Method for extracting, separating and purifying glycollic acid from CMC industrial production wastewater

A glycolic acid and extraction technology, which is applied in the separation/purification of carboxylic acid compounds, preparation of carboxylate, organic chemistry, etc., can solve the problem of high cost, achieve the effects of reducing emissions, obvious economic benefits, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

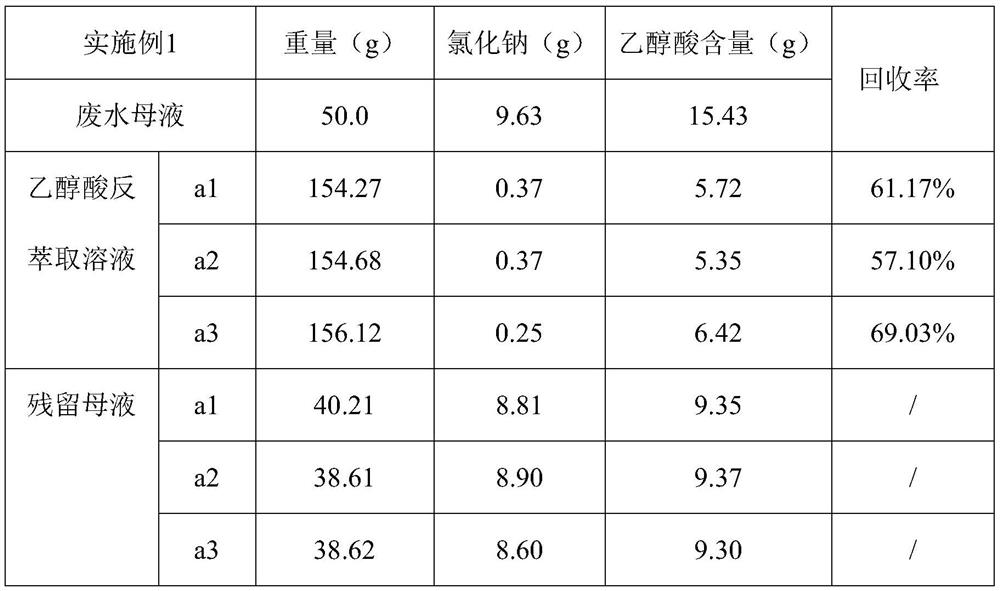

Embodiment 1

[0016] Embodiment 1: a kind of method for extracting, separating and purifying glycolic acid in CMC industrial production wastewater:

[0017] (1) 50g of CMC industrial production wastewater mother liquor is adjusted to pH between 0 and 1 with hydrochloric acid, and the precipitate is separated, and the acidified wastewater solution is separated by siphon method;

[0018] (2) Under normal temperature conditions, use methyl isobutyl ketone as the extractant, mix and stir the extractant with the waste water solution after acidification in step (1) in a mass ratio of 3:1, leave standstill, and separate the water phase and the oil phase;

[0019] (3) Under normal temperature conditions, add the same mass of water to the oil phase in step (2) for back extraction, stir for 30 minutes, let it stand for 60 minutes, separate the extractant and glycolic acid in the oil phase, and repeat the extraction and utilization of the extractant to step (1) , the glycolic acid solution is reproces...

