Patents

Literature

63results about How to "Solve easy caking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

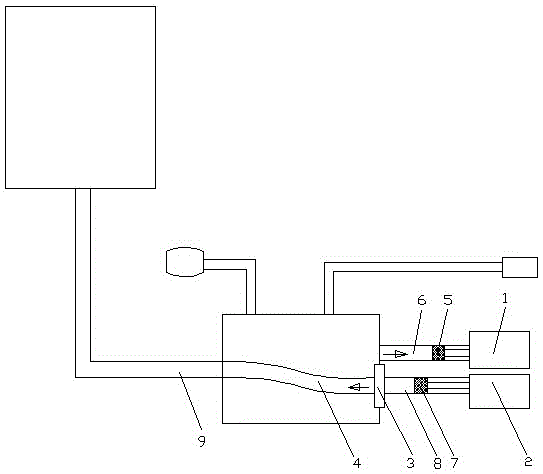

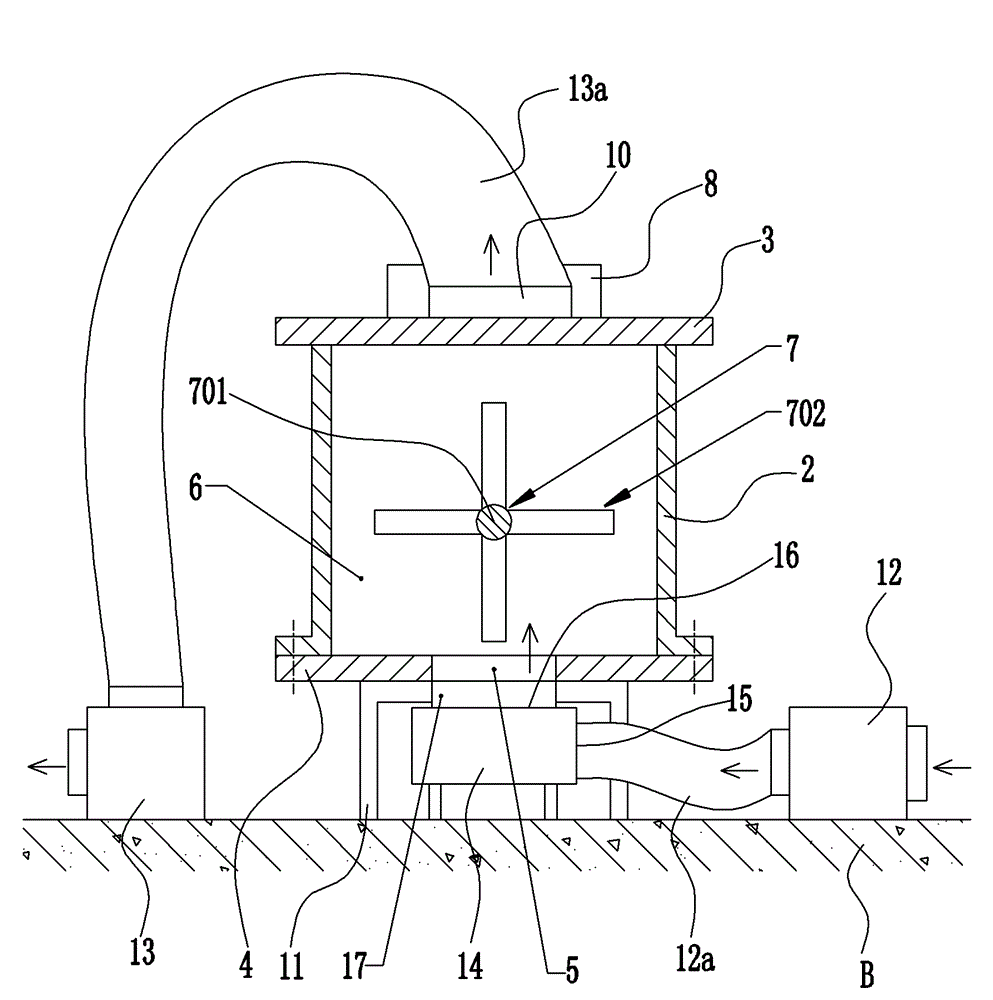

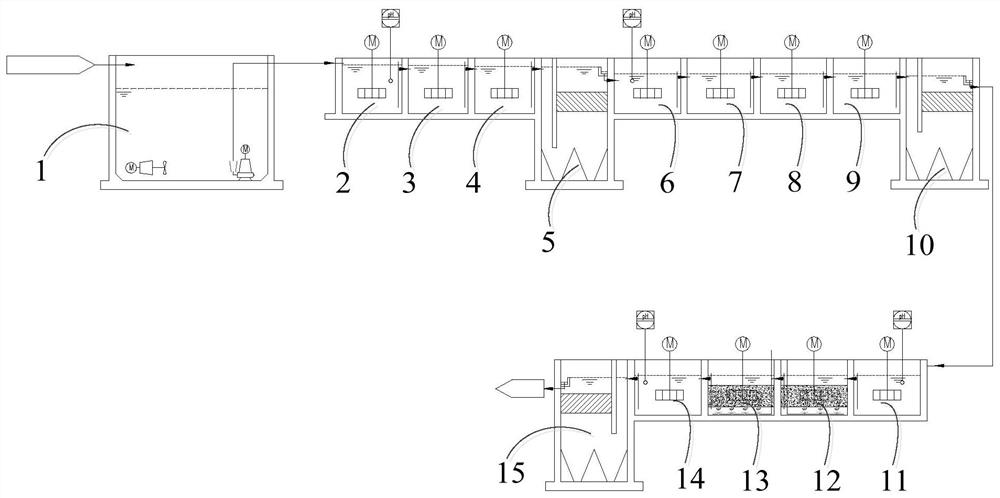

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

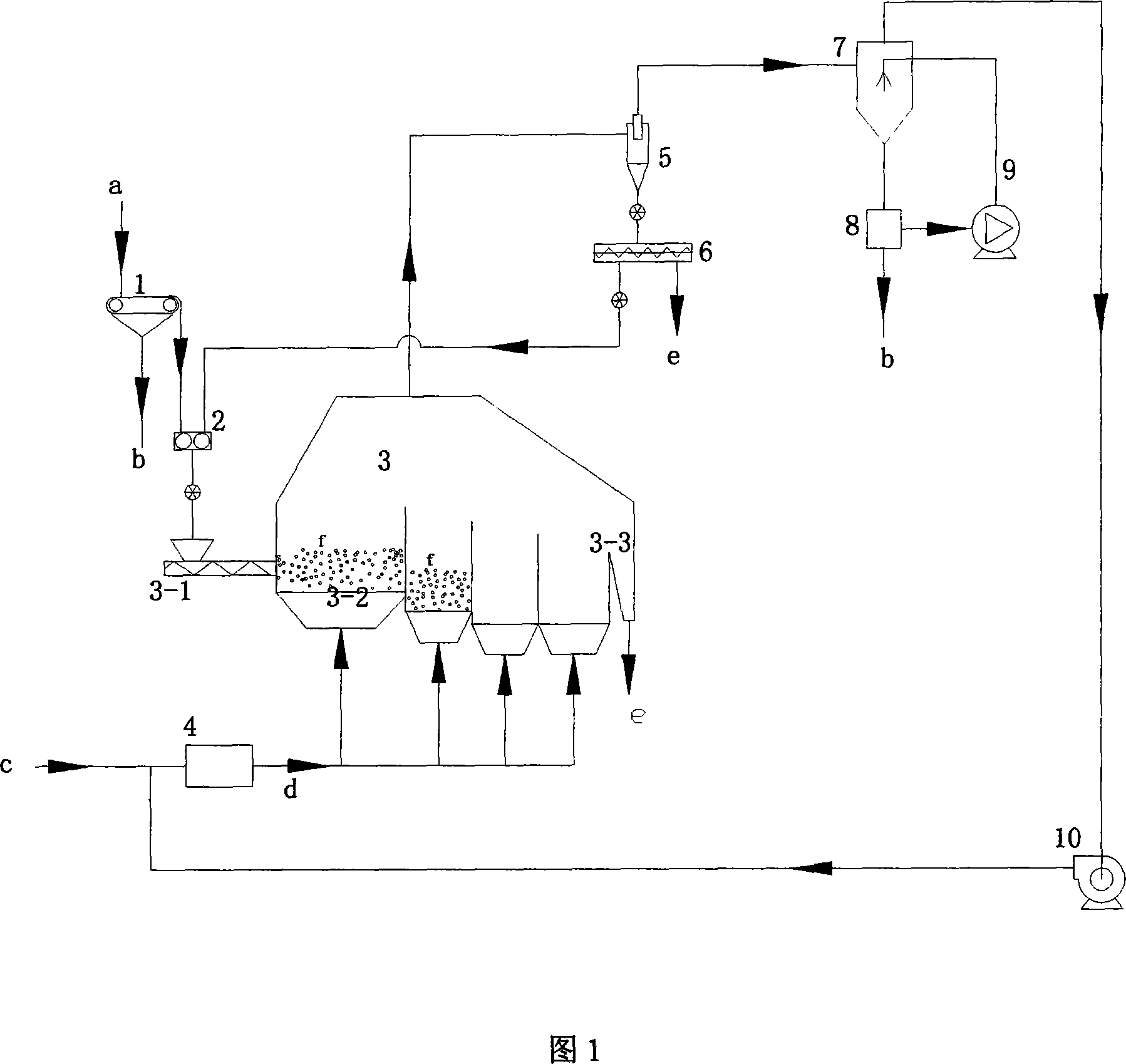

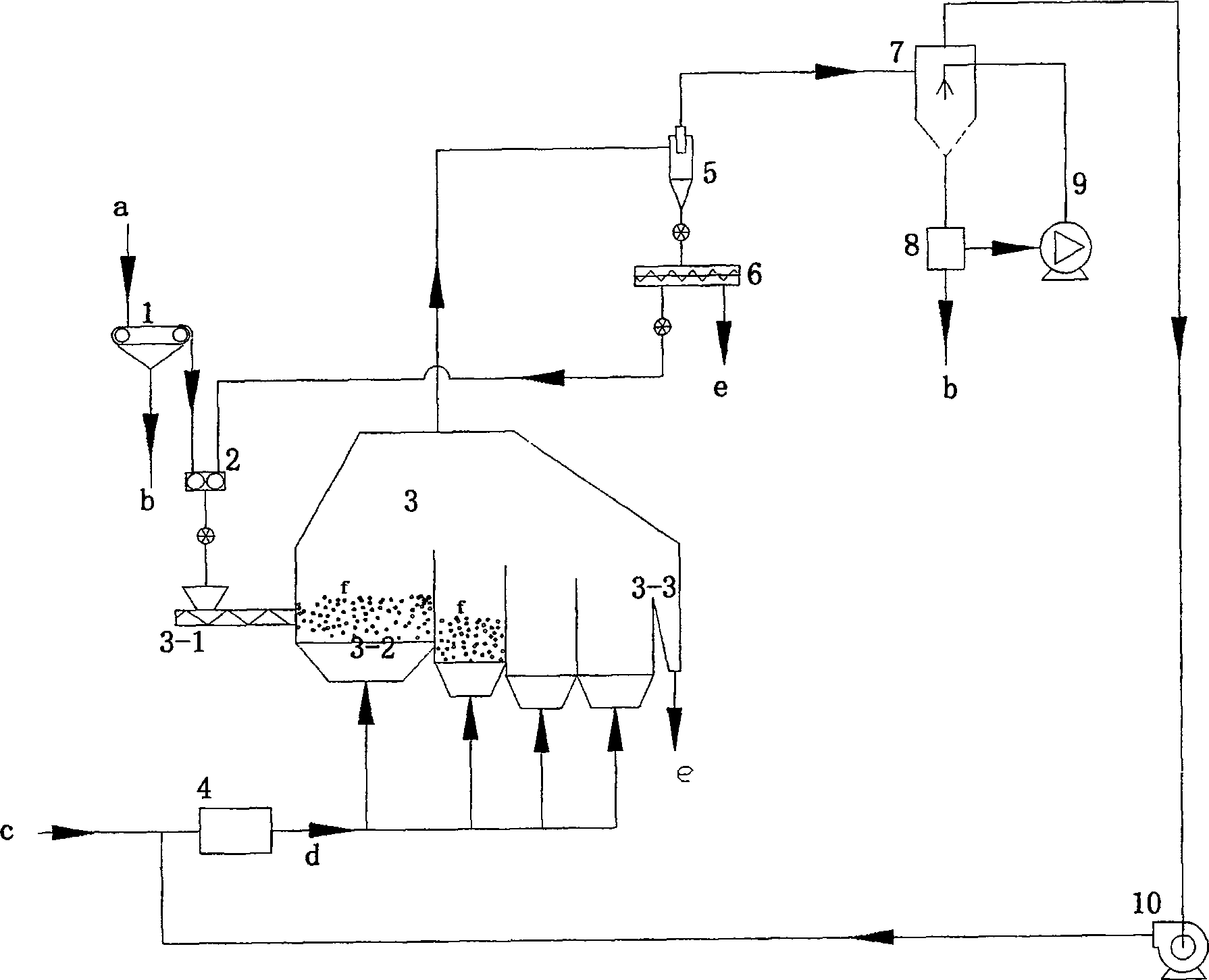

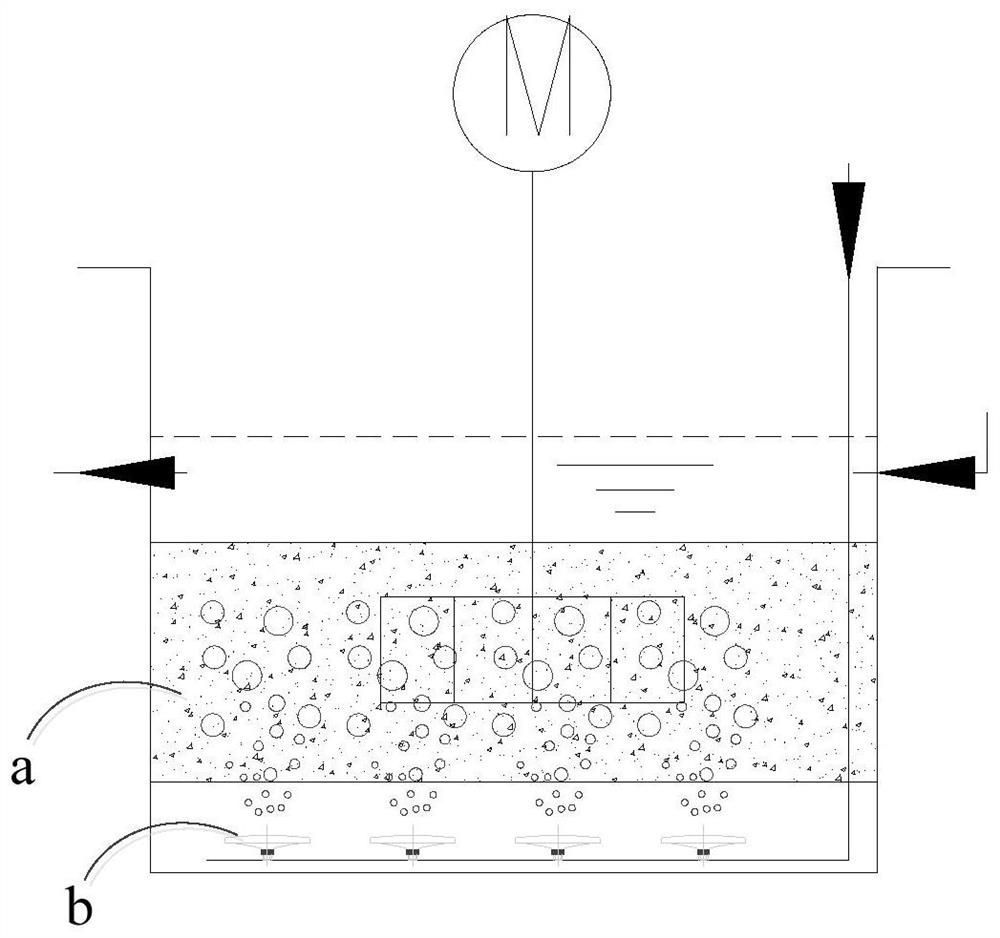

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

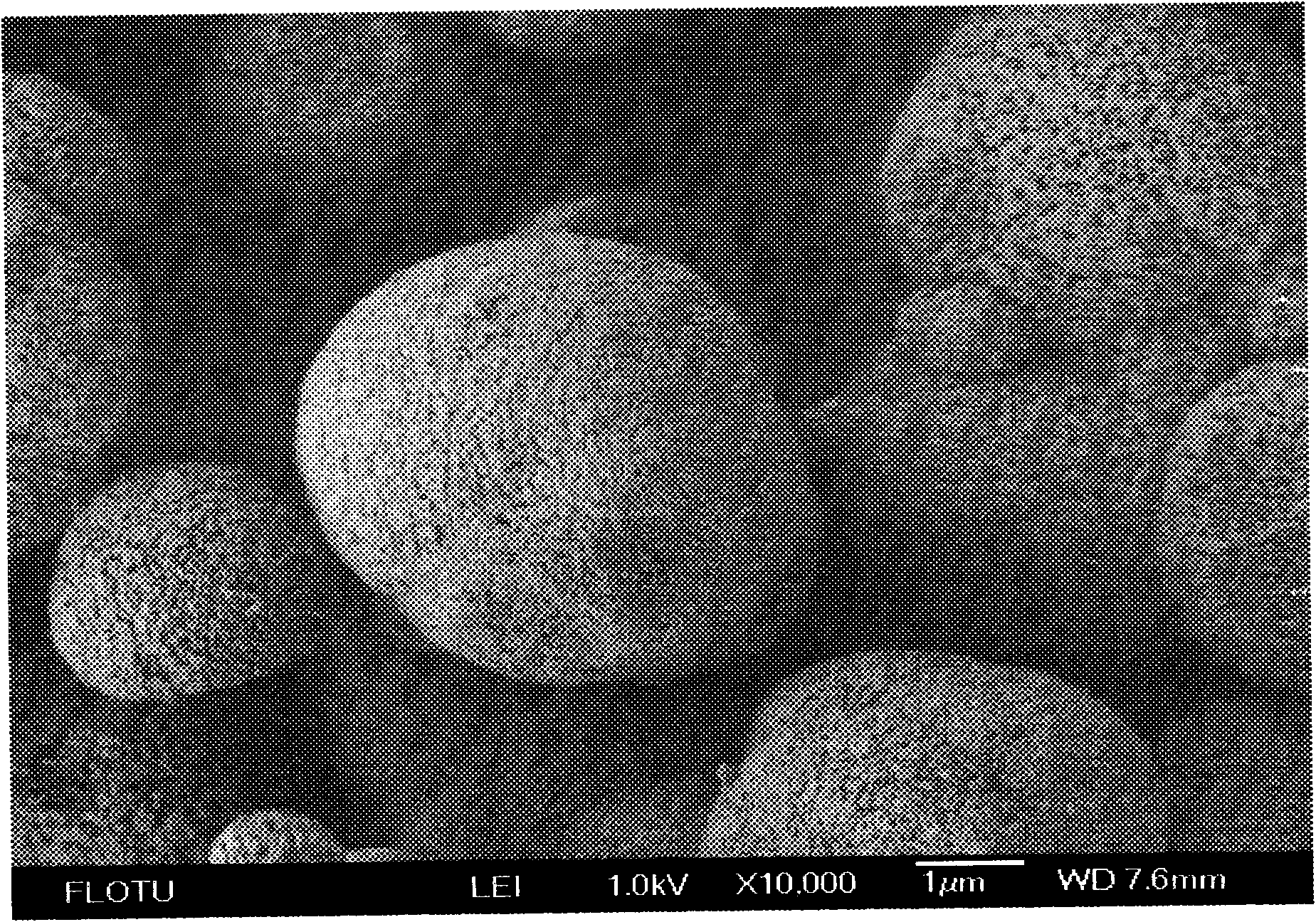

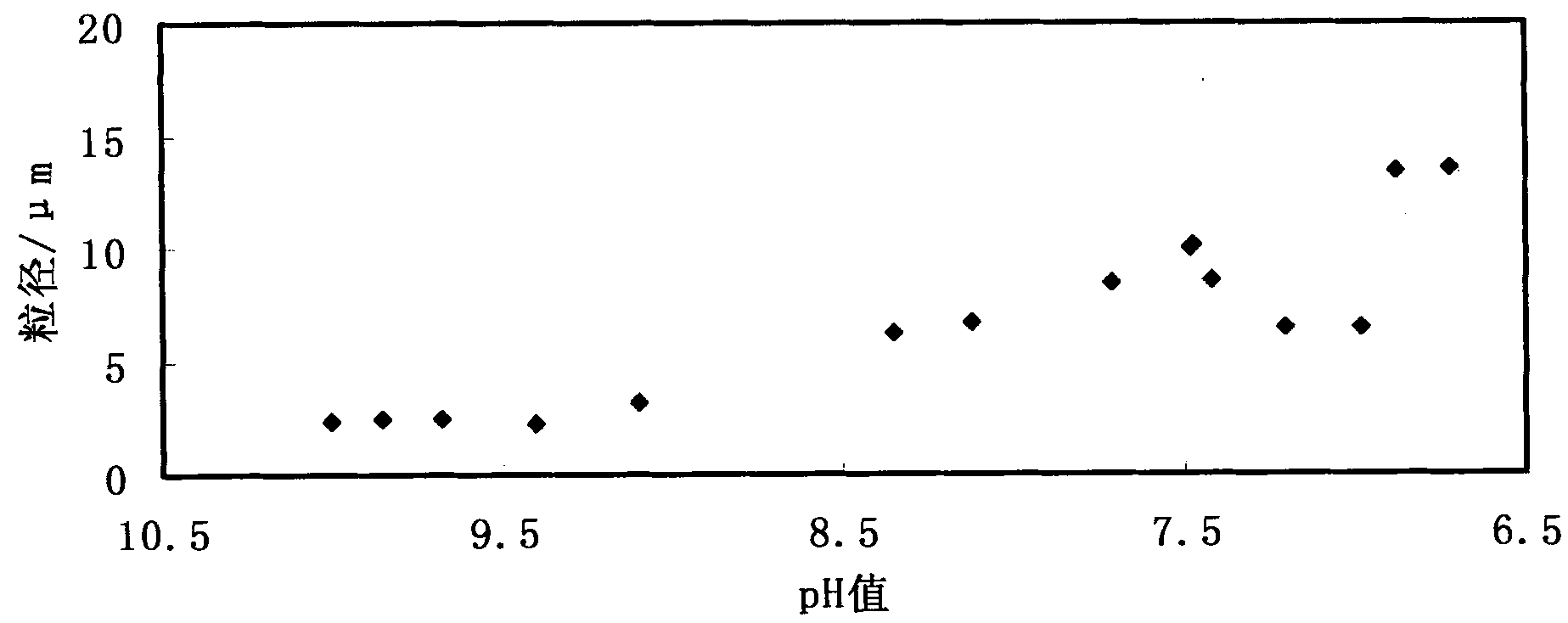

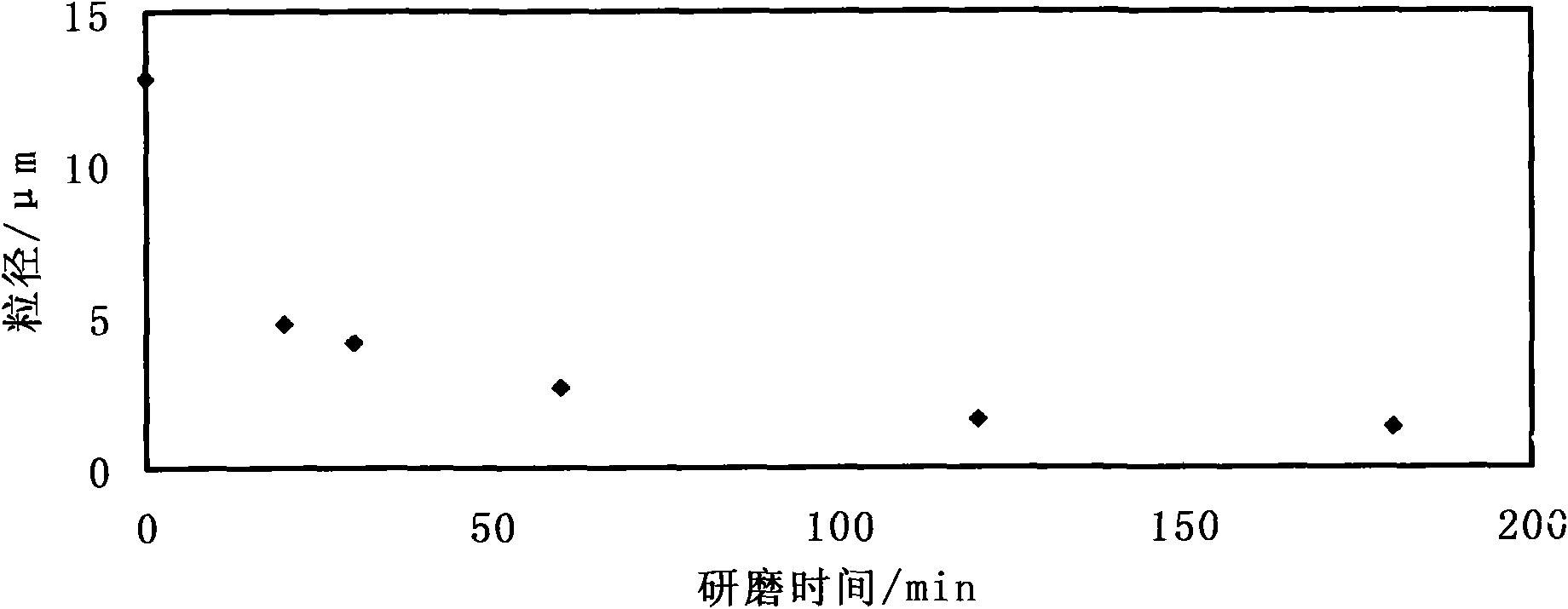

Novel method for producing superfine calcium carbonate by using carbide slag as raw material

InactiveCN101993104ASolve the possibility of industrializationRealize the possibility of industrializationCalcium/strontium/barium carbonatesCosmetic preparationsSlagCarbide

The invention relates to a method for preparing superfine calcium carbonate by adopting glycine as a dissolving agent, a modifying agent and an acid-binding agent, extracting effective calcium from calcium sources, such as carbide slag or lime, and the like and charging carbon dioxide into a reactor for calcifying, filtering and washing and application of the superfine calcium carbonate to paper making, paint production, and the like.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

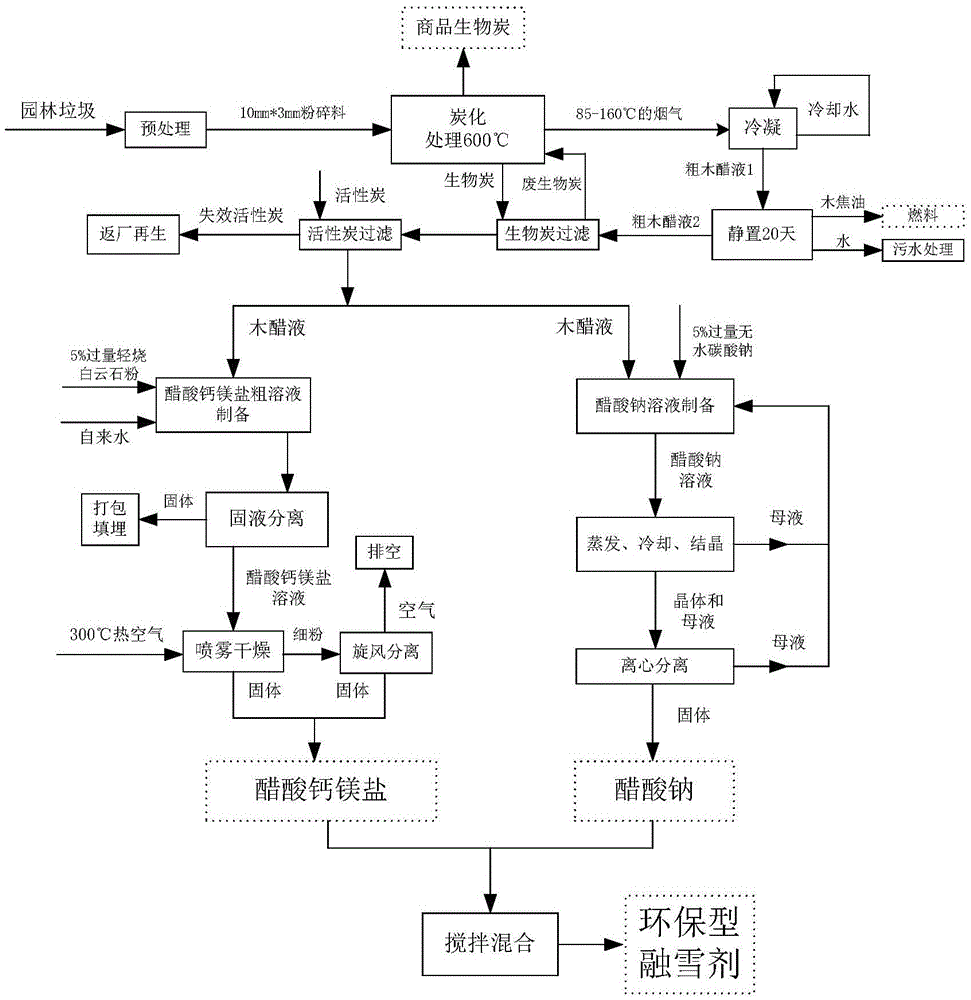

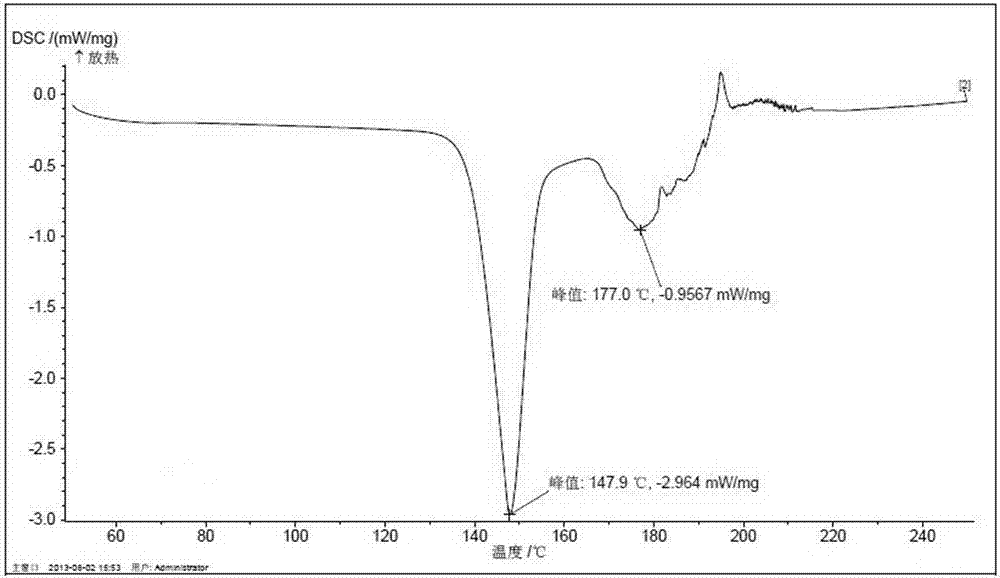

