Method for producing inorganic macromolecule flocculant polymerization iron aluminum chloride

A polyaluminum ferric chloride, inorganic polymer technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as unindustrial utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

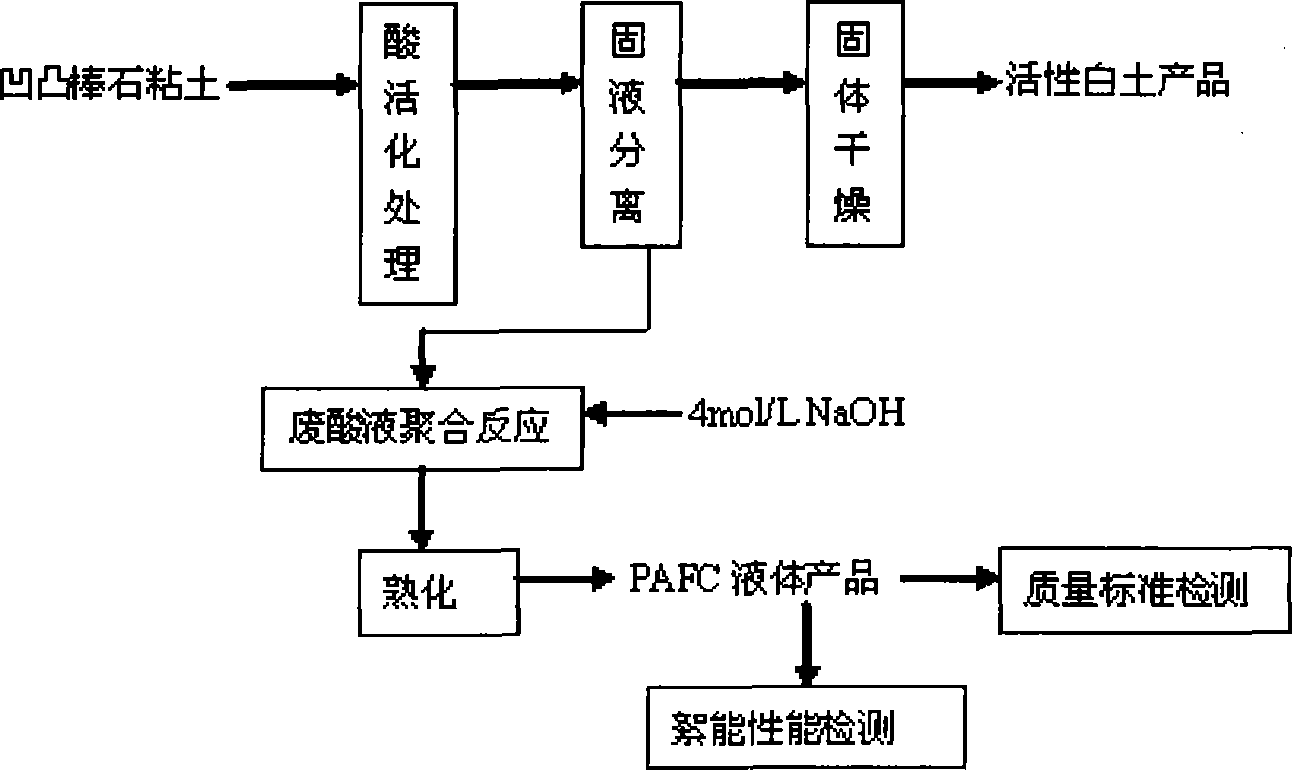

[0012] A production method of polyaluminium-ferric chloride, an inorganic polymer flocculant, in which alkaline substances such as sodium hydroxide or potassium hydroxide, quicklime, and sodium carbonate are added to the acidified waste liquid produced in the process of producing activated clay from attapulgite clay Or sodium bicarbonate, stir, adjust the pH of the solution to 4.0, and heat to 80-90°C, then fully stir and react for 4-5 hours to make it polymerized to generate an inorganic polymer flocculant polyaluminum ferric chloride liquid product, this liquid After the product is matured and dried under certain conditions, it becomes a solid polyaluminum ferric chloride product. The properties of liquid products are shown in the table below

[0013] Product index comparison

[0014] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com