Patents

Literature

69results about How to "Eliminate grinding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

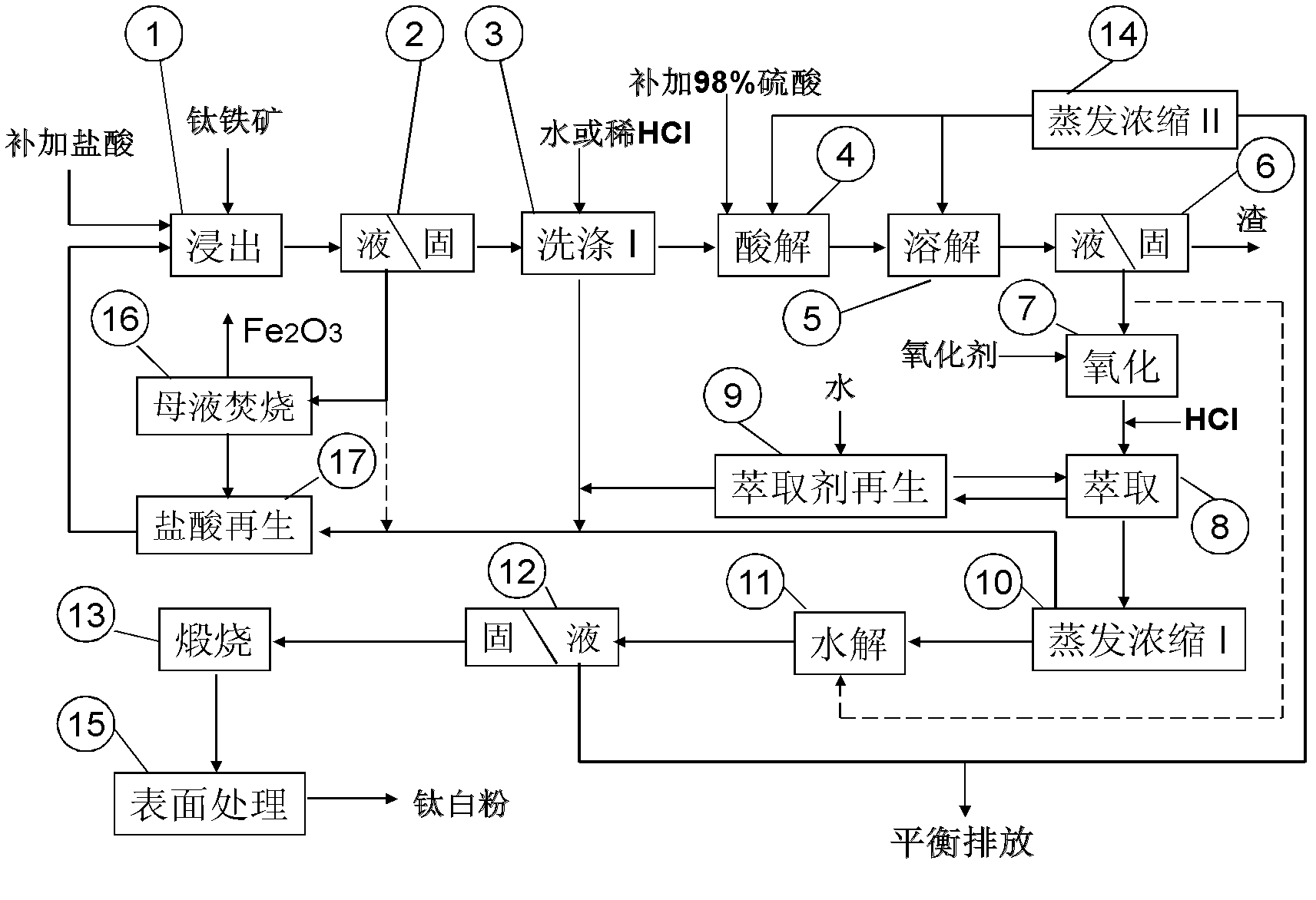

Method for preparing titanium white

The invention provides a method for preparing titanium white. The method comprises the following steps of: preparing titanium solution from high titanium hydrochloric acid leaching residue, which is prepared from a titanium iron material through a hydrochloric acid leaching method, serving as a raw material or one of raw materials through acidolysis by using sulfuric acid; oxidizing the titanium solution, performing organic extraction and purification, and hydrolyzing to obtain metatitanic acid; and performing washing, salt treatment, calcination and surface treatment on the metatitanic acid to prepare the titanium white. According to the method, hydrochloric acid composite system solution containing chlorate is subjected to diffluent disposal and is recycled after the titanium iron material is leached, and is organically matched with a cyclic process of an organic extraction and purification and sulfuric acid system of the titanium solution, so that the titanium solution treatment process and the cost are reduced; and since the used hydrochloric acid, sulfuric acid and organic extraction agent can be recycled, ferrous sulfate (green vitriol) is not produced; and thus, the discharge of dilute sulfuric acid and acidic wastewater is effectively reduced, and the quality of the titanium white is obviously improved. According to the method provided by the invention, high efficiency, cleanness, low cost, low energy consumption and low waste discharge effects of an entire flow are realized; a novel process technology is provided for producing the titanium white by a sulfuric acid method; and fine grained rock type ilmenite with high calcium and magnesium content at the Panxi area can be effectively utilized.

Owner:攀枝花新中钛科技有限公司

Method for preparing modified asphalt

ActiveCN101161778AGood dispersionAvoid damageWorking-up pitch/asphalt/bitumenBuilding insulationsMolten stateAsphalt

The invention discloses a method for preparing modified asphalt by coal direct liquefaction oil residue, wherein, 150 DEG C to 280 DEG C molten coal direct liquefaction oil residue and 100 DEG C to 180 DEG C molten base asphalt are mixed evenly at 150 DEG C to 280 DEG C to form liquid melt so as to obtain modified asphalt. With simple process, energy saving, environmental protection and high efficiency, the method improves the quality of modified asphalt.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

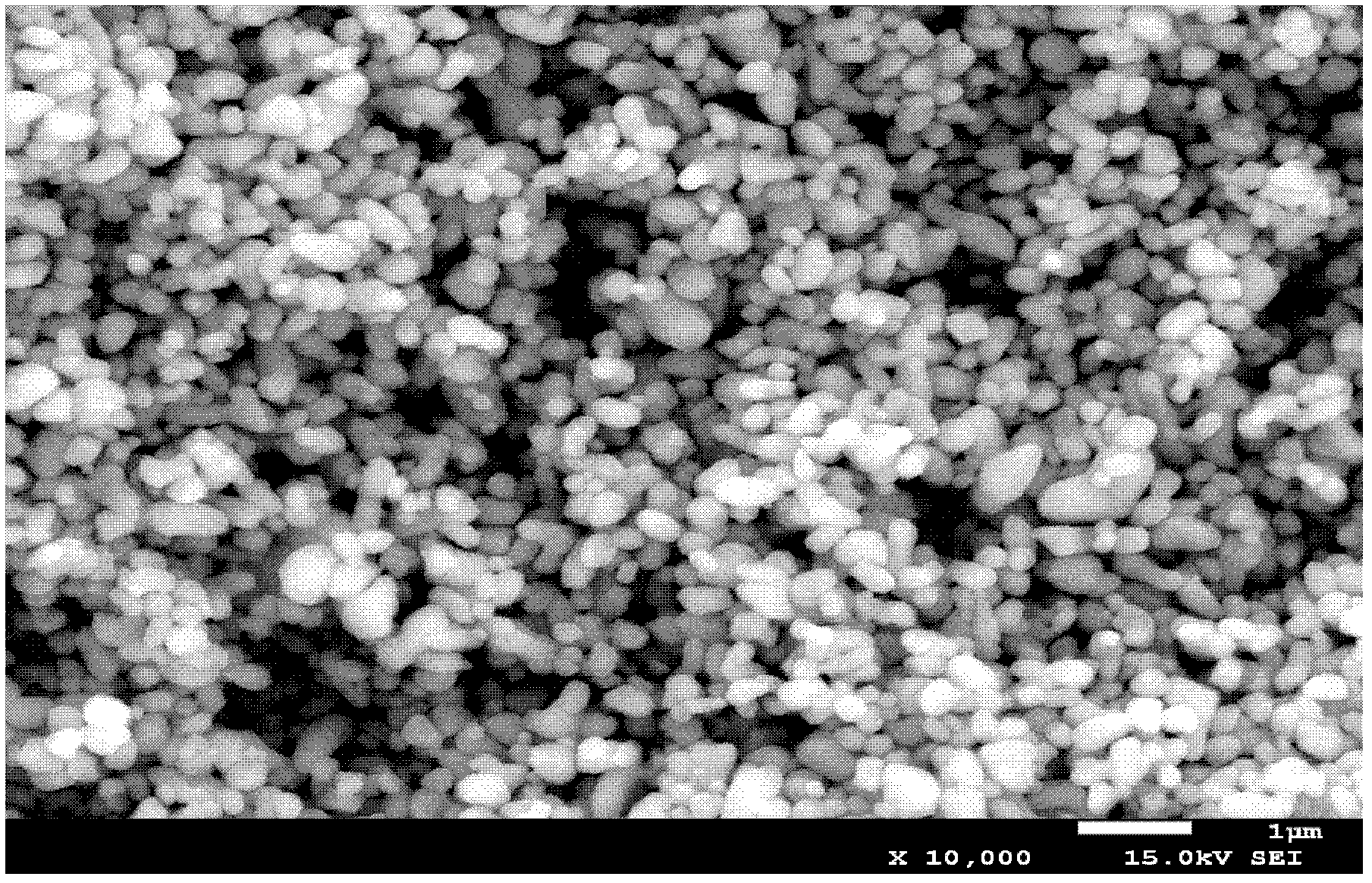

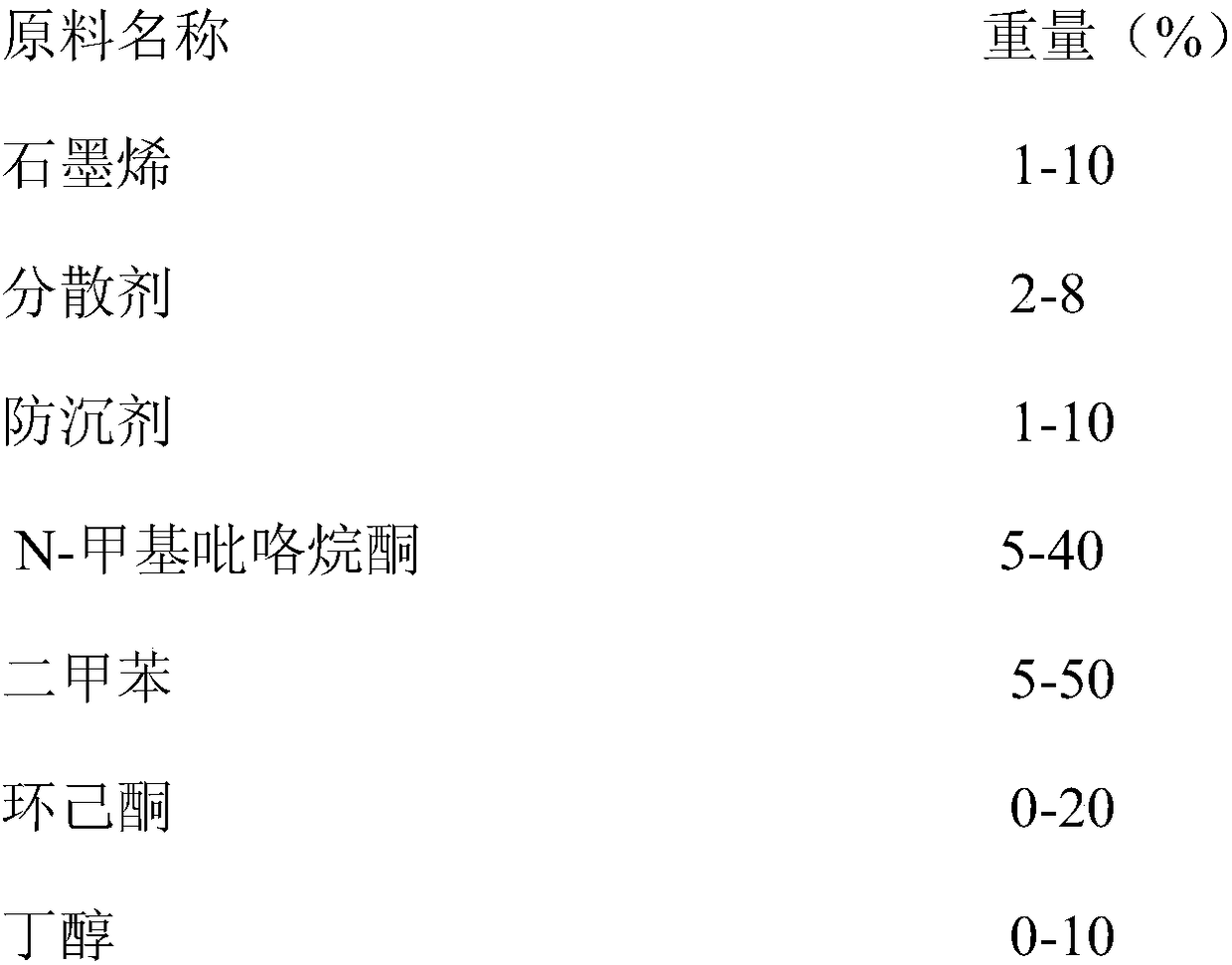

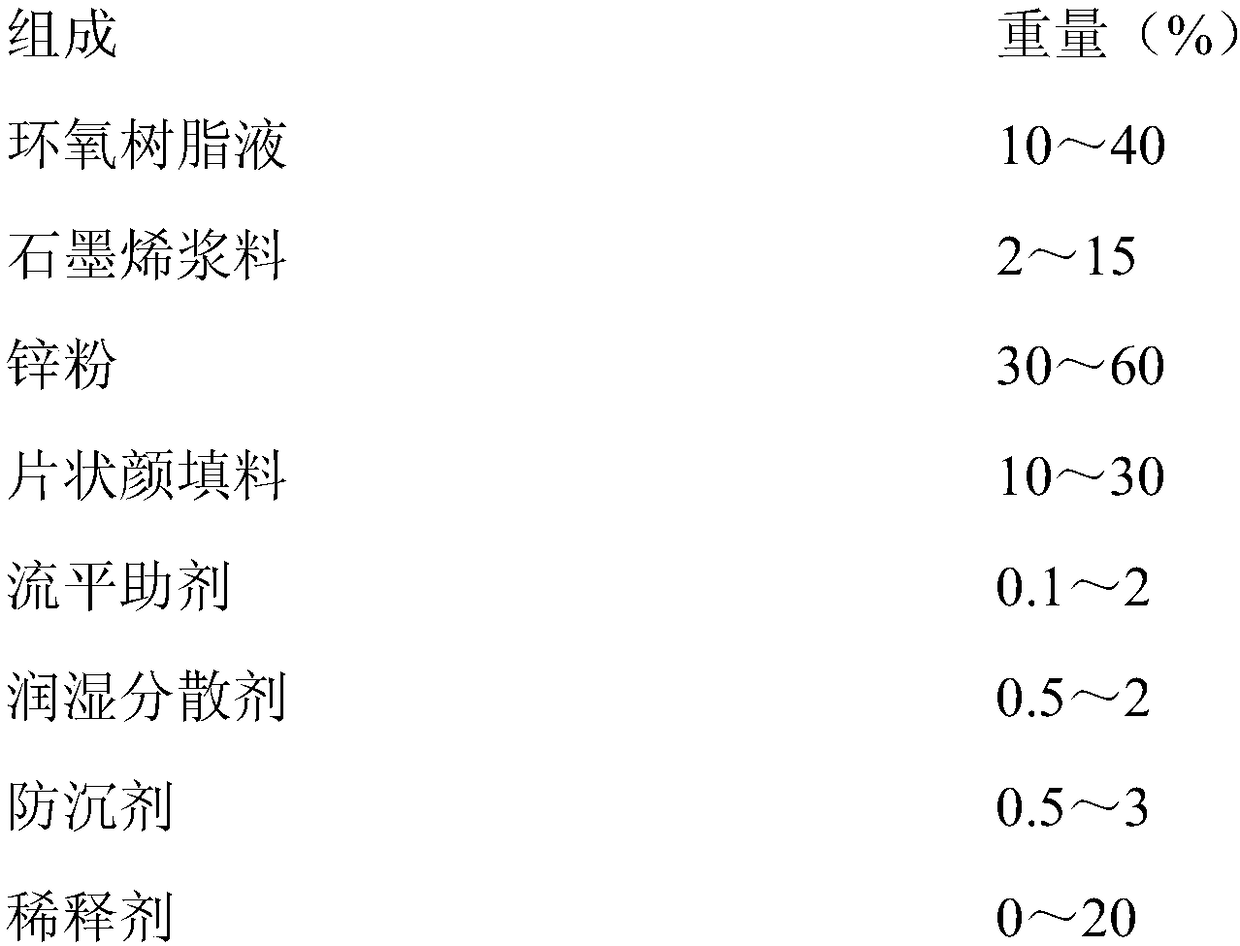

Thin-coating two-component anticorrosive coating for surface of precise steel structural part and preparation method thereof

InactiveCN108300146AImprove the effect of cathodic protectionImprove anti-corrosion efficiencyAnti-corrosive paintsEpoxy resin coatingsEpoxyCyclohexanone

The invention provides a thin-coating two-component anticorrosive coating for the surface of a precise steel structural part, wherein the two-component anticorrosive coating is composed of a componentA and a component B. The component A is composed of an epoxy resin liquid, graphene slurry, a zinc powder, flaky pigments and fillers, an auxiliary agent and a diluent. The component B is composed ofa polyamide curing agent and a mixture of xylene, n-butanol and cyclohexanone. The component A and the component B are evenly mixed according to the weight ratio of (5-15):1. The graphene slurry is prepared by adding powdery graphene and a dispersant into a mixed solvent under a stirring state, and dispersing in an ultrasonic oscillator to obtain the stable dispersed slurry. A coating layer has excellent cathodic protection effect, can be thin-coated to about 10-15 microns, still has good corrosion resistance, and can partly replace traditional phosphorization and oxidation processes.

