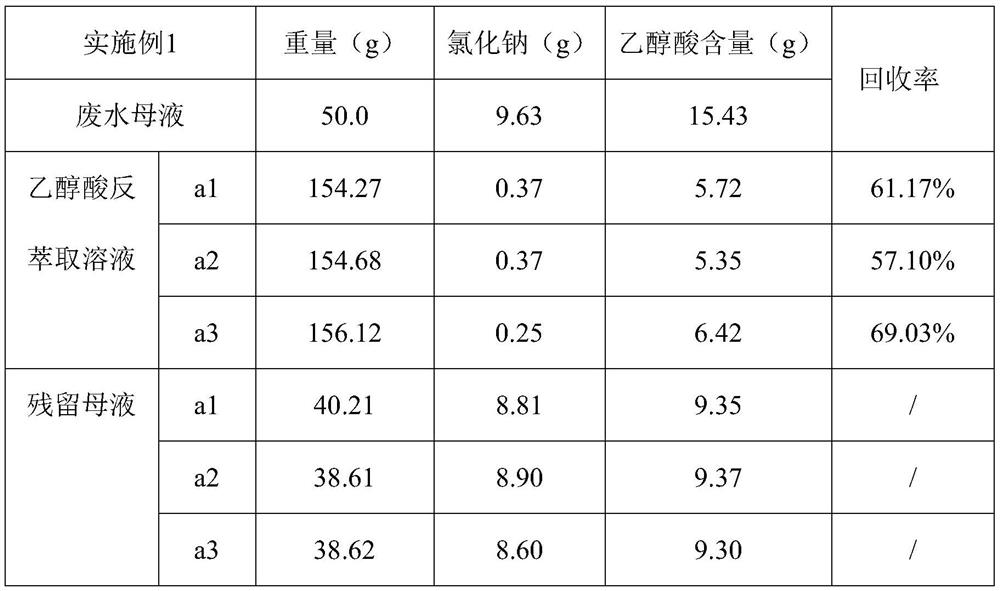

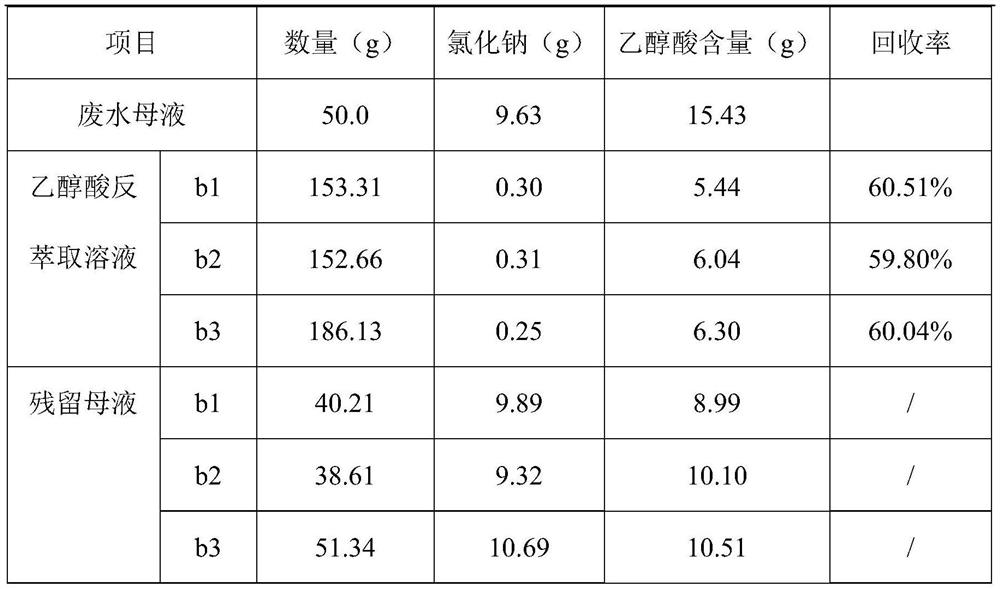

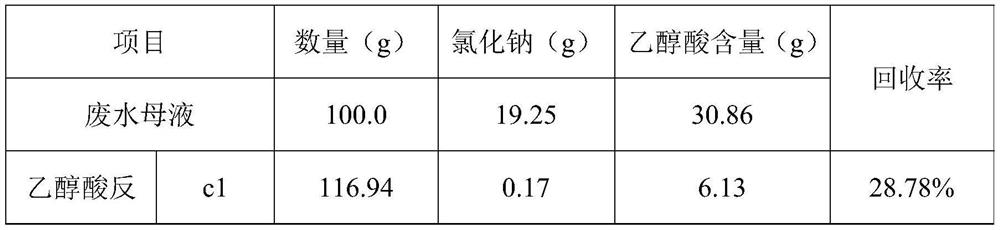

Method for extracting, separating and purifying glycollic acid from CMC industrial production wastewater

PendingCN112961044AChange direct processingEmission reductionPreparation from carboxylic acid saltsCarboxylic compound separation/purificationIndustrial waste waterPulp and paper industry

The invention provides a method for separating glycollic acid. The method mainly comprises the following steps of: (1) acidifying, precipitating and filtering industrial wastewater mother liquor containing sodium glycollate to convert the sodium glycollate into glycollic acid; (2) extracting the solution obtained in the step (1) by using an extracting agent, and conducting separating to obtain an extract and a residual solution; and (3) carrying out back extraction separation on the extract obtained in the step (2) to obtain a glycollic acid solution. The method for separating the glycollic acid has the main beneficial effects that operation is simple, the purity of the obtained glycollic acid is high, the wastewater mother liquor is effectively utilized, the waste is turned into the wealth, and production cost is greatly reduced.

Owner:恒达亲水胶体泰州有限公司

A kind of energy storage lead-acid battery life extension liquid and preparation method thereof

