A treatment method for reclaiming distillation raffinate from cellulose ether solvent

A cellulose ether, recovery and distillation technology is applied in the field of treatment of cellulose ether solvent recovery distillation residue, which can solve the problems of environmental pollution, affecting the development of cellulose ether, and unsatisfactory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

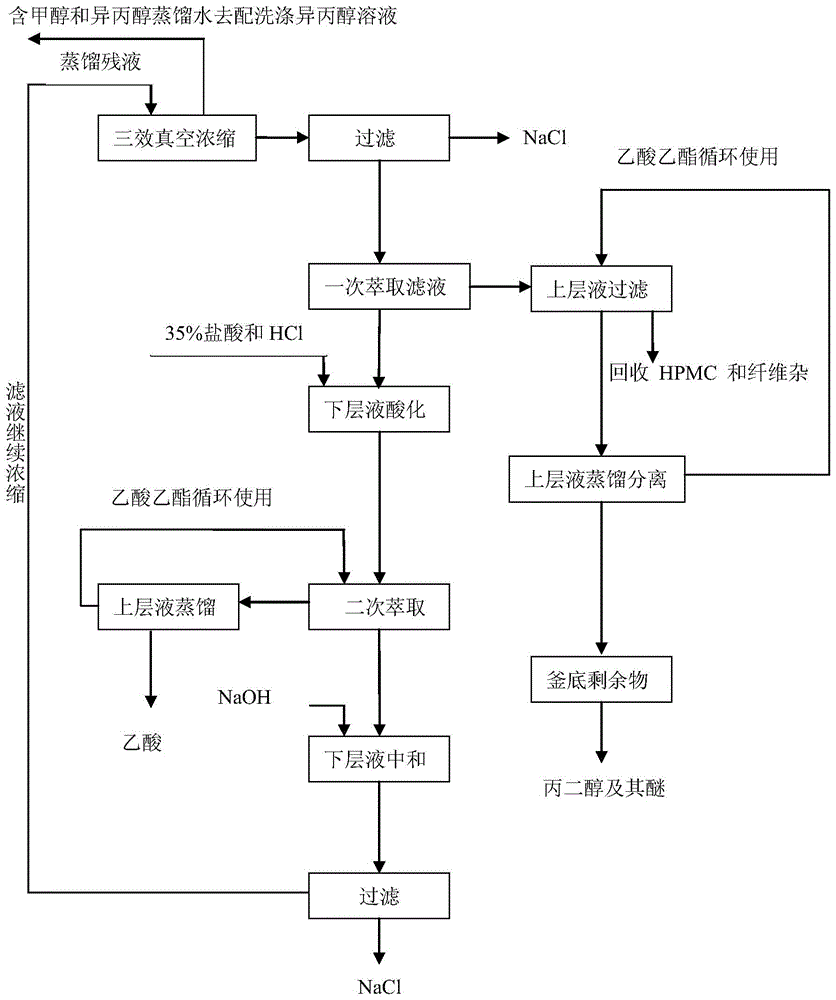

[0028] Hydroxypropyl methyl cellulose (HPMC) separation waste liquid treatment process after solvent recovery:

[0029] Table 1: Chemical composition of the primary separation liquid after precipitation in the HPMC production process

[0030] Substance name

Sodium chloride

Sodium acetate

HPMC

methanol and isopropanol

water

content

4-8%

0.5-1.2%

1.5-2..5%

0.2-0.3%

0.5-0.8%

93.3-87.2%

[0031] Note: Due to the different models of HPMC, the chemical substance content of the separated waste liquid is also different.

[0032] Waste liquid treatment process: use a three-effect vacuum evaporator to concentrate the HPMC separation waste liquid to a sodium chloride content of 40-60%, the concentrated hot water contains methanol and isopropanol to mix the HPMC washing liquid, and the concentrated liquid is centrifuged for chlorination Sodium; the centrifuge is cooled to 0-60°C to the ex...