Owner:MARINE CHEM RES INST +1

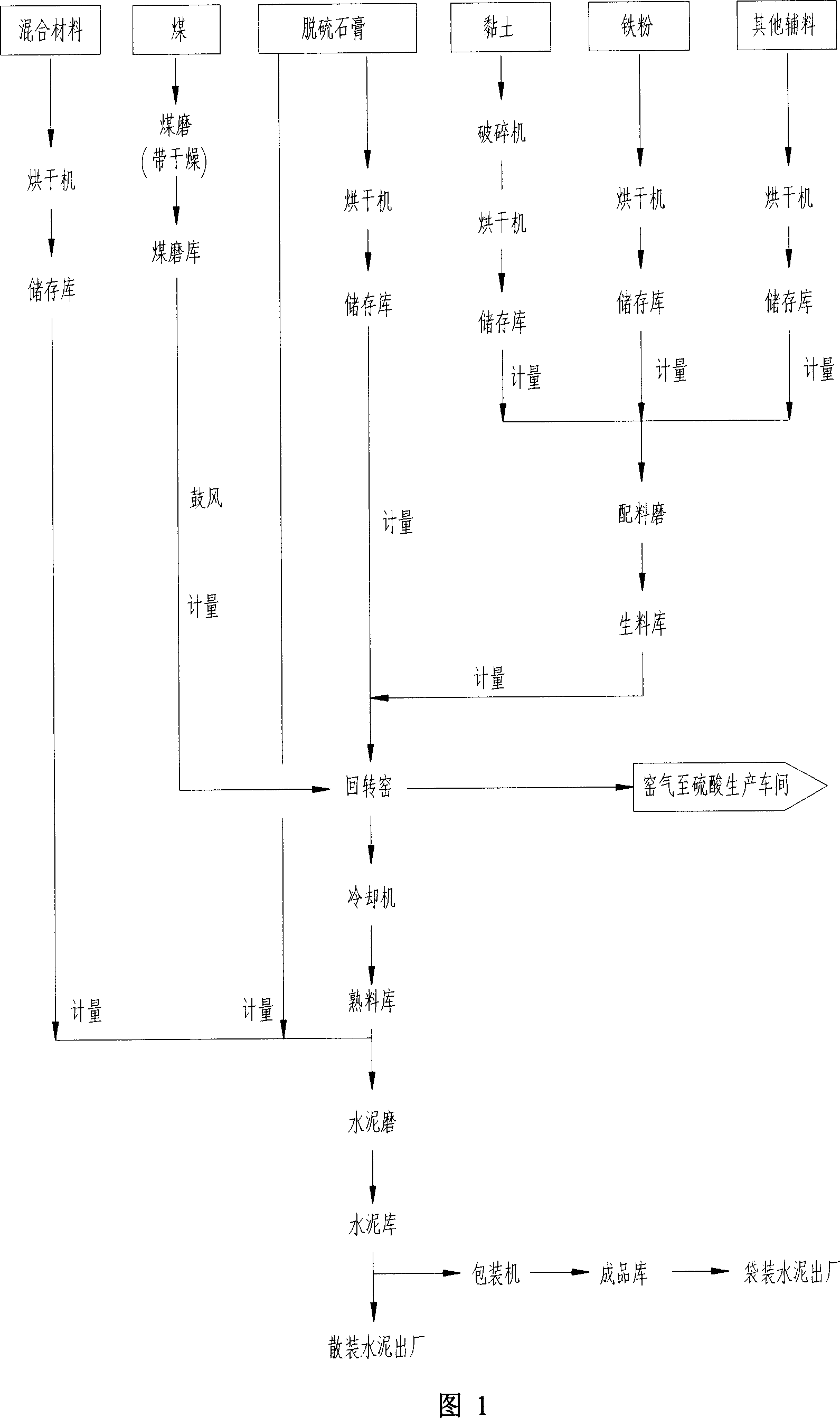

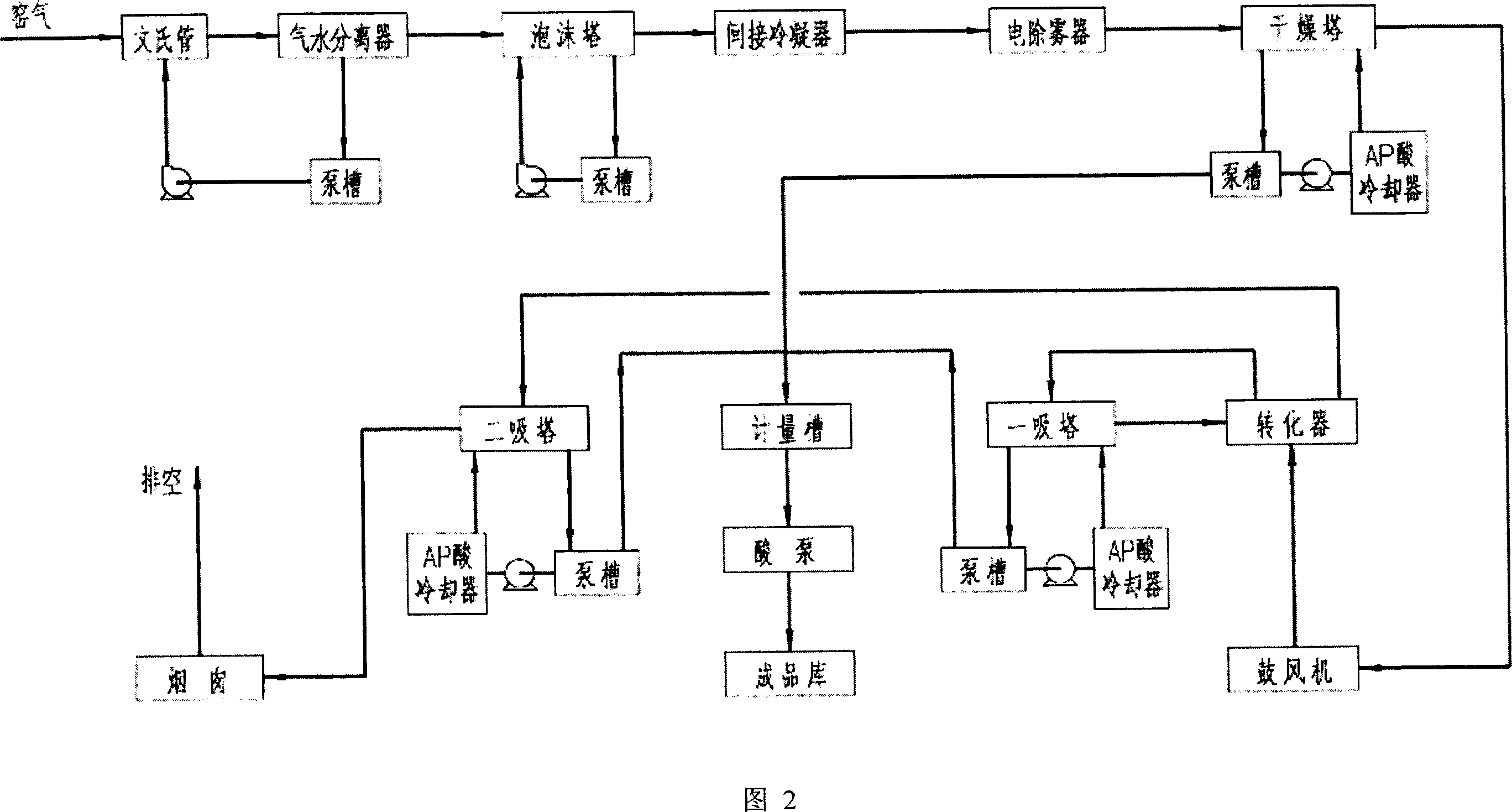

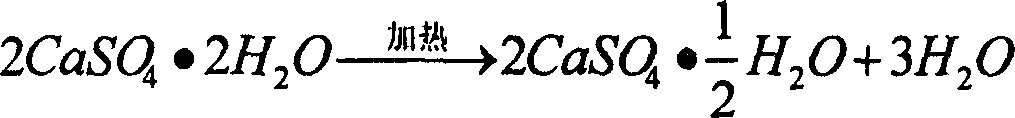

Method for producing cement and vitriol from desulfurized gesso of flue gas

InactiveCN1958498AAvoid secondary pollutionTypical circular economy developmentSulfur-trioxide/sulfuric-acidSilicon dioxidePollution

This invention discloses a method for manufacturing cement and sulfuric acid from flue-gas desulfurized gypsum. The method comprises: (1) drying flue-gas desulfurized gypsum to remove all of free water and part of water of crystallization and form hemi-hydrated gypsum; (2) adding substances containing Fe2O3, Al2O3 and SiO2, adding substances containing carbon, mixing, and heating to 900-1450 deg.C to obtain SO2 gas and cement clinker; (3) washing and purifying SO2 gas with Venturi tube and foam column to remove dust in flue gas, demisting by an electrodemistor, drying by concentrated sulfuric acid, and manufacturing industrial sulfuric acid by double transformation and double absorption method. By this method, flue-gas desulfurized gypsum can be utilized, thus solving the problems of land occupation and second pollution. The method is suitable for treating flue-gas desulfurized gypsum produced from both thermal power plants and desulfurization kilns. The method has such advantages as simple process, low energy consumption and high profit.

Owner:YONKER ENVIRONMENTAL PROTECTION

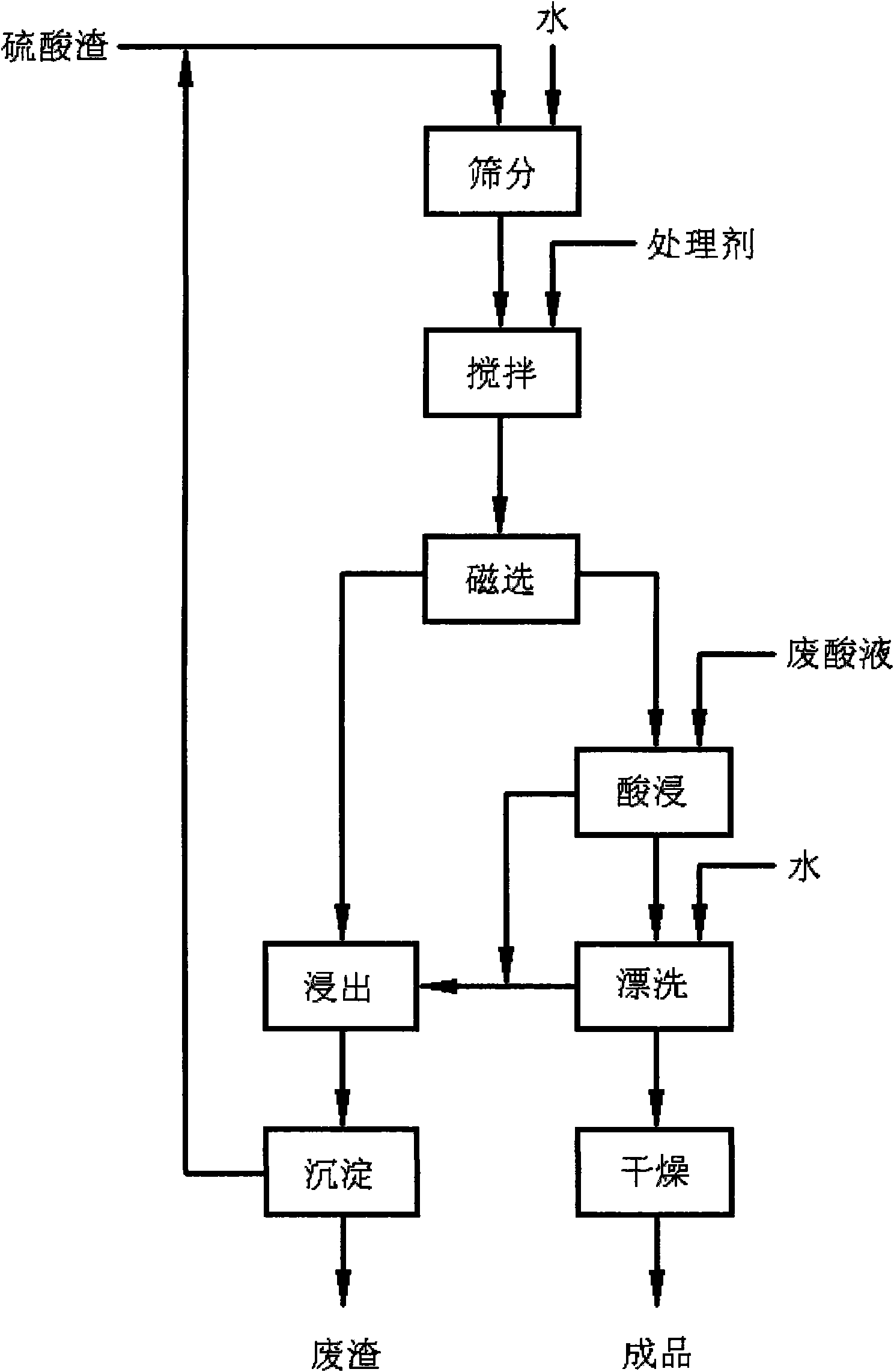

Method for recycling industrial waste sulfate slag

InactiveCN101554613ANo change in physical propertiesHigh recovery rateSolid waste disposalWet separationSocial benefitsSlag

The invention provides a method for recycling industrial waste sulfate slag, which comprises the steps of sieving, stirring, magnetic separation, acid dipping, rinsing and drying to obtain iron-bearing materials. The method not only reallocates the available resource of the sulfate slag which is difficult to be processed and has high pollution, but also reduces the severe contamination of the sulfate slag to the environment and simultaneously lowers the production cost greatly; the metal recovery rate is 50 to 82 percent, high quality iron concentrate with the grade of iron being larger than 60 percent, the grade of sulfur being smaller than 0.3 percent and the grade of arsenic being smaller than 0.1 percent is obtained; simultaneously the recovery processing capacity is large, the equipment is simple, the investment is small, the operation is convenient, the sulfate slag material is not limited, both the sulfate slag with high iron content and the sulfate slag with low iron content can be recycled, and the method has good social benefit and remarkable economic effect.