ActiveCN108923078BImprove cycle lifeReduce the speed of capacity decayLead-acid accumulatorsAcid electrolytesSebacic acidChromium(III) chloride

Owner:GUANGDONG YINGYEDA ELECTRONICS CO LTD

Efficient rustproof water-based cleaning solution

The invention discloses an efficient rustproof water-based cleaning solution. The efficient rustproof water-based cleaning solution is made from, by weight, 2.5-4.3 parts of alkyl amide taurine salt, 2.3-3.5 parts of anti-rusting agents, 4.5-6.6 parts of tallow bi-quaternary ammonium sulphate, 7.1-8.3 parts of diethylenetriamine penta(methylene phosphonic acid) sodium, 2.3-4.5 parts of ethy diaminedhephen acetic-Na, 5.6-7.4 parts of sodium glycollate, 5.3-7.2 parts of water and 0.9-1.5 parts of aromatic carboxylic acid. The efficient rustproof water-based cleaning solution has the beneficial effects that the cleaning efficiency is high, and the decontamination ability is high; the safety is good, and no environmental pollution is caused; energy is saved, and the washing cost is low; no damage is caused to metal equipment in the washing process, and no corrosion is caused to the metal equipment after washing; after the ethy diaminedhephen acetic-Na is added, the cleaning difficulty is lowered, black metal parts are not corroded, the decontamination ability is high, and the cleaning speed is high.

