Device for drying sludge with bottom air admission structure

A technology of sludge drying and sludge, which is applied in the direction of sludge treatment through temperature control, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of uneven drying degree, achieve improved drying efficiency, low energy consumption, The effect of improving porosity and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

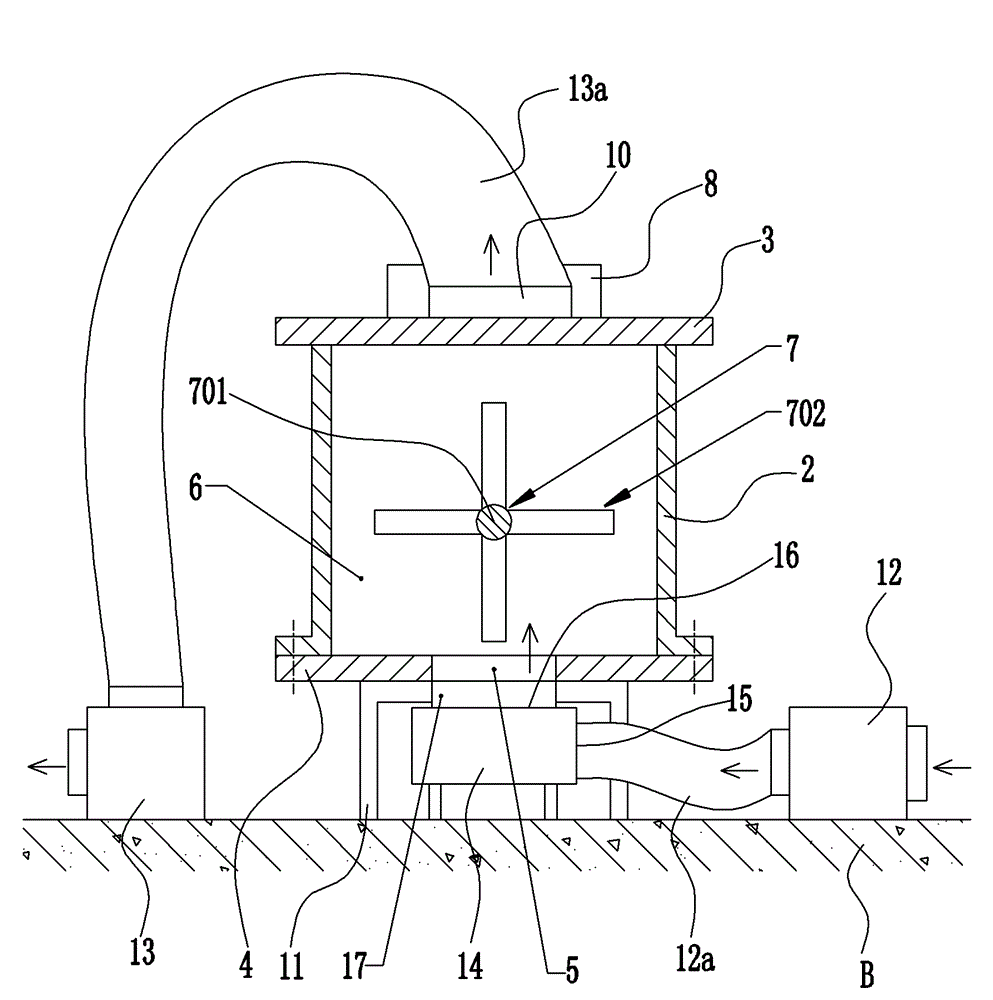

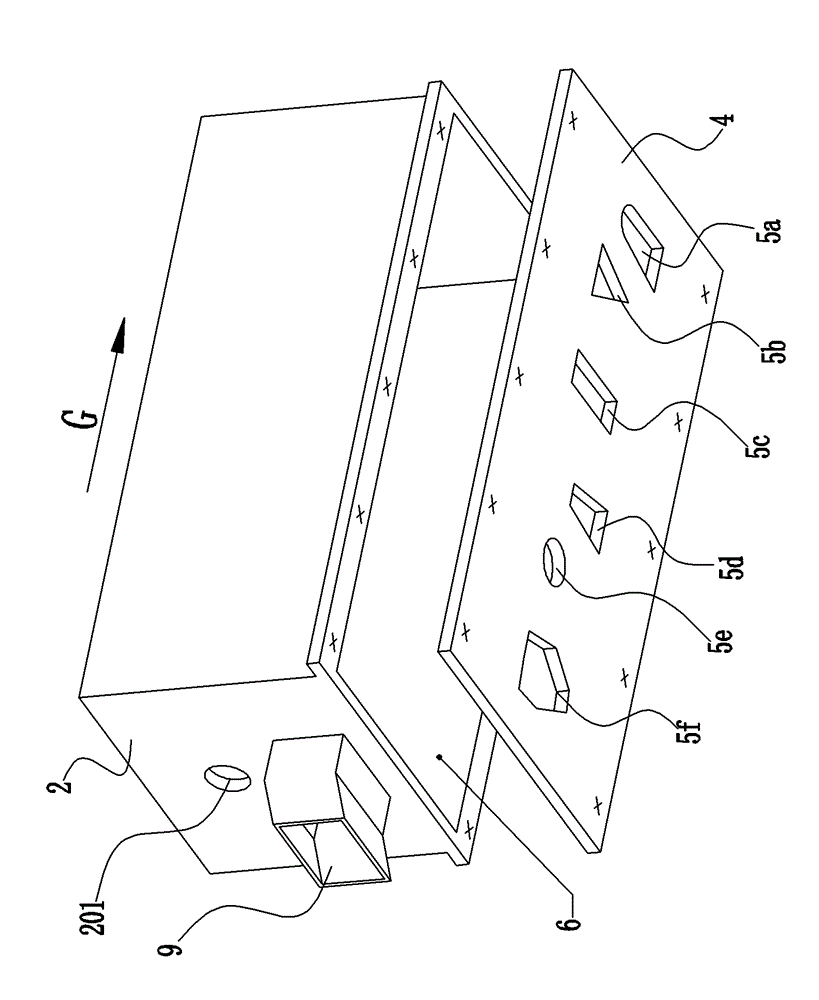

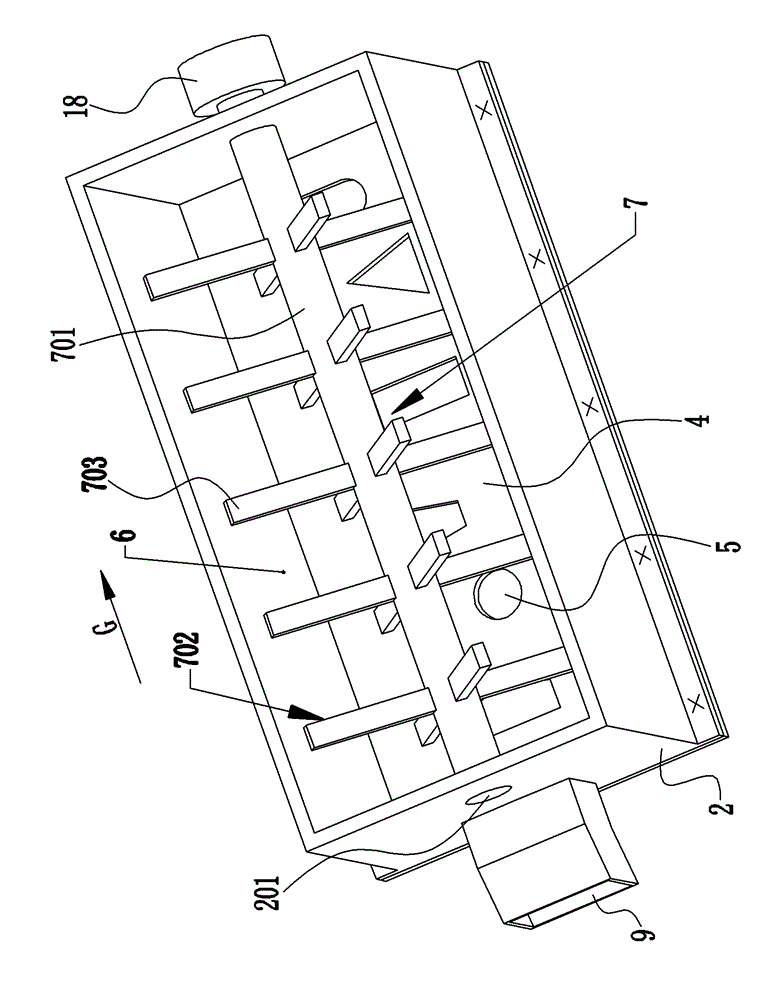

[0021] figure 1 and 2 A preferred embodiment of the sludge drying device with bottom air intake according to the present invention is shown, wherein the structure of the device is schematically represented by a longitudinal partial section view and a transverse section view respectively. As shown in the figure, the bottom air inlet sludge drying device 1 generally has a housing (or casing), a turning device 7 and a supporting device 11 . The casing includes a body 2 , an upper cover (or cover) 3 and a bottom plate 4 arranged on the body 2 . The main body 2, the upper cover 3 and the bottom plate 4 together form a drying chamber 6 with a certain inner space. The turning device 7 is arranged in the drying chamber 6 and is used for shearing, crushing and turning the sludge piled on the bottom plate 4 . The supporting means 11 raises the housing a certain distance h from the ground or floor B. As shown in FIG.

[0022] As shown in the figure, the upper cover 3 of the housing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com