Owner:房志强 +1

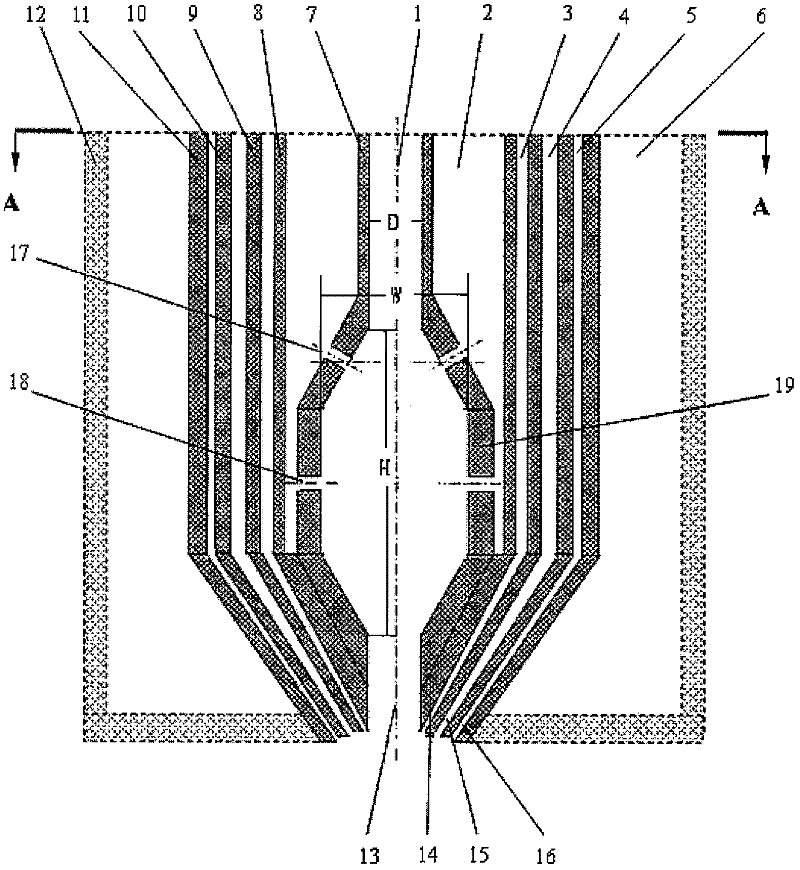

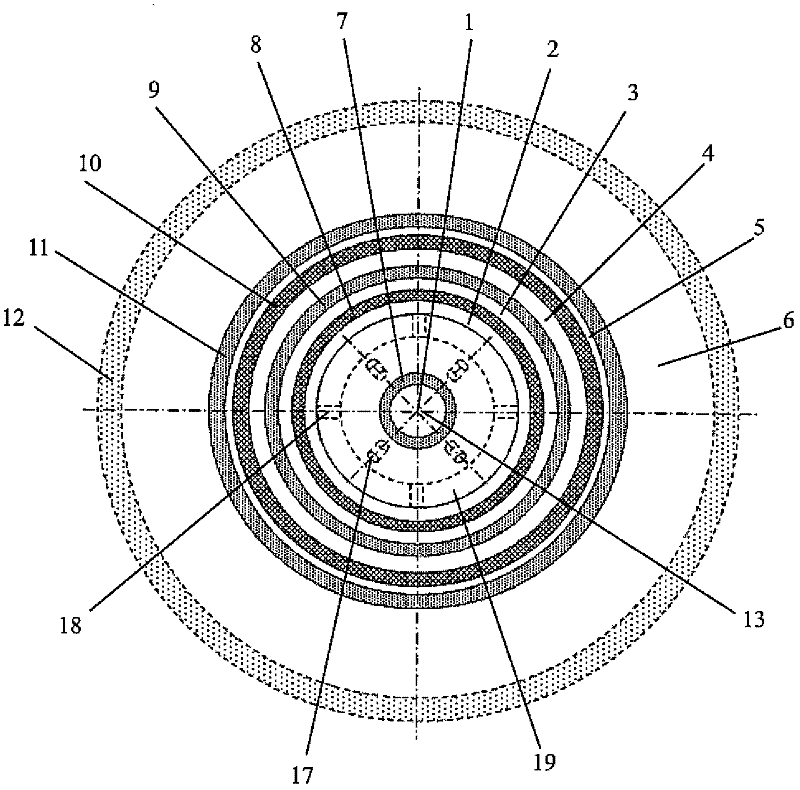

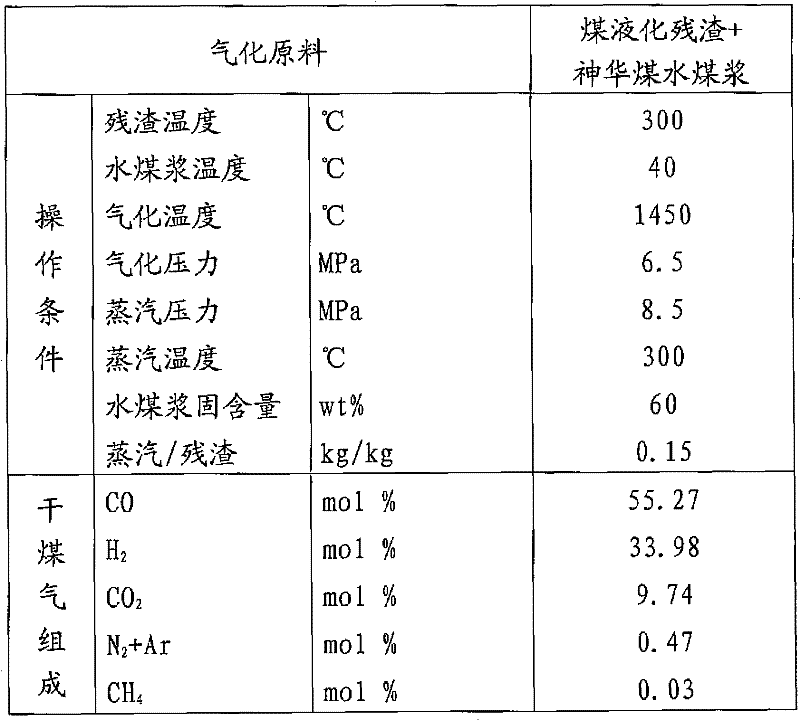

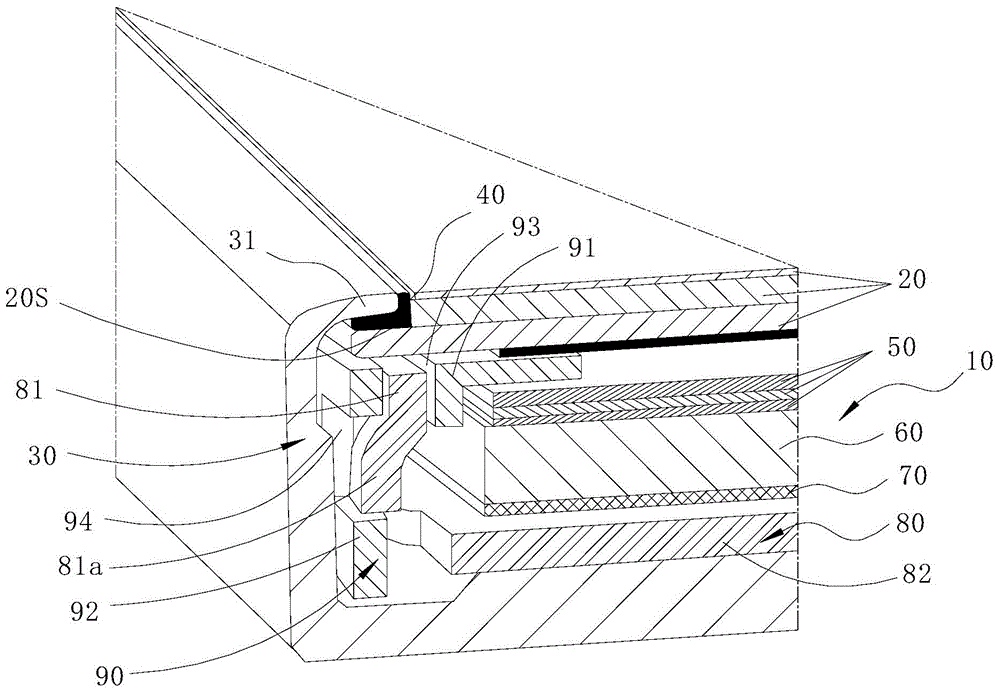

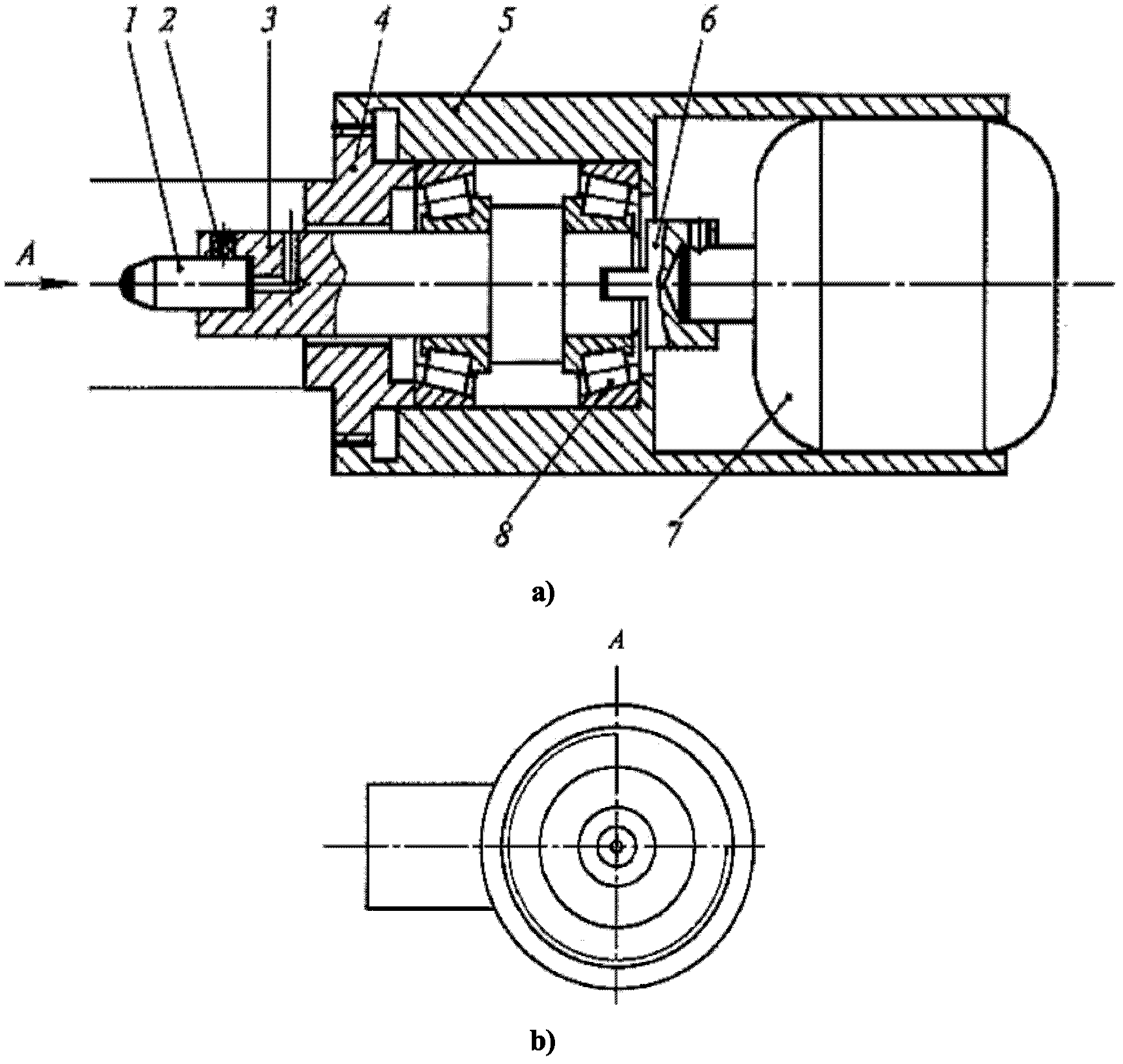

A joint gasification nozzle of coal liquefaction residue and coal water slurry and its application

ActiveCN102268300AImprove atomization effectCompact structureLiquid spraying apparatusGranular/pulverulent flues gasificationCoal waterLiquid state

The invention discloses a coal liquefaction residue and coal water slurry combined gasification nozzle which comprises a coal liquefaction residue pipe, a steam circular pipe, an inner circular oxygen pipe, a coal water slurry circular pipe, an outer circular oxygen pipe, a water-cooling circular pipe and a coal liquefaction residue and steam mixing chamber, wherein the coal liquefaction residue pipe, the steam circular pipe, the inner circular oxygen pipe, the coal water slurry circular pipe, the outer circular oxygen pipe and the water-cooling circular pipe are coaxially arranged from inside to outside in sequence; one end of the coal liquefaction residue and steam mixing chamber is communicated with the tail end of the coal liquefaction residue pipe, and the other end of the mixing chamber is communicated with a coal liquefaction residue and steam nozzle orifice; the wall of the mixing chamber is provided with a steam nozzle orifice which is communicated with the steam circular pipe; the tail end of the steam circular pipe is closed; the tail end of the coal water slurry circular pipe is communicated with the coal water slurry nozzle orifice; the tail end of the inner circular oxygen pipe is communicated with the inner circular oxygen nozzle orifice; and the tail end of the outer circular oxygen pipe is communicated with the outer circular oxygen nozzle orifice. By using the gasification nozzle, combined gasification of viscous heavy fuels such as molten coal liquefaction residues, high-temperature liquid-state heavy oil, residual oil and the like and coal water slurry can be realized.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for preparing modified asphalt

ActiveCN101161778BGood dispersionAvoid damageWorking-up pitch/asphalt/bitumenBuilding insulationsMolten stateAsphalt

The invention discloses a method for preparing modified asphalt by coal direct liquefaction oil residue, wherein, 150 DEG C to 280 DEG C molten coal direct liquefaction oil residue and 100 DEG C to 180 DEG C molten base asphalt are mixed evenly at 150 DEG C to 280 DEG C to form liquid melt so as to obtain modified asphalt. With simple process, energy saving, environmental protection and high efficiency, the method improves the quality of modified asphalt.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

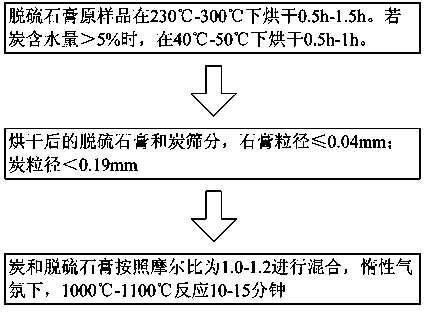

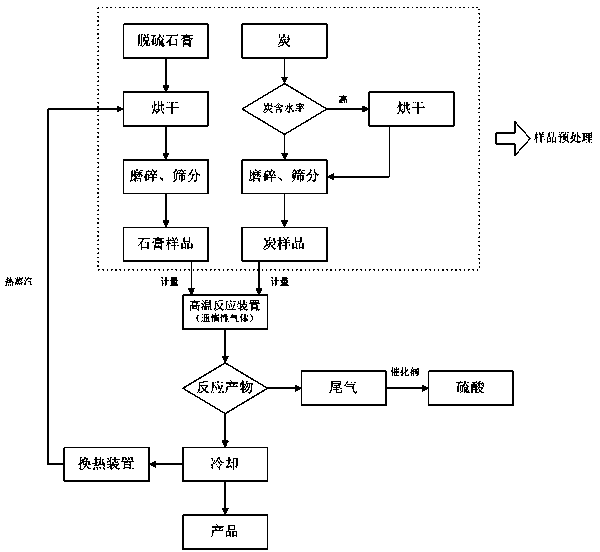

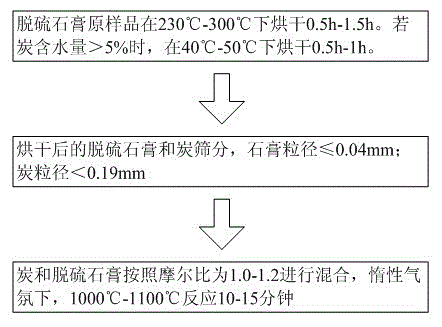

Production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum

ActiveCN103482584AAvoid secondary pollutionReduce miningSulfur compoundsCalcium/strontium/barium oxides/hydroxidesNitrogen gasAtmospheric pollution

The invention discloses a production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum. The technology comprises the following steps: drying desulfurized gypsum at 230-300DEG C for 0.5-1.5h, wherein drying pretreatment is carried out at 40-50DEG C for 0.5-1h if the water content of carbon is above 5%; screening the desulfurized gypsum and the carbon for controlling the gypsum particle size below 40mum and the carbon particle size below 187.5mum; and mixing the screened carbon and the screened desulfurized gypsum according to a carbon-to-calcium sulfate mole ratio of 1:1-1.2:1 to obtain a mixed sample, putting the mixed sample in a high temperature reaction device, and reacting at 1000-1100DEG C under the protection of nitrogen or an inert gas under a gas flow velocity of 4-10m / s for 10-15min. The technology has the advantages of high reaction efficiency, fast reaction speed, less carbon consumption, high finally-obtained product quality, and no atmospheric pollution.