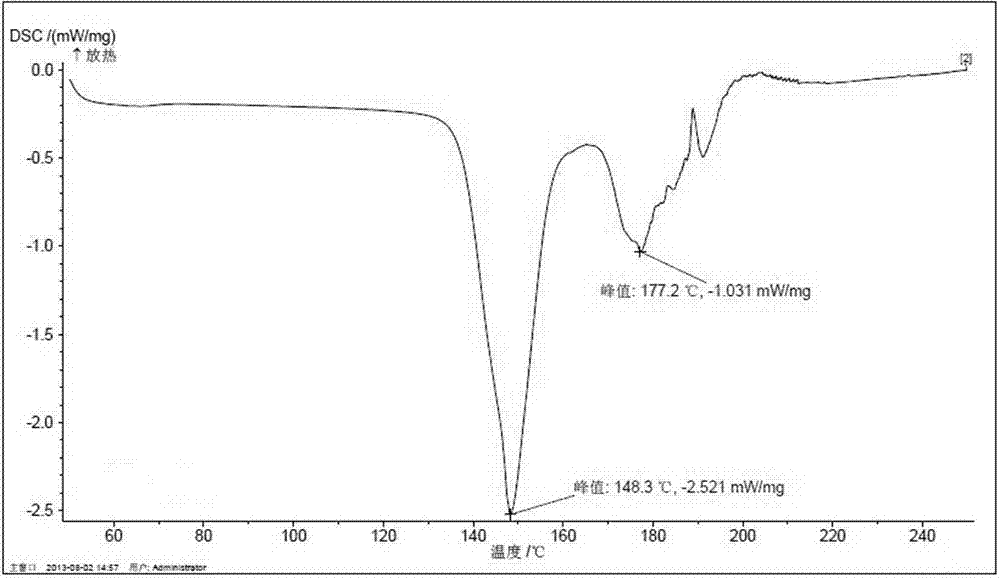

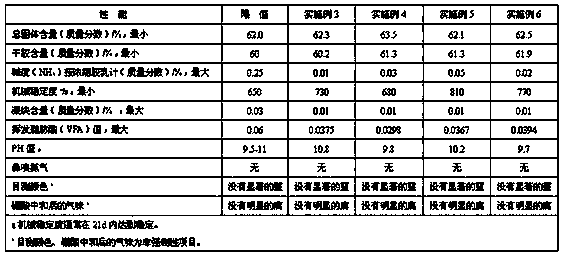

Preparation method of environment-friendly snow melting agent

ActiveCN105567163AReduce manufacturing costNot corrosiveOther chemical processesSodium acetatePlanting seed

The invention provides a preparation method of an environment-friendly snow melting agent. The environment-friendly snow melting agent is prepared from, by weight, 30%-50% of calcium magnesium acetate and 50%-70% of sodium acetate. The environment-friendly snow melting agent is prepared through the following steps that collected garden waste is utilized to prepare pyroligneous liquor; the obtained pyroligneous liquor reacts with commercially-available lightly-roasted dolomite powder to prepare calcium magnesium acetate; the obtained pyroligneous liquor reacts with commercially-available industrial-grade anhydrous sodium carbonate to prepare sodium acetate, the prepared calcium magnesium acetate and sodium acetate are added into a mixer, stirring is performed for 15 minutes to enable the materials to be mixed uniformly, and then the environment-friendly snow melting agent is obtained. According to the method, the preparation cost of the snow melting agent is reduced, the environment-friendly snow melting agent meets the requirements of the Beijing snow melting agent standard (DB11 / T 161-2012) and almost has no corrosiveness on bridges and roads, and the relative damage degree to plant seeds is smaller than 40%.

