Green environment-friendly concentrated natural latex and preparation method thereof

A natural latex, green and environmentally friendly technology, applied in the field of rubber, can solve problems such as polluting the environment, affecting the working and production environment, and affecting product quality, and achieve the effects of reducing waste water and waste gas emissions, maintaining the inhibition of bacterial flora, and improving overall fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

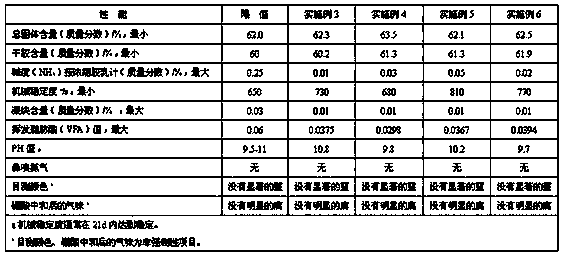

Examples

Embodiment 1

[0035] The present embodiment provides a kind of preparation method of green environmental protection type concentrated natural latex, comprises the following steps:

[0036] (1) Collection, storage and transportation of fresh latex: When collecting fresh latex, keep the forest section, tree body and various utensils clean, and add ammonia-free preservative to the collected fresh latex in time, and replenish it as needed during transportation No ammonia preservative, control the pH value of fresh latex ≥ 9;

[0037] (2) Treatment of fresh latex: The fresh latex collected in step (1) is filtered to remove impurities and clots, then add weak alkali salt, and then clarify and settle for 8 to 72 hours to control the alkalinity of fresh latex to 0.06% to 0.1 %, TT / ZnO content≤0.09%, dry rubber content≥22%, volatile fatty acid value≤0.08, free calcium and magnesium content≤5mmol / kg;

[0038] (3) Concentration treatment: The clarified and settled fresh latex obtained in step (2) is ...

Embodiment 2

[0050] This embodiment is a preferred solution based on Embodiment 1. In this example, the amount of each raw material of the ammonia-free preservative is further optimized, and the source and quality of each reagent in this example are the same as those in Example 1.

[0051] The raw material of described ammonia-free preservative comprises sodium bisulfite, sodium tripolyphosphate, sodium carbonate, sodium silicate pentahydrate, citric acid, sodium benzoate, and the weight and number ratio of each raw material is:

[0052] Sodium bisulfite 2—2.5 parts

[0053] Sodium tripolyphosphate 2-4 parts

[0054] Sodium carbonate 1-2 parts

[0055]6-8 parts of sodium silicate pentahydrate

[0056] 2-3 parts of citric acid

[0057] 1-3 parts of sodium benzoate.

Embodiment 3

[0059] This embodiment is a preferred solution based on Embodiment 1. The processing conditions of the preparation method of the green environment-friendly concentrated natural latex described in this example are further refined, and the consumption of each raw material of the described ammonia-free preservative is further optimized. The source and quality of each reagent in this example are the same as those in this example. 1 are the same.

[0060] A kind of preparation method of green environmental protection type concentrated natural latex, comprises the following steps:

[0061] (1) Collection, storage and transportation of fresh latex: when collecting fresh latex, keep the forest section and tree body, rubber knife, rubber cup, rubber tongue, rubber scraper, and rubber collection bucket clean (the "six cleans" of the rubber garden), and Add a 20% ammonia-free preservative solution to the collected fresh latex in time, and if necessary, add an appropriate amount of compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com