Owner:NANJING UNIV OF SCI & TECH

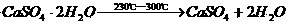

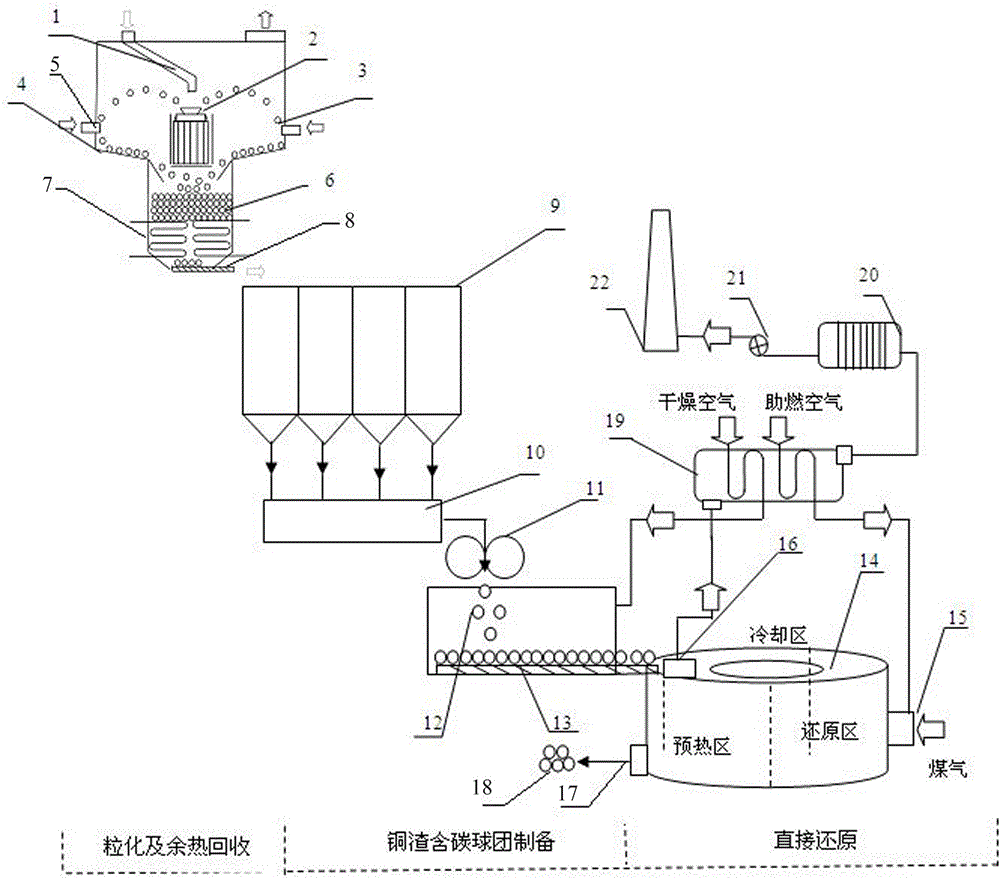

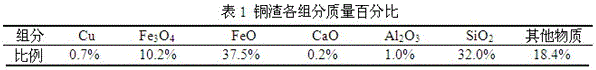

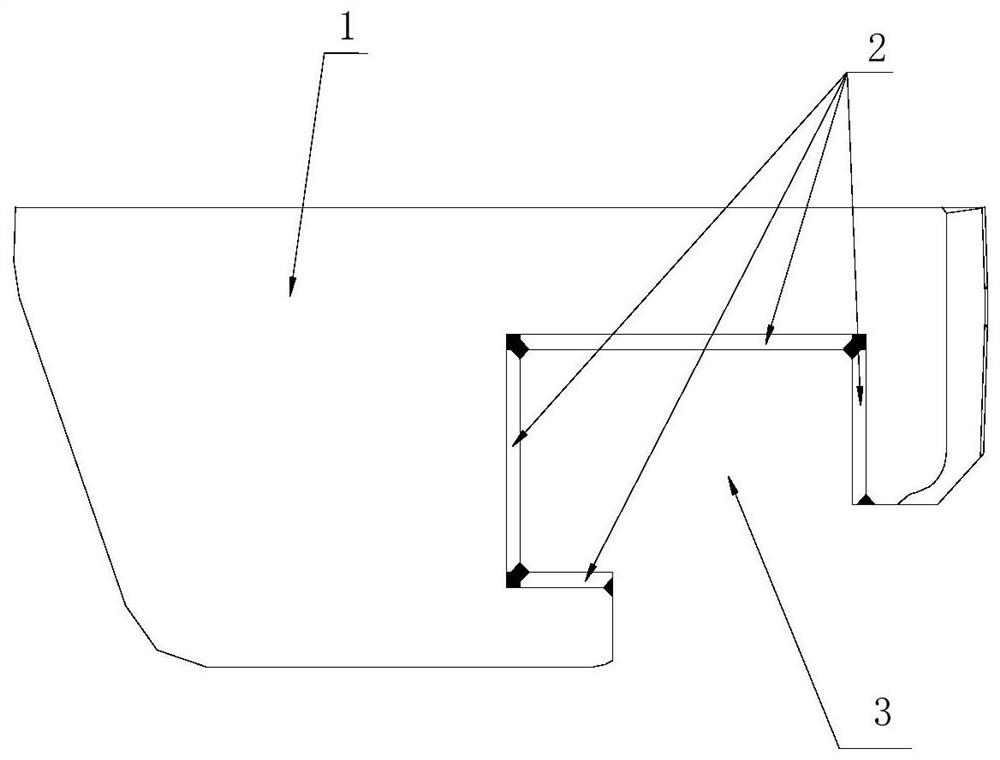

System and method for recycling copper slag waste heat and directly reducing and extracting iron

ActiveCN106086276AEliminate the grinding processReduce energy consumptionShaft furnaceHearth type furnacesFerrous metallurgyFlue gas

The invention belongs to the technical field of non-ferrous metallurgy and particularly relates to a system and method for recycling copper slag waste heat and directly reducing and extracting iron. According to the system and method for recycling the copper slag waste heat and directly reducing and extracting the iron, granulated copper slag particles are directly prepared into copper slag carbon-containing particles, the ore grinding procedure is omitted, and the energy consumption in the pelleting process of pellets in the prior art is reduced; in a drying furnace, the compressive strength of dried copper slag carbon-containing pellets is improved, and a guarantee is provided for direct reducing; according to the system and method for recycling the copper slag waste heat and directly reducing and extracting the iron, by controlling the temperature of a reducing furnace, the reducing rate of the iron in copper slag is increased; and by recycling flue gas waste heat in the furnace, the waste heat recycling rate is increased, the production cost is reduced, the energy conservation and emission reduction purposes are achieved, and the problem that copper slag waste heat recycling and iron recycling are different at current is solved.

Owner:NORTHEASTERN UNIV

Plastering mortar using high-volume slag and preparation method thereof

The invention relates to a plastering mortar using high-volume slag and a preparation method thereof. Every cubic meter of plastering mortar using the high-volume slag comprises the following components in percentage by mass: 16 to 30 percent of ordinary Portland cement, 5 to 10 percent of pulverized fuel ash, 30 to 70 percent of sand, 0 to 30 percent of slag and 1.2 to 3.0 percent of plastering mortar master batch. The preparation method comprises the following steps of: firstly, drying the slag and machine-made river sand respectively until the water content is less than 0.2 percent, sieving the dried slag and machine-made river sand through a 3-millimeter sieve to remove large particles of more than 3 millimeters and feeding the slag and the machine-made river sand into a sand cabin for later use; secondly, metering the selected plastering mortar master batch serving as a raw material according to a mass proportion, fully mixing the materials in a mixing machine for 4 to 6 minutes and feeding the mixture into an additive cabin for later use; and lastly, metering the plastering mortar components according to the mass proportion in a formula and mixing the components in the mixing machine for 3 to 5 minutes so as to obtain a finished product. The slag is used instead of a part of river sand and machine-made sand, so that cost is low, environmental pollution is reduced, and social and economic benefits are remarkable.

Owner:JIANGSU NIGAO SCI & TECH +1

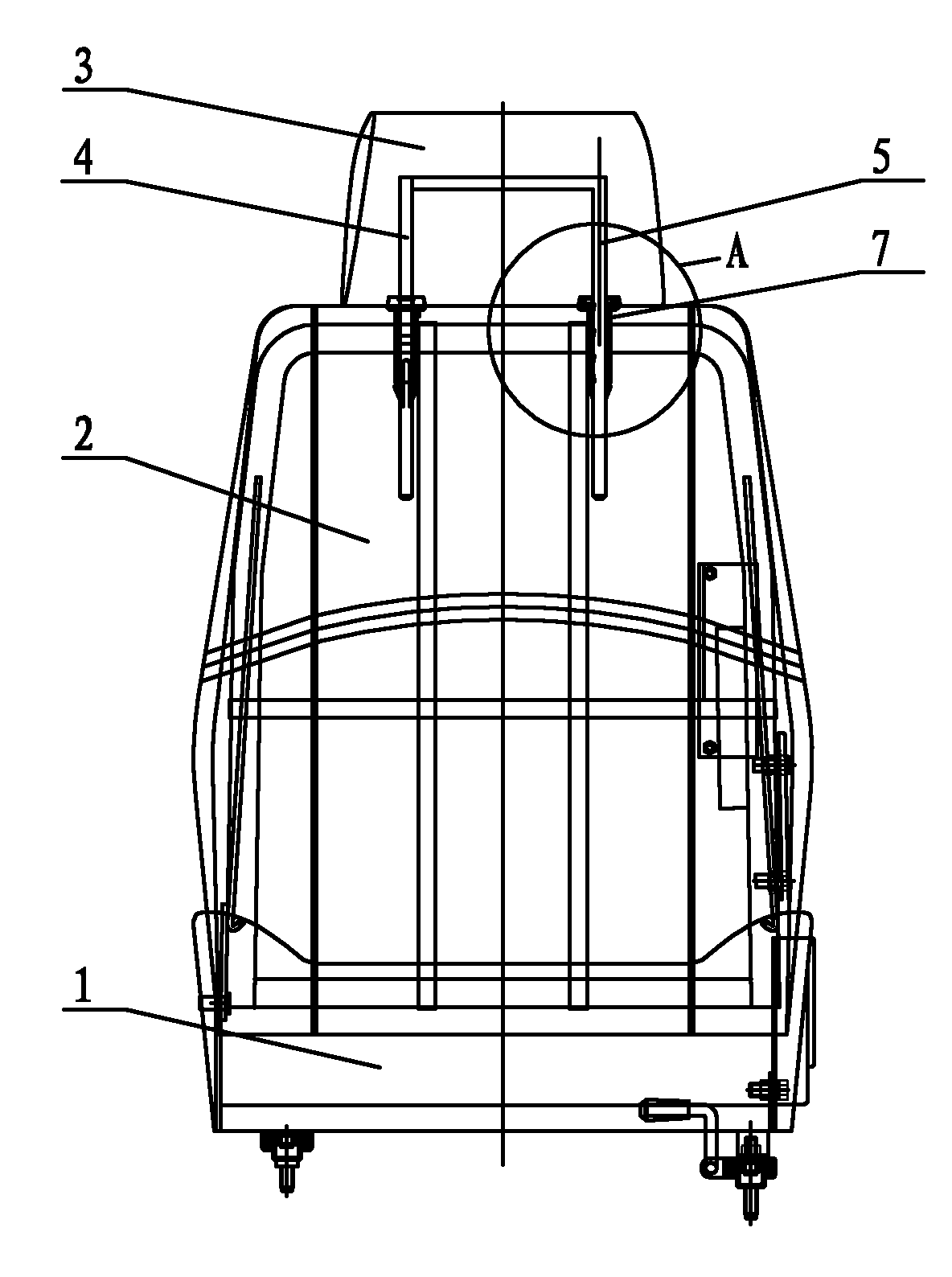

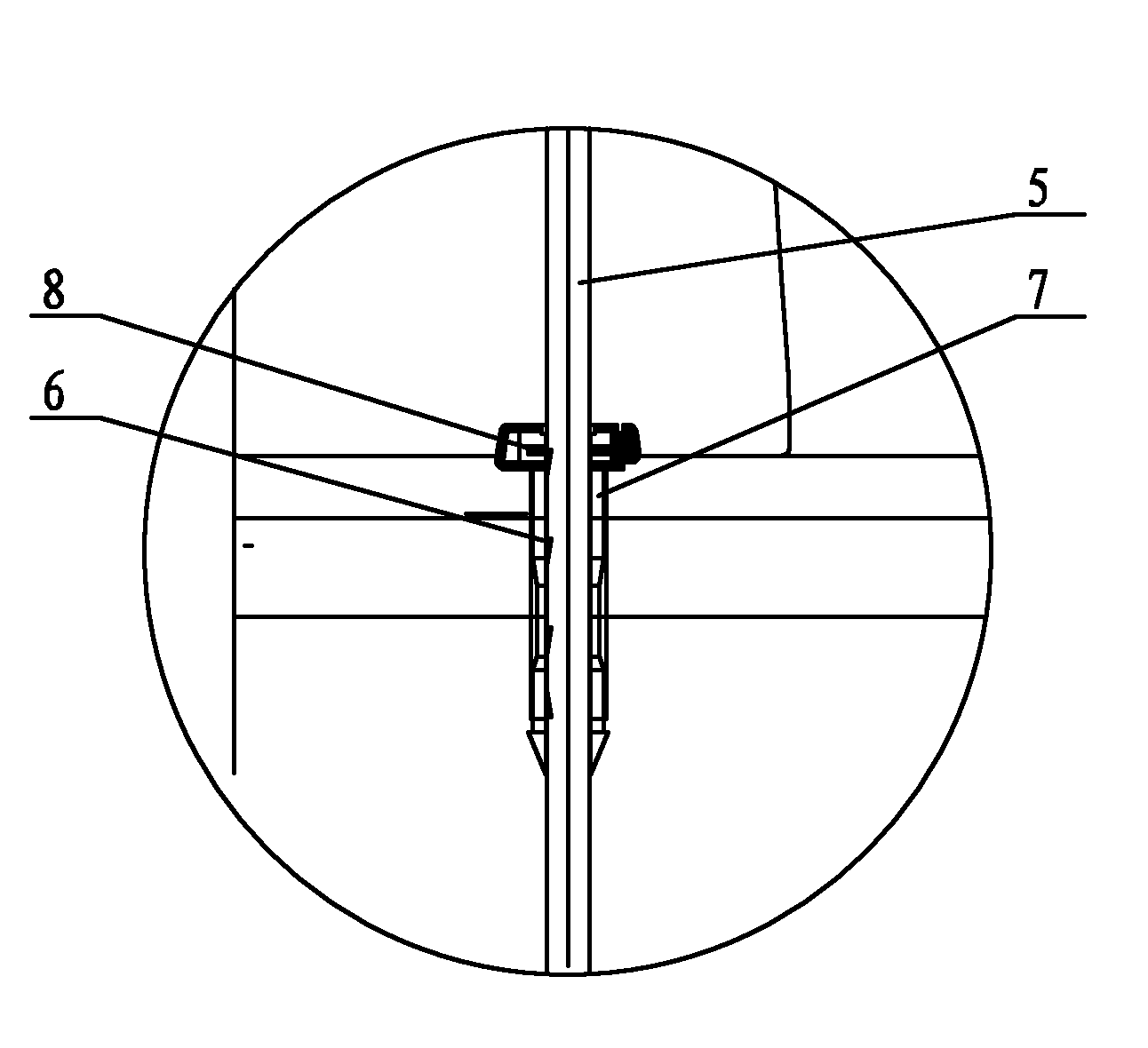

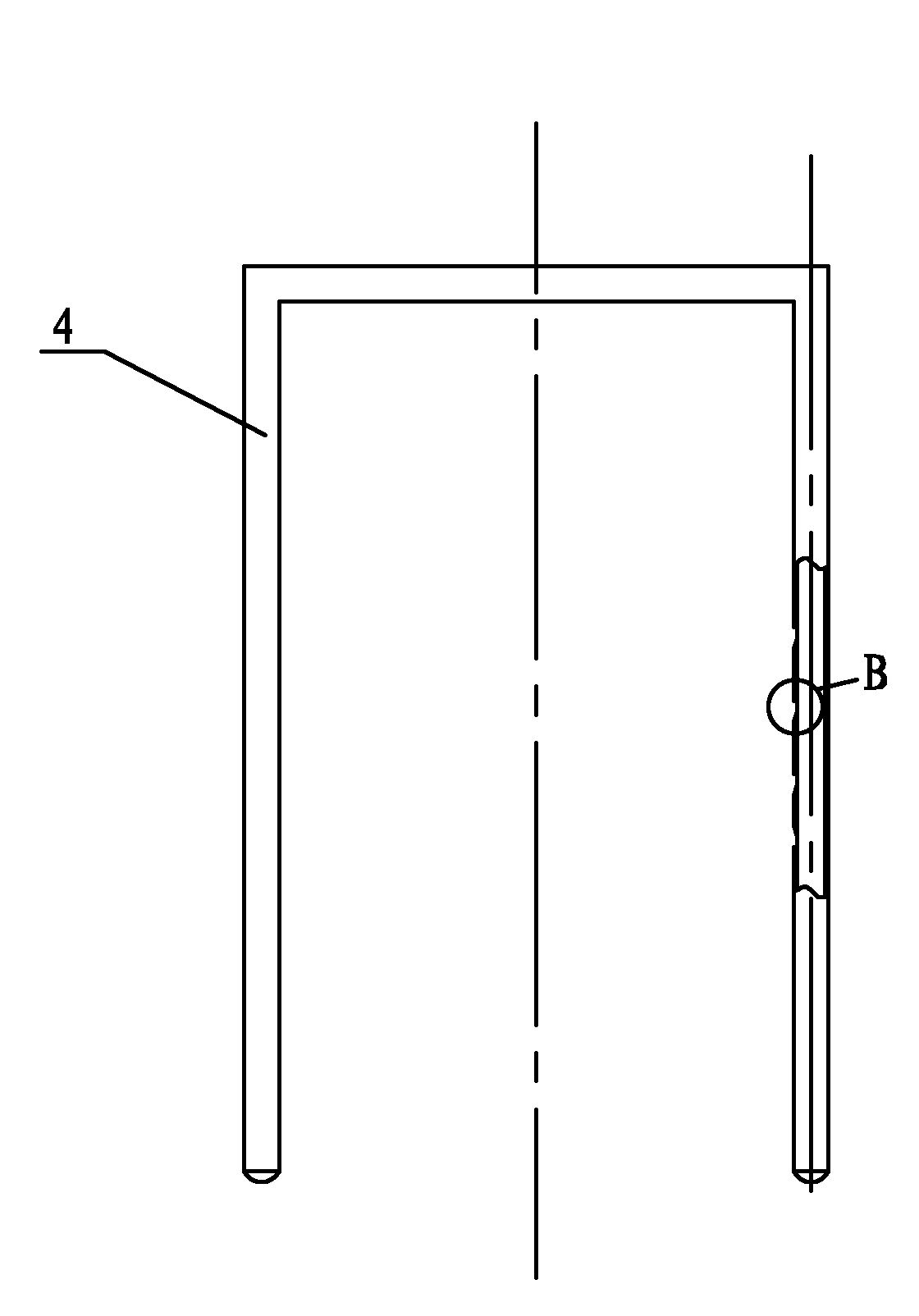

Seat headrest rod and manufacturing process thereof

ActiveCN102267409BReduced impact strengthIncrease productivitySeat framesStoolsEngineeringMechanical engineering

The invention provides a seat headrest rod and a manufacturing process thereof and relates to the seat headrest rod with a positioning opening slot and the manufacturing process thereof. The invention aims to provide a safe and reliable seat headrest rod and a seat headrest rod manufacturing process with high processing quality and high production efficiency. The seat headrest rod comprises a cross bar and two upright rods, wherein the two upright rods are respectively fixedly connected to the two ends of the cross bar; the upright rods are hollow tubes; a plurality of opening slots are formed on at least one of the upright rods along longitudinal direction; the opening slots are composed of upper side walls, slot bottoms and lower side walls; the external ends of the upper side walls arevertically connected to the tube walls of the upright rods; the upper ends of the slot bottoms are vertically connected to the internal ends of the upper side walls; the internal ends of the lower side walls are fixedly connected to the lower ends of the slot bottoms; the external ends of the lower side walls are fixedly connected to the tube walls of the upright rods; the lower side walls are inclined downward from inner to outer; and the thicknesses of the upper side walls, the slot bottoms and the lower side walls are almost as same as the thicknesses of the tube walls of the upright rods.

