High-purity nylon 5X salt and purification method thereof

A purification method and nylon technology, applied in the separation/purification of carboxylic acid compounds, amino compound purification/separation, organic chemistry, etc., can solve problems such as affecting the mechanical properties of nylon and limiting the growth of nylon molecular weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

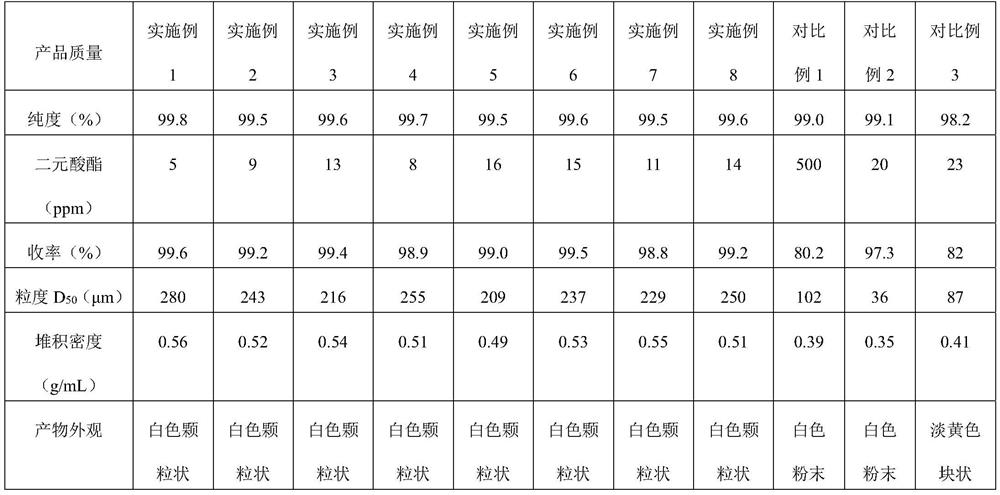

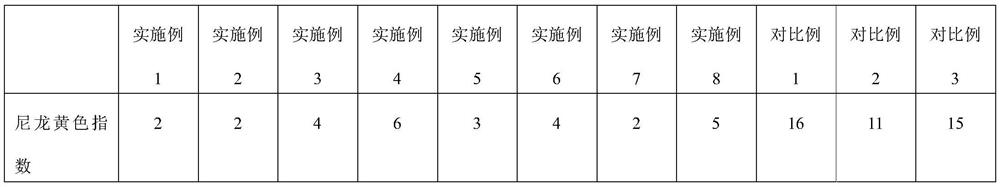

Examples

preparation example 1

[0074] Referring to CN201410004636.3 and CN201810022432.0, the lysine fermentation liquid is passed through a ceramic membrane to obtain a pure lysine collection liquid, and after deamination, adipic acid and lysine are used to react to form a lysine adipate solution , to control the pH of the reaction solution between 5 and 7. Add the cultured lysine decarboxylase fermentation liquid to the above-mentioned treated lysine adipate feed liquid, and the added amount of the lysine decarboxylase fermentation liquid is 8 wt.% of the lysine adipate. During the conversion process, the pH is controlled to 7.1, controlled by adding adipic acid solids, and converted into an aqueous solution of pentamethylenediamine adipate, and the aqueous solution of pentamethylenediamine adipate is filtered through a ceramic membrane to obtain a nylon 56 salt solution. Then, the nylon 56 salt feed solution was added into lysine fermentation broth with 3wt.% activated carbon to decolorize the total amou...

preparation example 2

[0077] Referring to CN201410790873.7, a crude nylon 56 salt was prepared using purchased 1,5-pentanediamine and adipic acid as raw materials.

Embodiment 1

[0079] Add the nylon 56 crude product prepared in Preparation Example 1 into a 100-liter enamel reaction kettle, add 95wt.% ethanol aqueous solution to obtain a mixture of nylon 56 salts, wherein the mass of the nylon 56 salt crude product in the mixture of nylon 56 salts The fraction is 54%, heat up to 66°C to dissolve the above mixture, keep at this temperature for 0.5h, until the solution is transparent, start to cool down at a rate of 5min / °C to the precipitation temperature point of 60°C, at this time, there are solid particles precipitated in the solution by naked eyes At this temperature for 1 hour, the particles in the solution continued to increase. After the heat preservation was over, the temperature was lowered to 30 degrees at a rate of 5 min / °C. After the temperature was maintained for 1 hour, the crystallization slurry was directly centrifuged. 56 salt crude product by weight) washed with 95% ethanol aqueous solution, placed in a vacuum oven at 50° C., and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com