Landfill leachate pretreatment method and system

A landfill leachate and pretreatment technology, which is applied in the direction of contaminated groundwater/leachate treatment, sedimentation treatment, water/sewage treatment, etc., can solve the problems of nutrient ratio imbalance and high ammonia nitrogen concentration, and reduce treatment costs and ammonia nitrogen content. The effect of high, high concentration of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

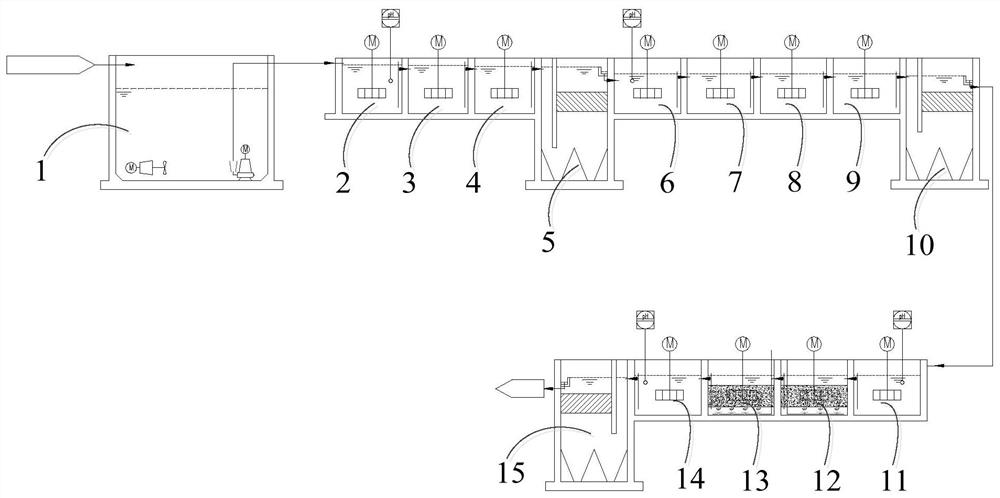

[0039] The landfill leachate pretreatment system of the present embodiment is as figure 1 As shown, according to the running direction of water flow, it includes: adjustment tank (1), first pH adjustment tank (2), first coagulation reaction tank (3), first flocculation reaction tank (4), first inclined tube sedimentation tank (5), the second pH adjustment tank (6), deamination reaction tank (7), the second coagulation reaction tank (8), the second flocculation reaction tank (9), the second inclined tube sedimentation tank (10), The third pH adjustment tank (11), iron-carbon fixed bed (12, 13), the third flocculation reaction tank (14), the third inclined tube sedimentation tank (15);

[0040] The regulating tank (1) can be used to store the raw water of landfill leachate;

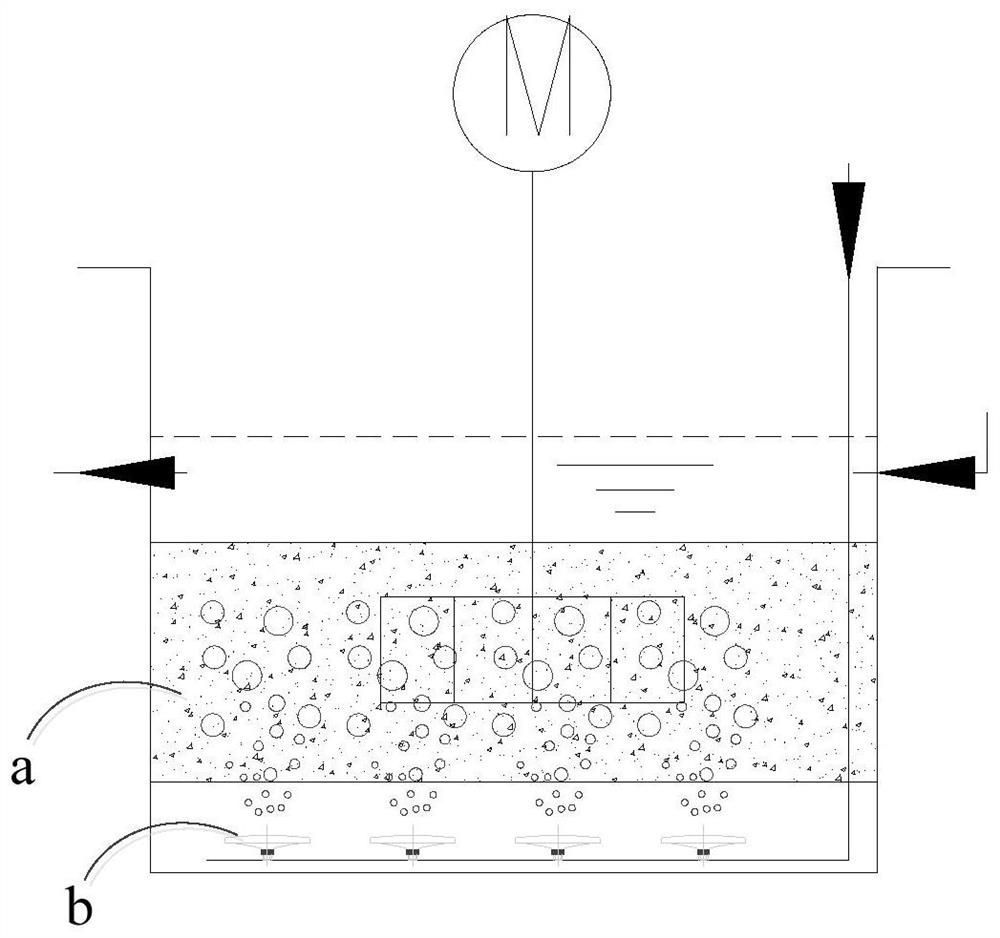

[0041] The internal structures of the iron-carbon fixed bed (12) and the iron-carbon fixed bed (13) are identical, and the specific structures are as follows: figure 2 As shown, the iron-carbon fixed bed...

Embodiment 2

[0043] Based on the landfill leachate pretreatment system in Example 1, the landfill leachate raw water with a COD content of 6000-8000 mg / L and an ammonia nitrogen content of 2500-3000 mg / L is treated.

[0044] The landfill leachate pretreatment method of the present embodiment comprises the following steps:

[0045] The first step, according to the running direction of the water flow, the raw water of the landfill leachate passes through the adjustment tank (1), the first pH adjustment tank (2), the first coagulation reaction tank (3), the first flocculation reaction tank (4), The first inclined tube sedimentation tank (5), in this process, the pH value of the first pH adjustment tank (2) is adjusted to 7.5-8.5, in the first coagulation reaction tank (3), add coagulant sulfurous acid Iron, the addition of ferrous sulfate is 500mg / L, in the first flocculation reaction tank (4), add flocculant polyacrylamide, the addition of polyacrylamide is 5g / L, through the first inclined t...

Embodiment 3

[0049] On the basis of embodiment 2, further carry out the following operations:

[0050] The third step, the second stage supernatant passes through the third pH adjustment tank (11), iron-carbon fixed bed (12, 13), the third flocculation reaction tank (14), the third inclined tube sedimentation tank (15) successively, In this process, the pH value of the third pH adjustment tank (11) is adjusted to 2.5-3.5, and the flocculant polyacrylamide is added in the third flocculation reaction tank (14), and the addition amount of polyacrylamide is 3-5mg / L, obtain the third stage supernatant after precipitation and separation in the third inclined tube sedimentation tank (15).

[0051] After testing, the COD content in the third-stage supernatant is 3000-4000mg / L, and the removal rate is about 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com