Owner:LANGFANG ZHONGDE AUTO SEAT MFG

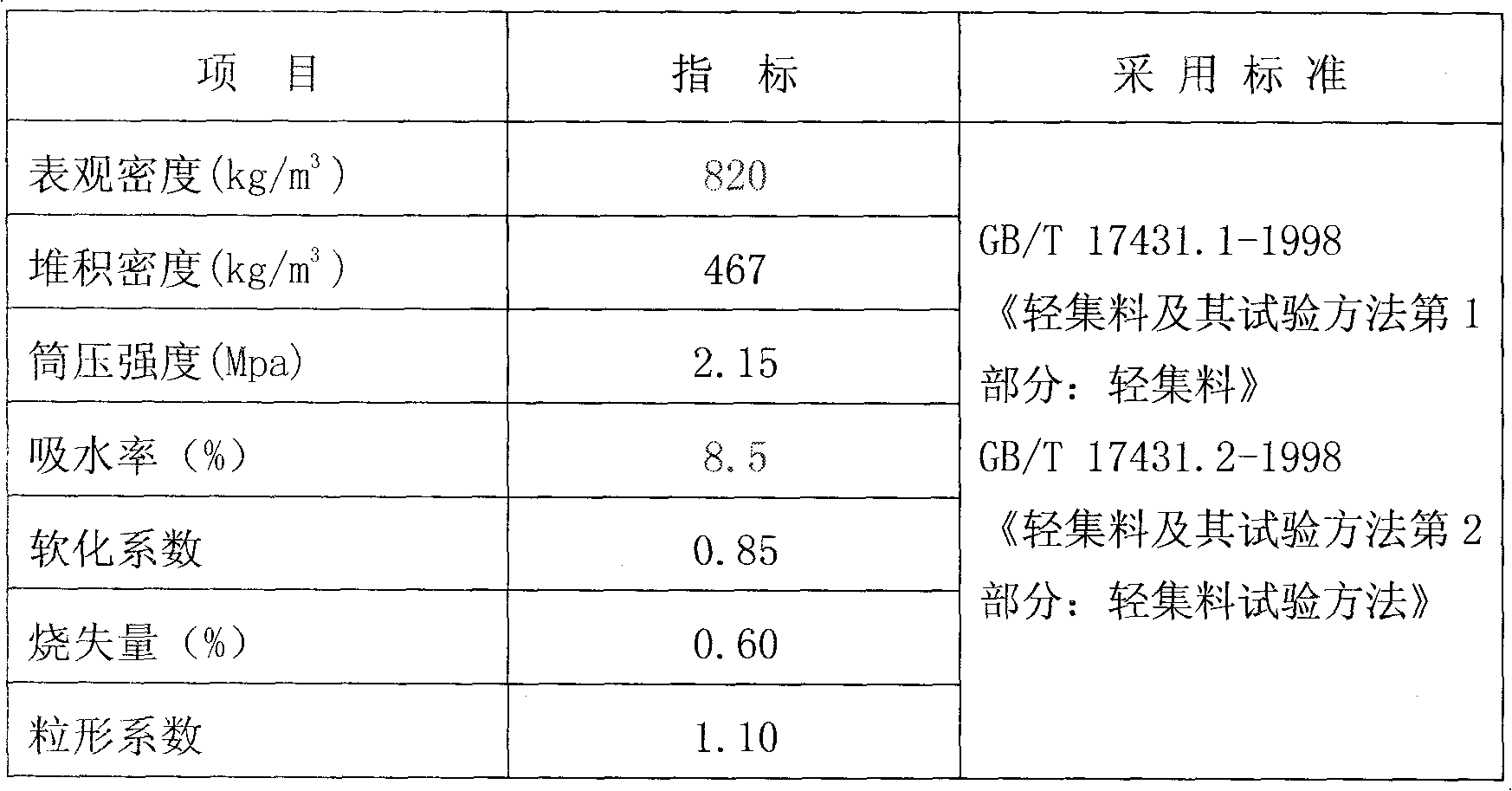

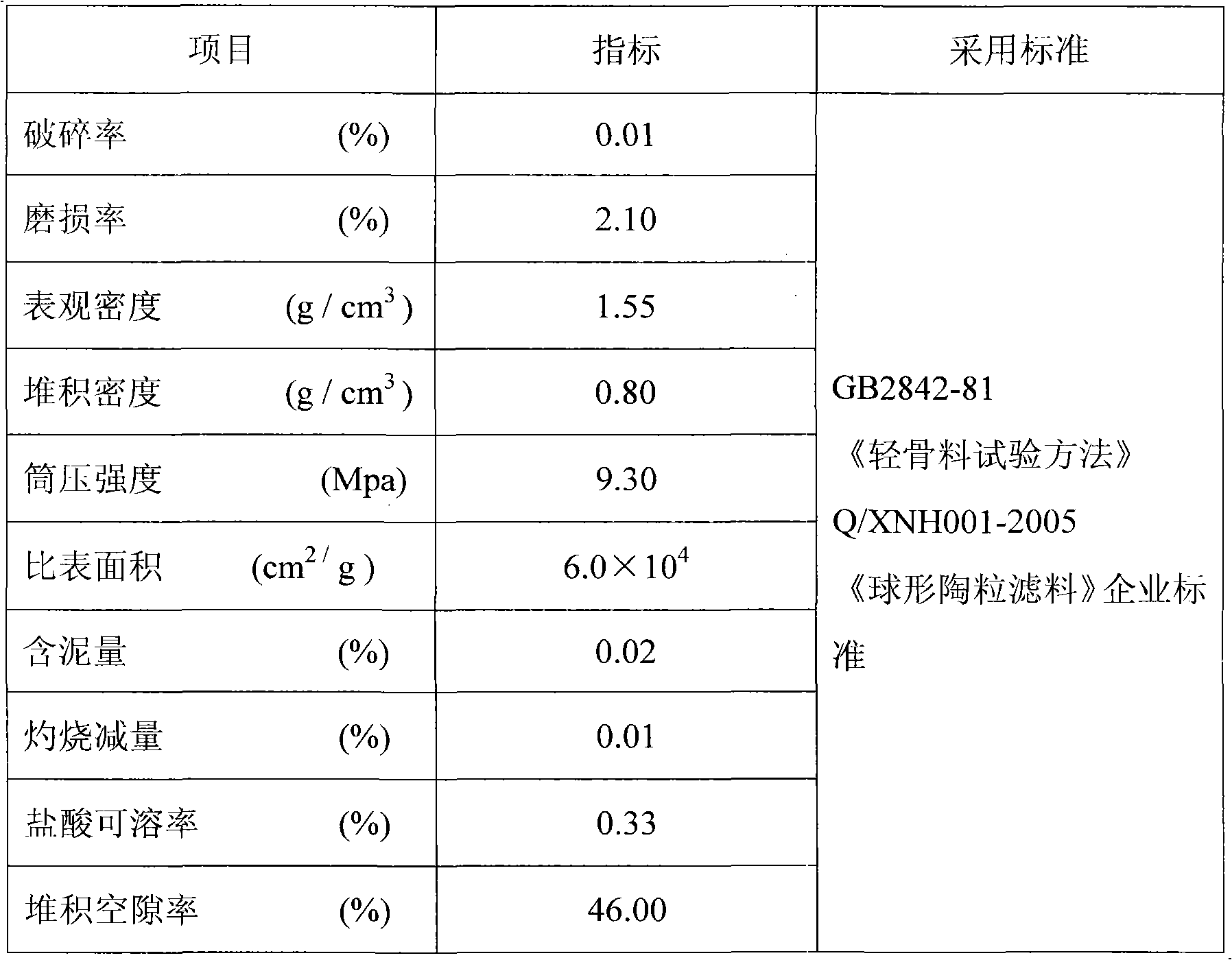

Method for preparing light building material ceramic particle by utilizing slate sawn mud

InactiveCN101851110ASimple production processReduce manufacturing costSolid waste disposalCeramicwareSodium silicateBuilding material

The invention relates to a method for preparing light building material ceramic particle by utilizing slate sawn mud. The product formula includes: 60-100% of slate sawn mud (containing 30% of moisture) and 0-40% of slate dry powder; and 1-2% of sodium silicate binder is additionally doped. The manufacturing processing step includes that the slate sawn mud is filtered until moisture is less than 30%, the slate sawn mud and powder material obtained by sieving crushed slate are pre-stirred into bulk particles in a dual spindle stirring machine, so as to form cue ball, when the moisture contained in the slate sawn mud is less than 15%, the slate sawn mud also can be independently stirred and broken into particles in the stirring machine, then the cue ball is fed into a ball forming mill to be sprayed with mist water, and a small amount of binder is added, so that the particle forms a spherical particle with the diameter Phi of 5-30mm by rolling, then the material ball is fed into a rotary kiln to be calcined, the calcining temperature is 1100-1200 DEG C, and calcining time is 25-40min, and the fiery material ball taken out from the kiln is cooled by adopting a monocular cooling machine. The method has simple production technology and low cost, and the prepared slate sawn mud ceramic particle has high tube pressure strength and wide application.

Owner:NANCHANG UNIV

Method for sealing conical surface by reaming and grinding cylinder cover valve

ActiveCN102218659ALow costImprove work efficiencyOther manufacturing equipments/toolsEngineeringHardness

The invention relates to a method for sealing a conical surface by a reaming and grinding cylinder cover valve, comprising the following steps: (1) installing a blank cylinder cover on a machining center; firstly, machining a positioning plane; machining a dowel hole on the positioning plane by the technical steps of drilling, boring and reaming; setting a positioning reference by using the dowel hole on the positioning plane; machining the inner bore of a valve conduit and a race conical surface by a guiding cutter; machining and shaping the inner bore of the valve conduit and a race hole by a compound tool; quenching the race conical surface by laser, wherein the hardness is 50HRC; clamping the part of the race conical surface on the tool; regulating a dedicated grinding head, wherein the bounce of a guiding part and a clamping part is not more than 0.015mm; moving the center of the cutter bar to the center of the valve conduit; regulating the revolving speed, the feeding speed and the feeding mode of a grinding wheel; machining the race conical surface; after machining, moving to the canters of other conduits; repeating the above working procedures; and finishing machining the part. According to the method, the problem that the race conical surface of which the hardness is more than 50HRC on the cylinder cover is difficult to machine is solved, the machining cost is low, the working efficiency is improved.

