Patents

Literature

121 results about "Lysine fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing 1,5-pentanediamine

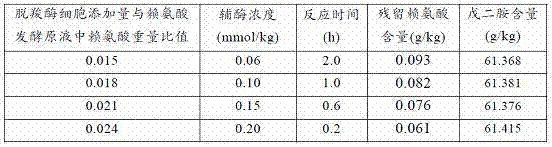

The invention relates to a method for preparing 1,5-pentanediamine. The method comprises the step of adding lysine decarboxylase into a lysine fermentation broth to synthesize 1,5-pentanediamine. The method utilizes the lysine fermentation broth but not purified lysine as the substrate, so that the process is simpler and more economical.

Owner:CATHAY R&D CENT CO LTD +1

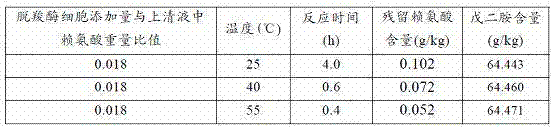

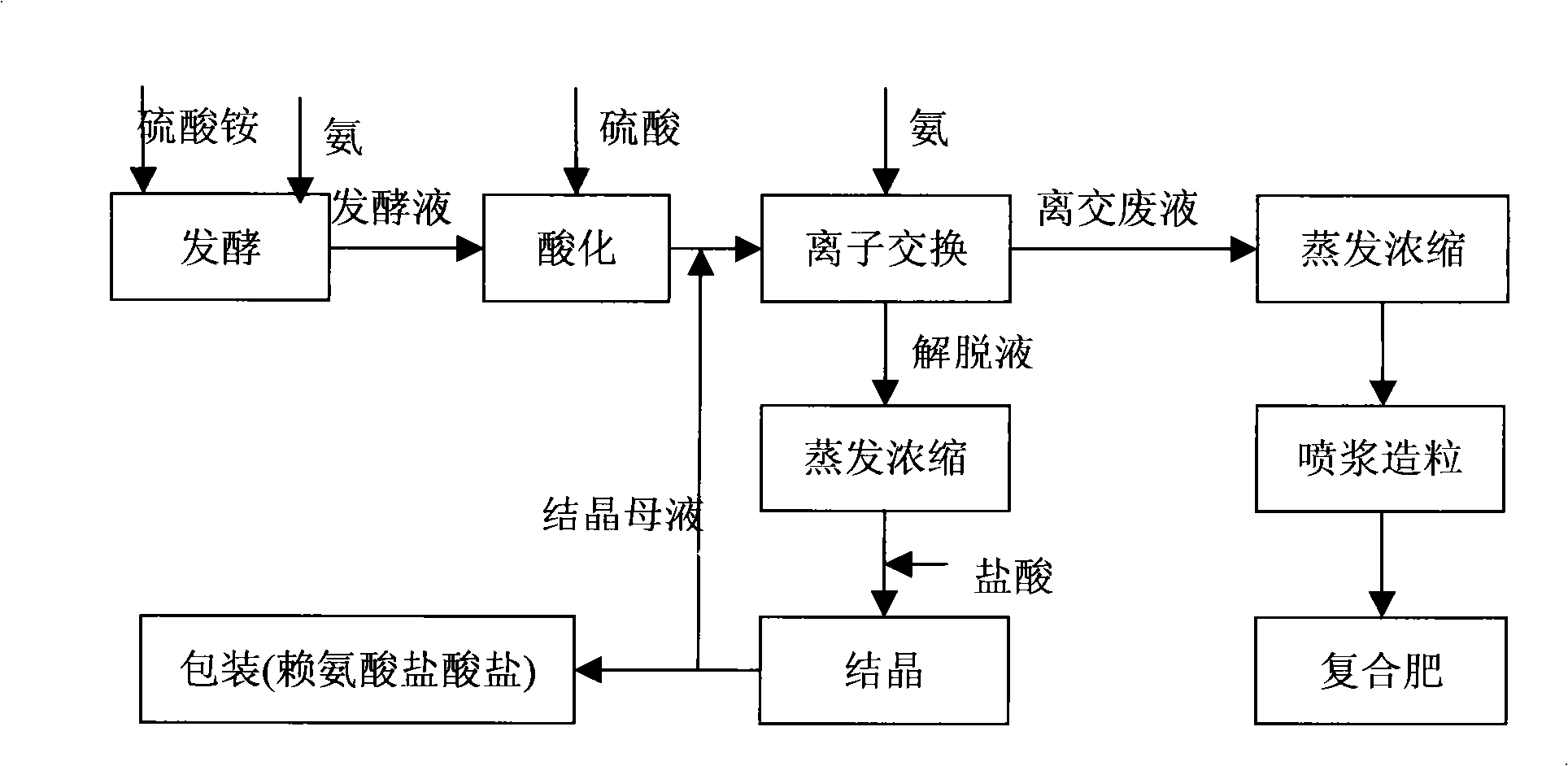

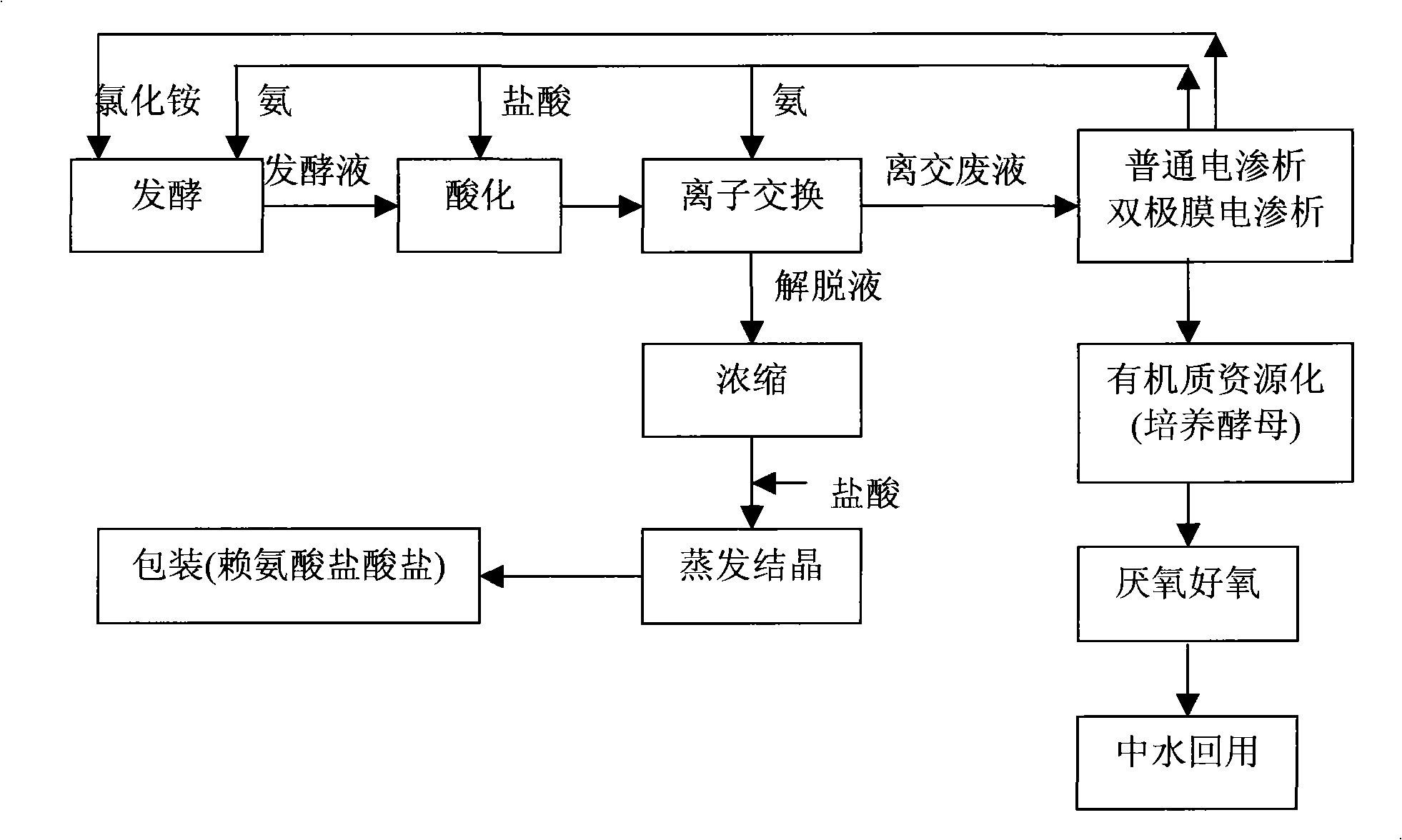

Method for processing ion exchange waste liquor of lysine production by fermentation method

InactiveCN101407350AFast growthLarge biomassAmmonium nitratesDispersed particle separationIon exchangeLysine fermentation

The invention belongs to the ferment industry, in particular relates to a treatment method of ion exchange waste liquor in lysine production by a fermentation method. The invention adopts a common electrodialysis technology to recycle ammonium sulfate, ammonium chloride or ammonium nitrate in the lysine ion exchange waste liquor produced by extracting the lysine from lysine fermentation production to water solution of ammonium sulfate, ammonium chloride or ammonium nitrate, or adopts a bipolar membrane electrodialysis technology to regenerate sulfuric acid, hydrochloric acid or nitric acid and NH3 by ammonium sulfate, ammonium chloride or ammonium nitrate in the lysine ion exchange waste liquor produced by extracting the lysine from the lysine fermentation production, or adopts the combination of the common electrodialysis technology and the bipolar membrane electrodialysis technology to recycle ammonium sulfate, ammonium chloride or ammonium nitrate in the lysine ion exchange waste liquor produced by extracting the lysine from the lysine fermentation production and regenerate sulfuric acid, hydrochloric acid or nitric acid and NH3. The invention realizes the resource recycling of the ion exchange waste liquor and clean production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

