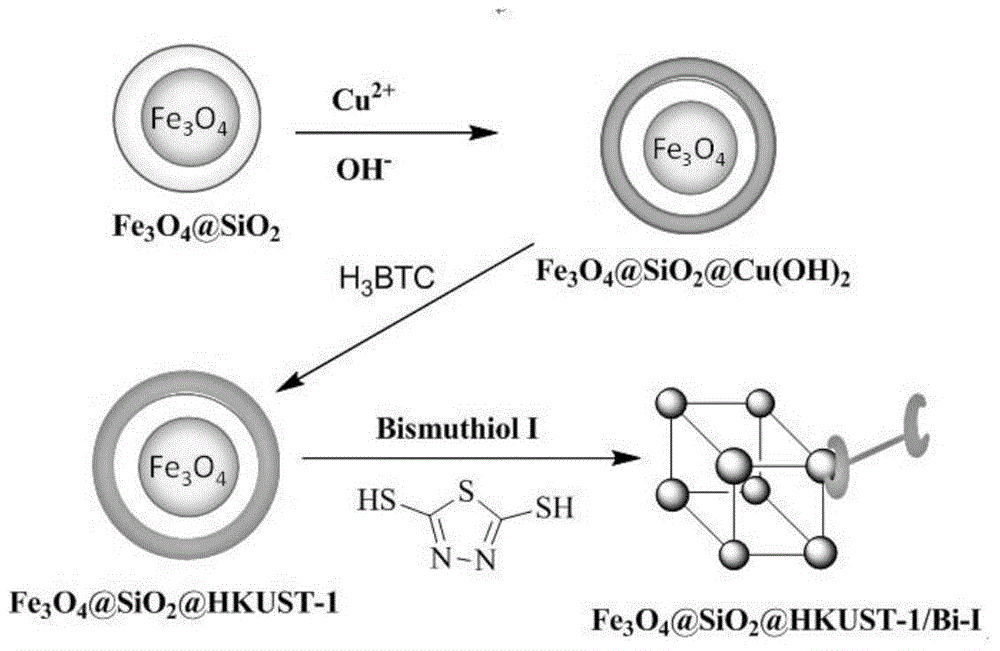

Magnetic MOFs solid-phase extractant, and preparation method and application thereof

A solid-phase extraction agent, magnetic technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., to achieve the effect of large adsorption capacity, low cost and fast adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0048] Preparation of Magnetic Fe with a Particle Size of 10-20nm by Co-precipitation 3 o 4 Nanospheres: Dissolve 11.68g of ferric chloride and 4.30g of ferrous chloride in 200mL of high-purity water, stir and heat to 85°C under nitrogen protection. Then add 20 mL of 30% NH 3 ·H 2 O, the color of the solution rapidly changed from orange to black. After reacting for half an hour, stop the reaction, cool to room temperature, and the obtained nanoparticles are washed with high-purity water and 0.02mol L -1 washed with NaCl until neutral, and finally stored with high-purity water.

[0049] Preparation of Fe with Core-Shell Structure by Silica Coupling 3 o 4 SiO 2 : Remove half of the Fe 3 o 4 Put the nanoparticles into a mixed solvent containing 160mL ethanol and 40mL high-purity water, and add 5mL of 30% NH 3 ·H 2 O and 6 mL of tetraethoxysilane (TEOS), then mechanically stirred at room temperature for 12 h. After the reaction, wash with high-purity water and ethano...

Embodiment 2

[0055] The difference from Example 1 is: Synthesis of Bi-I modified magnetic MOFs solid-phase extraction agent: Weigh 200mg of Fe after drying at 150°C for 12h 3 o 4 SiO 2 HKUST-1 was placed in a 50mL round bottom flask, 20mL of anhydrous ether was added, and then 100mg of Bi-I was added to the suspension, and the reaction was carried out at room temperature for 24 hours under magnetic stirring. After the reaction was completed, it was washed with anhydrous ether (30 mL×5), and dried under vacuum at room temperature.