Owner:CHINA NORTH IND GRP NO 70 RES INST

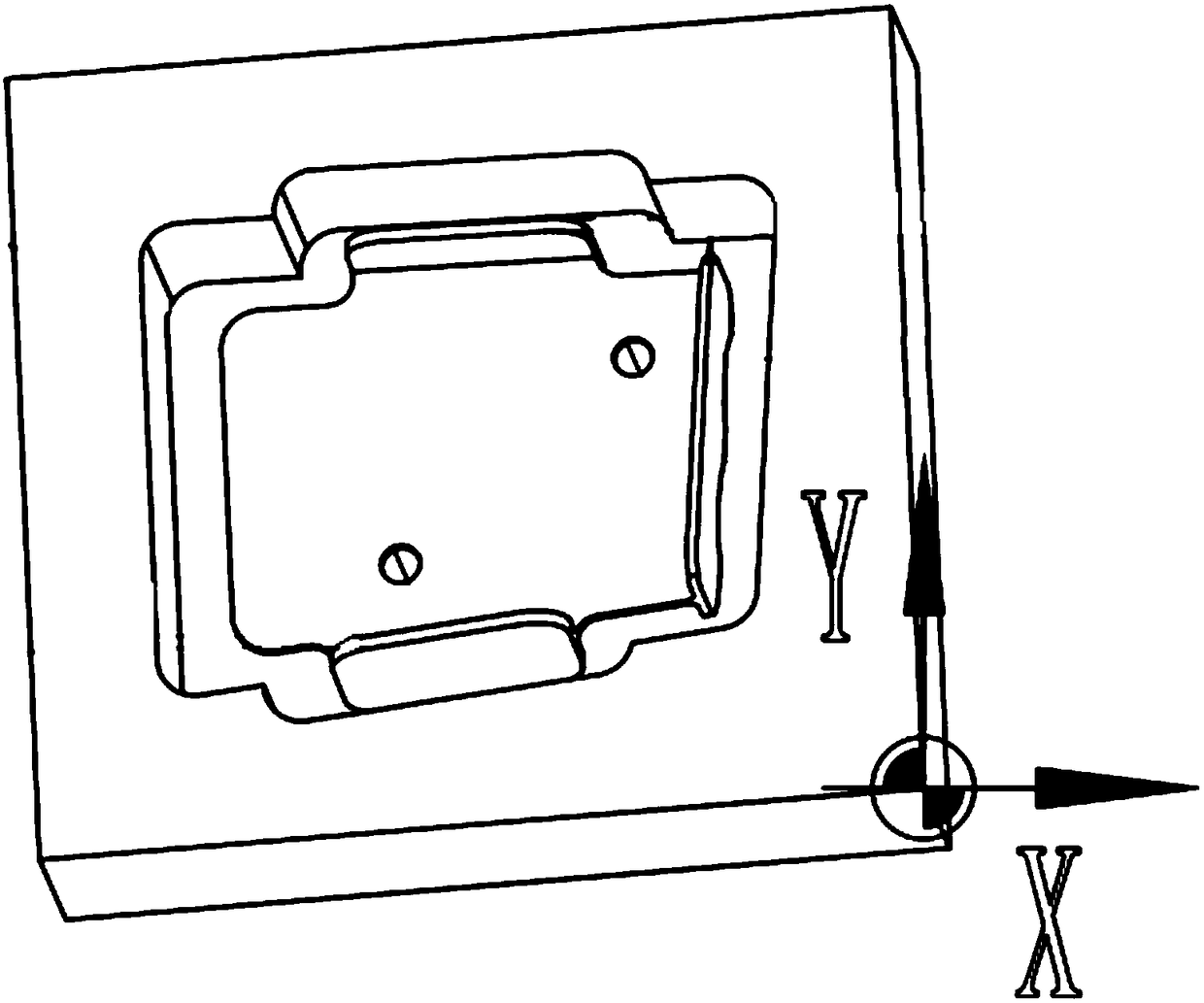

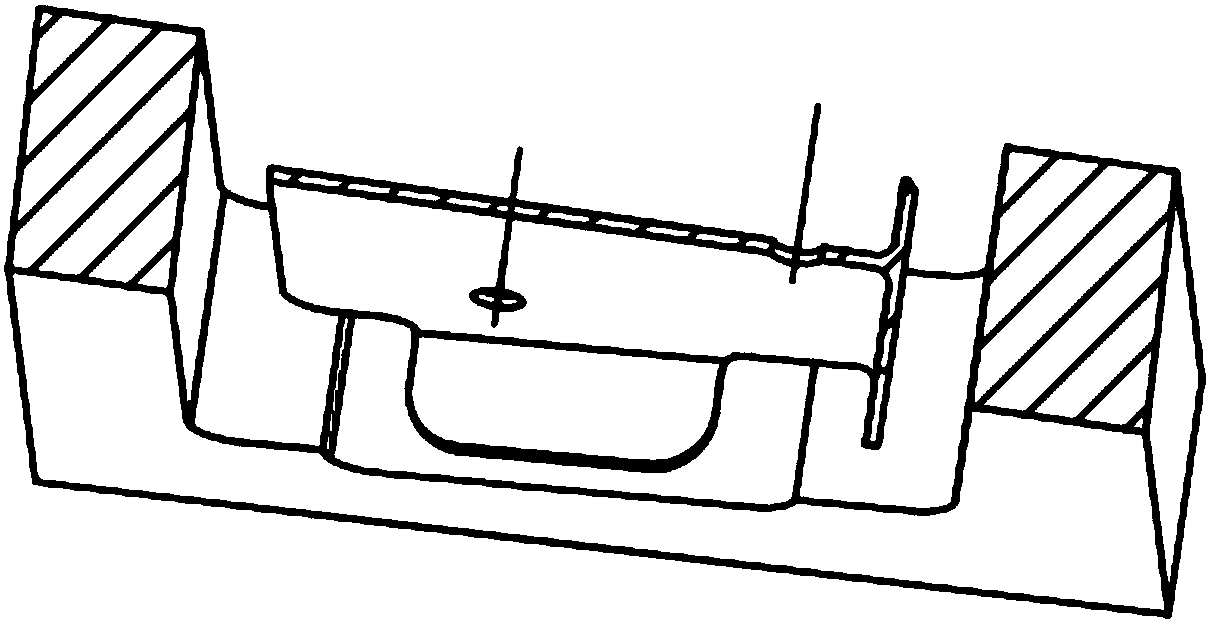

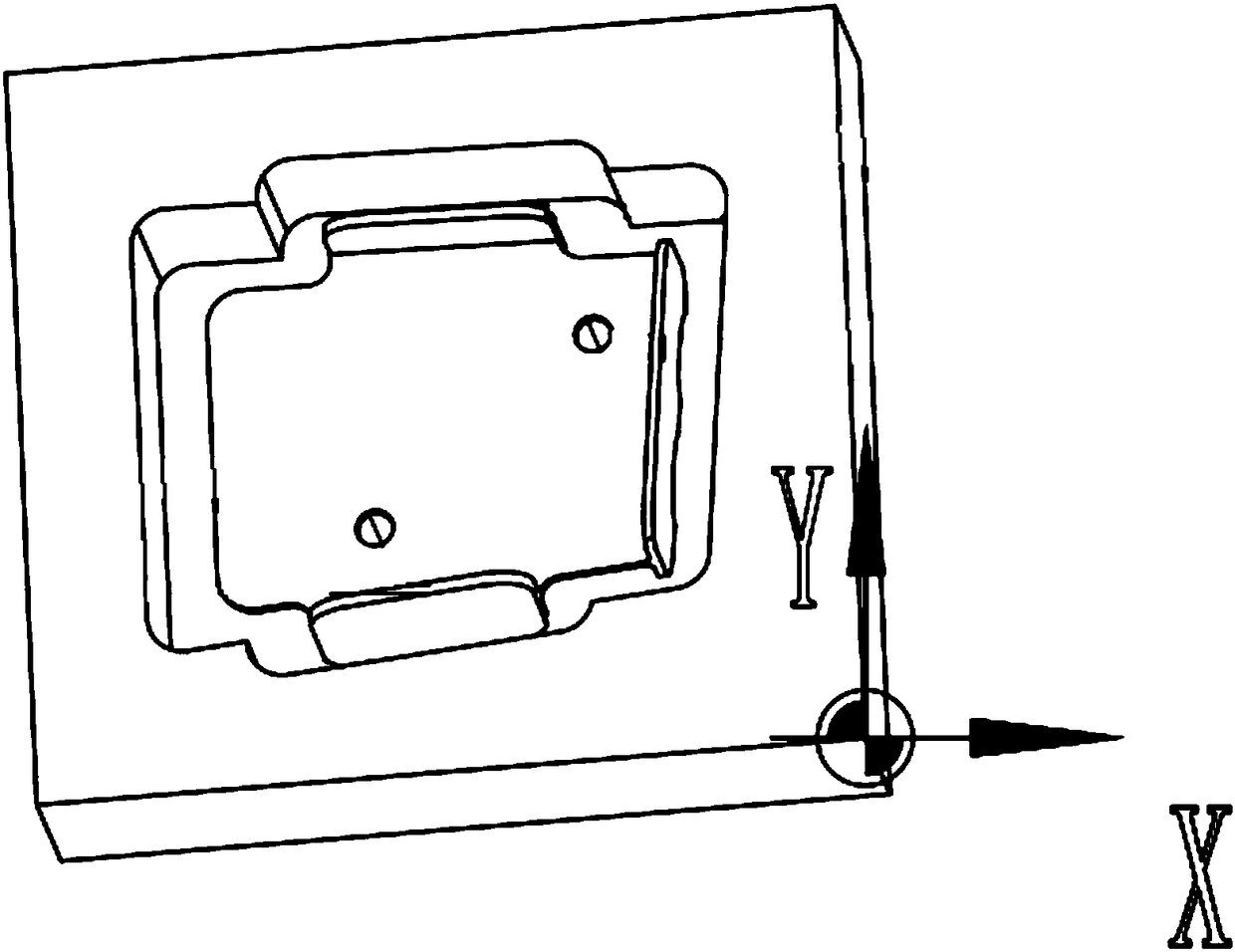

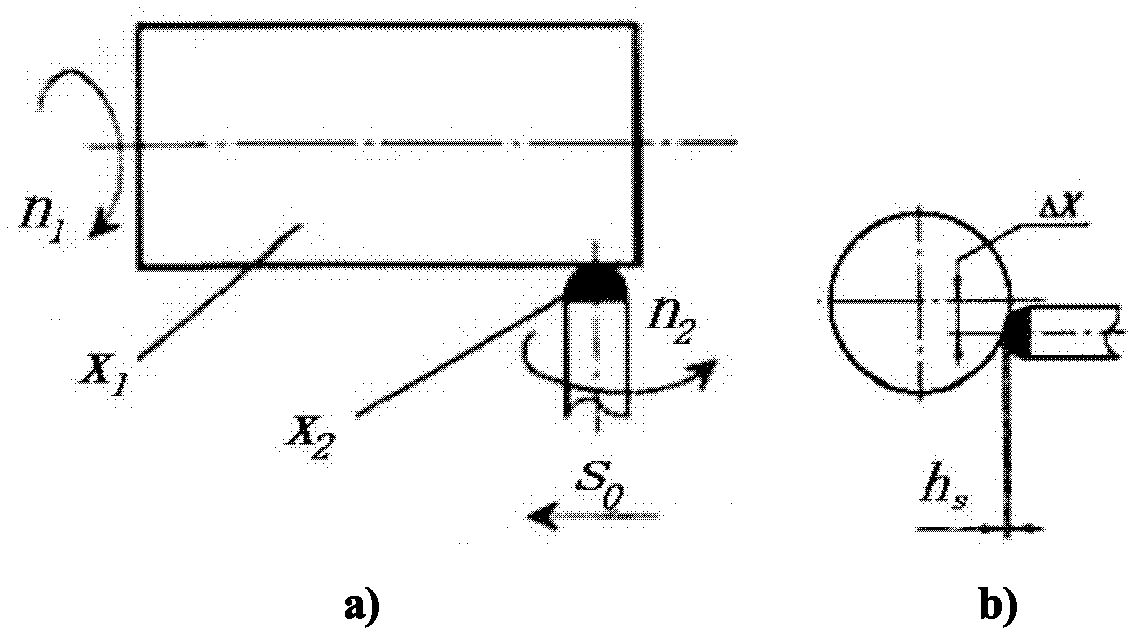

Processing method capable of preventing thin sheet part processing vibration

ActiveCN108515218AEliminate the grinding processFix flutterMilling equipment detailsMilling cutterEngineering

The invention provides a processing method capable of preventing thin sheet part processing vibration. The method comprises the steps that 1, a coordinate system is built, cylinders with the thicknessof 25-30 mm are preserved on the surface of the position of to-be-processed holes, and the cylinders are adopted as supporting columns to support the part web portion; 2, a web is processed, and a margin of 1.5-2.5 mm is left for the thickness of a thin sheet; 3, a whirlwind milling method is adopted, primary knifing is in place, and the transverse knifing depth is ten percent of the tool diameter; 4, a milling cutter is adopted for conducting hole milling on the positions of the to-be-processed holes on the other side of the part, the processed holes are deeper than the supporting columns by0.08 mm, and then a tool is adopted to directly knock off the cylinders to obtain a product part. The processing method is high in processing precision and little in technical process, the technicalproblems are solved that in the prior art, the size precision cannot be guaranteed due to web vibration, and meanwhile, the processing process is tedious, the cycle is long, and the cost is high.

Owner:沈阳百祥机械加工有限公司

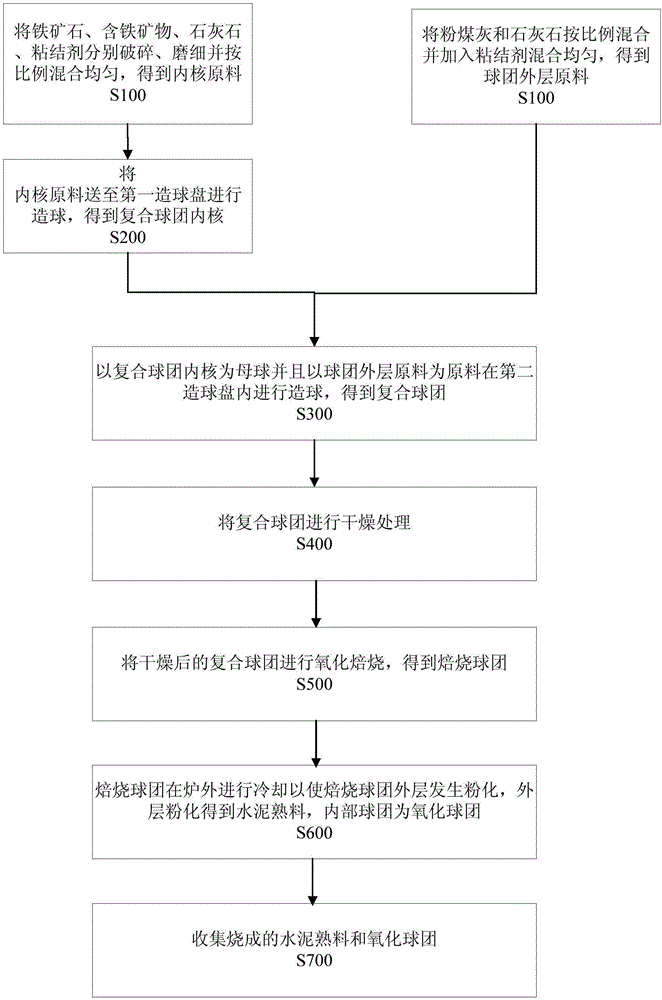

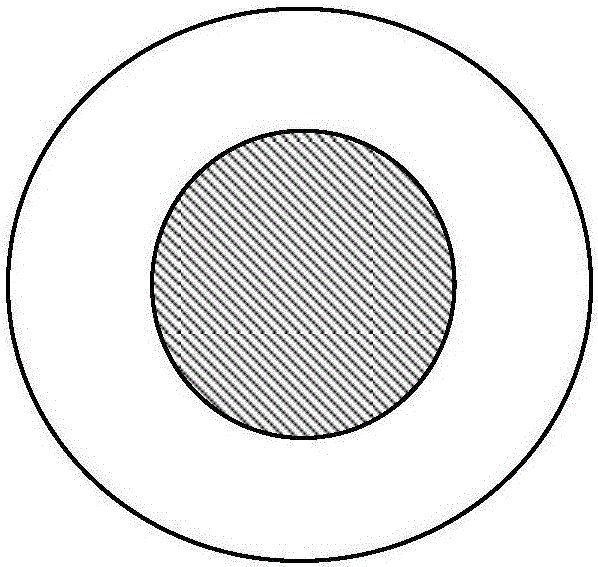

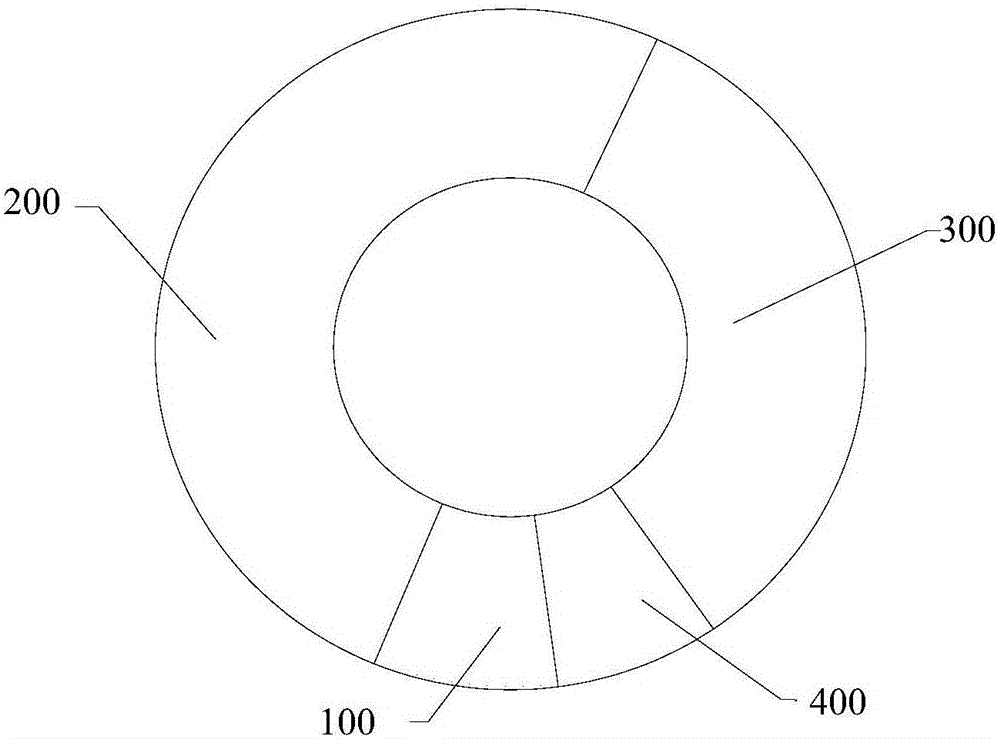

Method for producing cement clinker and oxide pellets

ActiveCN106636627AIncrease productivityGood metallurgical performanceClinker productionOxideAdhesive

The invention discloses a method for producing cement clinker and oxide pellets. The method comprises the following steps: (1) respectively crushing and grinding iron ores, iron-bearing minerals, limestone and adhesive, uniformly mixing according to a proportion to obtain an inner core raw material, mixing pulverized fuel ash and limestone according to a proportion, adding adhesive, and uniformly mixing to obtain an outer layer raw material of pellets; (2) pelletizing the inner core raw material to obtain pellet inner cores; (3) pelletizing by using the pellet inner core as female parent pellets and the outer layer raw material of pellets as a raw material to obtain compound pellets; (4) drying the compound pellets; (5) roasting the dried compound pellets in the air to obtain roasted pellets; (6) cooling the roasted pellets out of a furnace to pulverize the outer layer of the roasted pellets, namely pulverizing the outer layer to obtain cement clinker, and obtaining inner pellets as oxidized pellets; and (7) collecting the roasted cement clinker and oxidized pellet ore. The method can be used for simultaneously producing cement clinker and oxidized pellet ore, so that the production efficiency is improved, and energy conservation and emission reduction can be achieved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method for manufacturing high-accuracy pure titanium rod

InactiveCN104493433ALow heating temperatureMetallographic structure has little influenceMicrometerTitanium

The invention discloses a method for manufacturing a high-accuracy pure titanium rod. The method includes the steps of blank preparation, blanking, cogging-down forging, deformation processing, annealing, thermal straightening, lathe machining, piece finishing and finished product packaging inspection. During lathe machining of a rod, diameter of the rod can be directly machined to be in the size of a finished product rod, and waste chips generated during turning of the rod can be recycled, so that economic value is increased; heating temperature is low during finishing, so that influence on metallographic structure of the rod is small, service life of the rod is prolonged, and mechanical strength of the rod is improved; due to low heating temperature, oxidation scale on the surface of the rod is extremely thin, total indentation of the rod is small during straightening, grinding is not needed after straightening, and requirements, on coarseness of 1.6 micrometers and size tolerance, of the finished product rod can be met by directly polishing for two times.