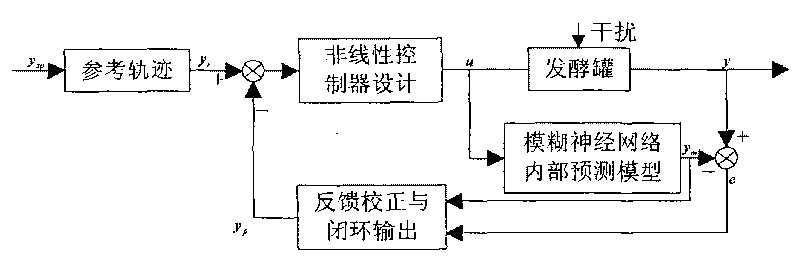

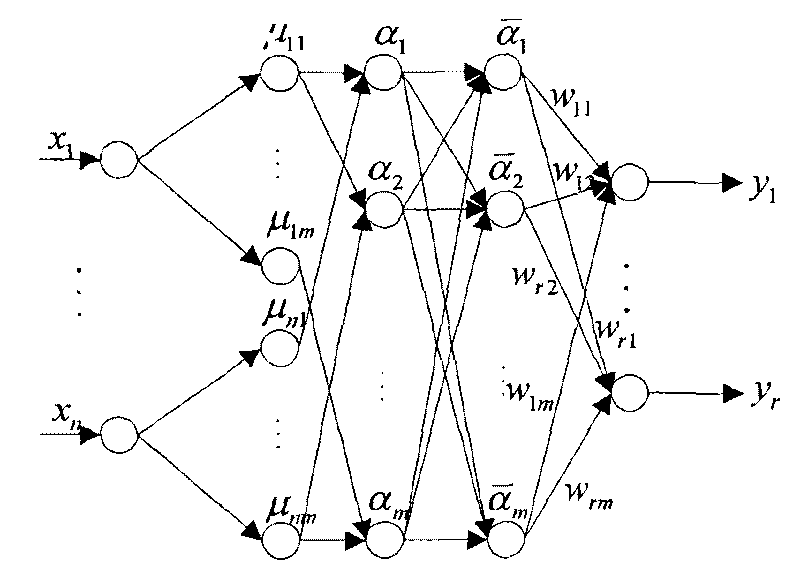

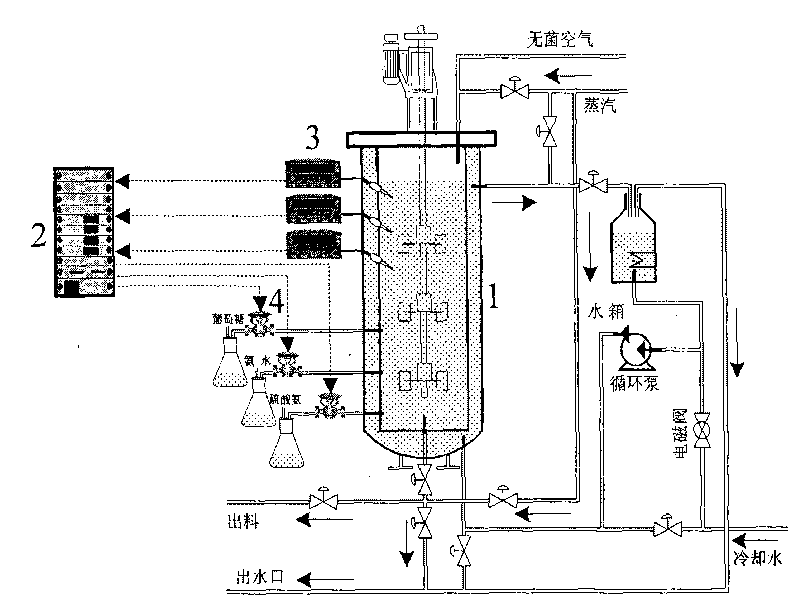

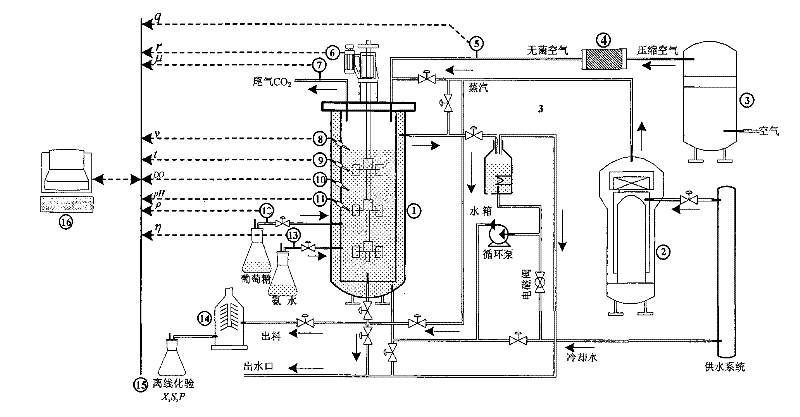

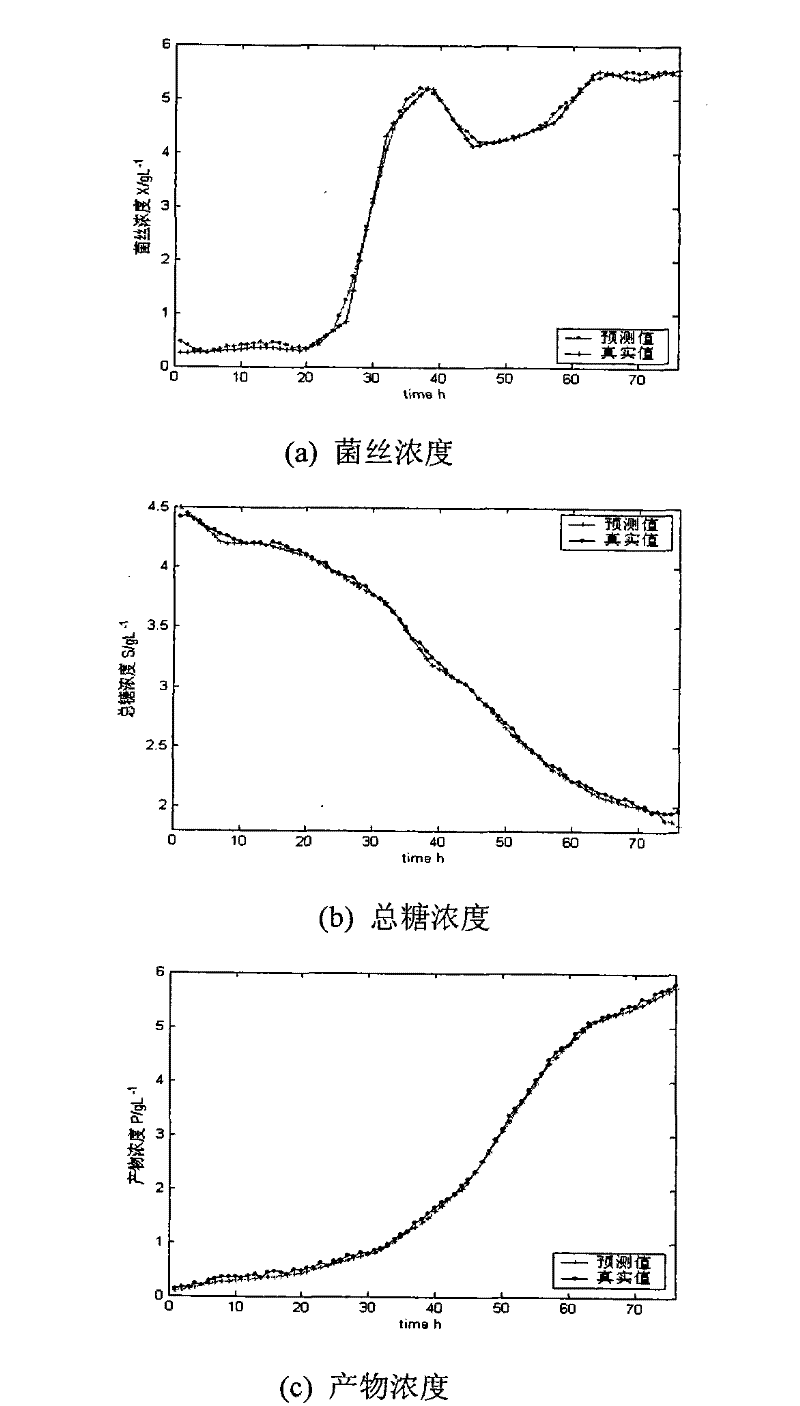

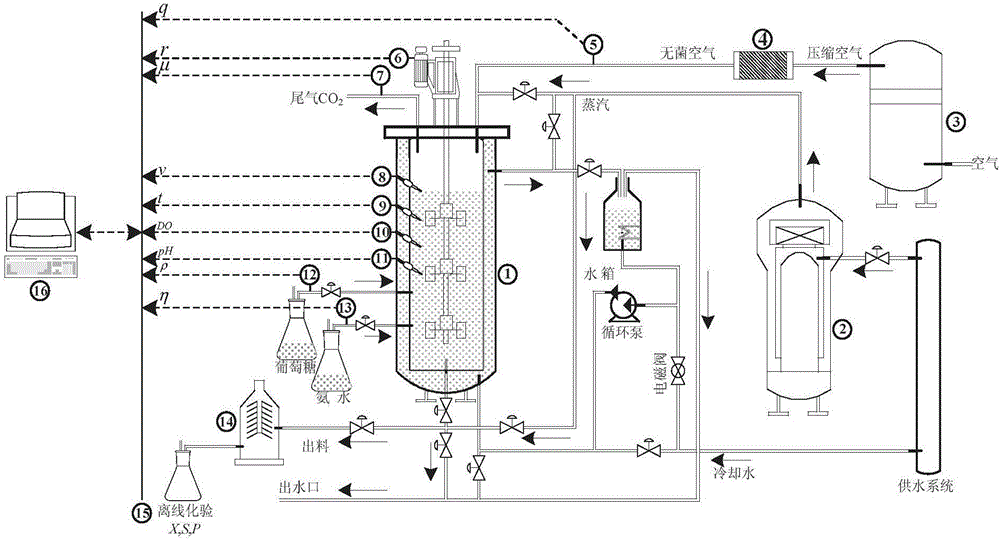

Lysine fermentation process feeding prediction control system and method based on fuzzy neural network

InactiveCN101763036AEasy to identifyFew adjustable parametersAdaptive controlPeristaltic pumpClosed loop

The invention relates to a lysine fermentation process feeding prediction control system and method based on a fuzzy neural network. The control method comprises the following steps: firstly using batch data to train the fuzzy neural network and establish a nonlinear prediction model of lysine fermentation process, secondly measuring the input / output information of model utilization history and future batch data to predict the future output of the lysine fermentation process, using the model to output error and perform feedback compensation so as to obtain closed loop output, finally comparing closed loop output and reference input trajectory, utilizing quadratic form performance index to perform rolling optimization, and calculating to obtain feeding control quantity which is needed to add in the system currently. The system comprises a site intelligent detecting instrument and peristaltic pump which are directly connected with a fermenter and an intelligent controller, wherein feeding prediction control algorithm is embedded in the system intelligently. The system and method of the invention can adapt to the dynamic characteristic of the lysine fermentation process and the coupling between strong open loops, thus obtaining good control effect.

