Treatment method adopting cellulose ether solvent to recycle vinasse

A cellulose ether, recovery and distillation technology is applied in the treatment of cellulose ether solvent recovery and distillation residue, which can solve the problems of difficult three-waste treatment, affecting the survival of the industry, and inability to produce new cellulose ether products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

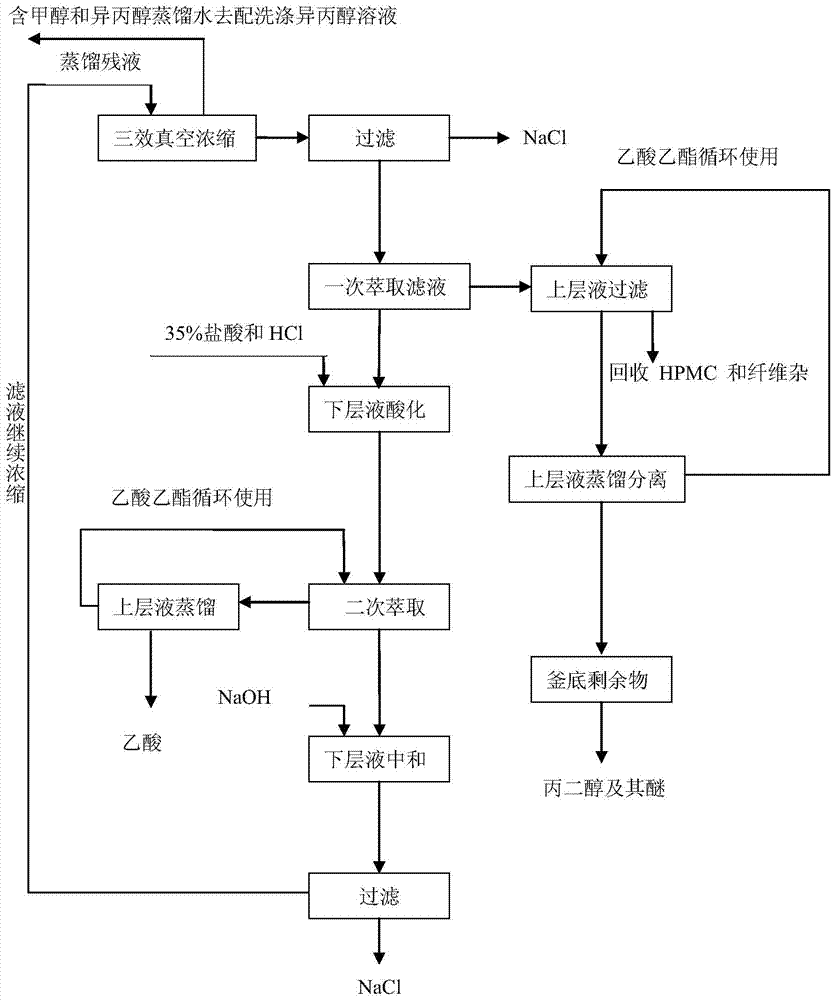

[0028] Hydroxypropyl methyl cellulose (HPMC) separation waste liquid treatment process after solvent recovery:

[0029] Table 1: Chemical composition of the primary separation liquid after precipitation in the HPMC production process

[0030] Substance name

Sodium chloride

Sodium acetate

HPMC

methanol and isopropanol

water

content

4-8%

0.5-1.2%

1.5-2..5%

0.2-0.3%

0.5-0.8%

93.3-87.2%

[0031] Note: Due to the different models of HPMC, the chemical substance content of the separated waste liquid is also different.

[0032] Waste liquid treatment process: use a three-effect vacuum evaporator to concentrate the HPMC separation waste liquid to a sodium chloride content of 40-60%, the concentrated hot water contains methanol and isopropanol to mix the HPMC washing liquid, and the concentrated liquid is centrifuged for chlorination Sodium; the centrifuge is cooled to 0-60°C to the ex...

