Thin-coating two-component anticorrosive coating for surface of precise steel structural part and preparation method thereof

A technology for anti-corrosion coatings and steel structural parts, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as poor shielding and porosity defects, and achieve high production efficiency, increased resin content, and good shielding effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

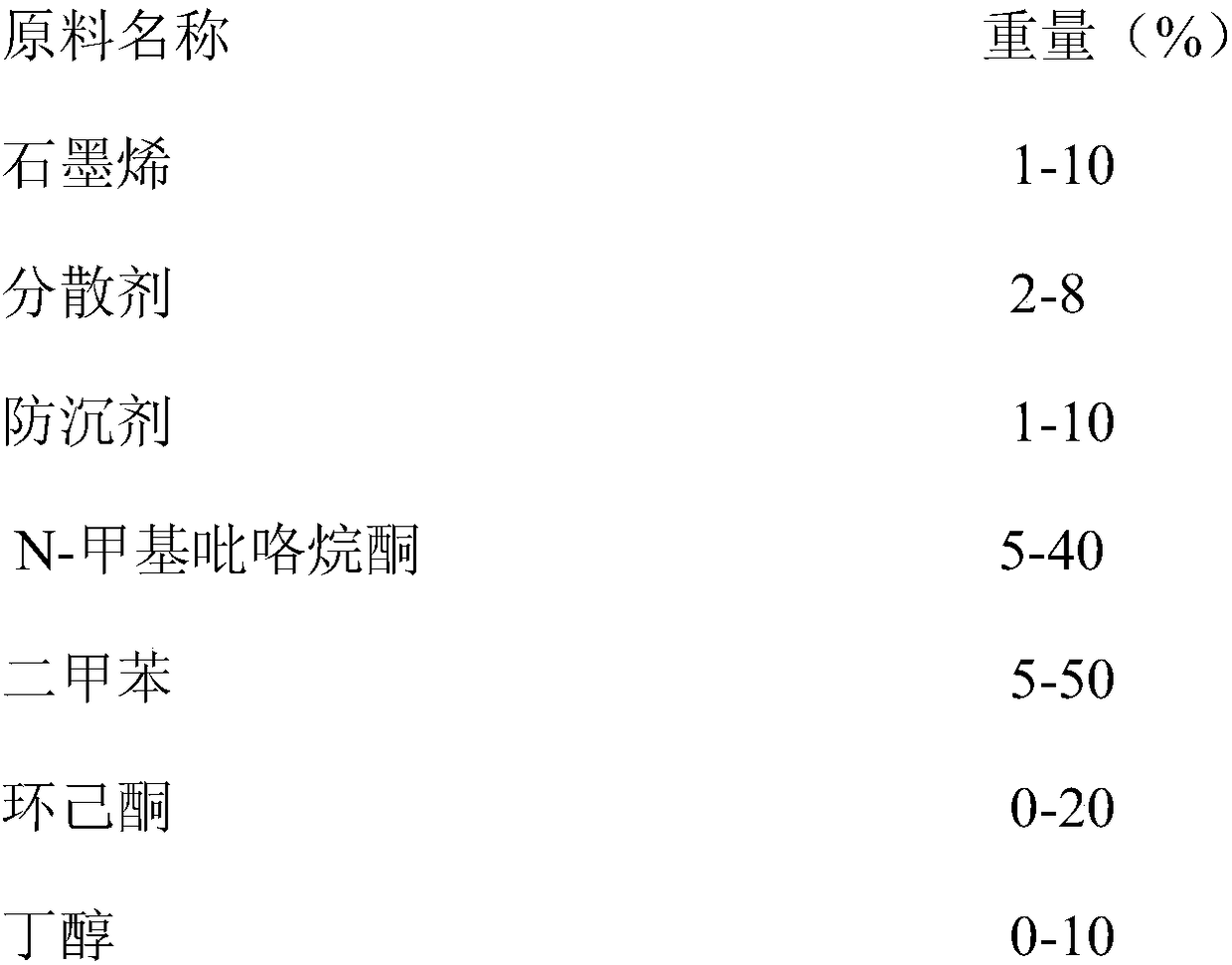

[0047] Embodiment 1: prepare a kind of dispersion stable graphene slurry

[0048]

[0049] The preparation method of graphene slurry is: add the solvent of formula quantity in the container, place under high-speed stirring, the rotating speed is 1000r / min, put the container in the ultrasonic oscillator that power is 240w to carry out ultrasonic oscillation at the same time, under stirring state successively Add the formulated amount of FX9086 and graphene, disperse for 30 minutes, then add anti-sedimentation agent BYK-410, and continue stirring for 30 minutes to obtain a stable graphene slurry.

[0050] The graphene slurry prepared in this example is a gray-black viscous mixture with a viscosity of 600 mPa.s and a storage stability period of 6 months.

Embodiment 2

[0051] Embodiment 2: prepare a kind of dispersion stable graphene slurry

[0052]

[0053] The preparation method of graphene slurry is: add the solvent of recipe amount in the container, place under high-speed stirring, the rotating speed is 1000r / min, put the container into the ultrasonic oscillator that power is 800w to carry out ultrasonic oscillation at the same time, under stirring state successively Add the formulated amount of BYK-110 and graphene, disperse for 20 minutes, add anti-sedimentation agent BENGEL958 and continue stirring for 20 minutes to obtain a stable graphene slurry.