Owner:JIANGSU UNIV

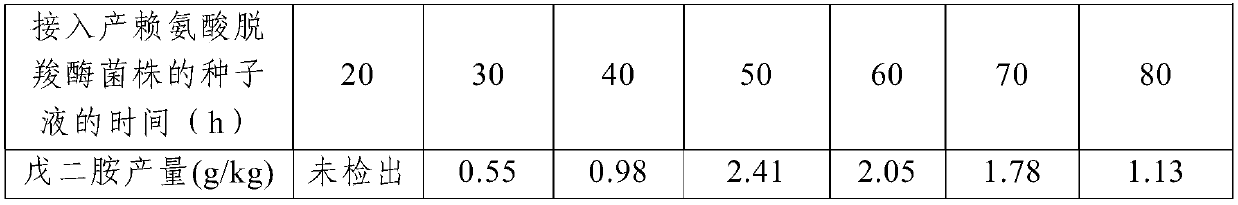

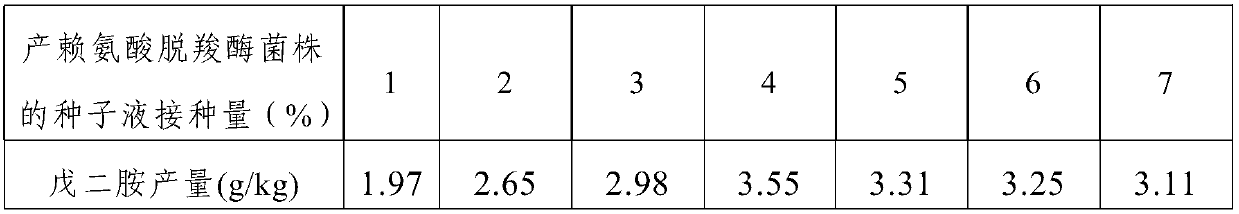

Preparation process of 1,5-pentamethylene diamine

PendingCN109536542AFacilitate the realization of industrial productionReduce toxic effectsMicroorganism based processesFermentationMicroorganismLysine fermentation

The present invention relates to a preparation process of 1,5-pentamethylene diamine. According to the method, a seed liquid containing lysine decarboxylase strains is introduced during lysine fermentation, and mixed fermentation is carried out. The method is suitable for industrial production of 1,5-pentamethylene diamine, minimizes toxicity of pentamethylene diamine to microorganisms to avoid adverse effects on fermentation, makes the subsequent process more simplified, and has certain commercial value.

Owner:CATHAY R&D CENT CO LTD +1

Nylon 5X salt and high-purity preparation method thereof

ActiveCN108129329AGuaranteed harmless disposalHigh purityAmino compound purification/separationOrganic compound preparationDesorptionIon exchange

The invention discloses a one-step production process of nylon 5X salt and the prepared high-purity nylon 5X salt. The one-step production process of the nylon 5X salt comprises the steps of carryingout ion exchange adsorption and desorption on a lysine fermentation fluid, obtaining a pure lysine collecting fluid, and after deaminizing, using a nanofiltration membrane for separating part of protein and inorganic salt; utilizing binary acid and lysine for reacting to generate lysine binary acid salt, controlling reaction PH to range from 5 to 6, during a conversion process, directly adding thebinary acid for buffering pH, utilizing a lysine decarboxylase fermentation fluid for one-step converting the lysine binary acid salt into a nylon 5X salt solution, and controlling PH after finishingconversion to be around 7; after filtering and sterilizing through a ceramic membrane, adsorbing impurities, concentrating, crystallizing, extracting and crystallizing a mother liquor through ethyl alcohol after crystallizing, and collecting the nylon 5X salt. The yield and the purity are improved, and the production pollution is reduced.

