Yttrium-nickel-iron alloy electroplate liquid and electroplating method thereof

A technology of iron alloy and electroplating solution, which is applied in the field of yttrium-nickel-iron alloy electroplating solution and its electroplating, which can solve problems such as dullness, unstable electroplating solution, and rough coating, and achieve beautiful color, high electroplating efficiency, and good flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

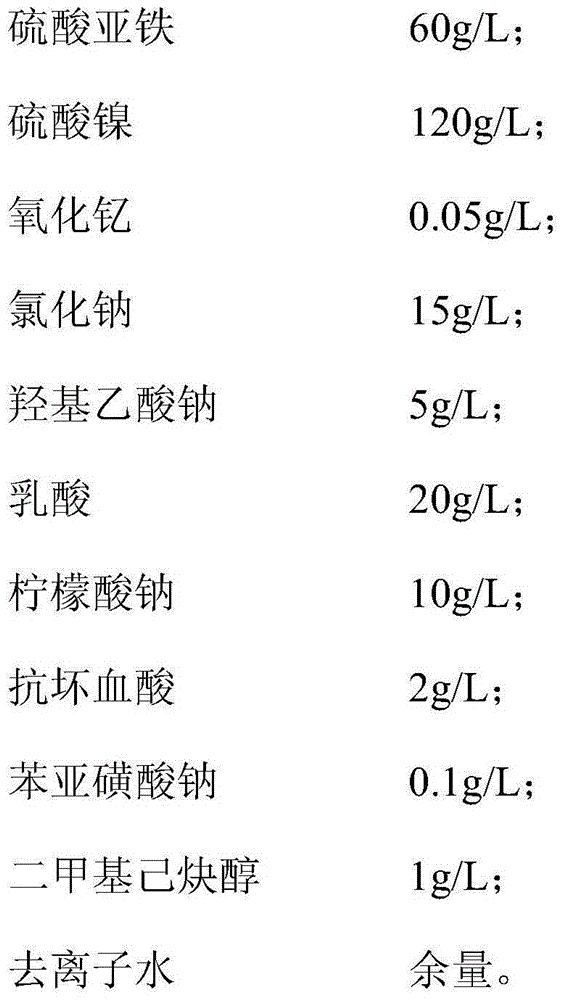

[0019] Embodiment 1: the yttrium-nickel-iron alloy electroplating solution of the present embodiment comprises following components:

[0020]

[0021] Use this yttrium-nickel-iron alloy plating solution electroplating method as follows:

[0022] Preparation of yttrium-nickel-iron alloy electroplating solution: 10 g of sodium citrate, 2 g of ascorbic acid, and 0.05 g of yttrium oxide were dissolved in deionized water to form a solution, and 20 g of lactic acid, 60 g of ferrous sulfate, 15 g of sodium chloride, and hydroxyl 5g of sodium acetate and 120g of nickel sulfate were stirred and dissolved to form a mixed solution, and 0.1g of sodium benzenesulfinate and 1g of dimethylhexynol were added to the mixed solution to dissolve, and then the remaining amount of deionized water was added until the total volume was 1L , to obtain the yttrium-nickel-iron alloy electroplating solution;

[0023] Adjust the pH of the electroplating solution to 5 with ammonia water, use a carbon el...