Owner:田丹 +1

Preparation method of low-permeability oral rehydration salt

ActiveCN103610692ASolve easy cakingThere will be no agglomerationPowder deliveryOrganic active ingredientsPotassiumFine powder

The invention discloses a preparation method of a low-permeability oral rehydration salt. The low-permeability oral rehydration salt comprises sodium chloride, potassium chloride, sodium citrate and glucosum anhydricum, wherein the granularity of the powder passing through a 100mesh sieve is greater than or equal to 95%. The preparation method is characterized by comprising the following steps: 1) respectively weighing prescription amount of sodium chloride, potassium chloride, sodium citrate and glucosum anhydricum for late use; 2) respectively taking a certain amount of one or more of glucosum anhydricum, sodium chloride, potassium chloride and sodium citrate to combine and crush in common, and filtering by the 100mesh sieve; 3) crushing the residual glucosum anhydricum and filtering by the 100mesh sieve; 4) evenly mixing the mixture in the step 2) with the glucosum anhydricum in the step 3) inside a mixer, and split charging. By adopting the preparation method, the problem that the sodium chloride, the potassium chloride and the sodium citrate are easily blocked after being crushed into fine powder is effectively solved; no agglomerate phenomenon is generated in the overall mixing process; the mixing process is quick and smooth; the mixing uniformity and the granularity achieve the requirements of Chinese pharmacopoeia 2010 version.

Owner:XIAMEN ENCHENG PHARMA CO LTD

Green environment-friendly concentrated natural latex and preparation method thereof

ActiveCN108690147AReduce waste water and exhaust emissionsReduce manufacturing costSodium silicateWater soluble

The invention discloses green environment-friendly concentrated natural latex and a preparation method thereof. The preparation method includes the steps of: collecting, preserving and transporting fresh latex, processing and concentrating the fresh latex, and performing accumulation treatment. A non-ammonia preservative is employed in the method and includes sodium hydrogen sulfite, sodium tripolyphosphate, sodium carbonate, sodium silicate pentahydrate, citric acid and sodium benzoate; by using the sodium tripolyphosphate instead of butyl p-hydroxybenzoate, bacteria inhibition effect of thenon-ammonia preservative is maintained, and problems that the butyl p-hydroxybenzoate is poor in water solubility and the latex, after long preservation time, is liable to cake can be solved. In addition, by reducing usage amount of sodium carbonate, raw material cost is reduced largely. The green environment-friendly concentrated natural latex can satisfy related quality index requirements in terms of basicity, total solid content, dry latex content, volatile fatty acid number, mechanical stability and the like.

Owner:北京天一瑞博科技发展有限公司

Method for preparing short-carbon-chain nylon through polycondensation

The invention belongs to the field of preparation of nylon, and particularly relates to a method for preparing short-carbon-chain nylon through polycondensation. The method for preparing the short-carbon-chain nylon through polycondensation comprises the following steps of (1) carrying out salt forming reaction on short-carbon-chain diamine and binary acid in a solvent at the temperature of 80-140DEG C under the conditions of heat preservation and pressure maintaining, and then removing the solvent to obtain dry nylon salt, 2) mixing nylon salt, an antioxidant, a catalyst, a surfactant and the pellets, and carrying out solid-phase pre-polymerization and solid-phase post-polymerization in a dynamic mixing state, in the solid-phase post-polymerization process, gradually reducing the systempressure to vacuum and keeping for at least 1 hour in a vacuum state. The temperature of the solid-phase post-polymerization is not lower than the termination temperature of the solid-phase pre-polymerization. The synthesis method solves the problem that the product is easy to cake and adhere to the wall in the industrial production process of nylon, the product is discharged in the form of powder, the melting point, intrinsic viscosity and initial thermal decomposition temperature indexes of the product are good, and the overall quality of the product is excellent.