Owner:SHANDONG SHOUGUANG JUNENG GOLDEN CORN CO LTD +3

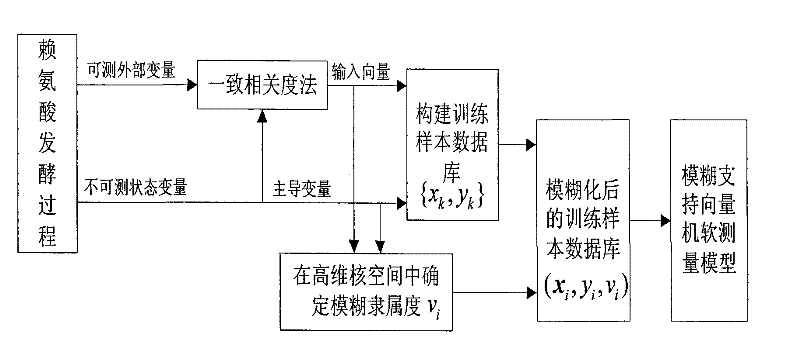

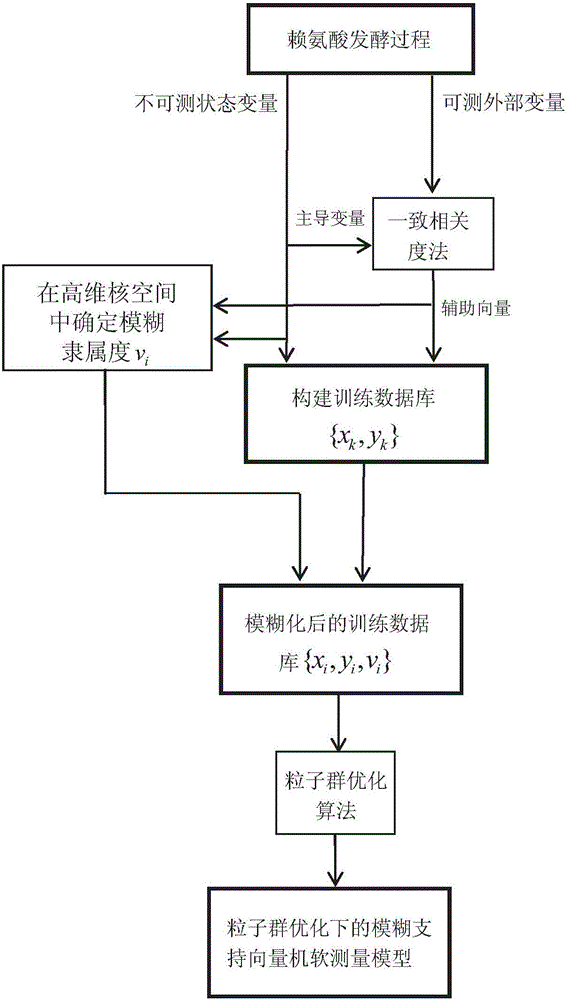

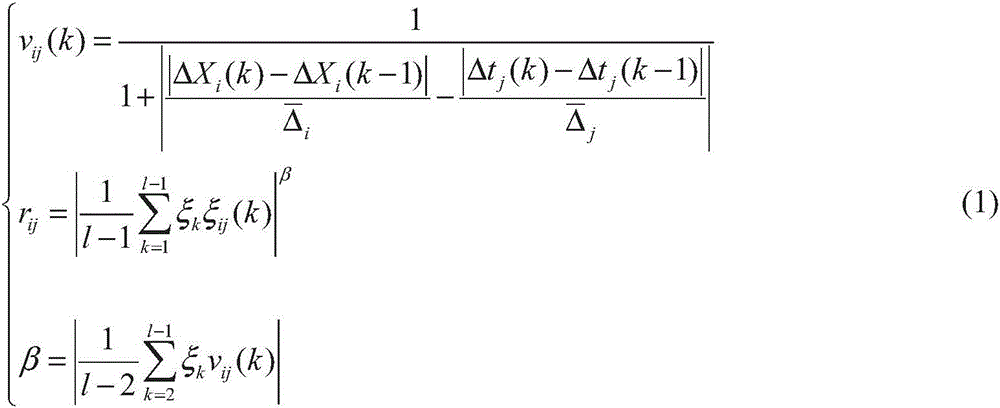

FSVM-based lysine fermentation process key state variable soft measuring method and system

InactiveCN101748186ASolve difficult problems that are difficult to detect onlineReduce workloadMicrobiological testing/measurementSpecial data processing applicationsProcess mechanismFuzzy support vector machine

Disclosed are a FSVM-based lysine fermentation process key state variable soft measuring method and a system; the method depends on a hardware platform, a measurement instrument, a computer system and an intelligent controller for software computation, the software obtains real-time process data for soft measurement through the measurement instrument. The method firstly analyze the process mechanism of the lysine fermentation process, selects proper auxiliary variables to create a training sample database according to the historical batch fermentation data, subsequently projects the training samples to a high dimensional nuclear space to calculate the fuzzy degree of membership corresponding to each sample point in the nuclear space; the training samples after fuzzification are trained by FSVM to build a soft measurement module; finally, the predication of key state variables is realized according to the latest input vector of the batch fermentation under predication. The invention realizes the online real-time predication of key state variable of lysine fermentation process, and has great significance on realizing the optimized control and operation of the lysine fermentation process.

Owner:JIANGSU UNIV

Method for fermenting lysine

The invention relates to a biology ferment technology field, in particular to a lysine fermentation method. The invention is characterized in that: the method includes the following steps: strains fostered 9 to 11 hours from a slant tube to a large seed bottle are transferred to a secondary seed pot with a seed rate of 0.2 to 0.3 percent and a foster temperature of 38 to 40 DEG C, which are transferred into third seed pot after 15 to 17 hours with a seed rate of 5 to 6 percent, and then transferred to ferment pot after fostering 9 to 11 hours to be fermented. After strains are inoculated to ferment pot, sugar and organic nitrogen are fed continuously, with a seed rate of 14 to 18 percent and a ferment L-sorbose of 2 to 8 percent. The invention is unique in technique with short ferment time which can save energy consumption by three steps of large seed rate intermittent feeding of sugar and nitrogen, with lysine produced at a rate more than 16.5 percent , glucose acid invert ratio above 62 percent, a single batch feeding volume 420 cubic meter by a 350 cubic meter ferment pot , and a ferment period 45 hours.

