Processing method capable of preventing thin sheet part processing vibration

A technology of parts processing and processing methods, which is applied in the field of numerical control machining, can solve the problems of difficult to guarantee dimensional accuracy, cumbersome processing process, long cycle, etc., and achieve the effect of solving tool wear problems, improving production quality, and solving vibration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The following is a specific application of using the method of the present invention to process the front section of the support arm.

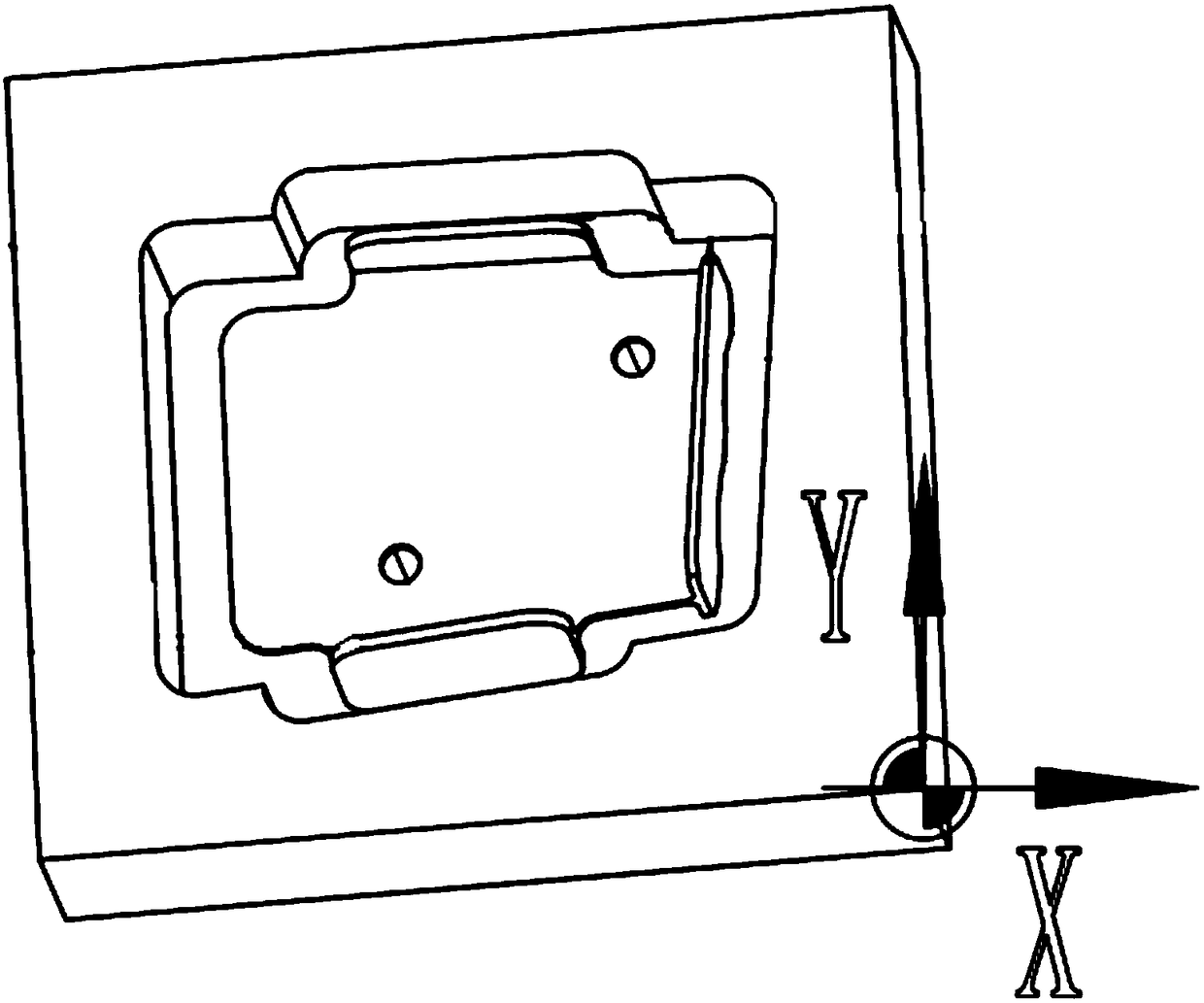

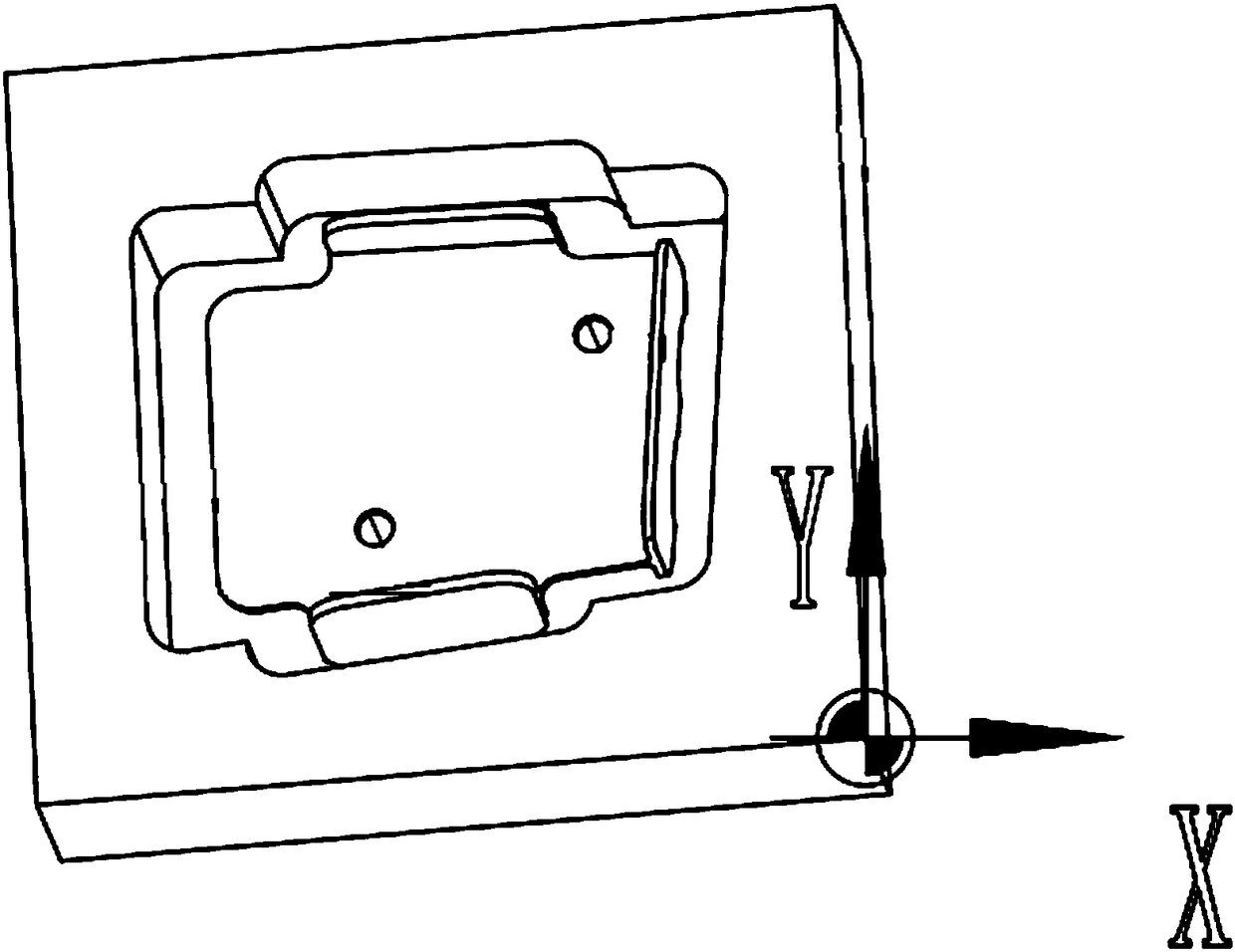

[0030] Process the front part of the support arm, mill the upper and lower parts of the front part of the support arm, with a thickness of 59±0.1mm, press image 3 Establish the coordinate system, the milling datum is the lower left corner, fix the front section of the support arm on the machine table with the pressure plate, and press the pressure plate around, and the edge is within 5mm. Use the edge finder to determine the machining zero point, the zero point of the tool setting is on the upper surface, install the Φ16R3 high-speed milling cutter for roughing and full type, leave 0.5mm for one side of the side wall of the part, leave 0.5mm for the web surface, leave a finishing allowance, and process the hole Become a cylinder with a height of Φ10mm and a height of 21.

[0031] Then install the Φ10R5 milling cutter for rib height, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com