Owner:ZHENGZHOU UNIV

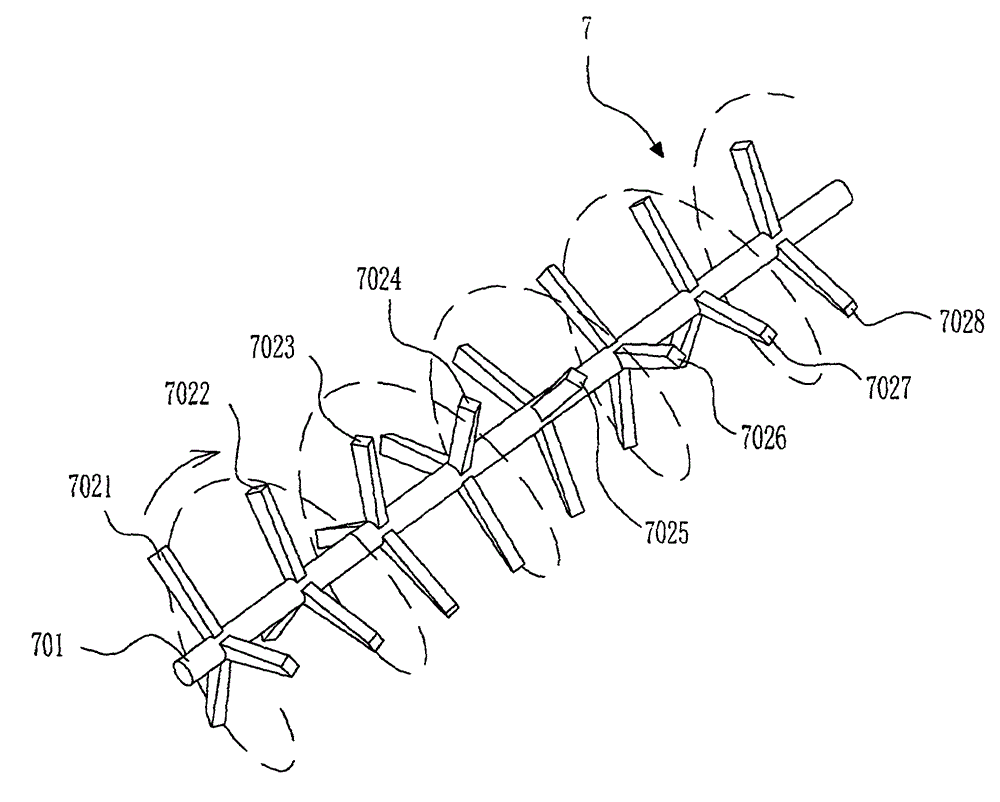

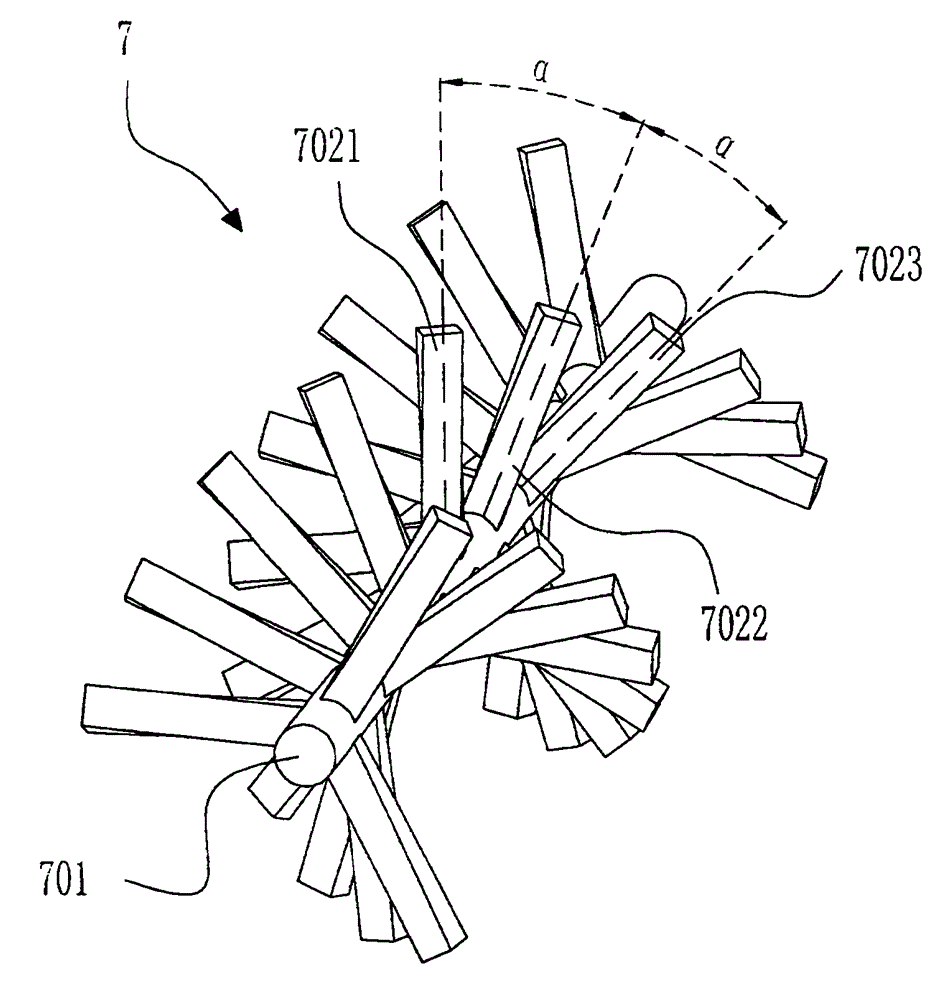

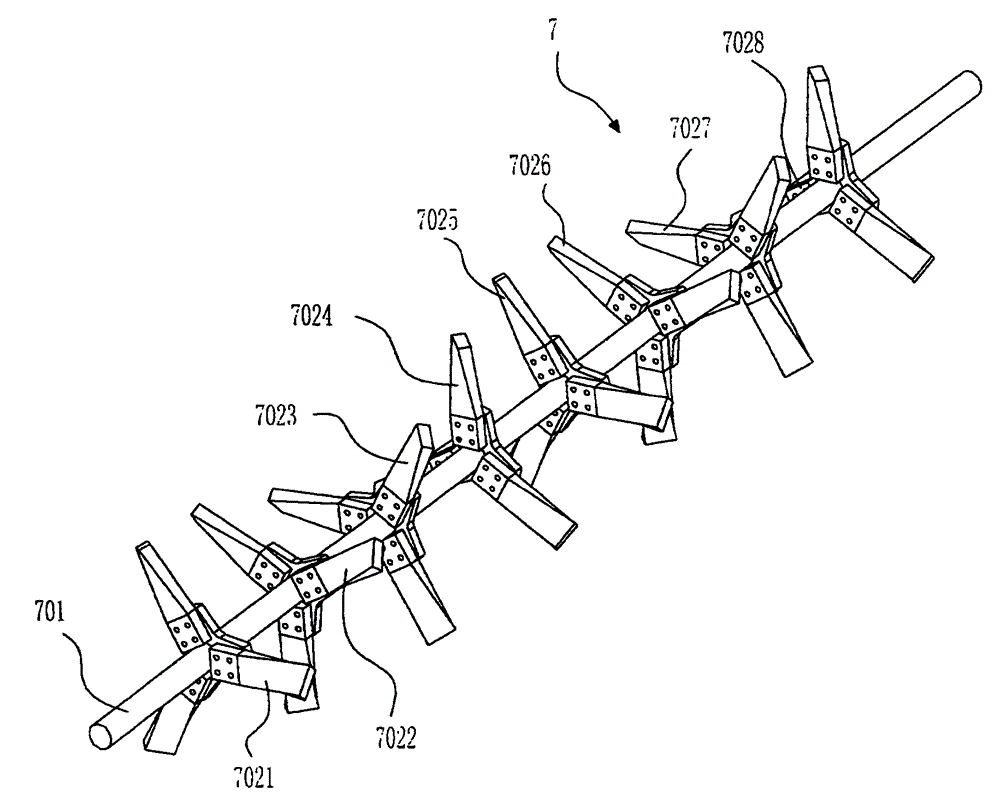

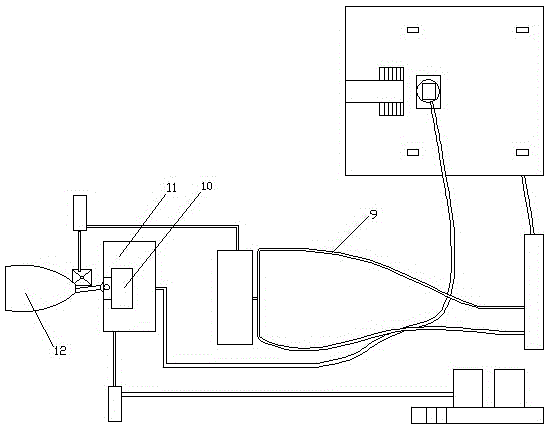

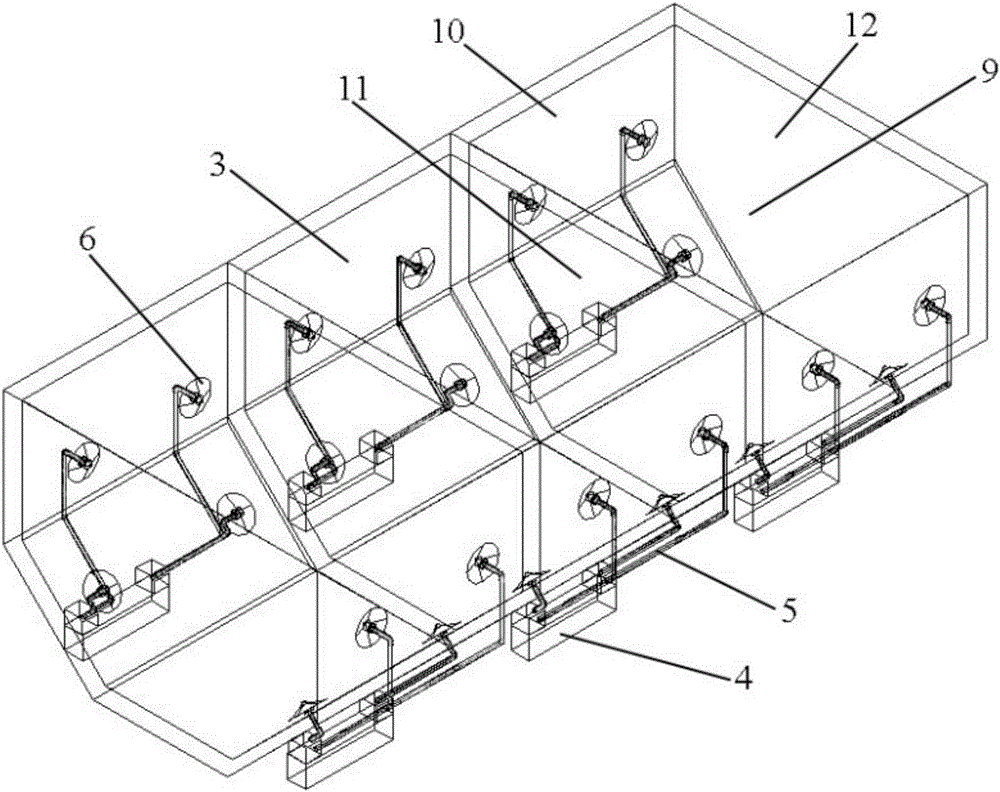

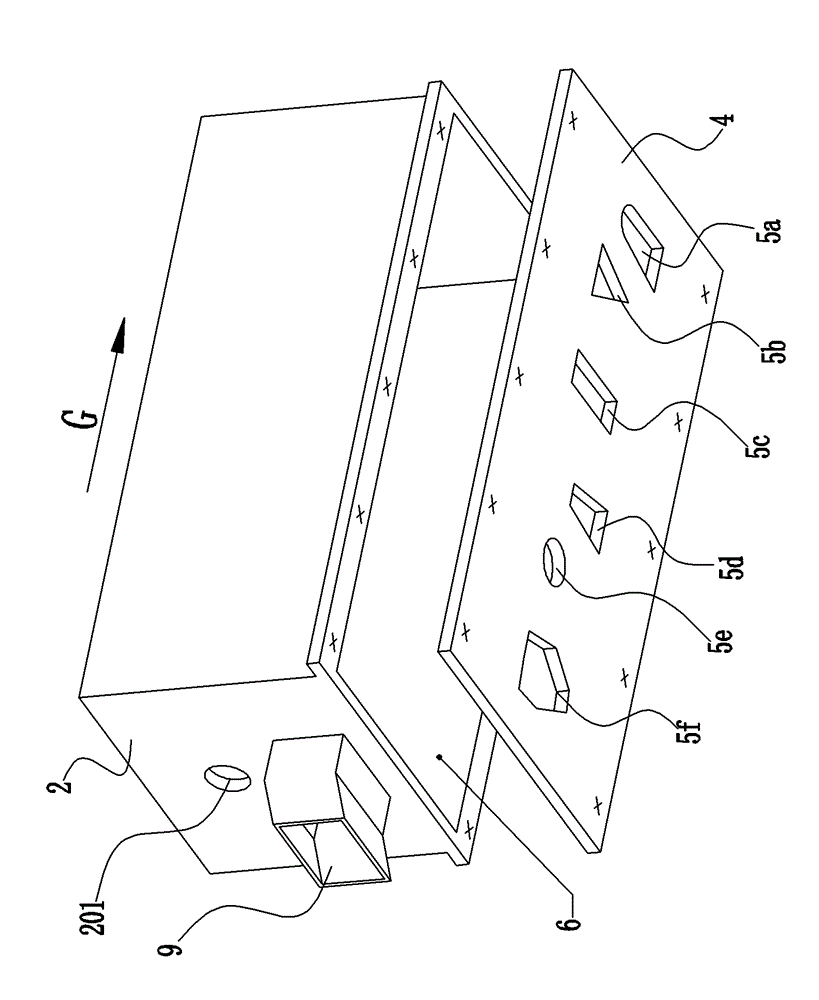

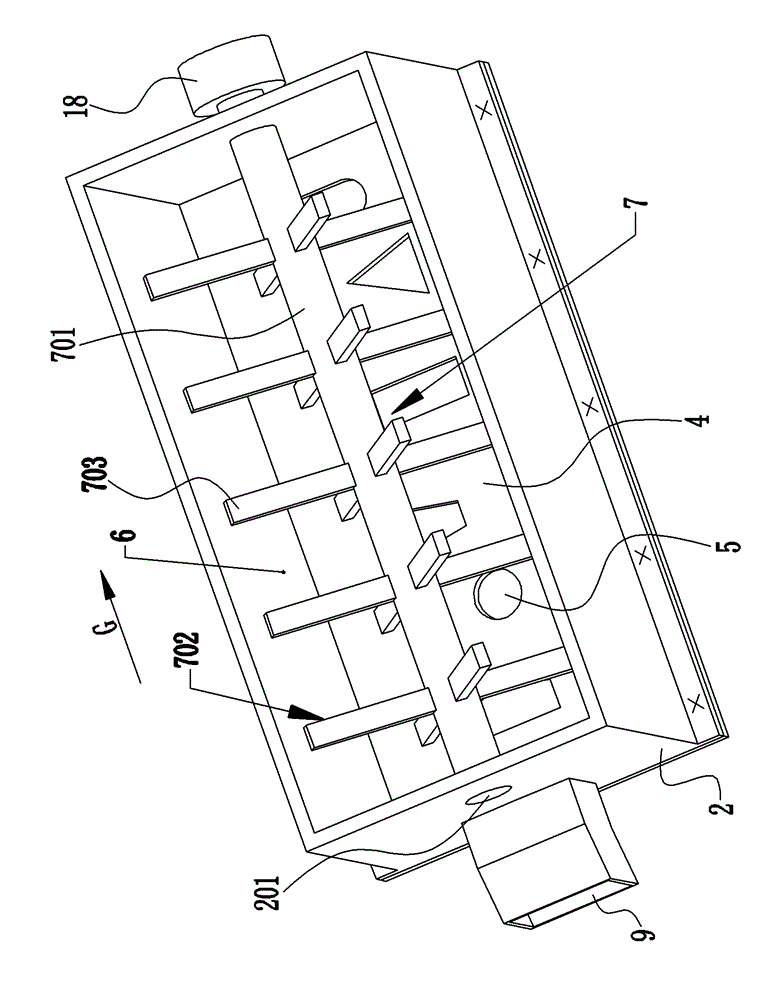

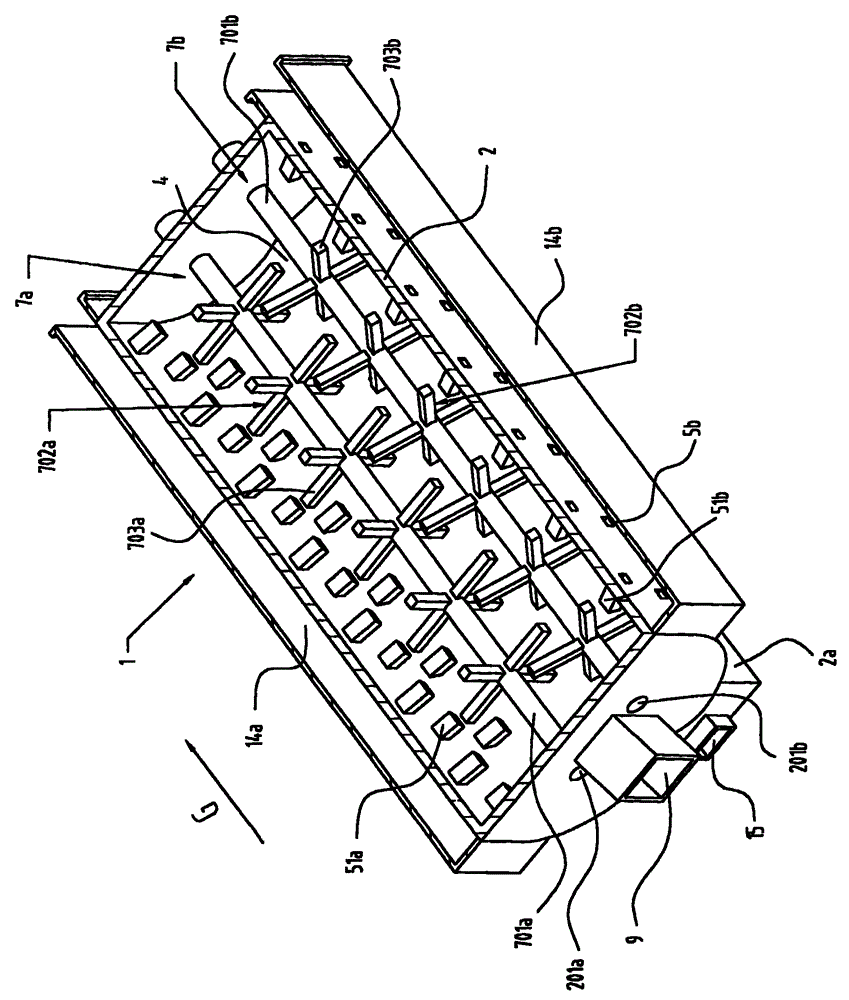

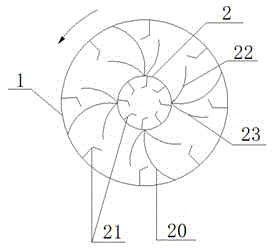

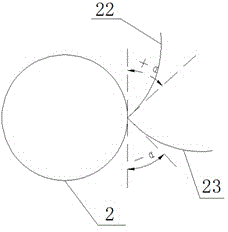

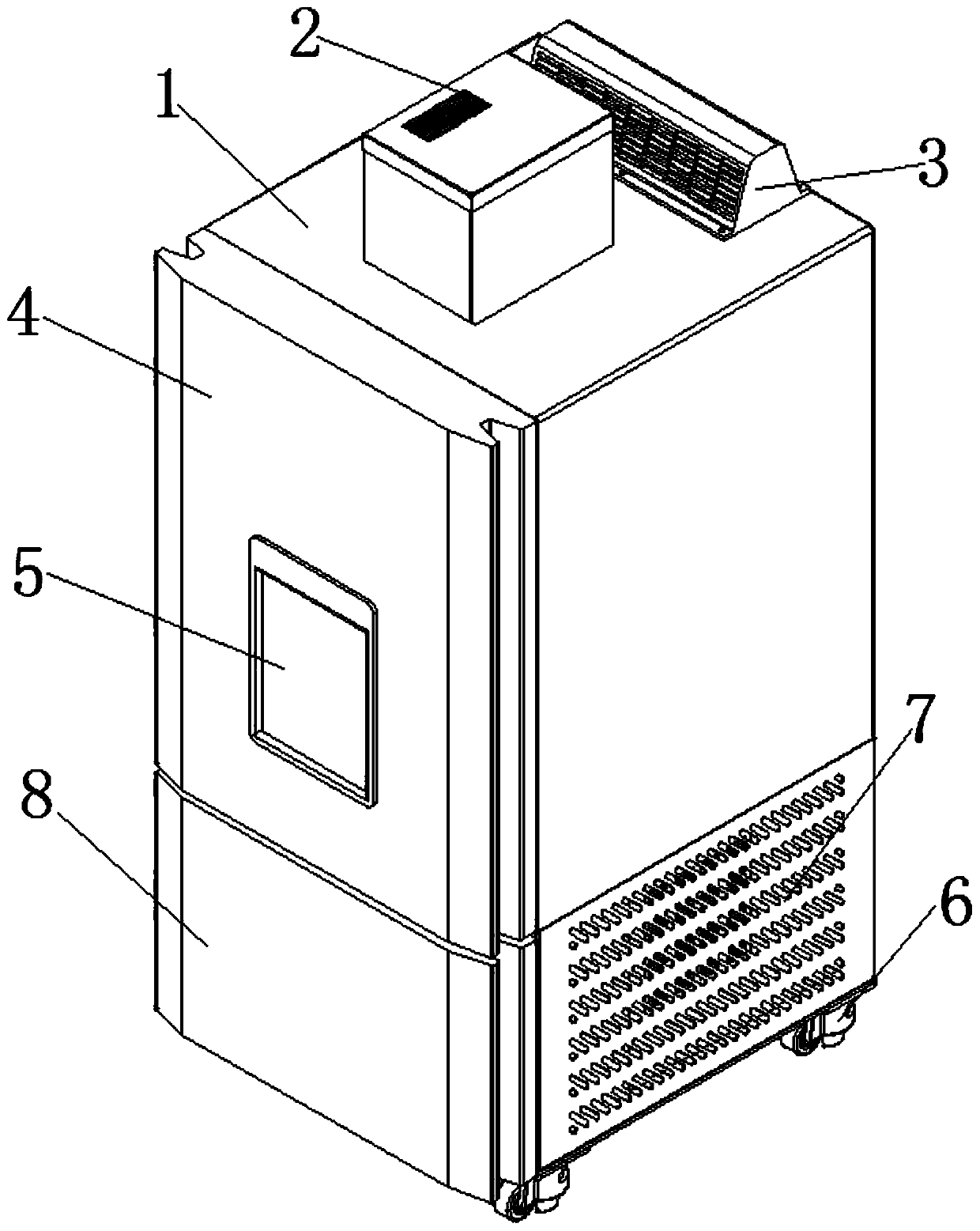

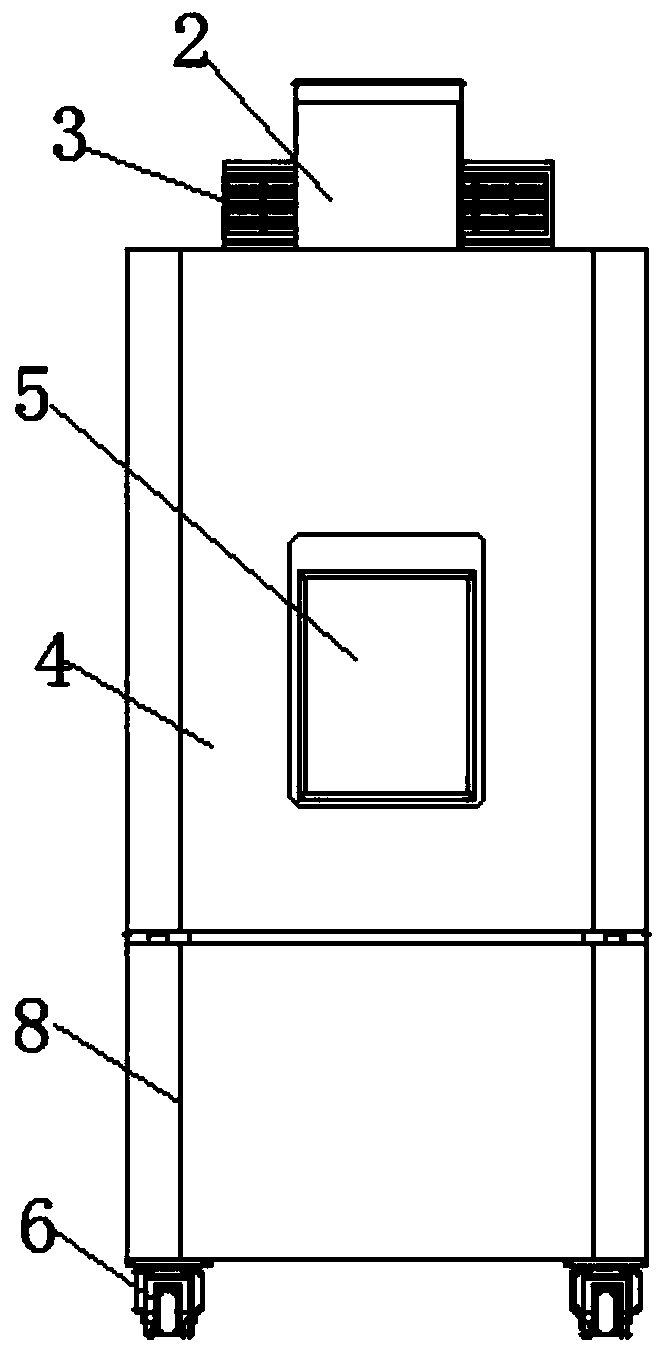

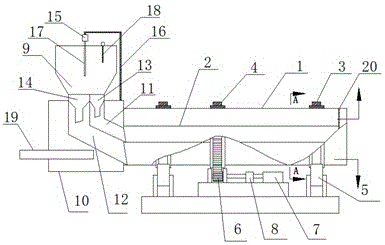

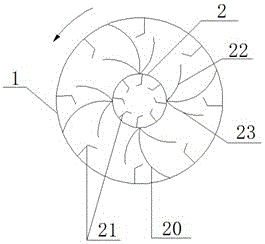

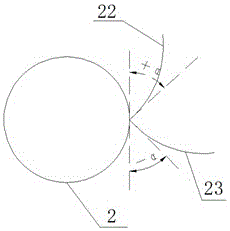

Stirring apparatus used for sludge drying device and drying apparatus thereof

ActiveCN105819658ASpeed up the flowImprove drying efficiencySludge treatment by de-watering/drying/thickeningDrying machinesSludgeEngineering

The invention provides a stirring apparatus used for sludge drying device. The stirring apparatus comprises a rotatable shaft, wherein, two ends of the rotatable shaft are arranged in shaft apertures at two end walls of a drying chamber arranged in the sludge drying device in a rotatable mode; several stirring components, wherein, several stirring components are fixedly arranged on the rotatable shaft with certain intervals and rotate with the rotatable shaft together, each stirring component in the several stirring components has blades or ratchets, wherein, the blades or the ratchets extend to outside along the shaft radial direction of the rotatable shaft; and every two adjacent stirring components in several stirring components between the blade or the ratchet have a separation angle of alpha along a circumference direction of the rotatable shaft. The invention also provides a drying apparatus by using the stirring apparatus.

Owner:广州正晟科技有限公司

Rapid dyeing process of jean fabric

ActiveCN111395013AImprove color fixation effectImprove color fastness to soapingDyeing processYarnPolymer science

The invention discloses a rapid dyeing process of jean fabric, and belongs to the technical field of fabric dyeing processes. The rapid dyeing process comprises the following steps of soaping; pre-impregnating, specifically, carrying out pre-impregnating and roll compacting on soaped warp yarns by adopting an accelerating agent; dyeing specifically, dyeing the pre-impregnated warp yarns by adopting an indigo dye, and carrying out roll compacting; oxidation, specifically, carrying out oxidation discoloration on the indigo dye by air; primary water washing, specifically, carrying out primary water washing and roll compacting on the oxidized warp yarns; color fixing, specifically, fixing the color of the warp yarns subjected to primary washing by using a color fixing agent, and performing roll compacting; secondary water washing, specifically, carrying out secondary water washing and roll compacting on the warp yarns subjected to color fixation; and drying, specifically, drying the warp yarns subjected to secondary water washing by adopting a steam drying roller. The accelerating agent is prepared from the following raw materials in parts by weight, 20-30 parts of diethylenetriamine;40-60 parts of polyepichlorohydrin-dimethylamine and 1000 parts of water. According to the rapid dyeing process, the problem that the jean fabric is easy to fade can be solved while rapid dyeing of the warp yarns is realized.