Owner:NINGXIA EPPEN BIOTECH

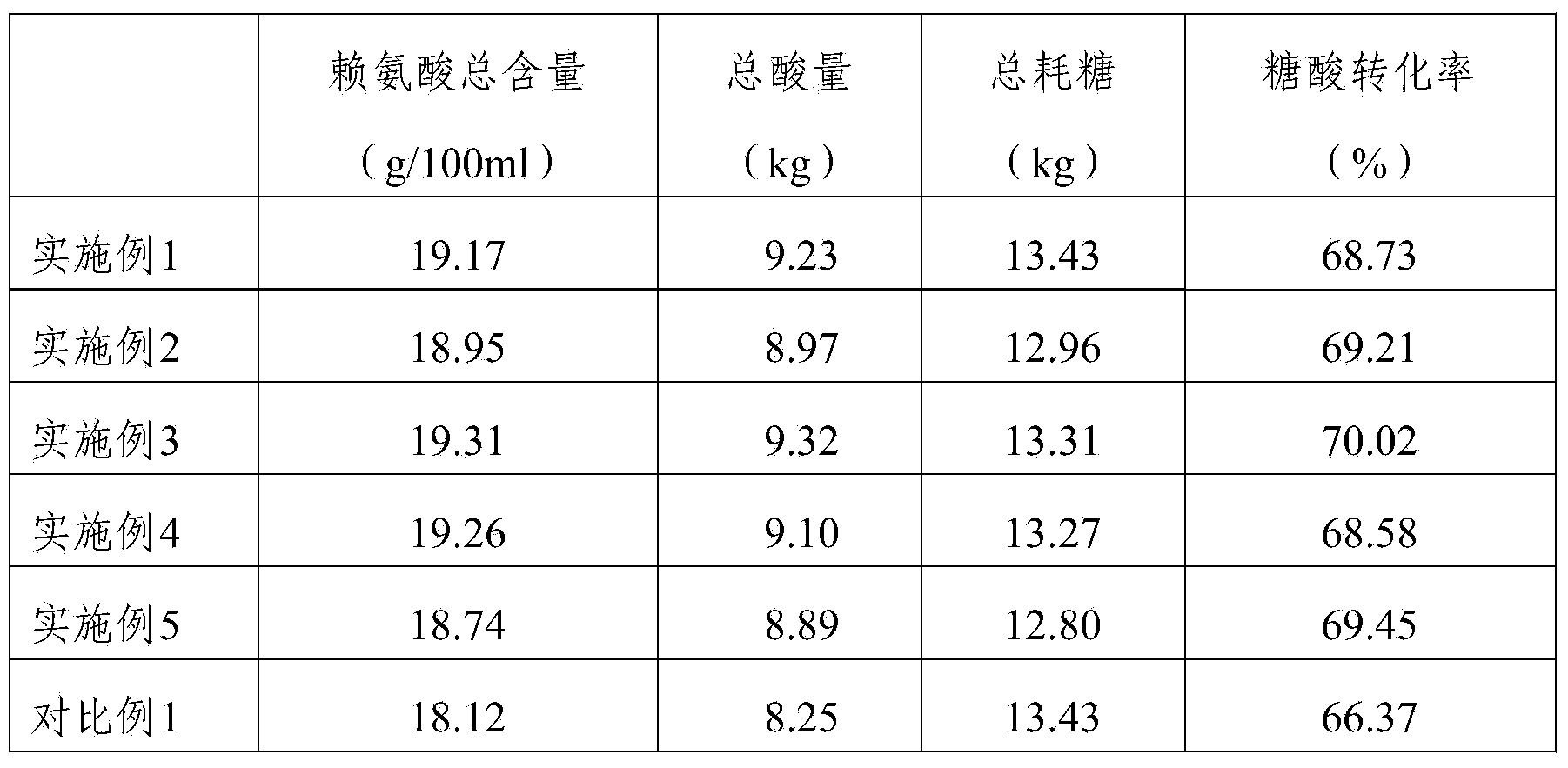

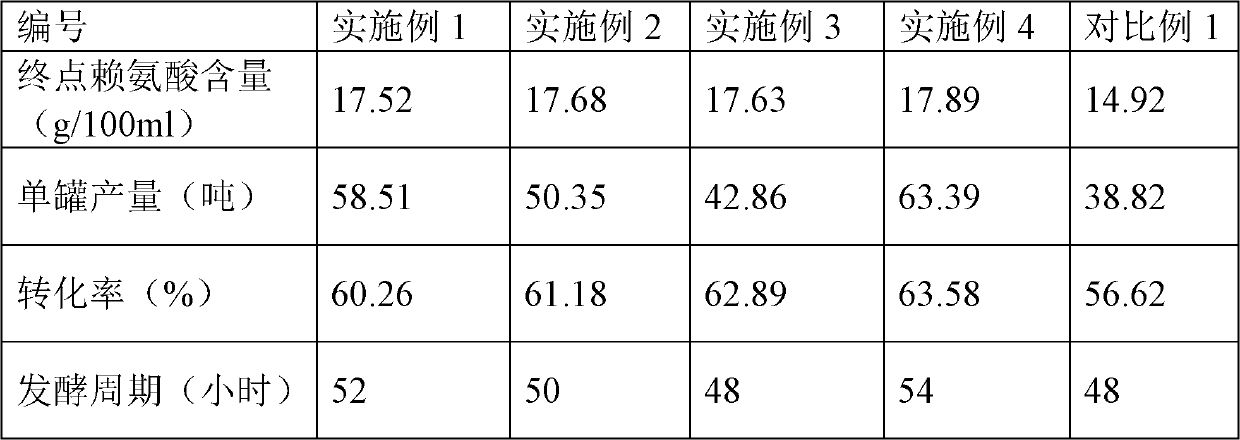

L-lysine fermenting method

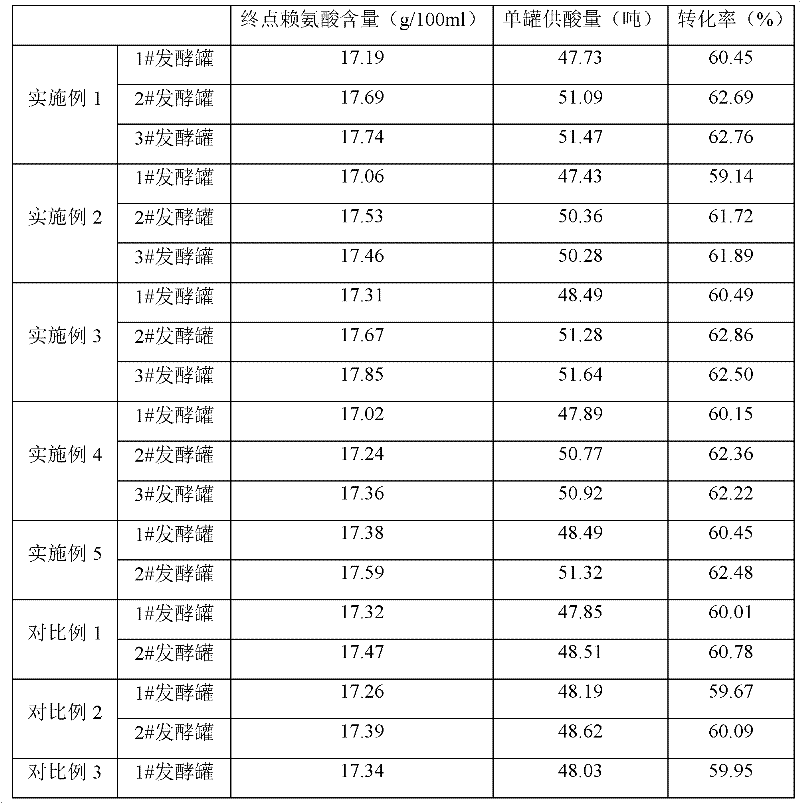

InactiveCN104250659AIncrease end-point lysine contentIncrease acidityMicroorganism based processesFermentationSaccharic acidD-Glucaric Acid

