Direct air-intake sludge drying apparatus and method thereof

A sludge drying and air intake technology, which is applied in the direction of temperature control sludge treatment, dewatering/drying/concentrating sludge treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

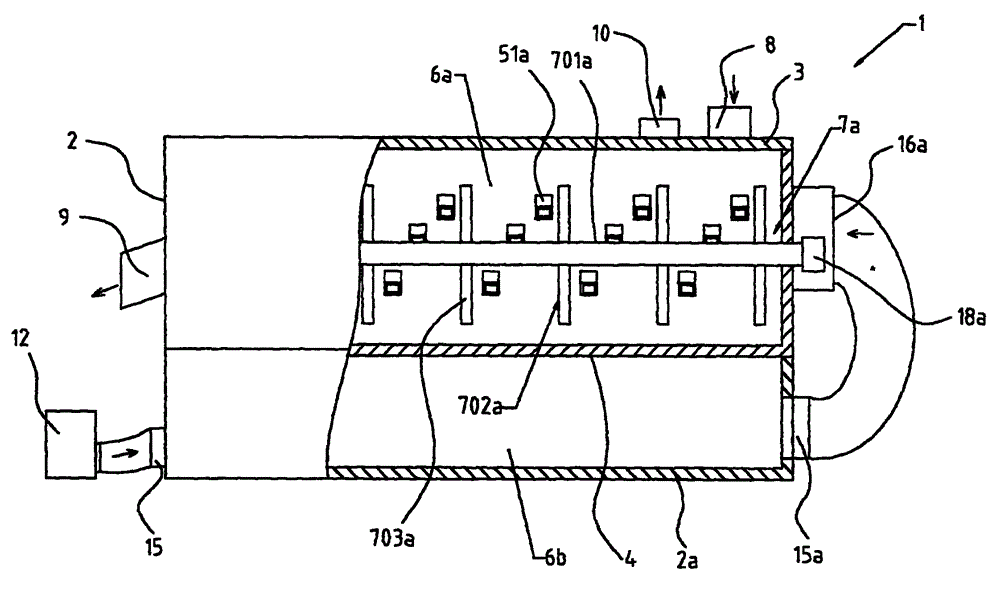

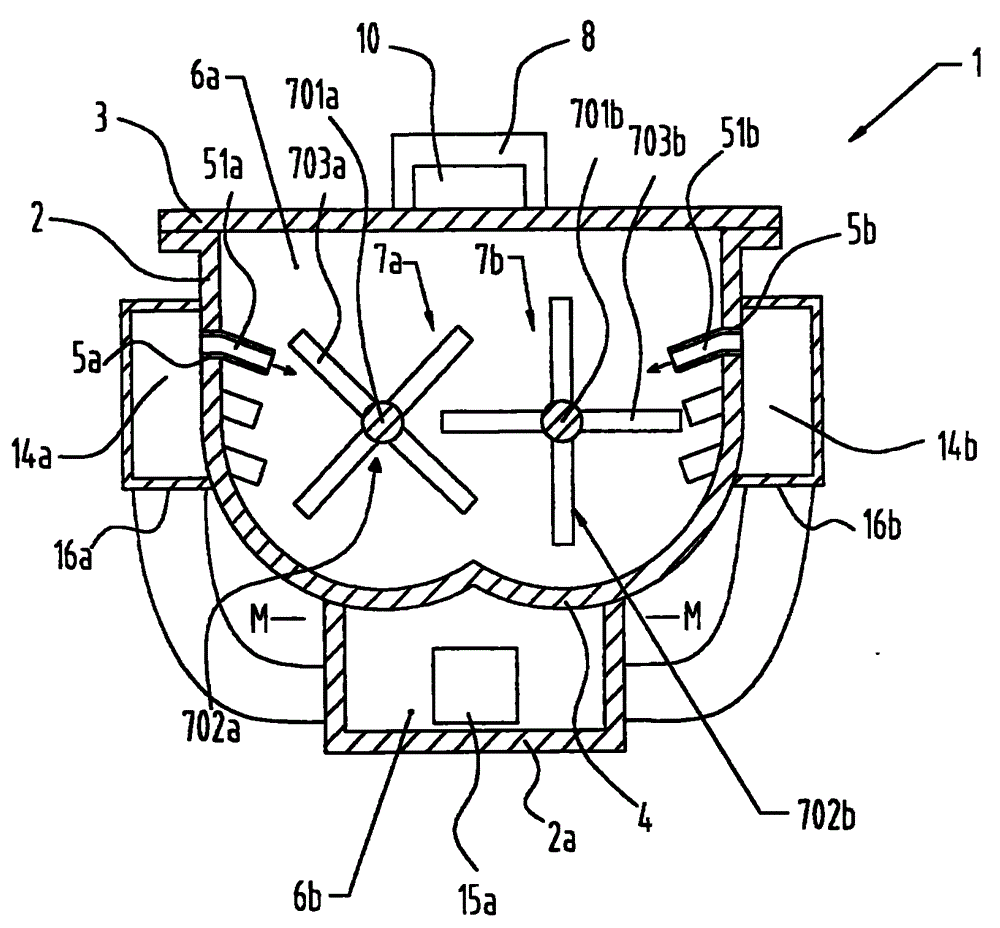

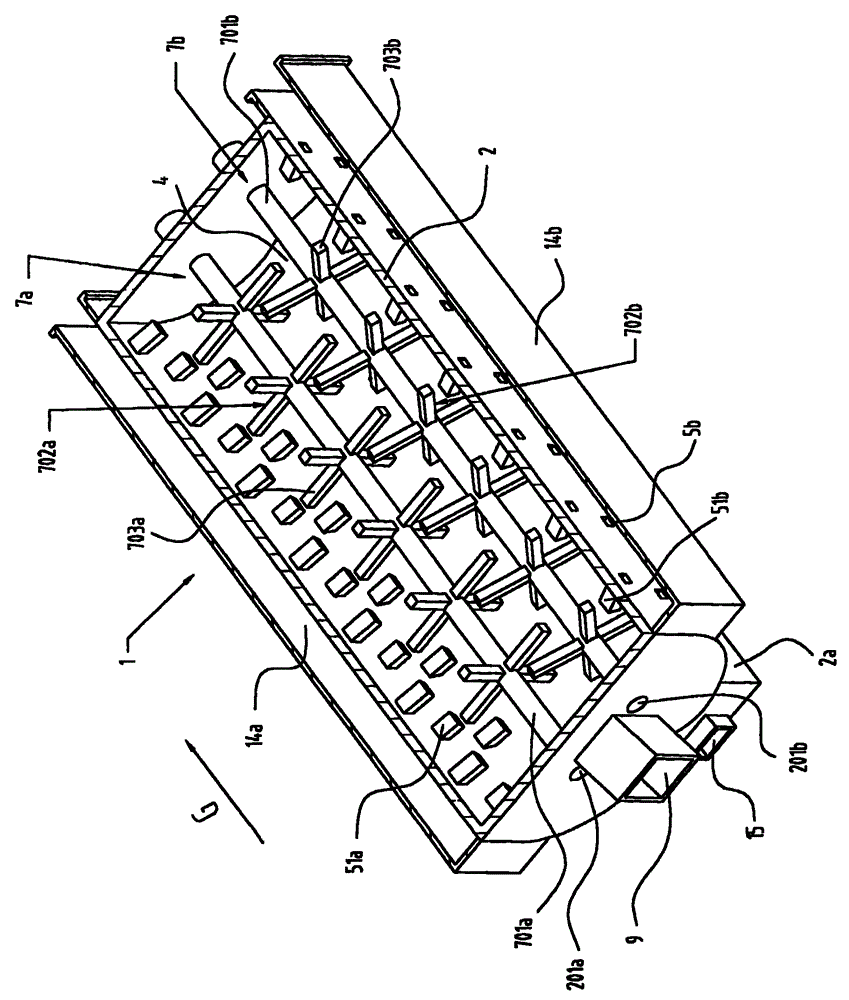

[0040] figure 1 A preferred embodiment of the direct-inlet type sludge drying device of the present invention is shown, and figure 2 Yes figure 1 A cross-sectional view of the sludge drying device in , which schematically shows a single-body sludge drying device. The direct-inlet type sludge drying device 1 includes a casing, wherein the casing includes an upper casing 2 , a lower casing 2 a and an upper cover (or cover) 3 . The bottom of the upper casing 2 serves as a partition wall 4 that divides the inner space of the casing into the first drying chamber 6a and the second drying chamber 6b. The upper casing 2 and the upper cover 3 constitute the first drying chamber 6a, and the bottom of the lower casing 2a and the upper casing 2, that is, the partition wall, constitutes the second drying chamber 6b. As shown in the figure, although the first drying chamber 6a and the second drying chamber 6b are arranged one above the other, other arrangements are also possible. Howev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com