Embodiment 2

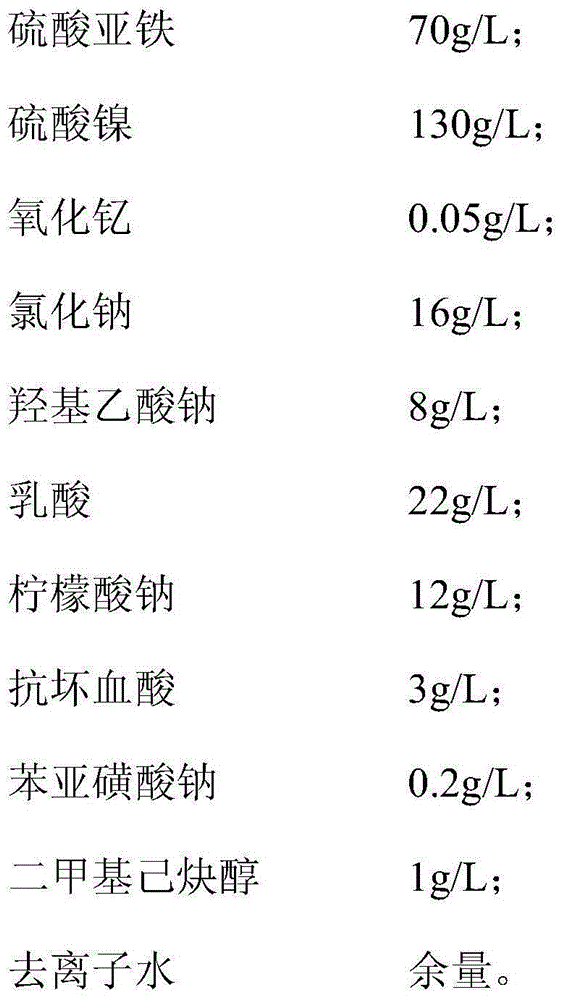

[0024] Embodiment 2: the yttrium-nickel-iron alloy electroplating solution of the present embodiment comprises following components:

[0025]

[0026] Use this yttrium-nickel-iron alloy plating solution electroplating method as follows:

[0027] Prepare yttrium-nickel-iron alloy electroplating solution: Dissolve 12g of sodium citrate, 3g of ascorbic acid, and 0.05g of yttrium oxide in deionized water to form a solution, add 22g of lactic acid, 70g of ferrous sulfate, 16g of sodium chloride, and Sodium acetate 8g, nickel sulfate 130g and stir to dissolve to make a mixed solution, add 0.2g sodium benzenesulfinate and 1g dimethylhexynol to the mixed solution to dissolve, then add the rest of deionized water to a total volume of 1L , to obtain the yttrium-nickel-iron alloy electroplating solution;

[0028] Adjust the pH of the electroplating solution to 5 with ammonia water, use a carbon electrode as the anode, and the workpiece as the negative electrode. The temperature of th...

Embodiment 3

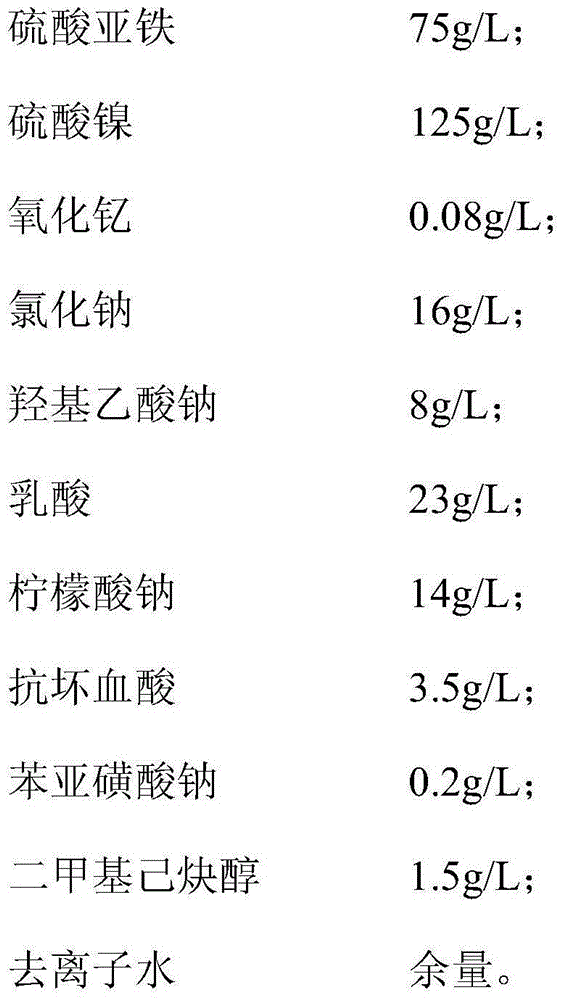

[0029] Embodiment 3: the yttrium-nickel-iron alloy electroplating solution of the present embodiment comprises following components:

[0030]

[0031] Use this yttrium-nickel-iron alloy plating solution electroplating method as follows:

[0032] Preparation of yttrium-nickel-iron alloy electroplating solution: 14g of sodium citrate, 3.5g of ascorbic acid, and 0.08g of yttrium oxide were dissolved in deionized water to form a solution, and 23g of lactic acid, 75g of ferrous sulfate, 16g of sodium chloride, Sodium glycolate 8g, nickel sulfate 125g are stirred and dissolved to make a mixed solution, 0.2g sodium benzenesulfinate and 1.5g dimethylhexynol are added to the mixed solution to dissolve, and then the remaining amount of deionized water is added to the total volume Be 1L, obtain yttrium-nickel-iron alloy plating solution;

[0033] Adjust the pH of the electroplating solution to 5 with ammonia water, use a carbon electrode as the anode, and the workpiece as the negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com