Owner:李盛强

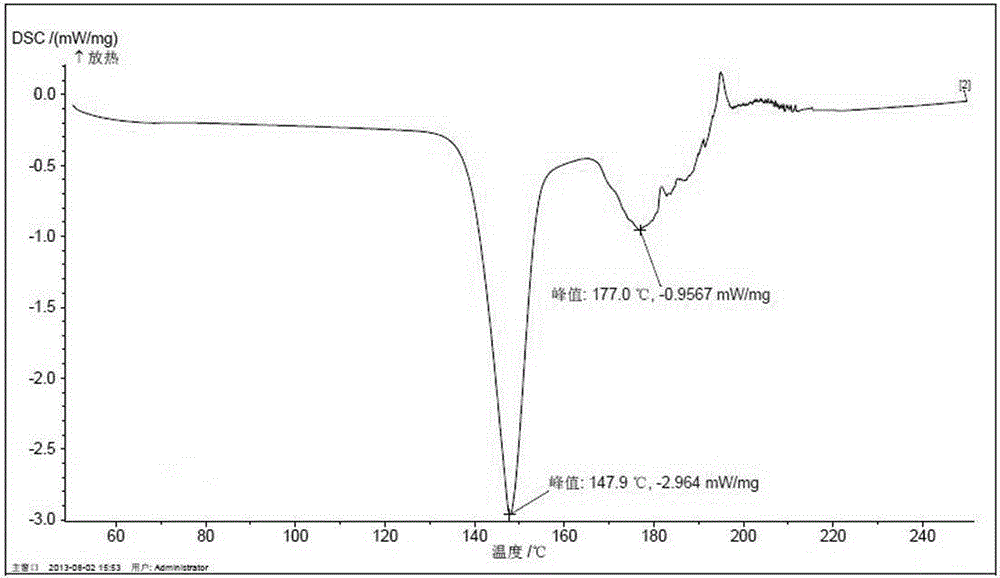

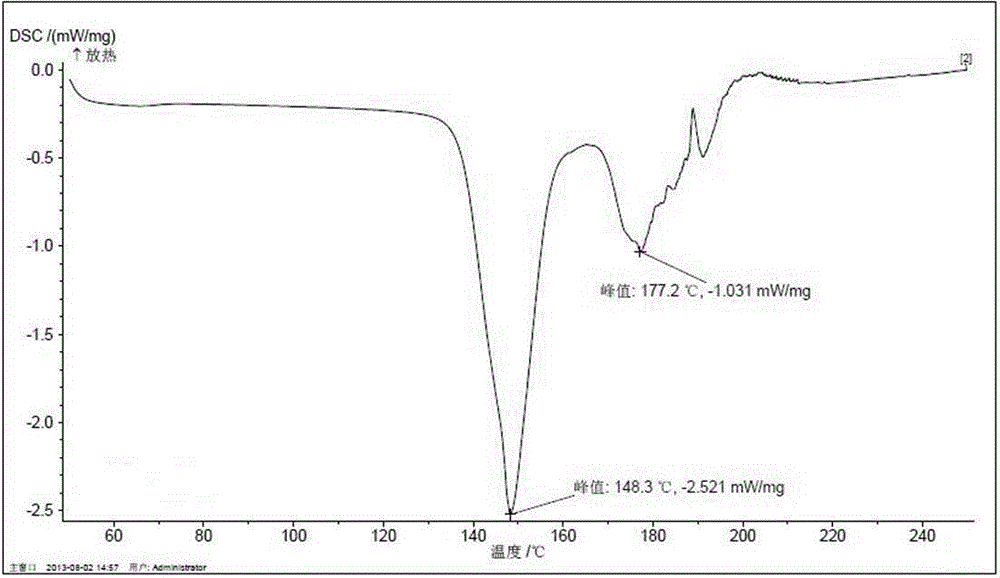

A kind of preparation method of hypotonic oral rehydration salt

ActiveCN103610692BSolve easy cakingThere will be no agglomerationPowder deliveryOrganic active ingredientsGranularityPotassium

The invention discloses a preparation method of a low-permeability oral rehydration salt. The low-permeability oral rehydration salt comprises sodium chloride, potassium chloride, sodium citrate and glucosum anhydricum, wherein the granularity of the powder passing through a 100mesh sieve is greater than or equal to 95%. The preparation method is characterized by comprising the following steps: 1) respectively weighing prescription amount of sodium chloride, potassium chloride, sodium citrate and glucosum anhydricum for late use; 2) respectively taking a certain amount of one or more of glucosum anhydricum, sodium chloride, potassium chloride and sodium citrate to combine and crush in common, and filtering by the 100mesh sieve; 3) crushing the residual glucosum anhydricum and filtering by the 100mesh sieve; 4) evenly mixing the mixture in the step 2) with the glucosum anhydricum in the step 3) inside a mixer, and split charging. By adopting the preparation method, the problem that the sodium chloride, the potassium chloride and the sodium citrate are easily blocked after being crushed into fine powder is effectively solved; no agglomerate phenomenon is generated in the overall mixing process; the mixing process is quick and smooth; the mixing uniformity and the granularity achieve the requirements of Chinese pharmacopoeia 2010 version.

Owner:XIAMEN ENCHENG PHARMA CO LTD

Compound formula and preparation method of plant dietary fiber ferric ammonium citrate

InactiveCN109770202AComposition and efficacy enhancementRegulate stomachFood preservationHealthy eatingStomach

The invention relates to a compound formula and preparation method of plant dietary fiber ferric ammonium citrate. The plant dietary fiber ferric ammonium citrate is formed by taking ferric ammonium citrate as a carrier and being fully compounded with konjac powder, oat powder, broccoli powder, sweet potato powder, asparagus powder and burdock powder and other plant nutrition powder through a modern preparation technology. The ingredients of the plant dietary fiber ferric ammonium citrate greatly improve the ingredients beneficial to the human body and effects through mutual coordination and promotion, and has several folds of effects compared with adopting a single ingredient; under the synergistic effect of the ingredients, the prepared plant dietary fiber ferric ammonium citrate has theeffects of regulating blood sugar, coordinating intestines and stomach, reducing blood fat and cholesterol and the like, is more conductive to being absorbed by the human body, serves as an innovative nutritional supplement agent and food anti-caking agent, and meets the needs of modern healthy diet. The compound formula of the plant dietary fiber ferric ammonium citrate is used for salt to effectively solve the problem that the salt easily cakes or goes bad.

Owner:天津保元堂生物科技有限公司

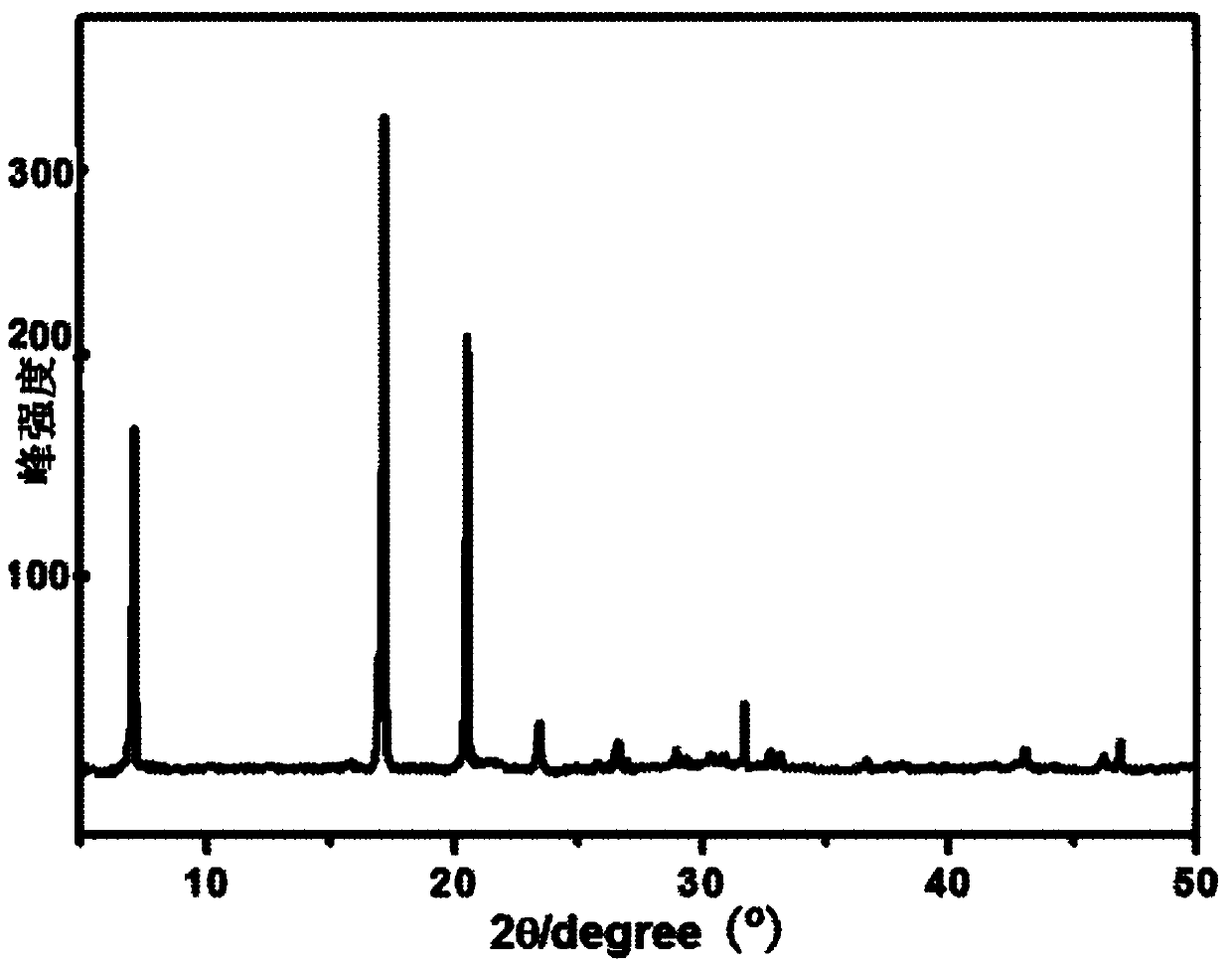

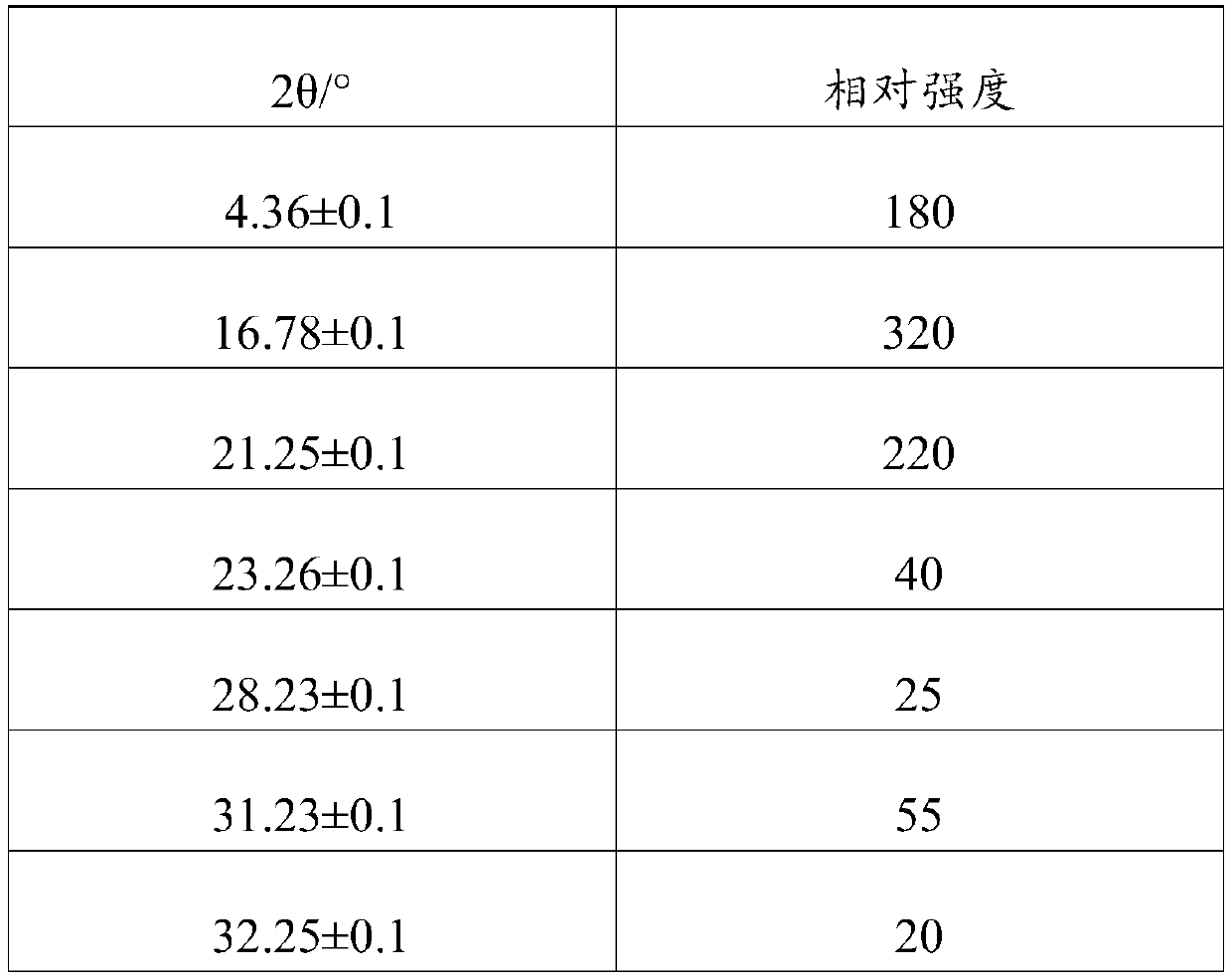

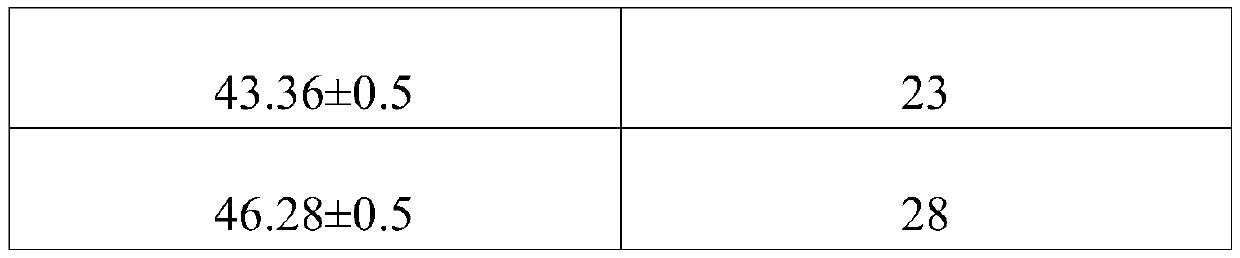

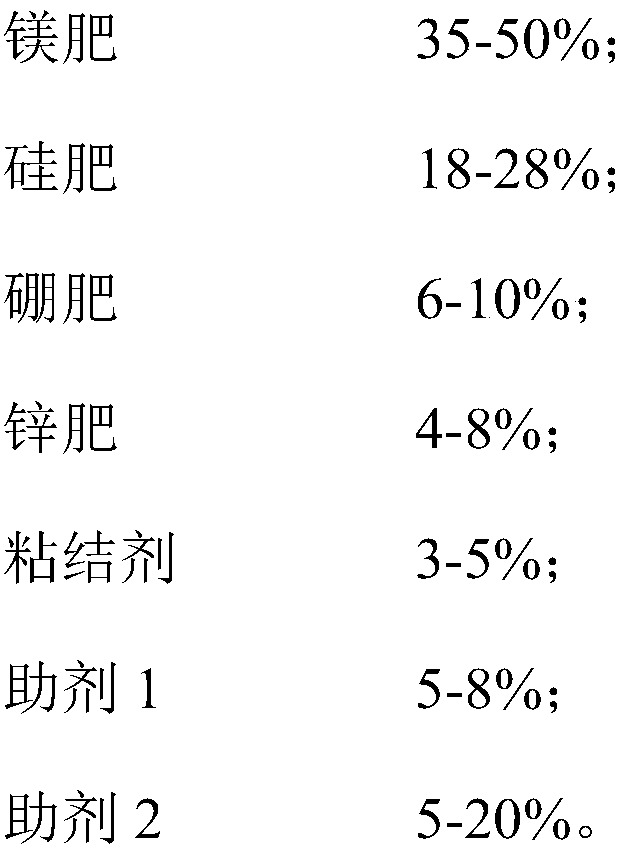

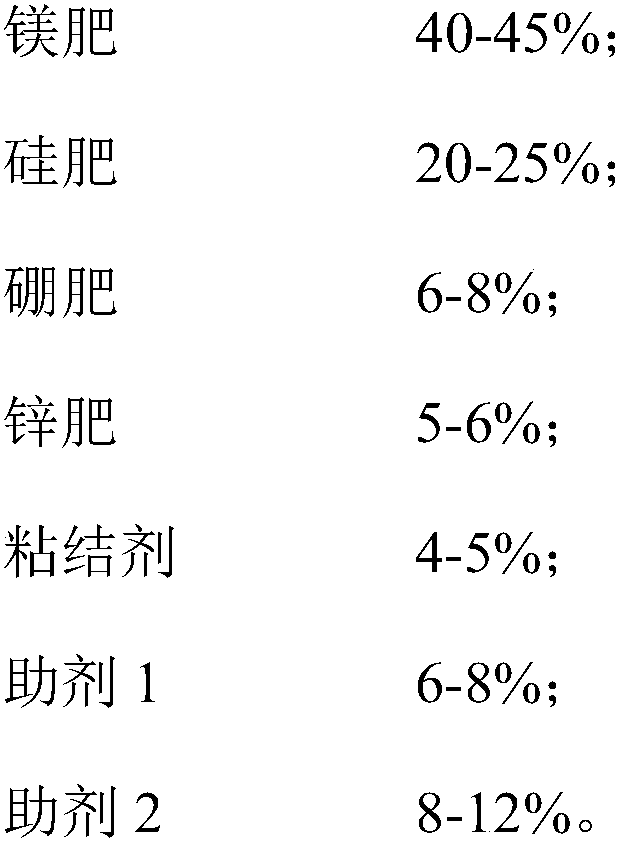

Moisture-proof silicon-magnesium-boron-zinc composite granular fertilizer and preparation method thereof

ActiveCN109180351AReduce storage difficultyImprove application efficiencyCalcareous fertilisersMagnesium fertilisersSodium metasilicateMoisture

The invention relates to moisture-proof silicon-magnesium-boron-zinc composite granular fertilizer. The moisture-proof silicon-magnesium-boron-zinc composite granular fertilizer is prepared from 20-70% by weight of magnesium fertilizer, 10-30% by weight of silicon fertilizer, 5-10% by weight of boron fertilizer, 3-8% by weight of zinc fertilizer, 3-5% by weight of a binder, 3-8% by weight of an aid 1 and 5-56% by weight of an aid 2. The magnesium fertilizer is at least one of anhydrous magnesium sulfate, magnesium sulfate monohydrate, magnesium sulfate pentahydrate and magnesium sulfate heptahydrate. The silicon fertilizer is at least one of sodium silicate and sodium metasilicate. The boron fertilizer is at least one of borax, boric acid and boron-magnesium fertilizer. The zinc fertilizeris at least one of zinc sulfate heptahydrate, zinc sulfate monohydrate and zinc oxide. The binder is at least one of sodium carboxymethylcellulose and corn starch. The aid 1 comprises quicklime and calcium-magnesium phosphate fertilizer in a mass ratio of 1-8: 1. The aid 2 comprises high clay and attapulgite in a mass ratio of 1: 1-3. The moisture-proof silicon-magnesium-boron-zinc composite granular fertilizer has excellent anti-mildew properties, is not easy to agglomerate and has a high fertilizer utilization rate.

