Modular improved iron-carbon microelectrolysis filler, preparation method, application and assembly method thereof

An iron-carbon micro-electrolysis, modular technology, applied in chemical instruments and methods, natural water treatment, chemical/physical/physical-chemical processes, etc. It can solve the problems of easy agglomeration of fillers, easy availability of raw materials, and excellent processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

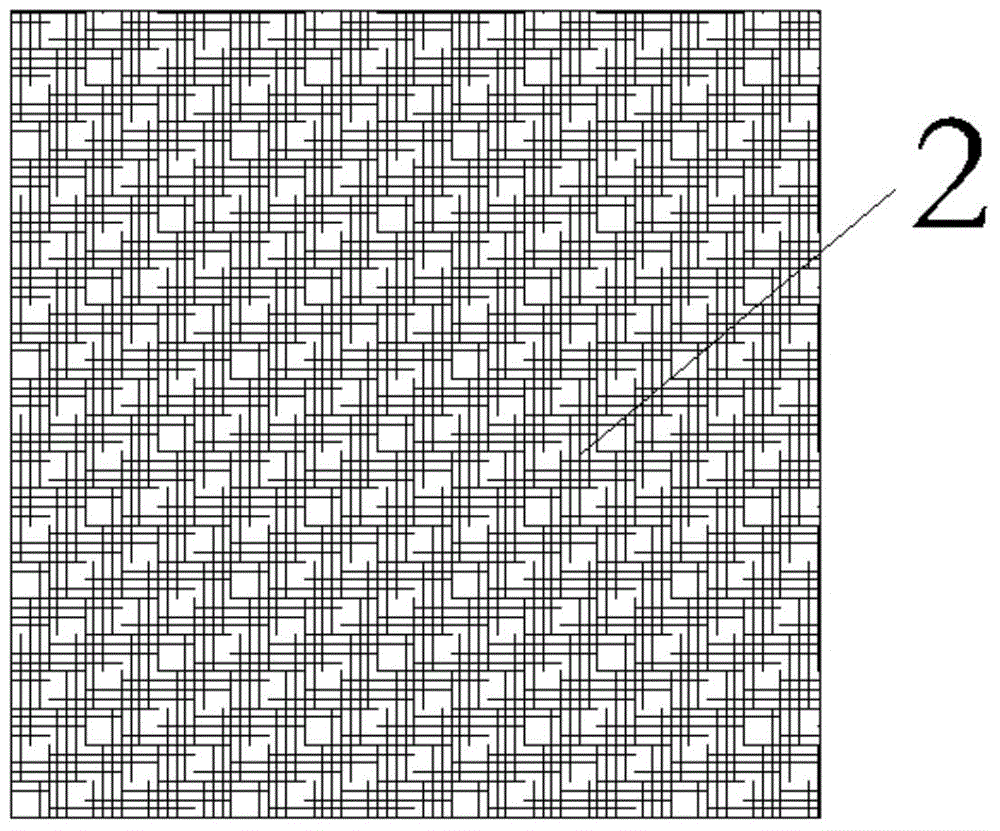

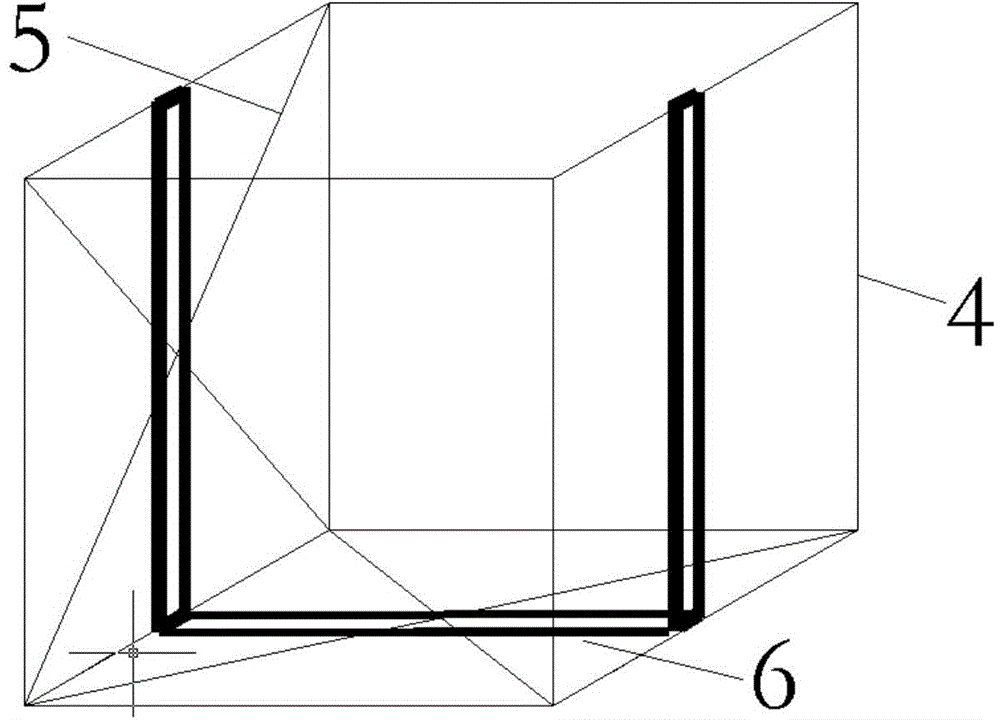

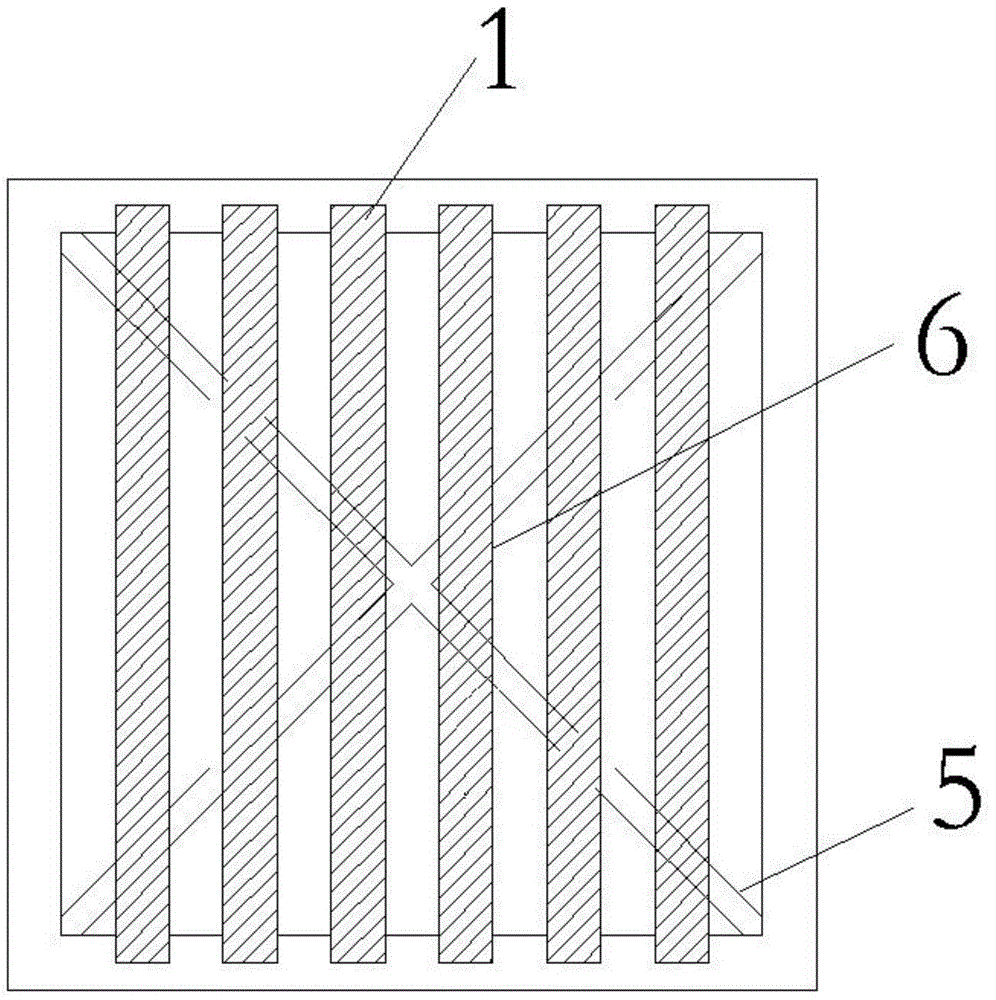

[0055] Such as figure 1 As shown, a modular improved iron-carbon micro-electrolytic filler, its composition and mass percentage are:

[0056] (a) Selection of cast iron scraps: cast iron scraps are weighed after removing impurities and passing through a 50-60 mesh screen, accounting for 55% of the mass ratio of the electrolytic filler;

[0057] (b) selection of ordinary coke powder: ordinary coke powder is weighed after removing impurities and passing through a 60-70 mesh screen, accounting for 35% of the mass ratio of the electrolytic filler;

[0058] (c) Copper powder: the copper powder is weighed after removing impurities and passing through a 50-60 mesh screen, accounting for 8% of the mass ratio of the electrolytic filler;

[0059] (d) Binder: The binder is composed of 70-80 mesh fine yellow sand and Portland cement, the mass ratio of fine yellow sand to Portland cement is 1:3, and the mass ratio of the binder to the electrolytic filler 2%;

[0060] A method for prepar...

Embodiment 2

[0082] A modular improved iron-carbon micro-electrolytic filler, its composition and mass percentage are:

[0083] (a) pig iron scraps: pig iron scraps are weighed after removing impurities and passing through a 50-60 mesh screen, accounting for 60% of the mass ratio of the electrolytic filler;

