Particle drilling method

A particle and drilling technology, which is applied in drilling equipment and methods, drilling equipment, earthwork drilling and mining, etc., can solve the problems of a large number of equipment, large weight and volume of injection devices, and inconvenient transportation, so as to reduce the risk of environmental pollution and simplify particle production. Effect of recovery process and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

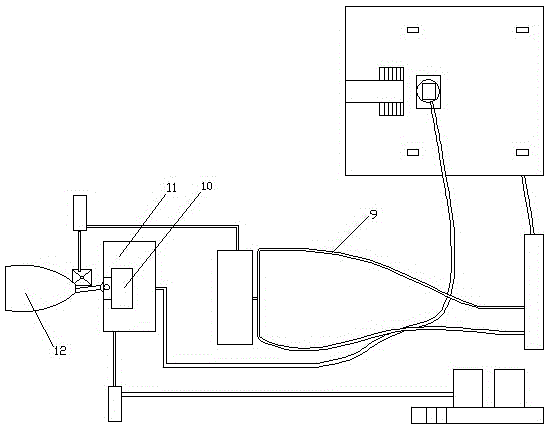

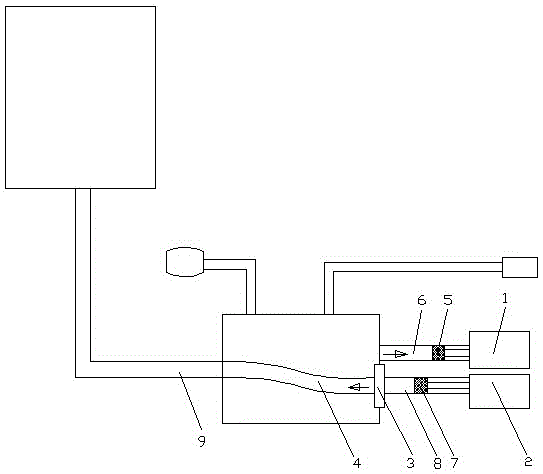

[0043] see figure 1 and figure 2 , a particle drilling method, comprising a particle injection step and a particle recovery step, the particle injection step refers to using an injection device to inject mud and particles into the well; the particle recovery step refers to the particles, cuttings and particles returned from the well The mud mixture relies on the fluid energy to flow directly to the recovery device through the outlet device at the wellhead of the drilling rig through the pipeline, and then the magnetic separator 10 in the recovery device sends the separated particles into the storage tank, and the cuttings and mud mixture are sent into the mud tank 11; the particles in the storage tank are transported to the injection device, injected into the well through the injection device and drilled again, forming a particle impact drilling cycle.

[0044] This embodiment is the most basic implementation mode, and the injection device and storage tank of the prior art c...

Embodiment 2

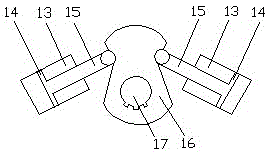

[0046] see Figure 1-Figure 3 , a particle drilling method, comprising a particle injection step and a particle recovery step, the particle injection step refers to using an injection device to inject mud and particles into the well; the particle recovery step refers to the particles, cuttings and particles returned from the well The mud mixture relies on the fluid energy to flow directly to the recovery device through the outlet device at the wellhead of the drilling rig through the pipeline, and then the magnetic separator 10 in the recovery device sends the separated particles into the storage tank, and the cuttings and mud mixture are sent into the mud tank 11; the particles in the storage tank are transported to the injection device, injected into the well through the injection device and drilled again, forming a particle impact drilling cycle.

[0047] The particle injection speed in the particle injection step is 0.5kg / s.

[0048] The particle injection pressure in the...

Embodiment 3

[0052] see figure 1 , image 3 and Figure 4 , a particle drilling method, comprising a particle injection step and a particle recovery step, the particle injection step refers to using an injection device to inject mud and particles into the well; the particle recovery step refers to the particles, cuttings and particles returned from the well The mud mixture relies on the fluid energy to flow directly to the recovery device through the outlet device at the wellhead of the drilling rig through the pipeline, and then the magnetic separator 10 in the recovery device sends the separated particles into the storage tank, and the cuttings and mud mixture are sent into the mud tank 11; the particles in the storage tank are transported to the injection device, injected into the well through the injection device and drilled again, forming a particle impact drilling cycle.

[0053] The particle injection speed in the particle injection step is 2kg / s.

[0054] The particle injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com