Owner:QINGDAO MATE RUIOU NEW MATERIAL TECH CO LTD

Liquid crystal display device

ActiveCN104614881AEliminate grinding processBreak the limitationsPlanar/plate-like light guidesNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a liquid crystal display device. The liquid crystal display device comprises a backlight unit, a display panel and a first frame. The first frame contains the backlight unit and the display panel. At least one side wall of the first frame extends to the middle portion, so that an arc-shaped extension portion is formed. The free end of the extension portion is opposite to the side wall of the display panel. According to the liquid crystal display device, the display panel is arranged in the first frame, the side walls of the first frame extend to the middle portion, so that the arc-shaped extension portions are formed, and therefore the display plane and the first frame can be in smooth transition; cover plate glass is omitted, the complicated grinding technology for the cover plate glass is omitted, the limit that a 2.5 D display screen can only be applied to a small-size display device is broken through, the production cost is reduced, and the application range of the display screen is greatly improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for industrially preparing aluminum hydroxide, alumina and aluminum fluoride from andalusite sericite phyllite as raw material

InactiveCN101717104AEliminate the grinding processEnergy savingAluminium oxide/hydroxide preparationAluminium fluoridesHydrogen fluorideNational standard

The invention discloses a method for industrially preparing aluminum hydroxide, alumina and aluminum fluoride from andalusite sericite phyllite as a raw material, which comprises the steps of: extracting aluminum hydroxide with the purity of 96-98.5 percent from the andalusite sericite phyllite as the raw material in a mode of ball production, calcinations, multistage separation and auxiliary agent addition; then calcinating the raw material to obtain the alumina; and reacting fluorine hydride gas with wet hydrogen alumina and dehydrating and drying to obtain the aluminum fluoride. The method solves the problem that pseudo andalusite-sericite phyllite ore in Qingliu County, Sanming City, Fujian Province cannot be utilized; and the prepared aluminum hydroxide, alumina and aluminum fluoride accord with national standard.

Owner:福建天筑新型材料有限公司

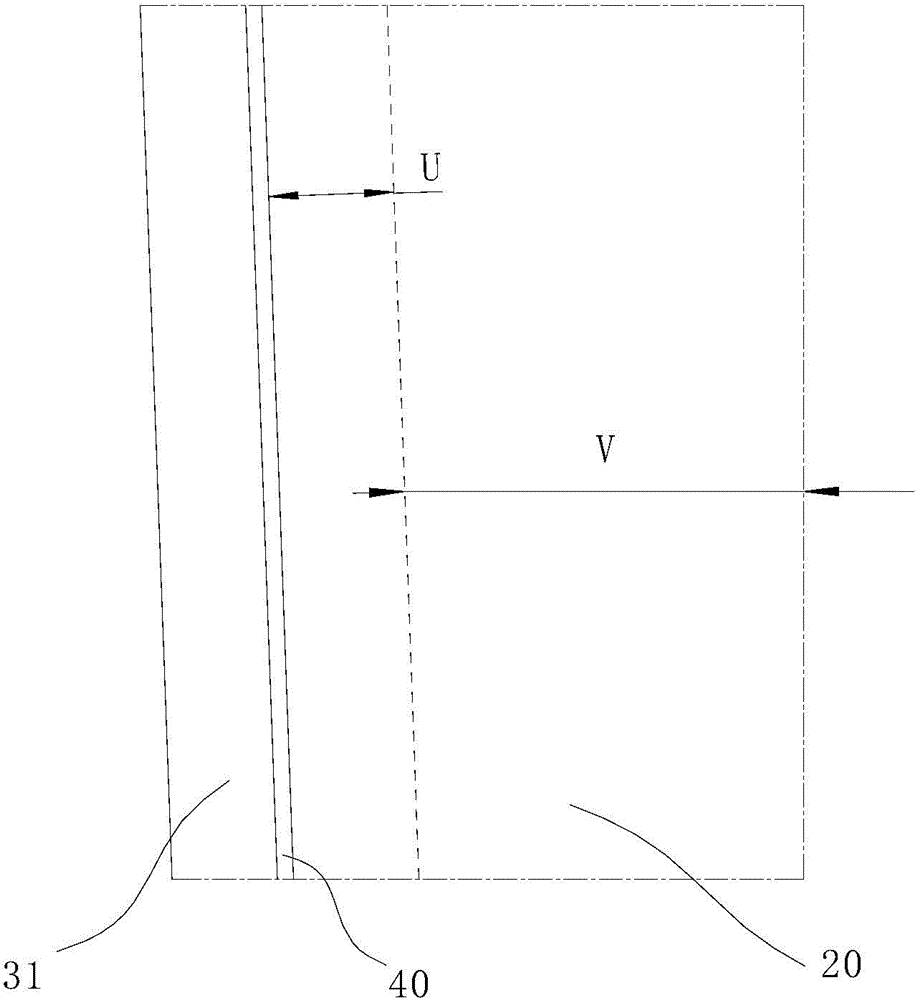

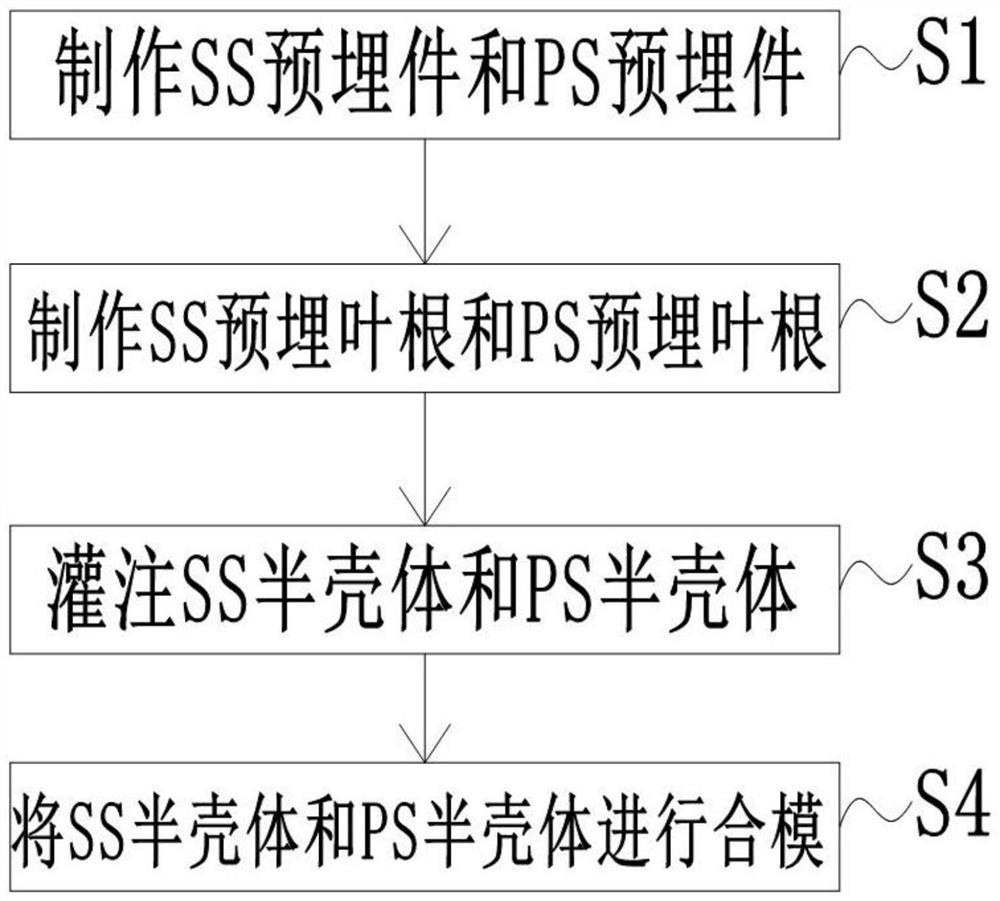

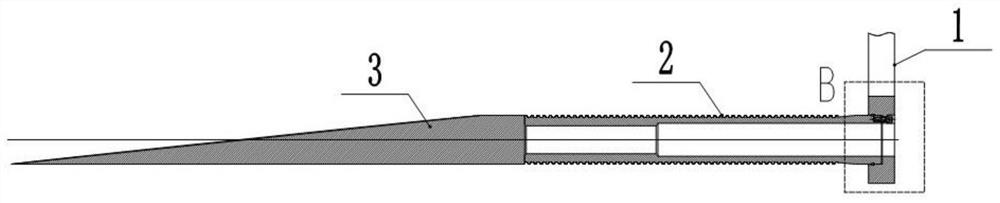

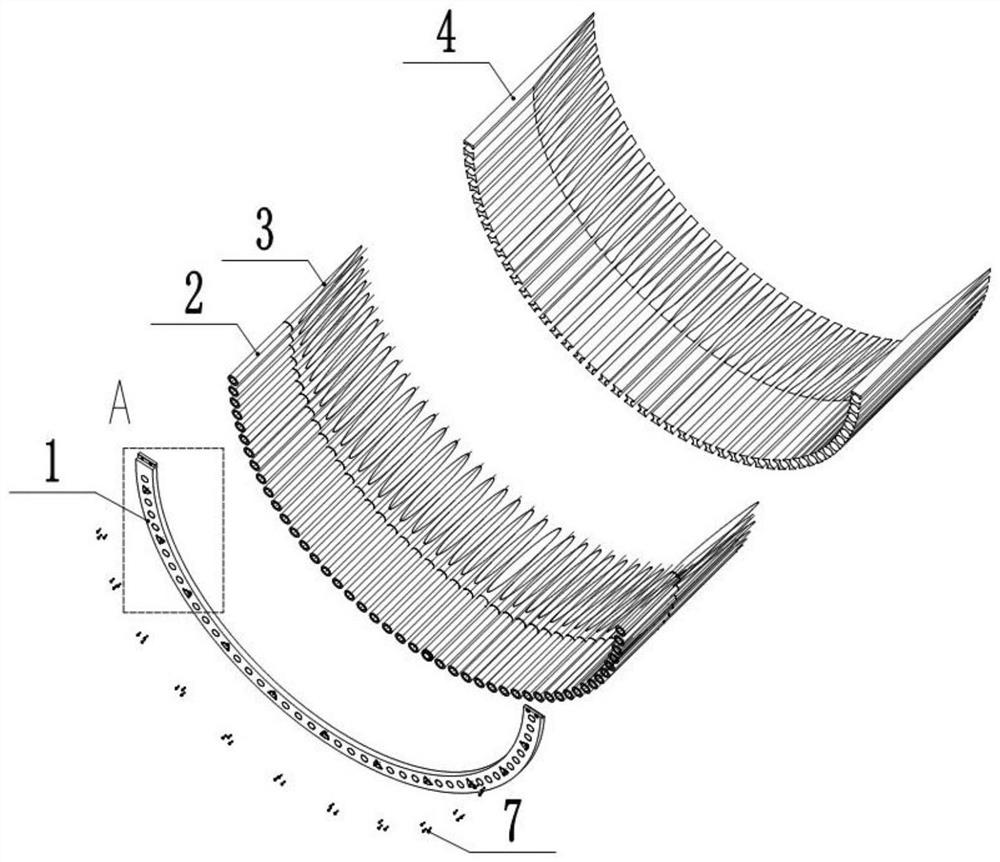

Preparation method of wind power blade

ActiveCN113733607AAvoid deformationReduce distortionFinal product manufactureDomestic articlesWind powerMold removal

The invention belongs to the technical field of wind power blades, and particularly discloses a preparation method of a wind power blade. The preparation method comprises the following steps that at S1, an SS embedded part and a PS embedded part are manufactured, specifically, the SS embedded part and the PS embedded part each comprise a connecting flange, a plurality of sets of thread inserts, a UD block, a wedge-shaped block and a sealing ring; at S2, an SS embedded blade root and a PS embedded blade root are manufactured; at S3, an SS half shell and a PS half shell are poured; and at S4, the SS half shell and the PS half shell are subjected to mold closing, specifically, the position of an embedded blade root flange is adjusted on a blade mold, and then the SS half shell and the PS half shell are bonded, and after bonding and curing, the embedded blade root flange is removed, demolding is performed, and finally the blade is manufactured. A positioning tool is arranged on the blade mold, and the positioning tool can position and adjust the position of the embedded blade root flange. According to the method, the problems that the deformation amount is large, and installation interference is caused by dislocation of thread insert holes and a connecting hole of a main engine bearing due to the adoption of an existing blade root embedding technology can be solved.

Owner:JILIN CHONGTONG CHENGFEI NEW MATERIAL

Production technology of calcium oxide and sulfur dioxide by desulfurization gypsum

ActiveCN103482584BAvoid secondary pollutionReduce miningSulfur compoundsCalcium/strontium/barium oxides/hydroxidesShielding gasNitrogen gas

The invention discloses a production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum. The technology comprises the following steps: drying desulfurized gypsum at 230-300DEG C for 0.5-1.5h, wherein drying pretreatment is carried out at 40-50DEG C for 0.5-1h if the water content of carbon is above 5%; screening the desulfurized gypsum and the carbon for controlling the gypsum particle size below 40mum and the carbon particle size below 187.5mum; and mixing the screened carbon and the screened desulfurized gypsum according to a carbon-to-calcium sulfate mole ratio of 1:1-1.2:1 to obtain a mixed sample, putting the mixed sample in a high temperature reaction device, and reacting at 1000-1100DEG C under the protection of nitrogen or an inert gas under a gas flow velocity of 4-10m / s for 10-15min. The technology has the advantages of high reaction efficiency, fast reaction speed, less carbon consumption, high finally-obtained product quality, and no atmospheric pollution.

Owner:NANJING UNIV OF SCI & TECH

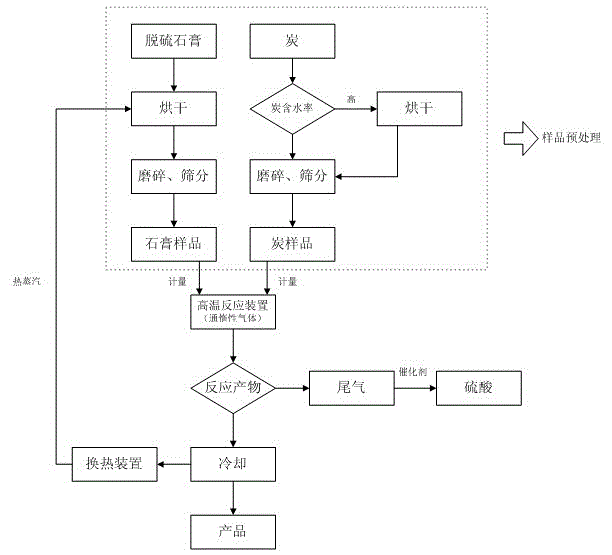

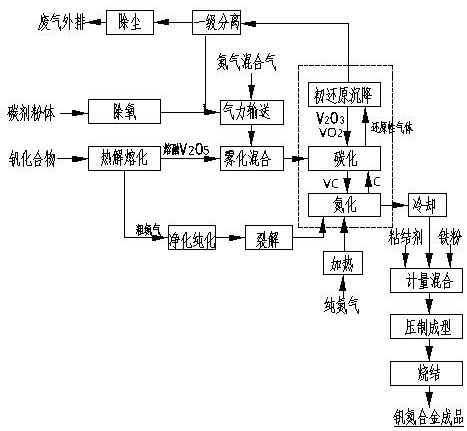

Efficient vanadium-nitrogen alloy production process

The invention discloses an efficient vanadium-nitrogen alloy production process which comprises the following steps: performing nitrogen atomization mixing primary reduction on carbon agent powder and molten-state V2O5, further performing carbon thermal reduction and nitridation to obtain vanadium-nitrogen alloy powder, cooling, adding iron powder, mixing, pressing and molding, and sintering and nitriding to obtain a vanadium-nitrogen alloy finished product. The method is good in product quality, high and stable in vanadium and nitrogen content, low in production cost, low in energy and material consumption and small in equipment occupied area.

Owner:王兆兵

Preparation method of medical high-precision titanium and titanium alloy bar material

InactiveCN102990283AHigh economic valueMetallographic structure has little influencePolymer scienceTitanium

The invention discloses a preparation method of a medical high-precision titanium and titanium alloy bar material. The preparation method comprises the following steps of: preparing a blank, discharging, forging in a cogging way, a machining in a deformation way, annealing, thermally straightening, turning, carrying out low-temperature precision straightening, polishing twice, and packing an inspected finished product. The preparation method has the beneficial effects that when the bar material is turned before being finely machined, the diameter of the bar material can be directly machined into the size of a finished bar material, so that the waste dregs generated when the bar material is turned can be recycled, and the preparation method is very high in economic value; the heating temperature is lower when the bar material is processed in a finishing way, so that the preparation method hardly influences or change the metallographic structure of the bar material, the service life of the bar material can be prolonged, and the mechanical strength of the bar material can be increased; and when the bar material is processed in a finishing way, the heating temperature is lower, an oxide skin on the surface of the bar material is extremely thin, and the whole bar material has few indentations when straightened, after being straightened the bar material is polished twice by a polisher without being ground to reach the requirements of a finished bar material on roughness (1.6 mu m) and dimensional tolerance.