Owner:广东省科学院南繁种业研究所

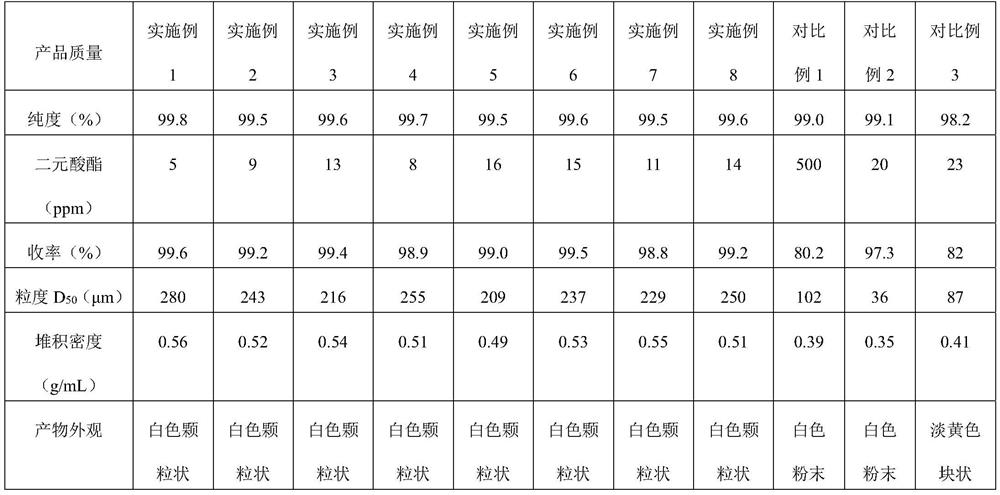

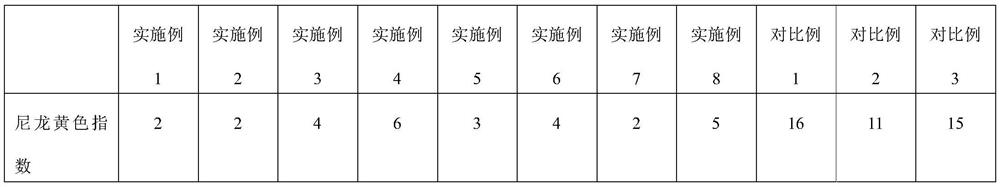

High-purity nylon 5X salt and purification method thereof

PendingCN111825557ALarge particlesHigh bulk densityAmino compound purification/separationCarboxylic compound separation/purificationDiamineAqueous solution

The invention relates to a high-purity nylon 5X salt and a preparation method thereof, wherein the purity of the nylon 5X salt reaches 99.5% or above, and the nylon 5X salt can be directly used for polymerization. According to the preparation method of the nylon 5X salt provided by the invention, pentamethylene diamine and nylon salt production processes are coupled together, and the nylon salt isproduced by a one-step method, so that the tedious and complex process flow is omitted, the equipment investment is reduced, and the production cost is saved; and the method provided by the inventionsolves the problem of low yield of nylon salt crystallization products by an aqueous solution method, the crystallization process is more effectively controlled, and explosion nucleation is avoided.

Owner:CATHAY R&D CENT CO LTD +1

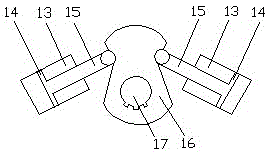

Particle drilling method

InactiveCN105134080ASimplify the screening processImproving the efficiency of percussion drilling operationsDrilling machines and methodsWell drillingParticle injection

Owner:CCDC PETROLEUM CORING TECH

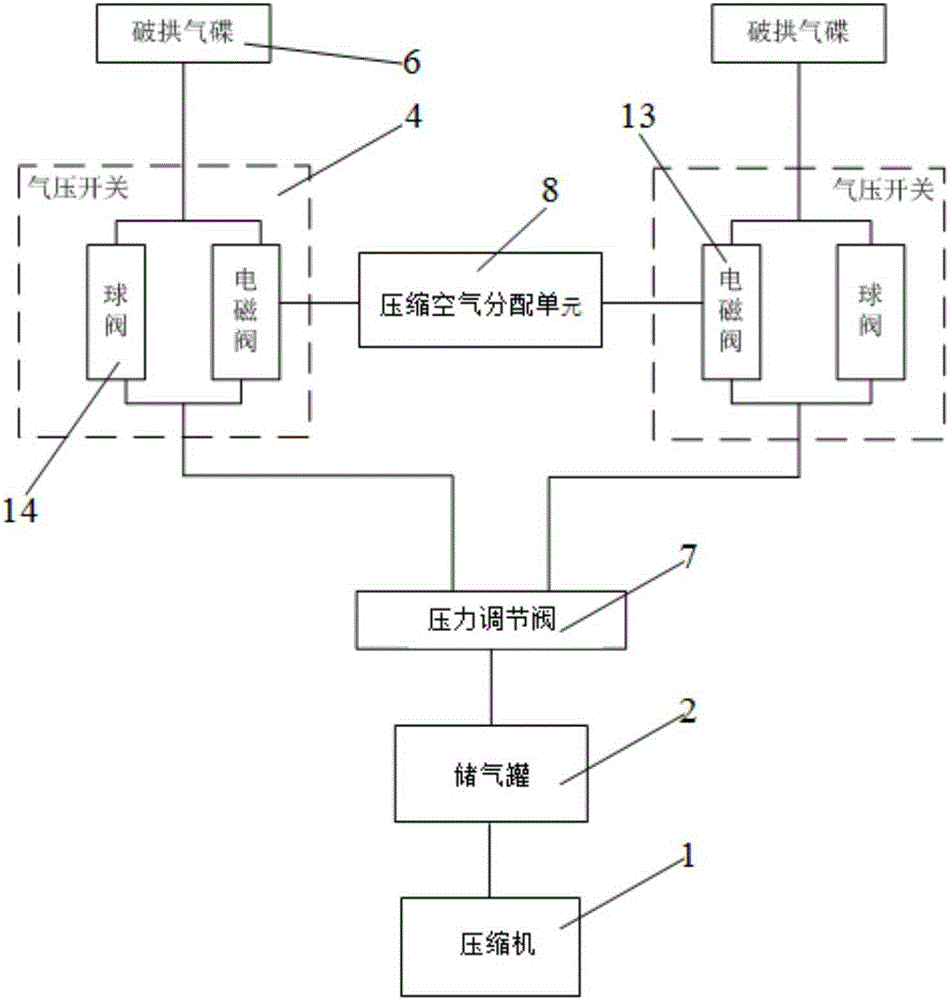

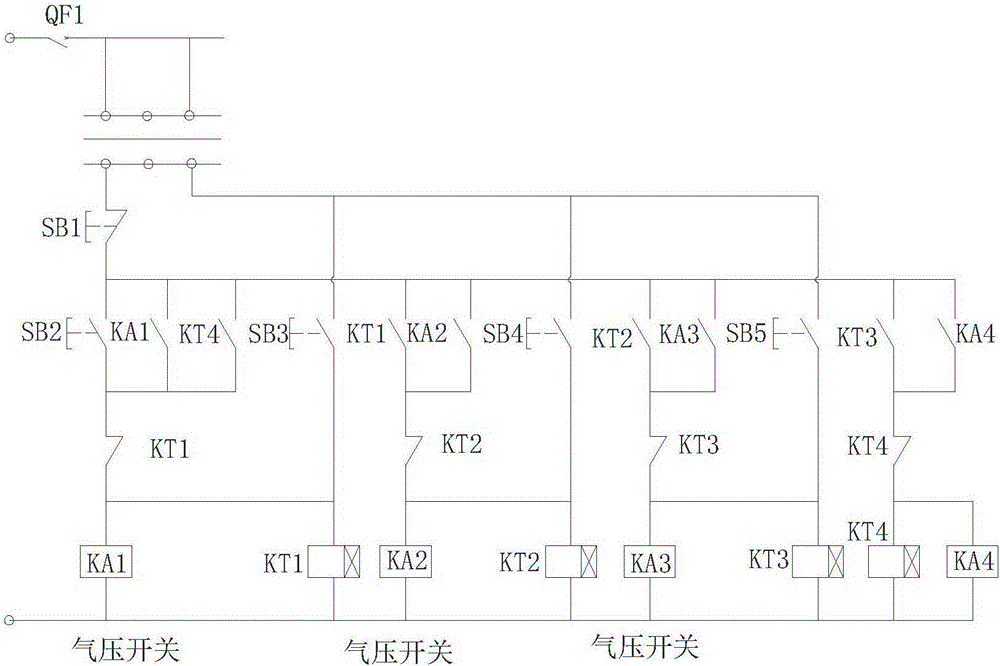

Automatic arch breaking device for ammonium nitrate fuel oil explosive mixing and charging vehicle

ActiveCN105217180ASolve easy cakingSolve the problem that the material cannot be cut normallyLarge containersFuel oilHigh pressure

The invention provides an automatic arch breaking device for an ammonium nitrate fuel oil explosive mixing and charging vehicle. The device comprises a compressor driving the mixing and charging vehicle, a gas storage tank connected with the compressor, a stock bin used for storing ammonium nitrate fuel oil explosives. The automatic arch breaking device further comprises a gas pressure switch connected with the gas storage tank, a compression gas pipe connected with the gas pressure switch, a plurality of arch breaking gas discs installed on the inner wall of the stock bin, and a compressed air distribution unit eclectically connected with the gas pressure switch. The arch breaking gas discs are connected with the compression gas pipe. The problems that in a high-temperature and humid environment, porous granular ammonium nitrate is likely to cake and normal discharge can not be achieved are solved. Besides, the labor intensity of operators is reduced, safety hidden hazards are avoided, the quality of the ammonium nitrate fuel oil explosives is improved, waste high-pressure air of the mixing and charging vehicle is reasonably used, extra power consumption can not be generated, and energy conservation and environmental friendliness are achieved.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

Process for drying potash magnesium sulphate fertilizer

InactiveCN102924129ASolve easy cakingSolve the problem of drying and easy "pressing bed"Magnesium fertilisersPotassium fertilisersSulphate IonHeat sensitive

A process for drying a potash magnesium sulphate fertilizer comprises the following steps: (1) wet material feed: feeding water-containing potash magnesium sulphate fertilizer into a strengthened airflow dryer; (2) hot air feed: heating the air, and pressurizing and feeding the heated air into the cone bottom of the strengthener of the strengthened airflow dryer; (3) drying process: keeping the wet material to be dried in the strengthened airflow dryer for 2-7 seconds, thereby obtaining the finished potash magnesium sulphate fertilizer containing less than or equal to 2wt% of free water; and (4) discharge, and tail gas treatment and emission: feeding the dried material into a discharge device along with the air flow, performing cyclone dust removal or removing dust through a water film or a cloth bag, and then collecting the dried potash magnesium sulphate fertilizer and emitting the tail gas. The process for drying the potash magnesium sulphate fertilizer provided by the invention is easy to control the drying temperature, simple and short in process, high in drying strength, good in adaptability, high in thermal efficiency, continuous, stable and reliable in drying process, even and reliable in quality of product, good in drying effect, and suitable for mass production and for drying heat sensitive materials.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

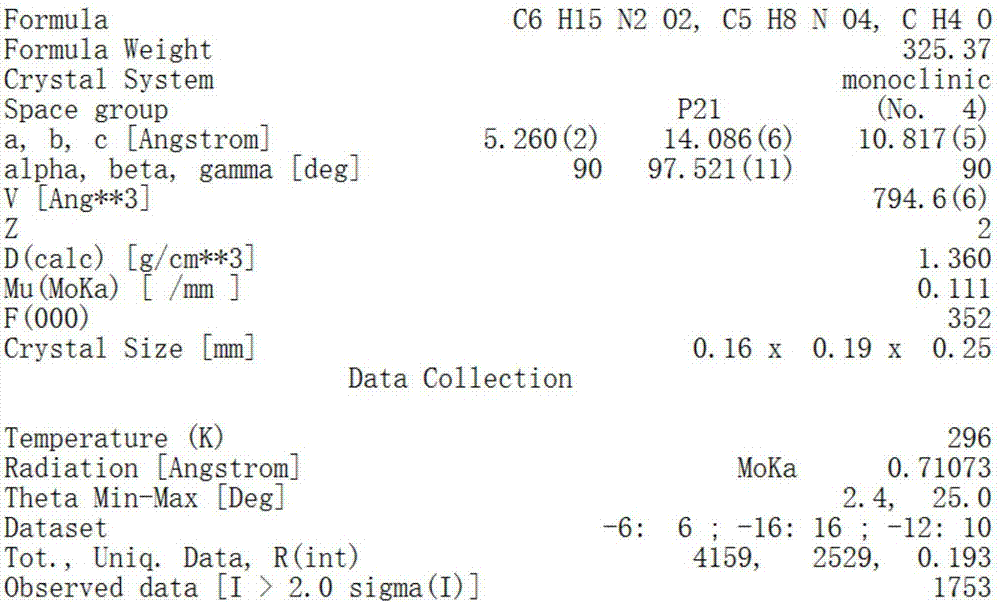

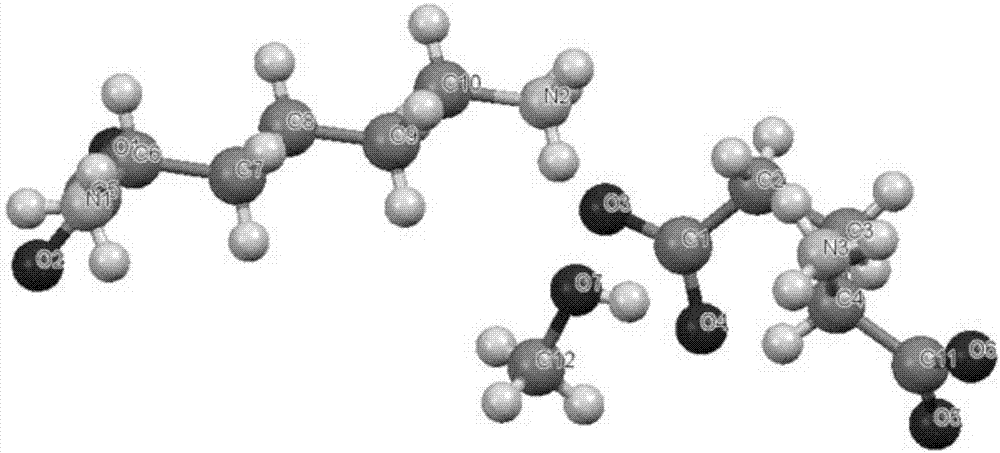

Crystalline powder of L-lysine L-glutamate

InactiveCN107325014ASolve easy oil analysisSolve viscosityOrganic active ingredientsMetabolism disorderMethanol waterL glutamate

The invention discloses crystalline powder of L-lysine L-glutamate and a preparation method of the crystalline powder of the L-lysine L-glutamate. The methanol content of the crystalline powder is less than 0.5wt%, the bulk density of the crystalline powder is more than 0.4g / ml, and the tapped density of the crystalline powder is more than 0.5g / ml. According to the preparation method, crystal obtained by crystallizing L-lysine L-glutamate methanol water is put into ethanol for converting, so that the problem that methanol is left over in a dilution crystallization process is effectively solved; compared with the existing products on the market, the prepared crystalline powder not only has good graininess, flowability and stability, but is also very low in amount of residual methanol.