[0054] The graphene slurry prepared in this example is a gray-black viscous mixture with a viscosity of 400 mPa.s and a storage stability period of 6 months.

Embodiment 3

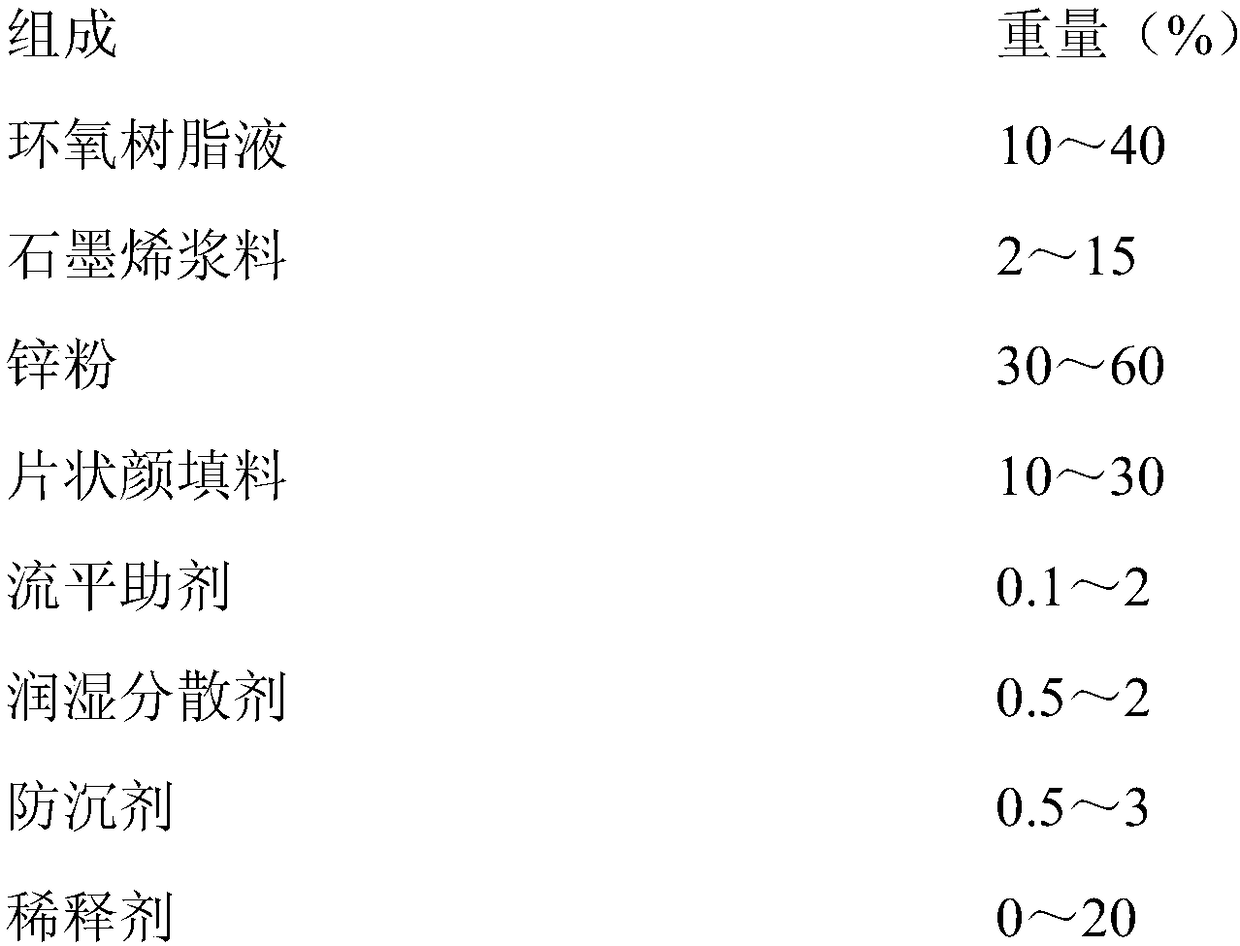

[0055] Embodiment 3: A kind of preparation based on graphene-modified epoxy zinc powder coating that can be thinly coated

[0056] The composition of component A is as follows:

[0057]

[0058]

[0059] The preparation method of component A is: add the epoxy resin liquid, graphene slurry, pigments and fillers, additives and diluents according to the above formula into the stirring container, and stir at a speed of 2000r / min for 30min until uniformly dispersed; Continue to stir the zinc powder for 30min until it is uniformly dispersed, filter through a sieve, measure and pack, and obtain component A (color paste);

[0060] The formula composition of B component is as follows:

[0061] The polyamide is mixed with xylene, n-butanol and cyclohexanone according to the following ratio, and stirred and dissolved to prepare component B (curing agent).

[0062]

[0063] A and B components are mixed and prepared at a weight ratio of 6:1.

[0064] Coatings are applied by spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com