Embodiment 2

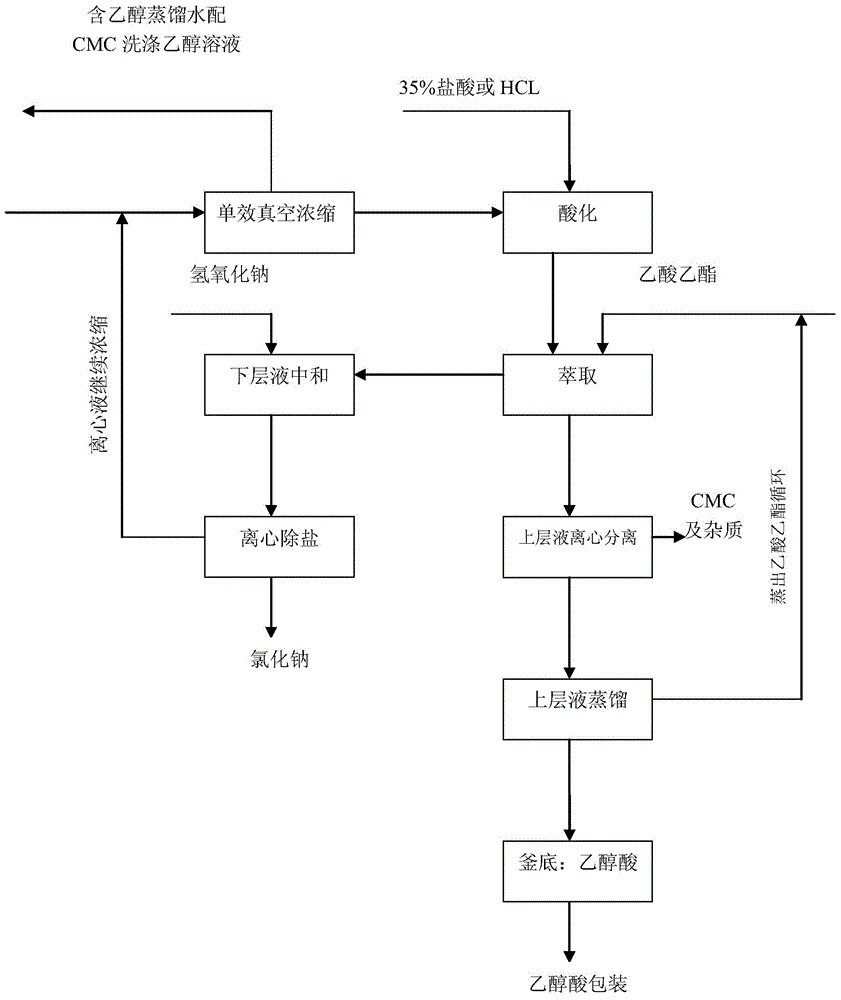

[0034] Embodiment 2, carboxymethyl cellulose (CMC) production process Solvent recovery distillation raffinate treatment process:

[0035] Table 2: The chemical composition of the residual liquid recovered by solvent distillation in the production process of pure CMC

[0036] Substance name

Sodium chloride

sodium glycolate

CMC

water

content

20-30%

8-15%

0.5%

1-1.5%

70.5-53%

[0037] Note: CMC product specifications are different, the chemical composition of the distillation raffinate is also different; the chemical composition is different with different distillation degrees.

[0038] Distillation raffinate treatment process: Distillation raffinate is concentrated by single-effect vacuum to a sodium chloride content of 50-60%, evaporated hot water contains ethanol, and is mixed with CMC washing liquid, the concentrated solution is filtered to recover sodium chloride, and the filtrate is cooled to 0- Add 3...

Embodiment 3

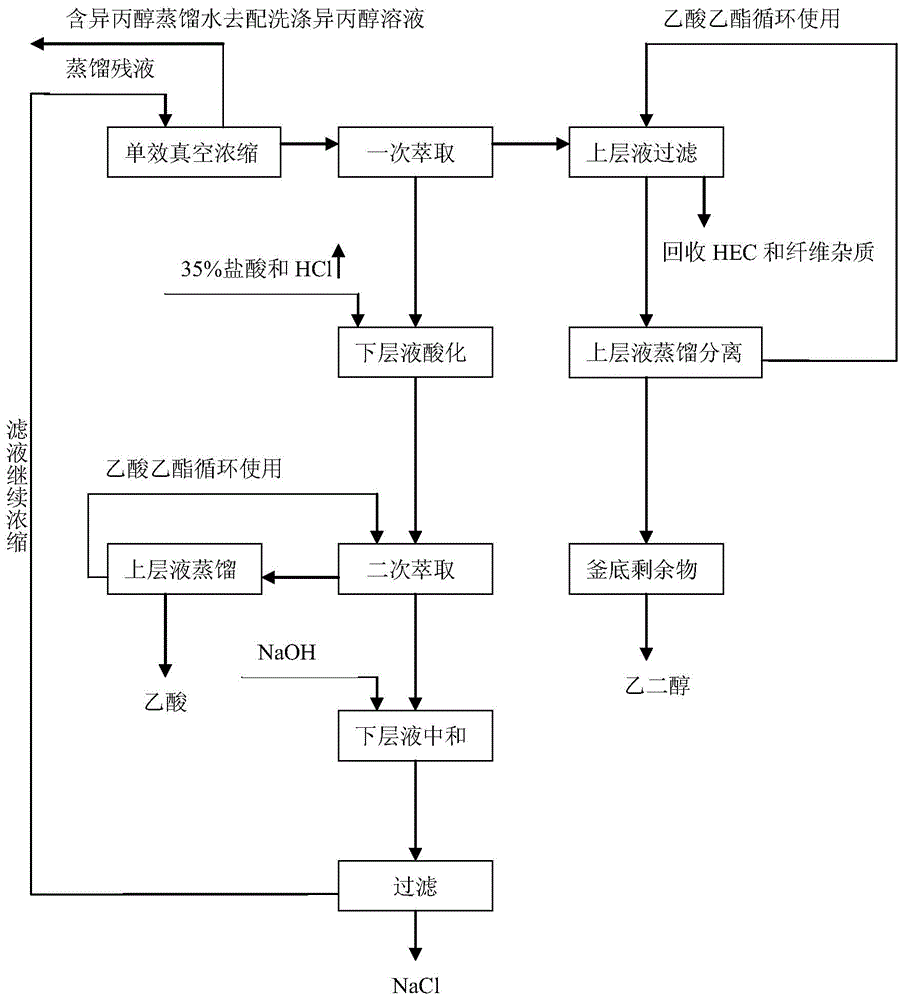

[0039] Example 3, hydroxyethyl cellulose (HEC) solvent recovery distillation raffinate treatment process:

[0040] Table 3: Chemical substance composition of the residual liquid recovered by solvent distillation in the production process of pure HEC

[0041] Substance name

Ethylene glycol and its ethers

Isopropanol

HEC

water

content

15-30%

20-35%

0.5%

1.5-2.0%

63-32.5%

[0042] Note: HEC product specifications are different, the chemical composition of the distillation raffinate is also different; the chemical composition is different with the degree of distillation.

[0043] Distillation raffinate treatment process: the above distillation raffinate is concentrated by single-effect vacuum evaporation, the moisture content of the raffinate is concentrated to 0%-35%, cooled to 25-70°C, and extracted once with ethyl acetate; ethyl acetate and concentrated The weight ratio of the raffinate = (0.5-10): 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com