Owner:NANJING UNIV OF TECH

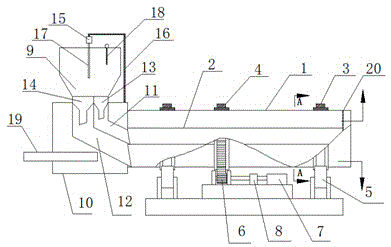

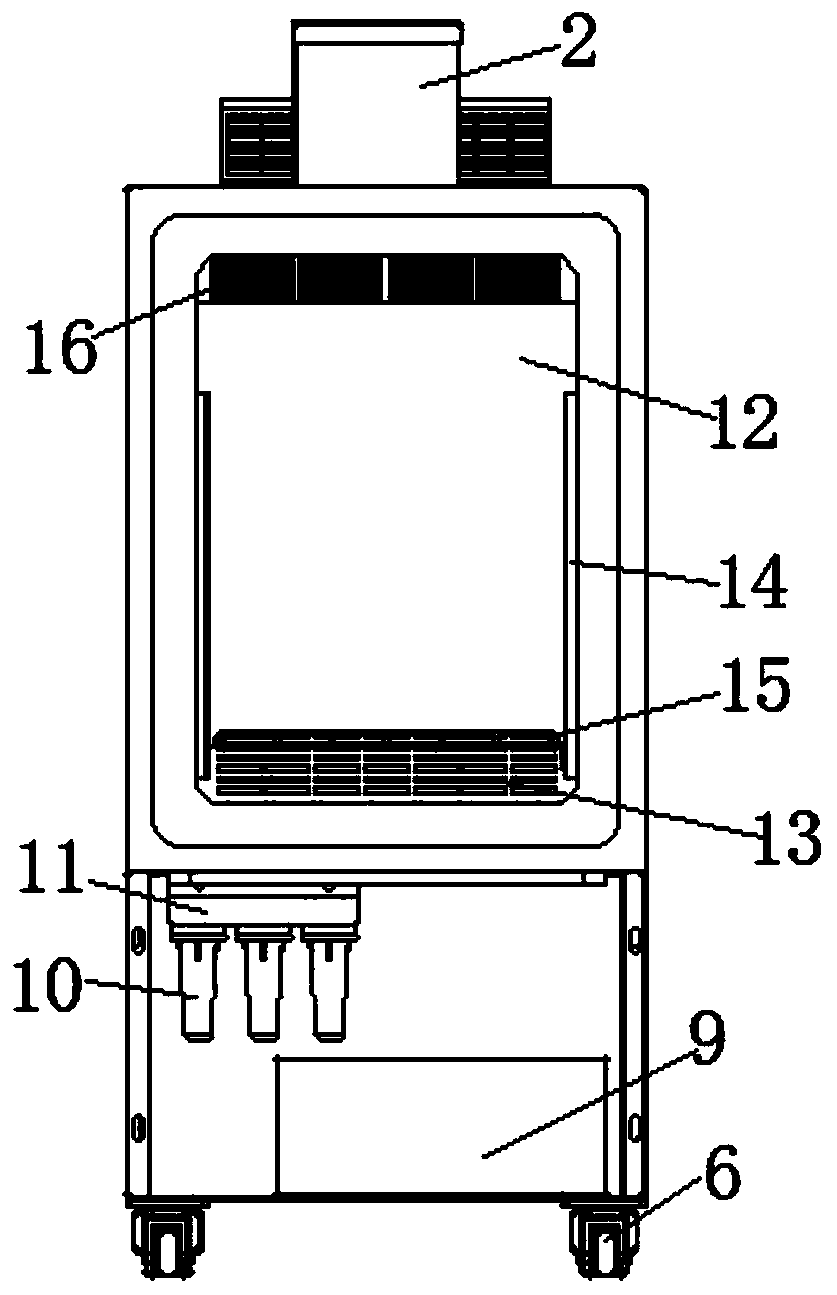

Device for drying sludge with bottom air admission structure

PendingCN105819651ASpeed up dryingIn the drying unit, the drying is accelerated bySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeMechanical engineering

The invention provides a device for drying sludge with a bottom air admission structure. The device comprises a casing, wherein, a drying chamber used for drying the sludge is formed by a space in the casing. A stirring device used for stirring the sludge is arranged in the drying chamber, wherein, the stirring device comprises a rotation shaft and a stirring component fixed on the rotation shaft. A feed inlet used for the to-be-dried sludge and an air outlet used for discharging the dried gas after the sludge is dried are arranged on the upper part of the drying chamber, and a discharge hatch used for the dried sludge is arranged on the circumferential wall of the drying chamber. A communication port is formed on a base plate of the casing, so that the dried gas outside the casing can be introduced into the drying chamber. A support apparatus is provided for supporting the casing, the base plate departs from the ground with a certain distance by the support apparatus, so that the casing and the base plate have a certain space. The invention also provides a method for drying the sludge by using the sludge drying device.

Owner:广州正晟科技有限公司

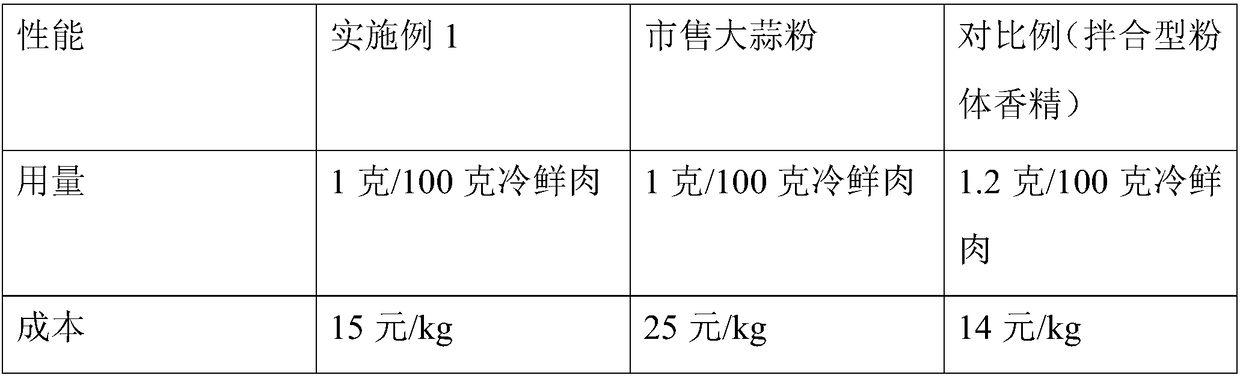

Blended type garlic essence and preparation method thereof

InactiveCN108967987AImproved and improved stabilityEnhance and improve fragrance retentionFood shapingFood ingredient as flavour affecting agentAdditive ingredientGARLIC POWDER

The invention provides a blended type garlic essence and a preparation method thereof. The blended type garlic essence is prepared from a capsule type garlic essence served as a main ingredient and other additional components, such as hydrolyzed plant protein powder, fresh ginger powder, onion powder, maltodextrin and corn starch, in the manner of combining a spray-drying technology and an efficient blending and pelletizing technology. The capsule type garlic essence with stable quality and slow fragrance release is prepared from natural flavors, such as garlic oil with strong volatility and long fragrance-holding time by adopting the technologies of emulsification, homogenizing, spray drying, and the like. The blended type garlic essence provided by the invention can effectively overcomethe defects of great price fluctuation, easiness in caking, easiness in causing microorganism exceeding standard under high temperature in summer, and the like, of the traditional garlic powder; fragrance stability and fragrance holding capacity of the garlic fragrance can be greatly promoted; the dissolving property of the essence is excellent; the blended type garlic essence is convenient for use and is widely applied to high / low temperature meat products and other foods at present.

Owner:LUOHE SHUANGHUI BIOLOGICAL ENG TECHCO

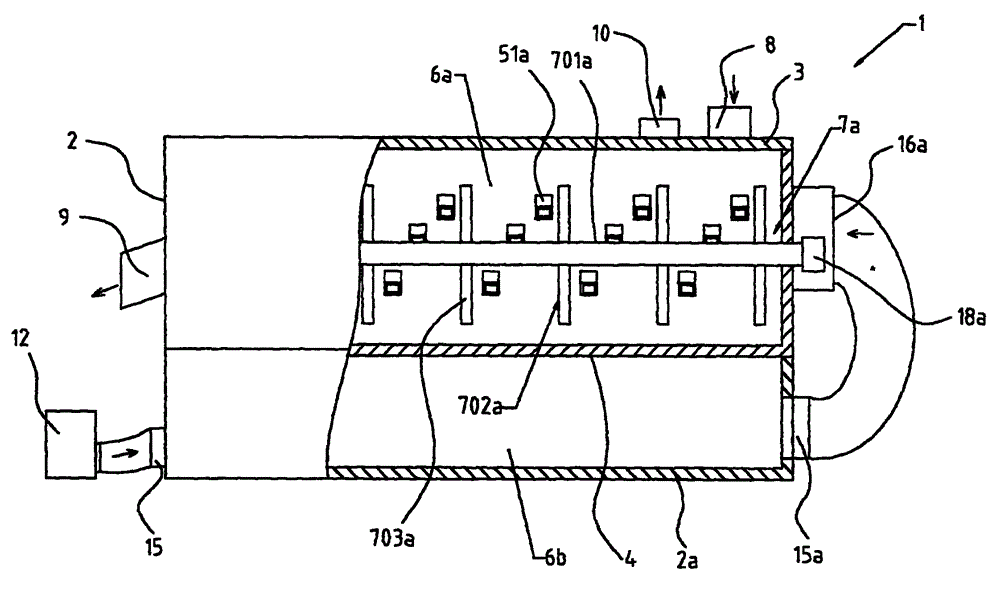

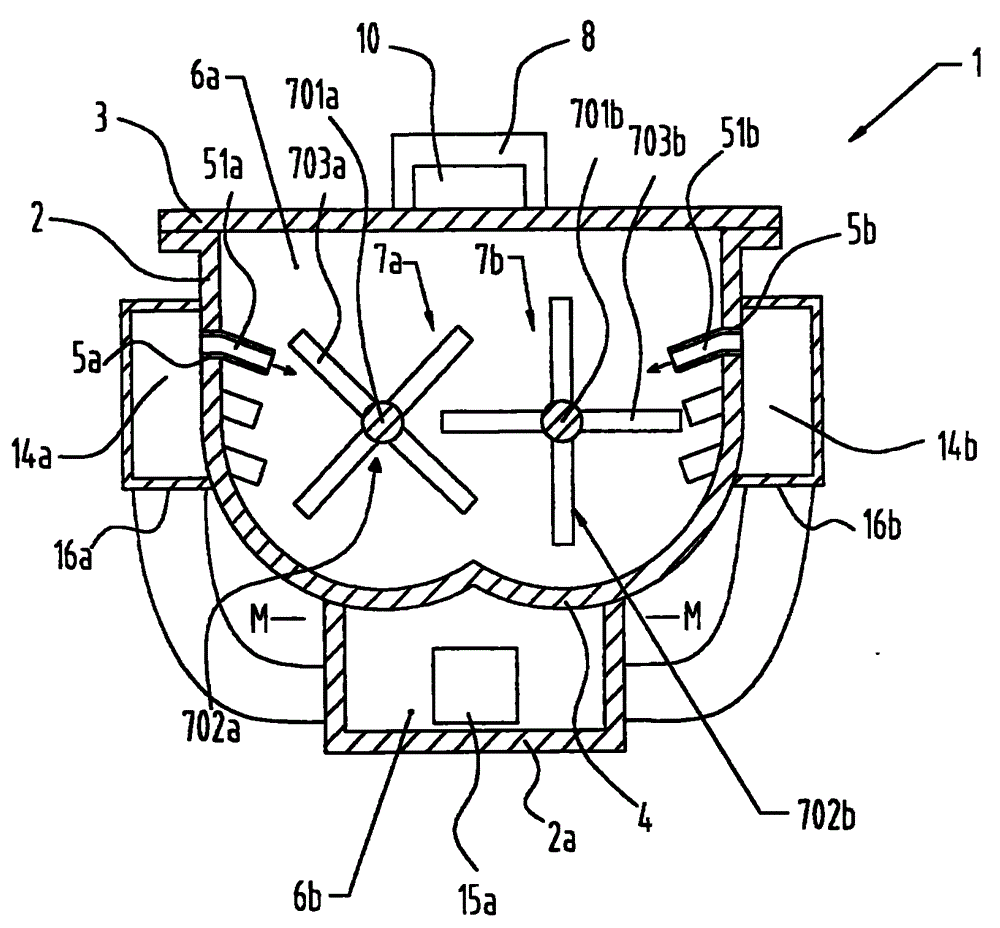

Direct air-intake sludge drying apparatus and method thereof

PendingCN105819657AFast dryingSolve stickySludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeMechanical engineering

The invention provides a direct air-intake sludge drying apparatus. The direct air-intake sludge drying apparatus comprises a casing, wherein, a dividing wall is arranged in the casing, so that the space in the casing is divided into a first drying chamber and a second drying chamber. A feed inlet and an air outlet are arranged on the upper part of the first drying chamber, and a discharge hatch is arranged on the circumferential wall of the first drying chamber. An air inlet and the air outlet are arranged on the circumferential wall or the bottom of the second drying chamber. A sludge stirring apparatus is arranged in the first drying chamber, wherein, the sludge stirring apparatus comprises a rotation shaft and a stirring component fixed on the rotation shaft. A distribution chamber is arranged at the outboard of a side wall of the first drying chamber, the air inlet and the side wall adjacent to the first drying chamber have the through holes, and the side wall of the first drying chamber drying chamber has the through hole. The through hole on the side wall of the first drying chamber is communicated with the side wall of the distribution chamber, and is communicated with the air outlet of the second drying chamber and the air inlet of the distribution chamber. The invention also provides a direct air-intake sludge drying method by using the direct air-intake sludge drying apparatus.

Owner:广州正晟科技有限公司

Convenient whole-grain instant powder capable of being brewed at any water temperature, and preparation method and application thereof

ActiveCN110742234ASolve easy cakingSolving Dispersion ProblemsMilk preparationFood preservationAlcohol ethylCereal grain

The invention discloses convenient whole-grain instant powder capable of being brewed at any water temperature, and a preparation method and application thereof, and belongs to the technical field offood processing. The preparation method of the instant powder includes the steps that cleaned shelled grain seeds are taken and placed in a container, an ethyl alcohol solution is added, soaking is conducted at the room temperature, then liquid on the surfaces of the grain seeds is drained off, and the soaked grain seeds are obtained; the obtained soaked grain seeds are conveyed into an extruder to be extruded, and strip-shaped grain extrudates are prepared; and the obtained strip-shaped grain extrudates are placed in a hot air drying box to be dried, then cooled, and placed in an ultrafine grinder to be ground, and the convenient whole-grain instant powder is obtained. Seasonings can be added into the obtained instant powder to prepare various flavors of whole-grain instant powder. The whole-grain instant powder prepared through an ethyl alcohol addition extrusion technology can be brewed at any water temperature to be eaten, the agglomeration rate of the whole-grain instant powder iseffectively decreased, and dispersion is improved.

Owner:JIANGNAN UNIV

Drying machine

InactiveCN104930833AEffective dispersionGood dispersionDrying machines with non-progressive movementsPreliminary solid treatment for dryingEngineeringVibration motor

The invention discloses a drying machine which comprises an outer cylinder. An inner cylinder coaxial with the outer cylinder is arranged in the outer cylinder, a feeding shell is arranged at one end of the outer cylinder, a gas inlet pipe is arranged in the feeding shell, a hopper is arranged above the feeding shell, and a hygrometer is arranged in the hopper. A first feeding funnel and a second feeding funnel are arranged at a discharging opening of the hopper. A support is arranged on the feeding shell and connected with a vibration bar through a vibration motor, and the vibration bar stretches in the hopper. The inner wall of the outer cylinder and the inner wall of the inner cylinder are provided with hook-shaped lifting boards, the outer wall of the inner cylinder is connected with the inner wall of the outer cylinder through an arc support, and an arc lifting device is arranged on the outer wall of the inner cylinder. According to the drying machine, dried fertilizer particles are good in appearance, little in powder and high in yield, the feeding amount can be effectively scattered, and smooth feeding is facilitated.

