Production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum

A desulfurization gypsum, sulfur dioxide technology, applied in the direction of calcium/strontium/barium oxides/hydroxides, sulfur compounds, chemical instruments and methods, etc., can solve the problem of large particle size of phosphogypsum and carbon particles, insufficient contact of reactants, Affect the utilization rate of sulfur dioxide and other issues, and achieve the effect of reducing mining, saving carbon consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

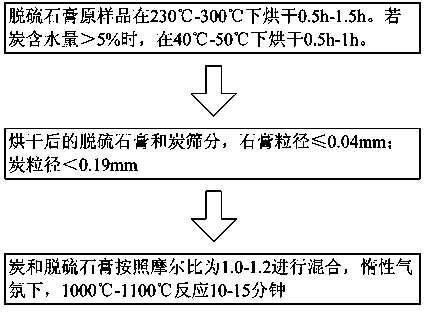

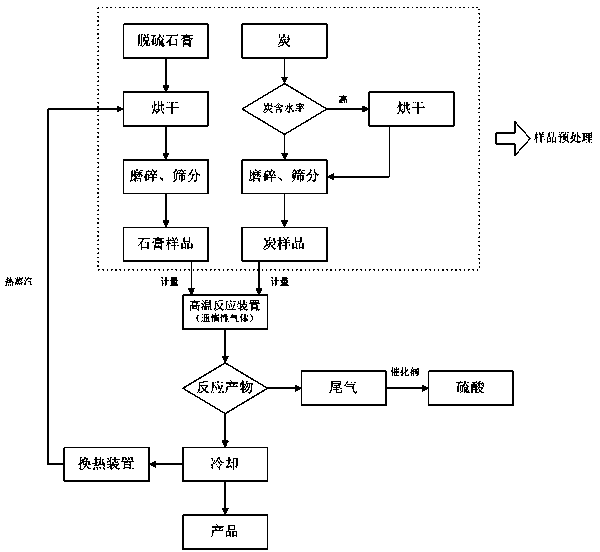

Method used

Image

Examples

Embodiment 1

[0037] 1. The raw material composition of desulfurization gypsum (excluding free water and crystal water) is shown in Table 1-1:

[0038] Table 1-1 Composition analysis of desulfurized gypsum

[0039] name SO 3 CaO SiO 2 al 2 o 3 Fe 2 o 3 MgO K 2 o TiO 2 SROs content% 55.9 40.1 2.12 1.23 0.29 0.18 0.073 0.035 0.018

[0040] Note: Data errors are within the allowable range.

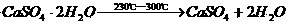

[0041] According to the composition analysis results, it can be known that the SO in desulfurized gypsum 3 content and CaO content is higher. Referring to the national standard for gypsum and anhydrite (GB / T5483-1996), gypsum is divided into three grades according to its grade, grade one: CaSO in gypsum 4 Mass fraction ≥ 80%, CaSO is required for secondary and tertiary 4 The quality fractions were 70% and 60%, respectively. CaSO in the desulfurization gypsum sample after removal of crystal water in the test 4 The composition is as high as 96%, ...

Embodiment 2

[0053] 1. The raw material composition of desulfurization gypsum (excluding free water and crystal water) is shown in Table 2-1:

[0054] Table 2-1 Composition analysis of desulfurized gypsum

[0055] name SO 3 CaO SiO 2 Al 2 o 3 Fe 2 o 3 MgO K 2 o TiO 2 SROs content% 53.8 38.0 3.12 2.23 1.29 1.18 0.10 0.235 0.045

[0056] Note: Data errors are within the allowable range.

[0057] According to the composition analysis results, it can be known that the SO in desulfurized gypsum 3 content and CaO content is higher. Referring to the national standard for gypsum and anhydrite (GB / T5483-1996), gypsum is divided into three grades according to its grade, grade one: CaSO in gypsum 4 Mass fraction ≥ 80%, CaSO is required for secondary and tertiary 4 The quality fractions were 70% and 60%, respectively. CaSO in the desulfurization gypsum sample after removal of crystal water in the test 4 The composition is as high as 91.8%,...

Embodiment 3

[0069] 1. The raw material composition of desulfurization gypsum (excluding free water and crystal water) is shown in Table 3-1:

[0070] Table 3-1 Composition analysis of desulfurized gypsum

[0071] name SO 3 CaO SiO 2 Al 2 o 3 Fe 2 o 3 MgO K 2 o TiO 2 SROs content% 56.8 40.5 1.98 0.20 0.23 0.18 0.072 0.028 0.010

[0072] Note: Data errors are within the allowable range.

[0073] According to the composition analysis results, it can be known that the SO in desulfurized gypsum 3 content and CaO content is higher. Referring to the national standard for gypsum and anhydrite (GB / T5483-1996), gypsum is divided into three grades according to its grade, grade one: CaSO in gypsum 4 Mass fraction ≥ 80%, CaSO is required for secondary and tertiary 4 The quality fractions were 70% and 60%, respectively. CaSO in the desulfurization gypsum sample after removal of crystal water in the test 4 The composition is as high as 97.3%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com