Owner:宁贻伟

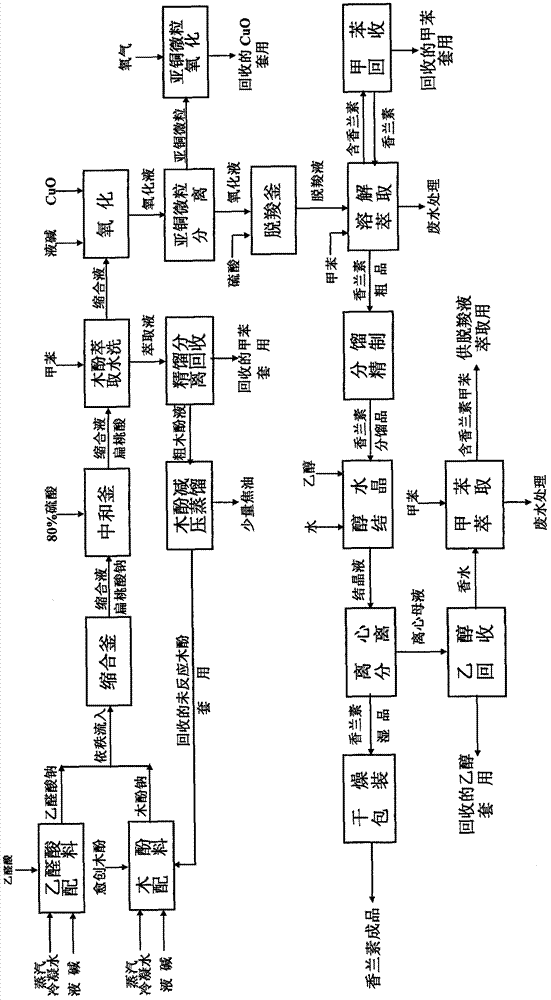

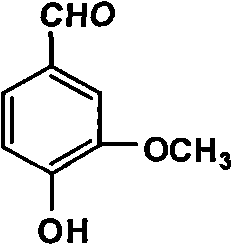

Productive technology of vanlillin by glyoxylic acid method

ActiveCN102010310BReduce consumptionReduce unit consumptionOrganic compound preparationCarbonyl compound separation/purificationKetonic acidsCatalytic oxidation

The invention discloses a productive technology of vanlillin by a glyoxylic acid method. The productive technology comprises a synthesis process, a fractionation process and a purification process, wherein the synthesis process comprises condensation treatment, oxidation treatment and decarboxylation treatment of methyl catechol and glyoxylic acid. The productive technology particularly comprisesthe following steps: respectively converting the methyl catechol and the glyoxylic acid into guaiacol sodium and sodium glyoxylate in a sodium hydroxide system; carrying out condensation treatment onthe guaiacol sodium and the sodium glyoxylate; after recovering the unreacted methyl catechol in a condensation liquid, carrying out oxidation treatment, namely carrying out catalytic oxidation on anethanol group in 4-hydroxy-3-methoxybenzene sodium glycolate by using copper oxide in the sodium hydroxide system to form a ketone group, thereby generating a corresponding ketonic acid compound; after separating red copper oxide particles from an oxidation liquid, carrying out decarboxylation treatment, namely using sulfuric acid to acidize the oxidation liquid, and simultaneously converting an acid group in the ketonic acid compound into carbon dioxide so as to generate 4-hydroxy-3- methoxybenzaldehyde; and carrying out the fractionation process and the purification process to obtain the vanlillin.

Owner:喜孚狮王龙香料(宁波)有限公司

A treatment method for reclaiming distillation raffinate from cellulose ether solvent

The invention discloses a treatment method adopting cellulose ether solvent to recycle vinasse, which comprises the following steps: during the production process of cellulose ether, an organic solvent medium is adopted to distill the vinasse generated during the recycling process to a supersaturated solution or until the moisture is completely evaporated to dryness, ethyl acetate is adopted to perform first extraction so as to filter and separate lost cellulose ether, the ethyl acetate is distilled for recycling, and the leftover after distillation is a secondary product of etherifying agent; first extraction is performed on the subnatant, quantitative hydrogen chloride is added for acidification, then ethyl acetate is added for secondary extraction so as to recycle acetic acid or glycollic acid, the ethyl acetate is distilled and recycled for recycling, the leftover after distillation is acetic acid or sodium glycollate, secondary extraction is performed on the subnatant, alkali is adopted for neutralization, concentration is performed continuously, and sodium chloride is filtered and recycled. According to the invention, as less organic solvent in the concentrated solution is evaporated, and the organic solvent can be used together with a washing solution in the production technology of cellulose ether, zero emission of the three wastes during the production process of the cellulose ether is realized, waste material is changed into things of value, and higher economic benefit is obtained.

Owner:湖北博斐逊生物新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com