[0084] (b) Ordinary coke powder: ordinary coke powder is weighed after removing impurities and passing through a 60-70 mesh screen, accounting for 30% of the mass ratio of the electrolytic filler;

[0085] (c) Copper powder: the copper powder is weighed after removing impurities and passing through a 50-60 mesh screen, accounting for 5% of the mass ratio of the electrolytic filler;

[0086] (d) Binder: The binder is composed of 70-80 mesh fine yellow sand and Portland cement, the mass ratio of the two is 1:3, and the mass ratio of the binder to the electrolytic filler is 5%;

[0087] A method for preparing a modular improved iron-carbon micro-electrolytic filler sheet unit,

[0088]...

Embodiment 3

[0109] A modular improved iron-carbon micro-electrolytic filler, its composition and mass percentage are:

[0110] (a) selection of pig iron and iron filings: pig iron and iron filings are weighed after removing impurities and passing through a 50-60 mesh screen, accounting for 58% of the mass ratio of the electrolytic filler;

[0111] (b) Ordinary coke powder selection: ordinary coke powder is weighed after removing impurities and passing through a 60-70 mesh screen, accounting for 32% of the mass ratio of the electrolytic filler;

[0112] (c) Copper powder: the copper powder is weighed after removing impurities and passing through a 50-60 mesh screen, accounting for 5% of the mass ratio of the electrolytic filler;

[0113] (d) Binder: The binder is composed of 70-80 mesh fine yellow sand and Portland cement, the mass ratio of the two is 1:2, and the mass ratio of the binder to the electrolytic filler is 5%.

[0114] A method for preparing a modular improved iron-carbon micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com