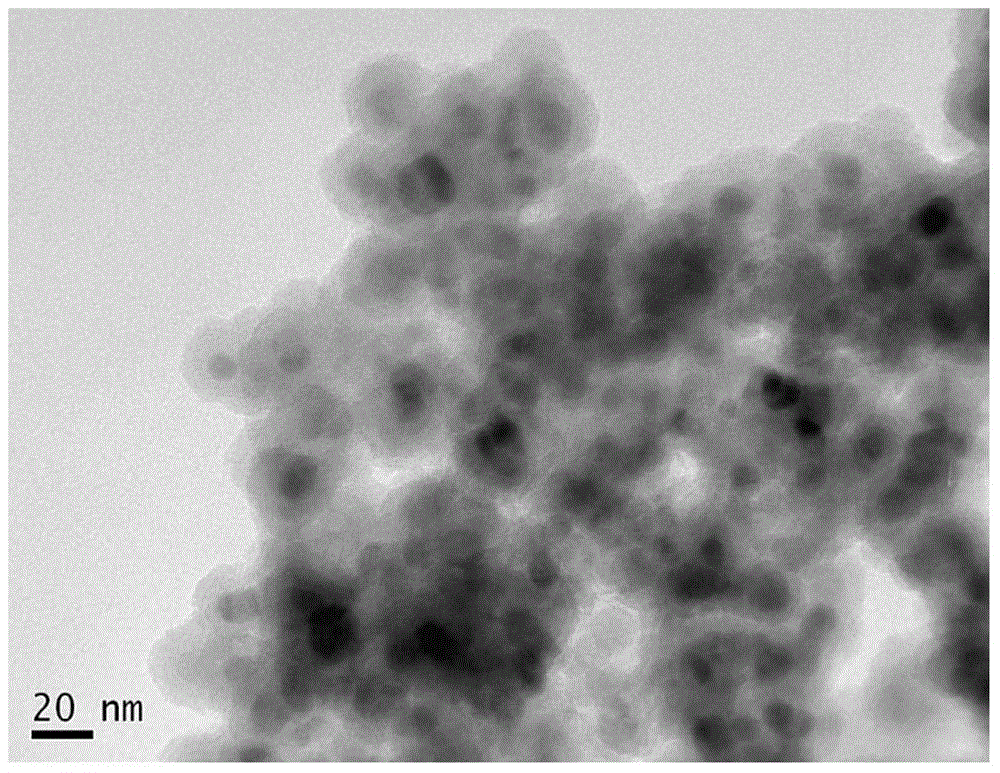

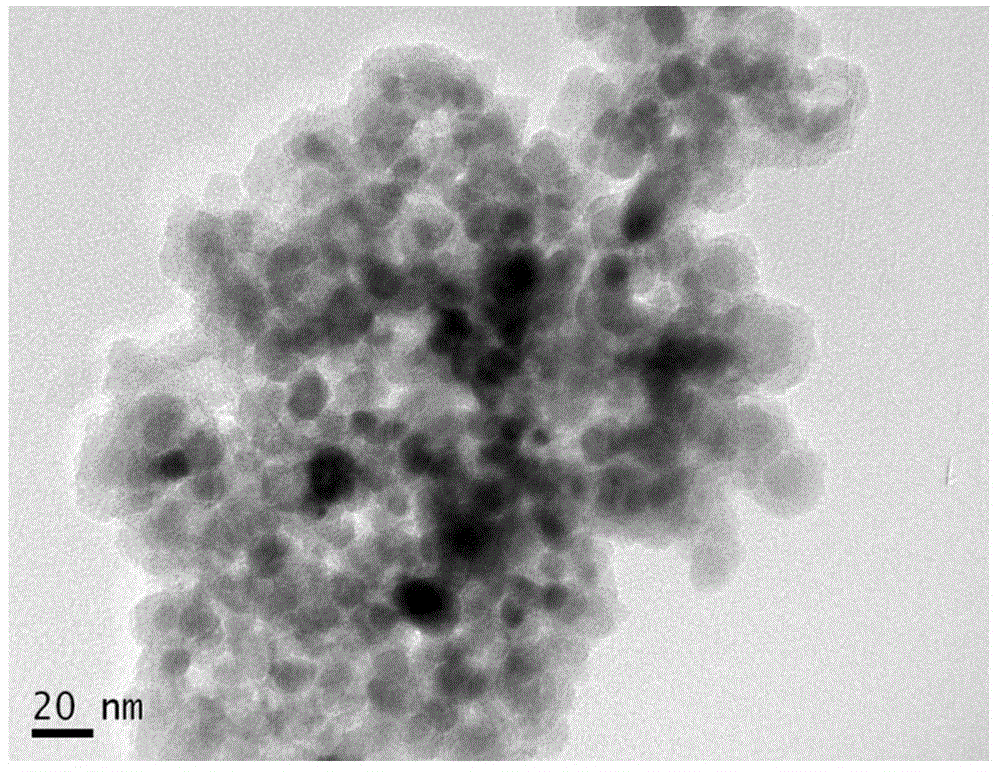

[0056] Adopt transmission electron microscope (TEM) to observe the core-shell type magnetic MOFs solid-phase extraction agent and its intermediate prepared in embodiment 2, and its TEM photograph is as follows Figure 2-5 shown. From figure 2 It can be seen that the prepared magnetic Fe 3 o 4 SiO 2 Nanoparticles have a spherical structure, and the darker part of the inner core is Fe 3 o 4 , the particle size is 10-20nm, and the lighter part of the midd...

Embodiment 3

[0071] The difference from Example 1 is: Synthesis of Bi-I modified magnetic MOFs solid-phase extraction agent: Weigh 200mg of Fe after drying at 150°C for 12h 3 o 4 SiO 2 HKUST-1 was placed in a 50mL round-bottomed flask, 20mL of anhydrous ether was added, and then 150mg of Bi-I was added to the suspension, and magnetically stirred at room temperature for 24 hours. After the reaction was completed, it was washed with anhydrous ether (30 mL×5), and dried under vacuum at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com