Environment-friendly neutral oil and rust removal passivation cleaning agent

A cleaning agent, an environment-friendly technology, which is applied in the field of environment-friendly neutral degreasing, derusting and passivation cleaning agents, and can solve problems such as troublesome post-processing, strong corrosion of equipment, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

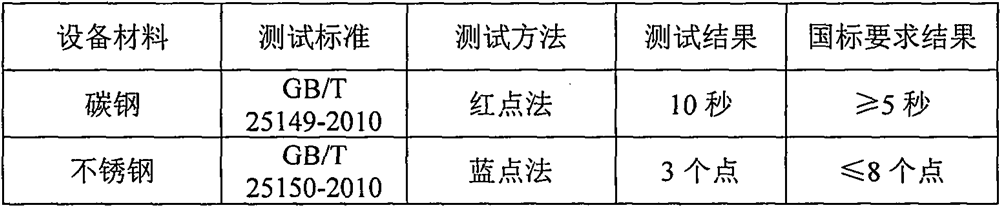

Image

Examples

Embodiment 1

[0029] Embodiment 1, 5kg sodium glycolate, 15kg disodium succinate, 64kg tetrasodium glutamate diacetate, 10kg 2-hydroxysuccinic acid, 1kg cocamidopropyl betaine, 5kg sodium fluoride are ground to 40 mesh, using a three-dimensional stirrer with a spindle speed of 30 rpm to stir for 2 hours to obtain the cleaning agent.

Embodiment 2

[0030] Embodiment 2, 15kg sodium glycolate, 20kg disodium succinate, 38kg trisodium methylglycine diacetate, 10kg 2,3-dihydroxysuccinic acid, 10kg fumaric acid, 1kg cocoamidopropyl Betaine, 3 kg of sodium cocoyl glutamate, and 3 kg of Na2SiF6 were ground to 35 mesh, and the cleaning agent was obtained by stirring for 2 hours with a three-dimensional agitator whose spindle speed was 30 revolutions per minute.

Embodiment 3

[0031] Example 3, 8kg sodium glycolate, 20kg disodium succinate, 20kg tetrasodium aspartic acid diacetate, 34kg tetrasodium iminodisuccinate, 6kg o-hydroxybenzoic acid, 3kg maleic acid, 2kg coconut Sodium oleoyl glutamate, 5kg of NH4HF2, 2kg of KTiF6 were ground to 45 mesh, and the cleaning agent was obtained by stirring with a three-dimensional stirrer with a spindle speed of 25 rpm for 2 hours and 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com