Owner:贵州省瓮安兴农磷化工有限责任公司

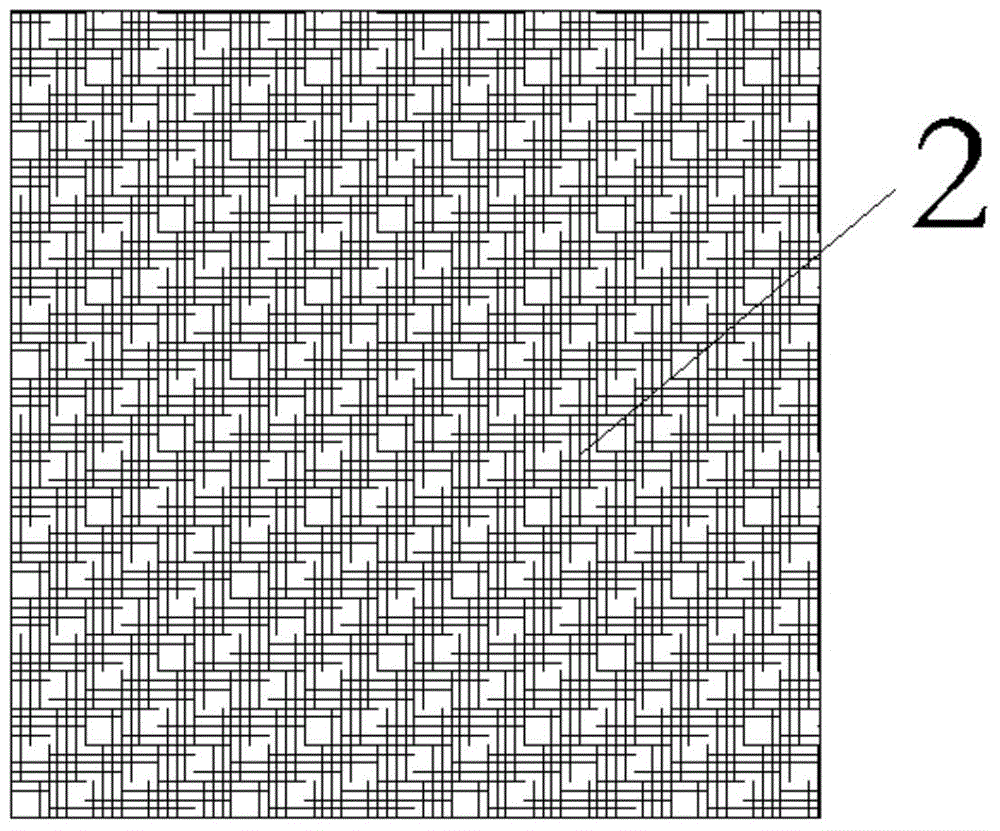

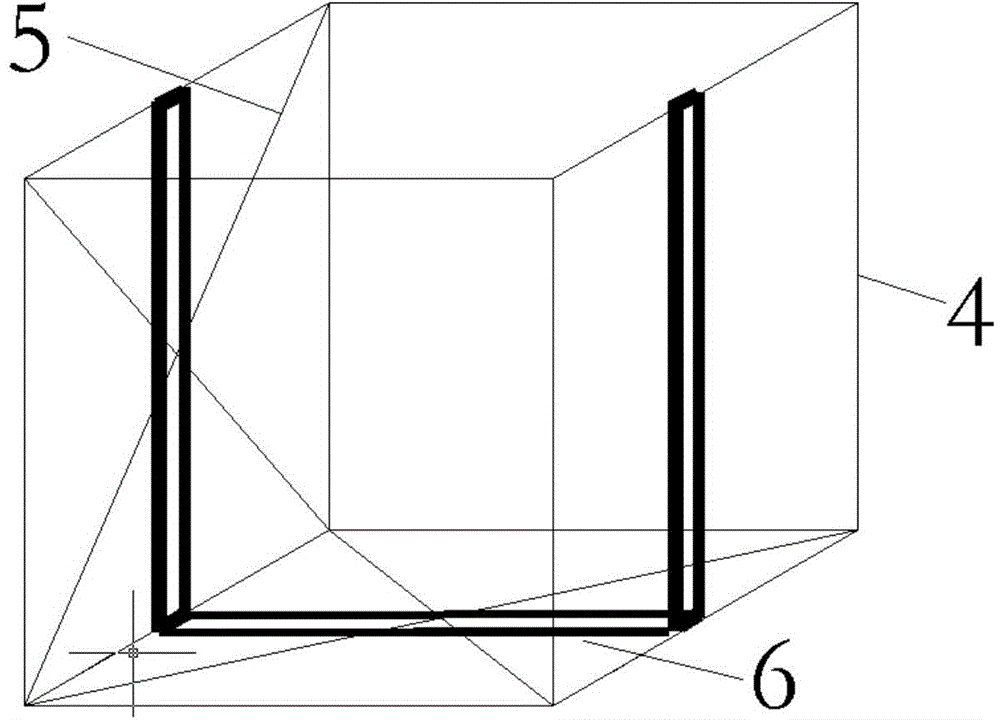

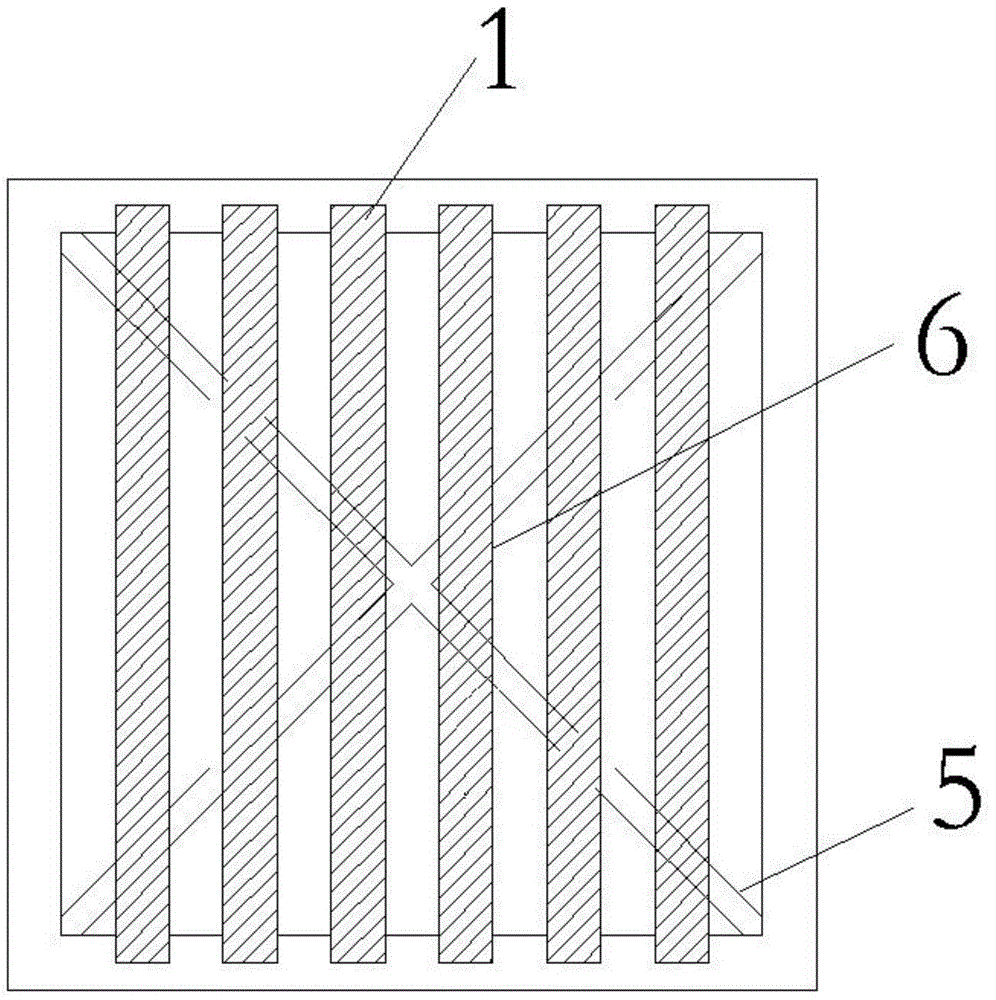

Modular improved iron-carbon microelectrolysis filler, preparation method, application and assembly method thereof

InactiveCN104961202AWide pH rangeReduce degradation energyWaste water treatment from metallurgical processWater/sewage treatmentChemical industryAdhesive

The invention discloses a modular improved iron-carbon microelectrolysis filler, a preparation method, application and assembly method thereof, belonging to the fields of water treatment and fillers. The method comprises the following steps: uniformly mixing scrap iron, common coke powder, copper powder, an adhesive and the like to form a mixture, putting the mixture on both sides of a wire net which is used as a skeleton, carrying out high-pressure compaction, sending into a furnace, and carrying out high-temperature calcination forming while charging protective nitrogen to obtain a modular improved iron-carbon microelectrolysis filler; and simply assembling the microelectrolysis filler units to form the modular improved microelectrolysis filler body. The improved microelectrolysis filler has the advantage of accessible raw materials. The microelectrolysis filler platy unit is simple in production method and convenient to assemble and use. The microelectrolysis filler does not have the phenomenon of hardening or blockage in the use process, and can be widely used in wastewater purification treatment engineering in printing, chemical industry, electroplating, coking and the like.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Concentrated natural centrifuged latex preserved without ammonia

Owner:海南天然橡胶产业集团金橡有限公司 +1

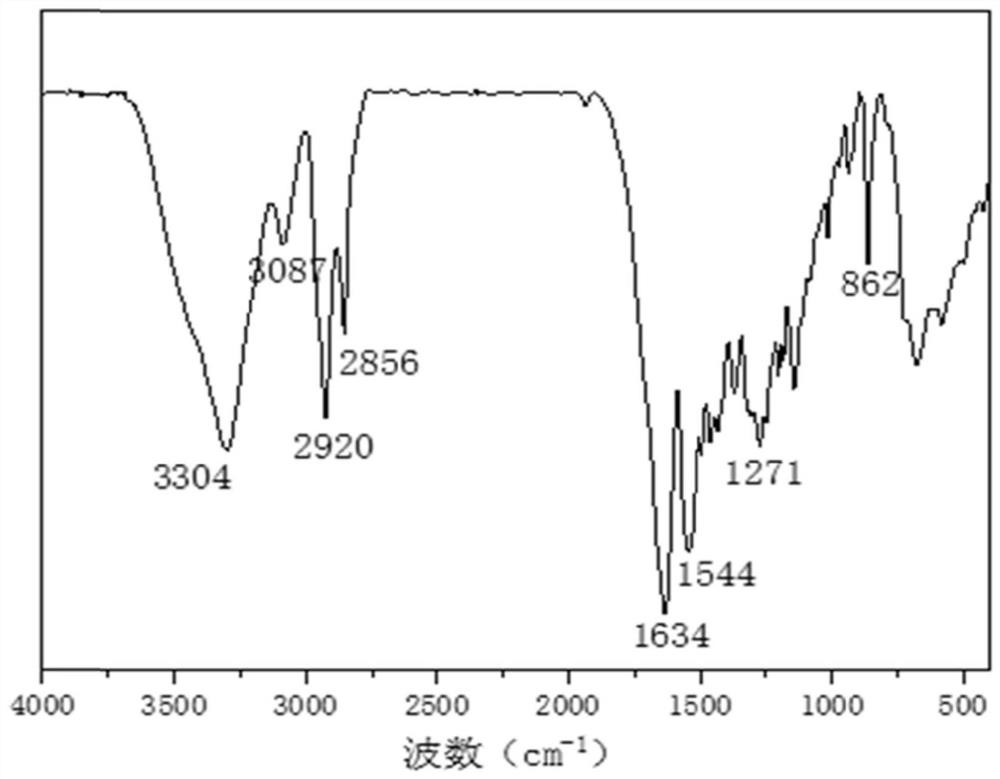

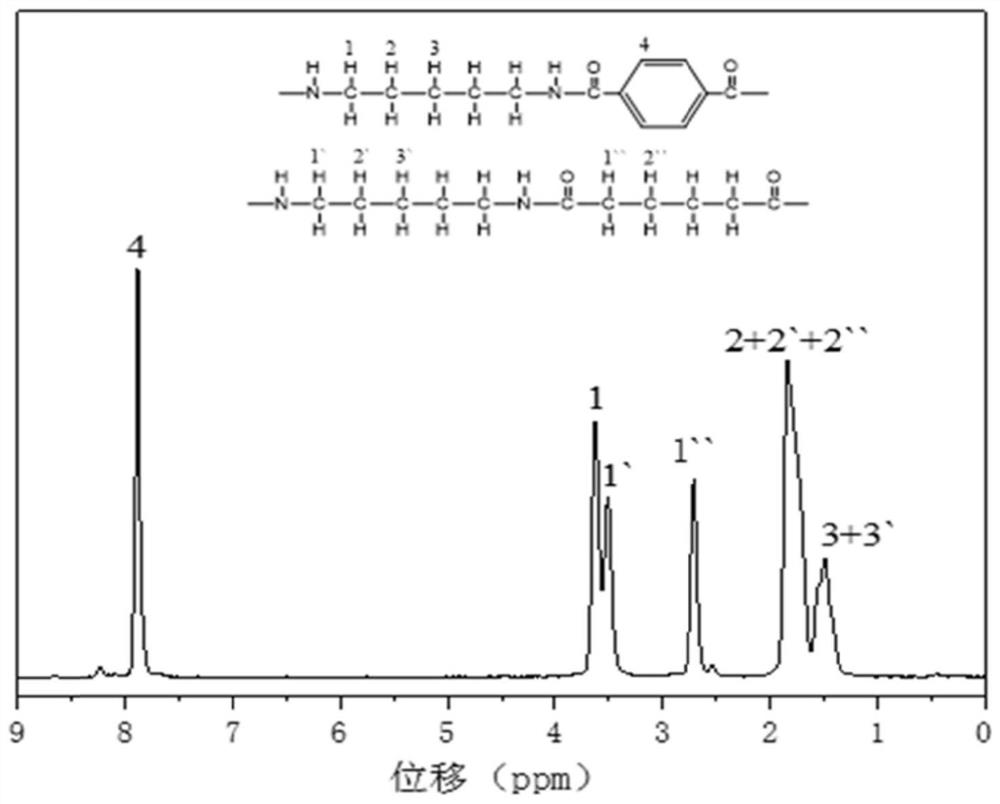

Preparation method of straw oil polyether polyol

The invention belongs to the technical field of polyether polyol and particularly relates to a preparation method of straw oil polyether polyol. The preparation method of straw oil polyether polyol comprises the following steps: neutralizing straw oil with an epoxy compound or alcohol; adding a base catalyst; and finally, adding the epoxy compound for a polymerization reaction to generate straw oil polyether polyol. According to the preparation method provided by the invention, the problems of easy acid corrosion, easy caking and easy coking in burning of the straw oil are solved, and the application field of the straw oil is widened. The straw oil polyether polyol prepared from the straw oil can be applied to the fields such as methanol gasoline additives, biodiesel, fuels, polyurethane additives, cutting grinding aids and lubricants.

Owner:ZIBO DEXIN LIANBANG CHEM IND

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN100523684CUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningDrying solid materials with heatLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

Pelleting process for composite manure

InactiveCN1530356AEasy to produceEasy to implementFertiliser formsFertilizer mixturesPolymer sciencePotassium

A process for granulating compound fertilizer includes such steps as proportionally mixing the basic fertilizers containing N, P and K, pulverizing at 30 deg.C under the 80% of relative humidity, granulating by coagulation in kiln, and drying in kiln. Its advantages are low cost, low energy consumption, and high fertility.

Owner:TONGLING CHEM IND GRP

Method for preparing instant high-calcium milk powder

InactiveCN111567621AGood water solubilityFix stability issuesMilk preparationMilk preservationBiotechnologyIron sulfate

The invention discloses a method for preparing an instant high-calcium milk powder. The instant high-calcium milk powder is produced from the following raw materials in parts by weight: 100 parts of amilk powder, 65-80 parts of a high-calcium protein powder, 10-30 parts of soy lecithin, 5-10 parts of white granulated sugar, 1-5 parts of xanthan gum, 1-5 parts of maltodextrin, 3-10 parts of multivitamins, and 2-8 parts of a mineral, wherein the multivitamins contain vitamin A and vitamin D with a ratio of 1:1, and the mineral contains one or more of iron sulfate, potassium iodide, magnesium sulfate, and manganese sulfate. The method can solve the problem commonly existing in the instant milk powder provided on the market that the stability of an emulsion is poor, the brewing property is poor, and the flavor is poor, and solve the problem that the milk powder on the market is easy to agglomerate, has poor instant dissolution property, and has short shelf life.

Owner:杭州中著智能科技开发有限公司

Landfill leachate pretreatment method and system

PendingCN113754151AEfficient removalReduce loadWater treatment compoundsWater contaminantsAmmoniacal nitrogenMicroorganism

The invention provides a landfill leachate pretreatment method and system, and relates to the technical field of wastewater treatment. The landfill leachate pretreatment method provided by the invention comprises the steps of (1) pretreating raw water of the landfill leachate by using a coagulant, and then adding a flocculating agent for precipitation and separation to obtain a first-stage supernatant; and (2) adjusting the pH value of the first-stage supernatant obtained in the step (1) to 10-11, adding a deamination agent, and reacting and precipitating to obtain a second-stage supernatant. According to the method, the landfill leachate raw water is subjected to coagulation pretreatment, so that most suspended solids and colloids in the landfill leachate raw water can be effectively removed, and the treatment load and treatment cost of the subsequent process are reduced; and a deamination agent reacts with NH4 < + > in the wastewater to generate an MgNH4PO4. 6H2O product with a very small solubility product, so that the inhibition effect of ammonia nitrogen in the leachate on microorganisms in the subsequent treatment process is reduced.

Owner:GUANGDONG YEANOVO ENVIRONMENTAL PROTECTION CO LTD

Economical high-efficiency Tofu coagulator and preparation method thereof

ActiveCN108576249AImprove bindingReduce releaseCheese manufactureFood sciencePolymer scienceDelta-gluconolactone

The invention discloses an economical high-efficiency coagulator used for Tofu production and a preparation method thereof. The coagulator comprises the following components in parts by weight: 30 to99 percent of gypsum, 0 to 60 percent of neutral filler, 0.1 to 5 percent of a retarder, 0 to 15 percent of glucolactone and 0 to 10 percent of amylopectin. The invention also discloses the preparation method of the Tofu coagulator, and the method comprises the following steps: fully and uniformly mixing the gypsum, calcium carbonate and the retarder,and then adding the glucolactone or the amylopectin, and conducting uniform mixing. On the one hand, the coagulator of the invention solves the problem that traditional gypsum is easy to cake in the storage process as a coagulator; and on the other hand, the coagulator of the invention solves the disadvantage that produced gypsum solidifies so fast in pulp adding process that the gypsum cannot be added as a coagulator. Besides, the coagulatorof the invention is very low in addition amount, low in raw material cost, and simple in process. The prepared Tofu is sufficient in water-retaining capacity, high in yield, good in elasticity and smooth in mouth feel, and maintains the due flavor of traditional Tofu.

Owner:朱荣大

a dryer

InactiveCN104930833BEffective dispersionGood dispersionDrying machines with non-progressive movementsPreliminary solid treatment for dryingEngineeringVibration motor

The invention discloses a drying machine which comprises an outer cylinder. An inner cylinder coaxial with the outer cylinder is arranged in the outer cylinder, a feeding shell is arranged at one end of the outer cylinder, a gas inlet pipe is arranged in the feeding shell, a hopper is arranged above the feeding shell, and a hygrometer is arranged in the hopper. A first feeding funnel and a second feeding funnel are arranged at a discharging opening of the hopper. A support is arranged on the feeding shell and connected with a vibration bar through a vibration motor, and the vibration bar stretches in the hopper. The inner wall of the outer cylinder and the inner wall of the inner cylinder are provided with hook-shaped lifting boards, the outer wall of the inner cylinder is connected with the inner wall of the outer cylinder through an arc support, and an arc lifting device is arranged on the outer wall of the inner cylinder. According to the drying machine, dried fertilizer particles are good in appearance, little in powder and high in yield, the feeding amount can be effectively scattered, and smooth feeding is facilitated.

Owner:贵州省瓮安兴农磷化工有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com