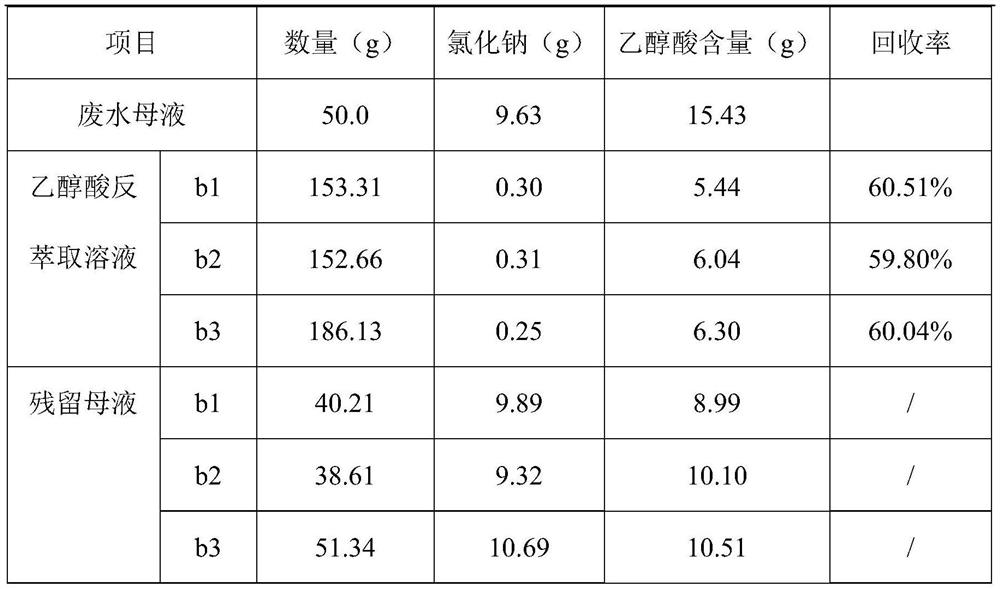

Embodiment 2

[0023] Embodiment 2: a kind of method for extracting, separating and purifying glycolic acid in CMC industrial production wastewater:

[0024] (1) 50g of CMC industrial production wastewater mother liquor is adjusted to pH between 0 and 1 with hydrochloric acid, and the precipitate is separated, and the acidified wastewater solution is separated by siphon method;

[0025] (2) At 5° C., using methyl isobutyl ketone as an extractant, mixing the extractant with the waste water solution after acidification in step (1) according to a mass ratio of 3:1, stirring, standing, and separating the water phase and the oil phase;

[0026] (3) Add the same mass of water to the oil phase in step (2) for back extraction, raise the temperature of the system to 60°C, stir for 30 minutes, let stand for 60 minutes, separate the extractant and glycolic acid in the oil phase, and extract the extractant to step (1) Repeated extraction and utilization, the glycolic acid solution is reprocessed and con...

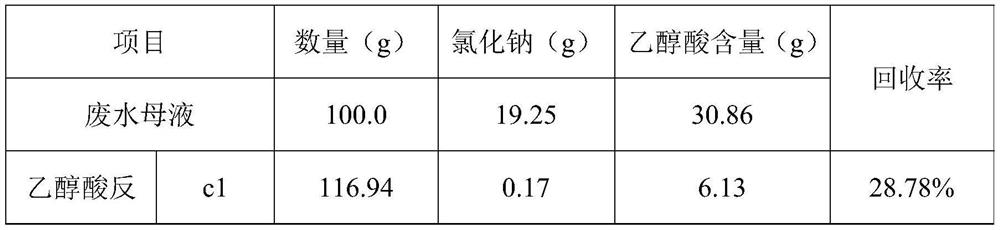

Embodiment 3

[0030] Embodiment 3: a kind of method for extracting, separating and purifying glycolic acid in CMC industrial production wastewater:

[0031] (1) 100g of CMC industrial production wastewater mother liquor is adjusted to a pH between 0 and 1 with hydrochloric acid, and the precipitate is separated, and the acidified wastewater solution is separated by a siphon method;

[0032] (2) Under normal temperature conditions, use methyl isobutyl ketone as the extractant, mix and stir the extractant with the waste water solution after acidification in step (1) in a mass ratio of 1:1, leave standstill, and separate the water phase and the oil phase;

[0033] (3) Under normal temperature conditions, add the same mass of water to the oil phase in step (2) for back extraction, stir for 30 minutes, let stand for 30 minutes, separate the extractant and glycolic acid in the oil phase, and repeat the extraction from the extractant to step (1) Utilize the glycolic acid solution to reprocess and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com