Embodiment 2

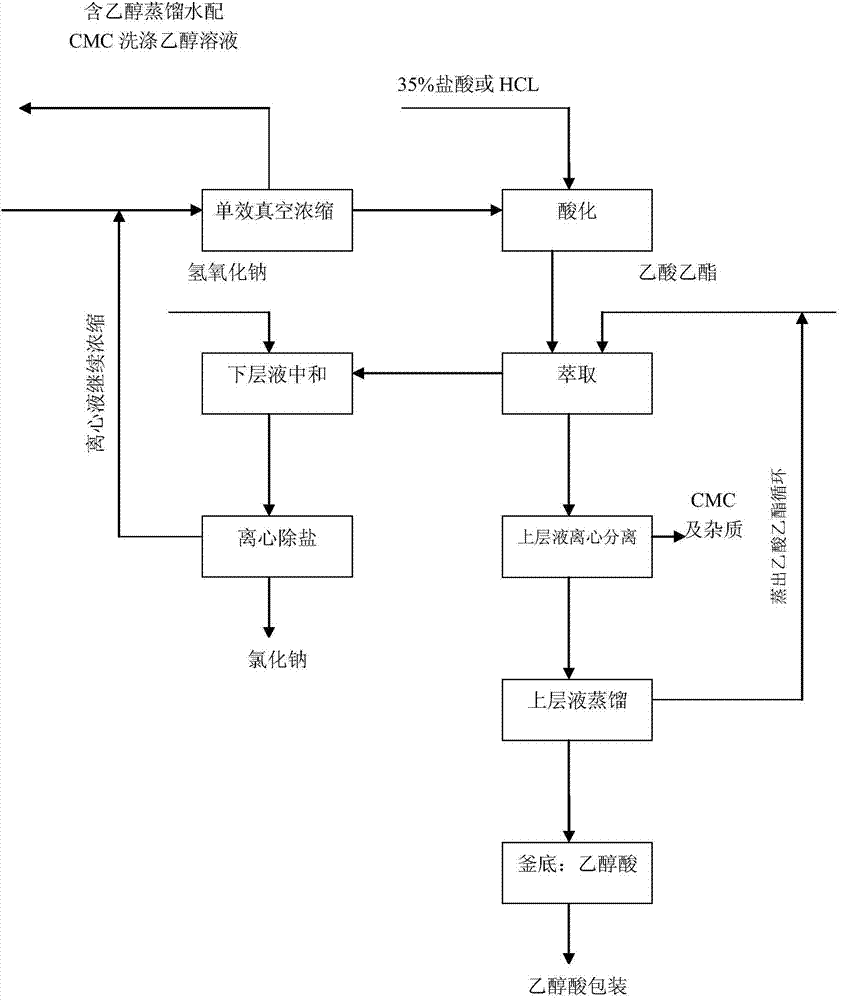

[0034] Embodiment 2, carboxymethyl cellulose (CMC) production process Solvent recovery distillation raffinate treatment process:

[0035] Table 2: The chemical composition of the residual liquid recovered by solvent distillation in the production process of pure CMC

[0036] Substance name

Sodium chloride

sodium glycolate

CMC

water

content

20-30%

8-15%

0.5%

1-1.5%

70.5-53%

[0037] Note: CMC product specifications are different, the chemical composition of the distillation raffinate is also different; the chemical composition is different with different distillation degrees.

[0038] Distillation raffinate treatment process: Distillation raffinate is concentrated by single-effect vacuum to a sodium chloride content of 50-60%, evaporated hot water contains ethanol, and is mixed with CMC washing liquid, the concentrated solution is filtered to recover sodium chloride, and the filtrate is cooled to 0- Add 3...

Embodiment 3

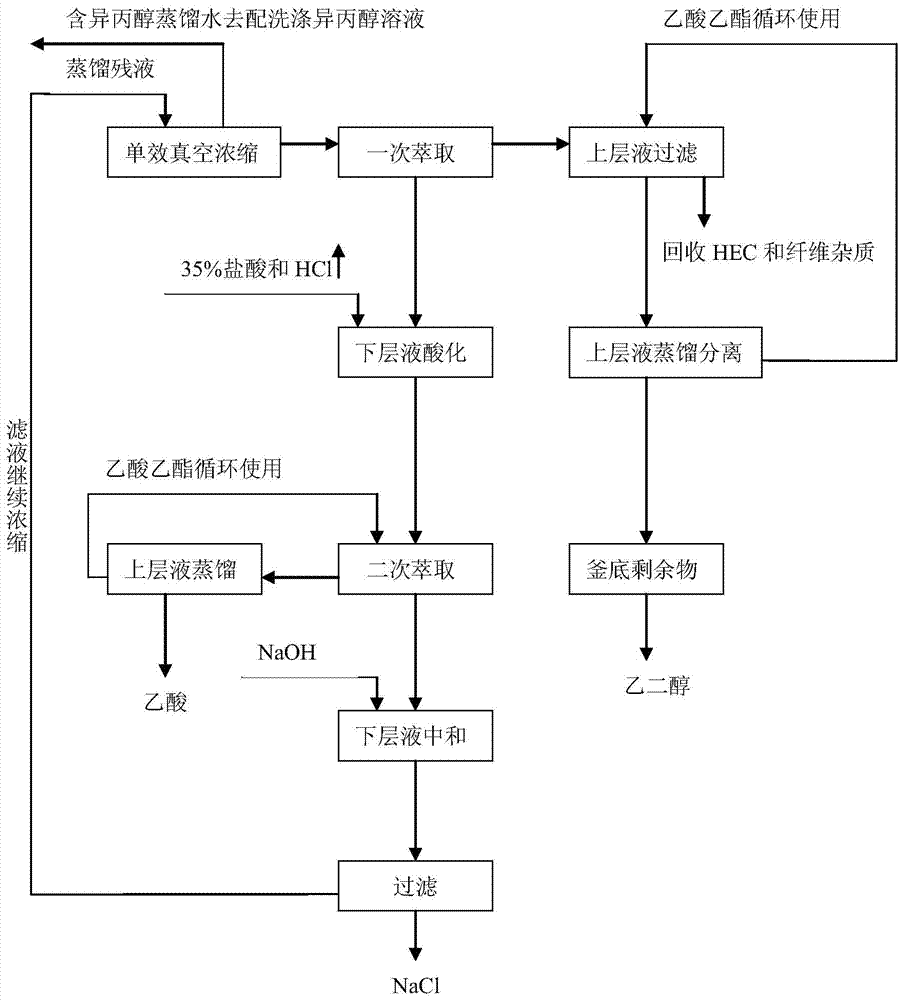

[0039] Example 3, hydroxyethyl cellulose (HEC) solvent recovery distillation raffinate treatment process:

[0040] Table 3: Chemical substance composition of the residual liquid recovered by solvent distillation in the production process of pure HEC

[0041] Substance name

Ethylene glycol and its ethers

Isopropanol

HEC

water

content

15-30%

20-35%

0.5%

1.5-2.0%

63-32.5%

[0042] Note: HEC product specifications are different, the chemical composition of the distillation raffinate is also different; the chemical composition is different with the degree of distillation.

[0043] Distillation raffinate treatment process: the above distillation raffinate is concentrated by single-effect vacuum evaporation, the moisture content of the raffinate is concentrated to 0%-35%, cooled to 25-70°C, and extracted once with ethyl acetate; ethyl acetate and concentrated The weight ratio of the raffinate = (0.5-10): 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com