Owner:BAOJI DELI TITANIUM IND

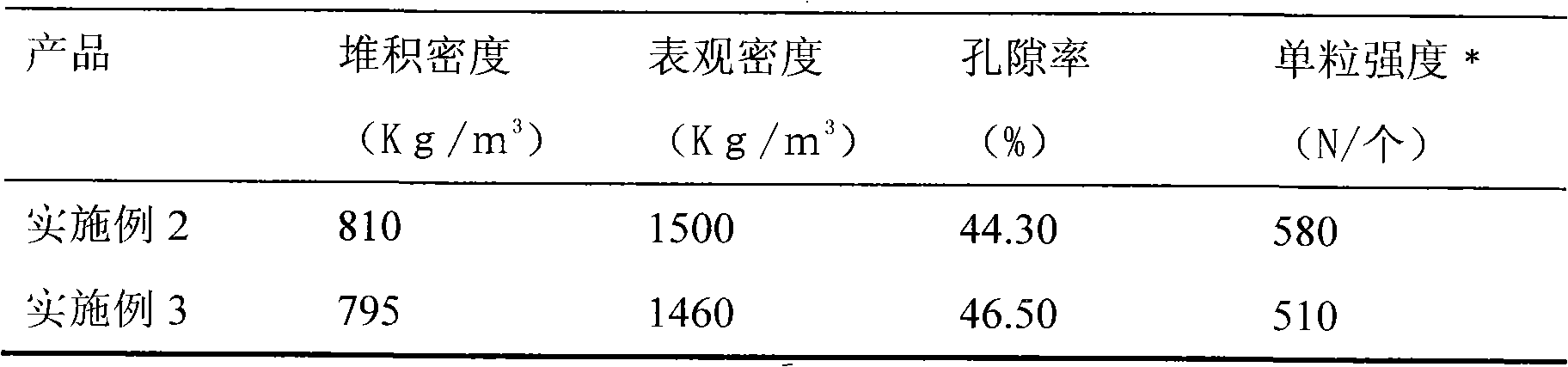

Method for preparing porous ceramsite filter material from slate saw mud

InactiveCN102068855AConducive to gas expansionSelf-inflatingFiltration separationDry basisFilter material

The invention discloses a method for preparing a porous ceramsite filter material from slate saw mud. According to a formula, a product prepared by the method comprises the following raw materials in percentage by mass: 60 to 80 percent of slate saw mud (a dry basis), 15 to 30 percent of dry slate powder and 5 to 10 percent of kieselguhr, wherein the raw materials are mixed and stirred into spherical particles, then calcined and cooled to obtain the product. The method has the advantages of simple process and low production cost, and has great significance to resource cycling and environmental protection.

Owner:NANCHANG UNIV

Environment-friendly production process of reclaimed rubber from tire

InactiveCN108178841ARealize desulfurization treatmentEliminate the grinding processPlastic recyclingMicrowaveFiltration

The invention provides an environment-friendly production process of reclaimed rubber from a tire. The process comprises the following steps: (1) waste rubber is smashed into waste rubber powder; (2)the waste rubber powder and reclaiming auxiliary materials are jointly conveyed to a microwave reclaimer, are subjected to microwave desulfurization and reclaiming treatment in a pipe of the microwavereclaimer and move from a feed port of the pipe to a discharge port under the conveying and mixing actions of a conveying screw in the pipe, wherein the reclaiming auxiliary materials comprise a reclaiming activator, a reclaiming softener and lemon essential oil, the reclaiming activator accounts for 0.2%-1.1% of the mass of the waste rubber powder, the reclaiming softener accounts for 2%-30% ofthe mass of the waste rubber powder, and the lemon essential oil accounts for 2%-3% of the mass of the waste rubber powder; (3) the rubber powder subjected to desulfurization treatment is refined andformed by a refiner, extrusion and filtration are performed, and the reclaimed rubber from the tire is obtained. The novel production process of the reclaimed rubber from the tire is energy-saving andenvironmentally friendly, and the produced reclaimed rubber has the advantages of high strength, stable quality and the like.

Owner:江苏华兴橡胶科技有限公司

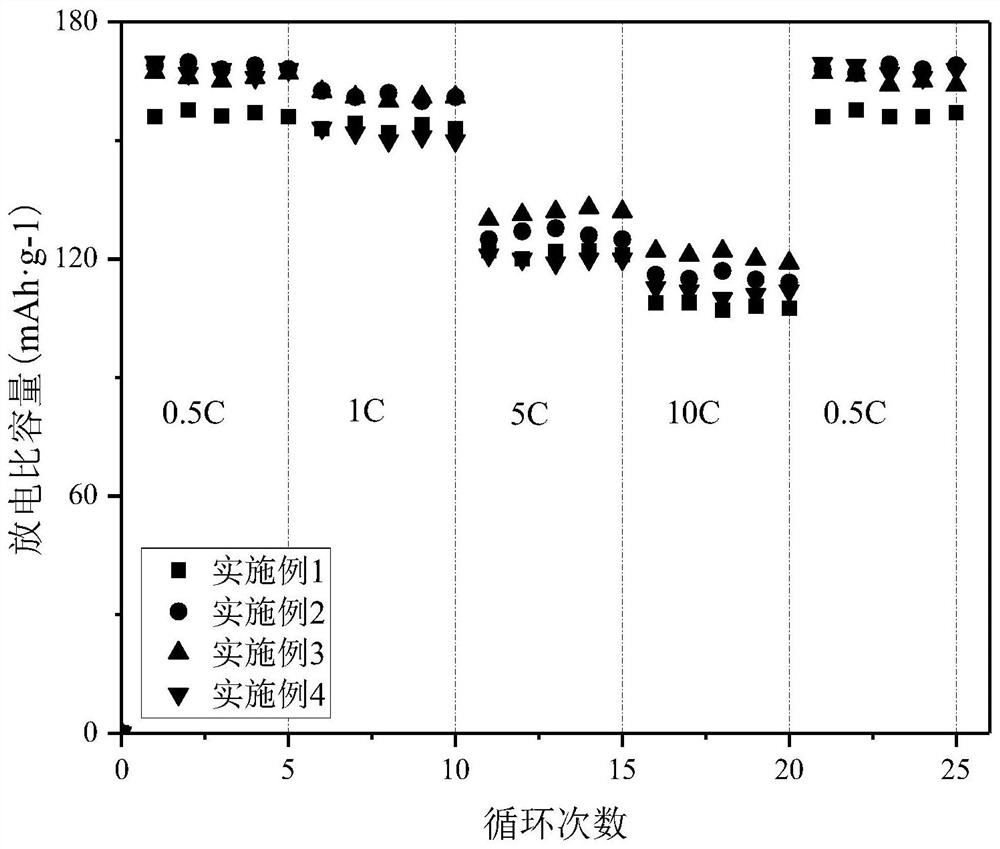

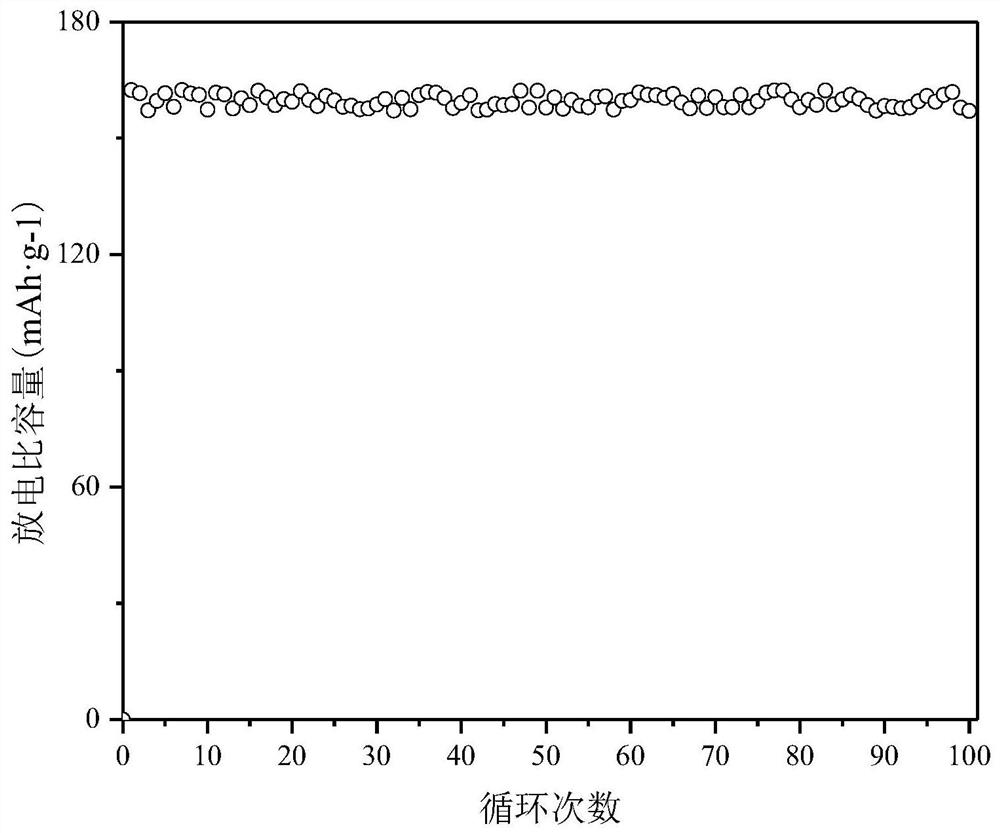

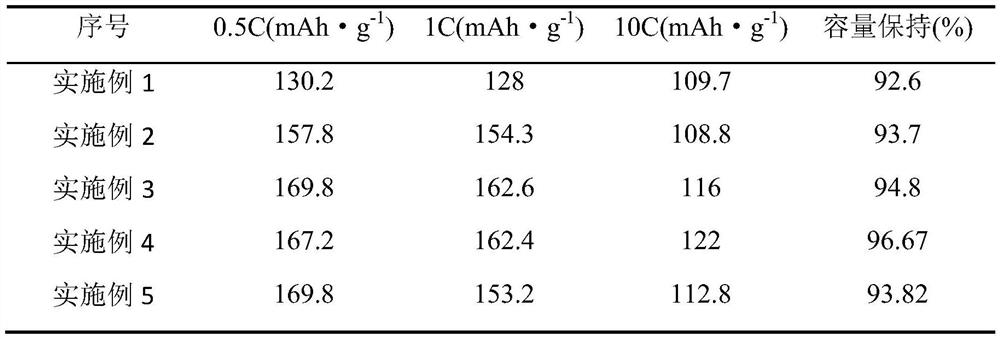

Preparation method of lithium vanadium phosphate positive electrode material

PendingCN113072050AEliminate grinding processReduce energy consumptionSecondary cellsPositive electrodesPhysical chemistryPhosphoric acid

The invention discloses a preparation method of a lithium vanadium phosphate positive electrode material. The preparation method comprises the following steps: 1) adding NH4VO3, LiOH, NH4H2PO4 and glucose into a certain amount of deionized water according to a certain mass ratio, heating in a water bath to 60-80 DEG C, and stirring to prepare slurry; (2) introducing the slurry into a spray dryer, atomizing and spraying to obtain a precursor, meanwhile, feeding dry airflow in the tangential direction of a spray head, wherein the airflow direction is the same as the solution spraying direction; 3) collecting and weighing the prepared precursor, weighing glucose accounting for 6-8% of the mass of the precursor, mixing the glucose with the precursor, then putting the mixture into a continuous sintering furnace, sintering for 6-8 hours under the protection of nitrogen at the sintering temperature of 600-800 DEG C, and pre-introducing nitrogen before sintering to ensure an oxygen-free environment; and 4) naturally cooling the sintered positive electrode material, crushing, grinding and sieving to form the final product. The lithium vanadium phosphate has good electrochemical stability, energy consumption is saved, and the lithium vanadium phosphate is safe, stable in quality and uniform in physical property.

Owner:天津斯科兰德科技有限公司

Production process of environment-friendly high-strength regenerated rubber

InactiveCN108047489ABreak through limitationsEliminate the grinding processPlastic recyclingMicrowavePolymer science

The invention provides a production process of environment-friendly high-strength regenerated rubber. The production process comprises the following steps that (1) waste rubber is pulverized into rubber powder; (2) the pulverized rubber powder in the first step enters a microwave desulfurization device for primary regeneration treatment firstly and then enters an ultrasonic desulfurization devicefor secondary regeneration to achieve complete desulfurization; (3) the completely-desulfurized rubber powder is subjected to refining formation through a refiner, extruded and filtered to obtain an available recyclable rubber raw material. By means of the production process of the novel energy-saving environment-friendly regenerated rubber, the produced regenerated rubber has the advantages of being high in strength, stable in quality and the like.

Owner:江苏华兴橡胶科技有限公司

Convenient whole-grain instant powder capable of being brewed at any water temperature, and preparation method and application thereof

ActiveCN110742234ASolve easy cakingSolving Dispersion ProblemsMilk preparationFood preservationAlcohol ethylCereal grain

The invention discloses convenient whole-grain instant powder capable of being brewed at any water temperature, and a preparation method and application thereof, and belongs to the technical field offood processing. The preparation method of the instant powder includes the steps that cleaned shelled grain seeds are taken and placed in a container, an ethyl alcohol solution is added, soaking is conducted at the room temperature, then liquid on the surfaces of the grain seeds is drained off, and the soaked grain seeds are obtained; the obtained soaked grain seeds are conveyed into an extruder to be extruded, and strip-shaped grain extrudates are prepared; and the obtained strip-shaped grain extrudates are placed in a hot air drying box to be dried, then cooled, and placed in an ultrafine grinder to be ground, and the convenient whole-grain instant powder is obtained. Seasonings can be added into the obtained instant powder to prepare various flavors of whole-grain instant powder. The whole-grain instant powder prepared through an ethyl alcohol addition extrusion technology can be brewed at any water temperature to be eaten, the agglomeration rate of the whole-grain instant powder iseffectively decreased, and dispersion is improved.

Owner:JIANGNAN UNIV

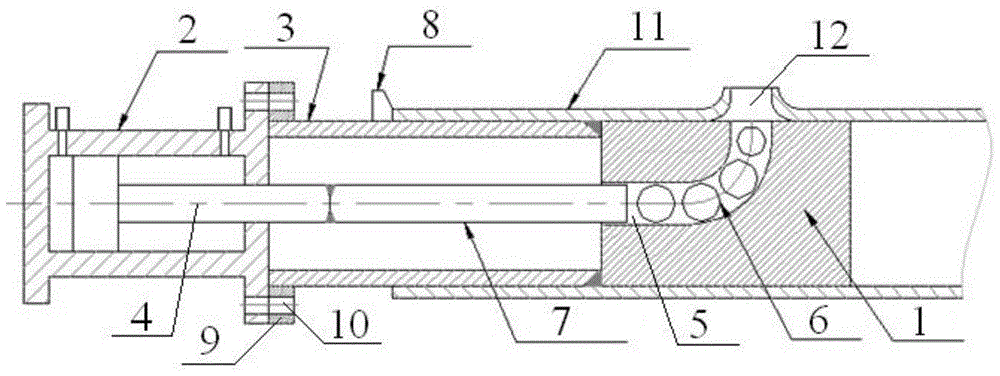

Small-diameter collecting pipe branch pipe drawing process tooling

The invention relates to a process tool for drawing a branch pipe of a small-bore collecting tube. The process tool is characterized in that the diameter of a mold and the outer diameter of a guide sleeve are equal to the inner diameter of the collecting tube; a telescopic rod of an oil cylinder, the guide sleeve and the mold are coaxially arranged, and the guide sleeve and the collecting tube are axially positioned by virtue of a positioning device; a horizontal ball hole matched with the telescopic rod is formed in one end, fixedly connected with the guide sleeve, of the mold, a vertical ball hole is formed in the side wall of the mold along the radial direction and is communicated with the horizontal ball hole to form a steel ball channel, a plurality of steel balls are placed in the steel ball channel, the diameter of the steel ball at the uppermost end in the steel ball channel is minimum, the diameters of the steel balls under the steel ball at the uppermost end gradually increase, and the number of the steel balls is larger than the drawing number of times of a to-be-formed branch pipe. The process tool has the beneficial effects that by adopting a mode of horizontal force application and vertical stress, the straightness and surface quality of the collecting tube can be well guaranteed, the intensive utilization of the thermal energy and the efficient utilization of materials are realized, the automatic control is realized in heating and drawing processes, and the labor intensity of a worker is greatly alleviated.

Owner:HEBEI HONGRUN NUCLEAR EQUIP SCI & TECH CO LTD

Surface strengthening treatment device for actively and rotatablely rolling and planishing head of roll compactor

Owner:JIANGSU BAOJIE FORGING

Guide sliding shoe remanufacturing method

ActiveCN112139632AImprove wear resistanceReduce labor intensityWelding accessoriesStructural engineeringStress relief

The invention discloses a guide sliding shoe remanufacturing method. The method comprises the following steps that a guide groove of a guide sliding shoe is machined so as to remove an original wear-resisting layer and expose a guide sliding shoe base body; a chamfer is machined at an end opening of the guide groove; wear-resisting plates are welded on the surface of the guide sliding shoe base body; a first groove matched with the chamfer is formed in the wear-resisting plate located at the position of the end opening in the length direction, and second grooves are formed in the connecting positions of the adjacent wear-resisting plates in the length direction; and stress relief annealing is conducted after welding. Compared with the prior art, the method has the beneficial effects that the grinding procedure after surfacing of the wear-resistant layer is omitted, the labor intensity of workers is reduced, the time is saved, meanwhile, the wear-resisting layer is made of the same material, the size and the wear-resisting hardness are easy to guarantee, the wear-resisting performance is enhanced, the service life is prolonged, the defects that the surface of the wear-resisting layer is uneven and uneven in hardness due to improper grinding can be avoided, the walking effect of a coal mining machine is good, and abrasion to a conveyor is reduced.

Owner:郑州煤机智能工作面科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com