The invention relates to the field of fermentation, in particular to an L-lysine fermenting method. The L-lysine fermenting method comprises the following steps: inoculating a lysine first stage seed medium with a lysine shake flask seed, culturing the seed till the seed is mature, then, inoculating the seed in a lysine second stage seed medium for culturing till the seed reaches a mature standard of a lysine second stage seed, inoculating a lysine fermenting medium with the second stage seed, and under conditions of a fed-batch carbon source and a fed-batch nitrogen source, performing fermentation culture till the end of fermentation, wherein the nitrogen source in the lysine primary seed medium, the lysine secondary seed medium and the lysine fermenting medium is ammonium chloride, and during fermentation culture, the fed-batch nitrogen source is an ammonium chloride solution. By the L-lysine fermenting method, the final content of lysine, the total acid amount and the conversion ratio of saccharic acid can be significantly increased.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

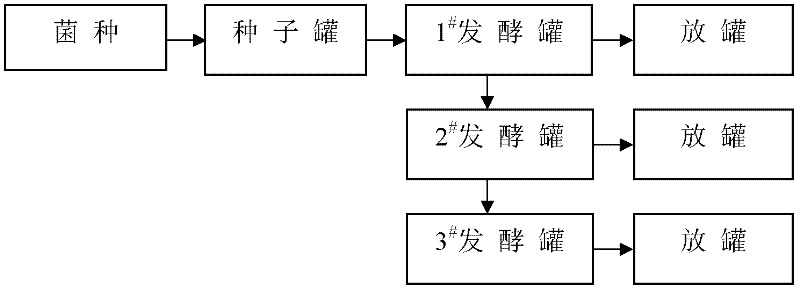

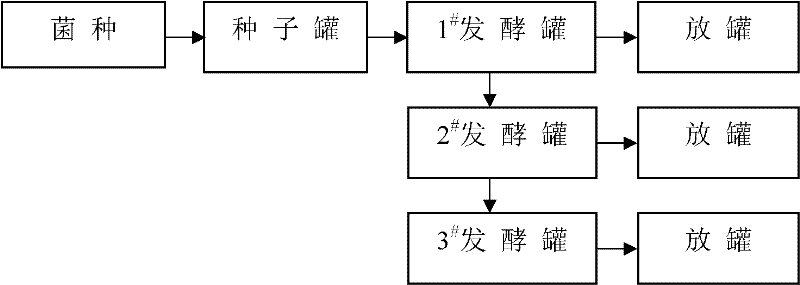

Method for continuously fermenting lysine

InactiveCN102533889AReduce fermentation costsTo promote metabolismMicroorganism based processesFermentationNitrogen sourceLysine fermentation

The invention discloses a method for continuously fermenting lysine, which comprises the following steps: inoculating a lysine fermentation strain into a lysine fermentation medium; under the conditions of a flow-feed carbon source and a flow-feed nitrogen source, and carrying out fermentation and culture. The invention is characterized in that nutrient substances required by lysine fermentation and culture are added into the fermentation liquid 20 hours after the fermentation and culture are started. The method disclosed by the invention greatly prolongs the fermentation and culture time, enhances the metabolic capability of the lysine strain, can carry out fermentation all along under the conditions that the equipment does not goes wrong and the fermentation medium is not contaminated by bacteria, increases the acid supply amount per unit time, and enhances the equipment utilization rate, thereby lowering the lysine fermentation cost.

Owner:COFCO BIOTECHNOLOGY CO LTD

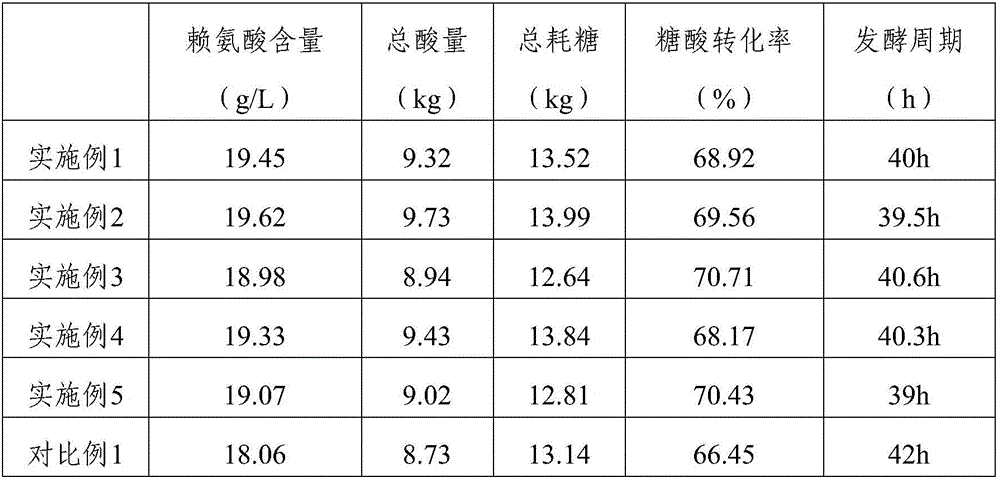

Method for fermenting L-lysine

The invention relates to the field of fermentation, and particularly provides a method for fermenting L-lysine. Acetate is added into lysine primary seed culture media, lysine secondary seed culture media and lysine fermentation culture media, and formulas and fermentation processes for the various culture media are optimized. The method has the advantages that growth of lysine producing thalli and synthesis of lysine can be promoted, accordingly, the endpoint lysine content, the total acid content and the saccharic acid conversion rate can be obviously increased, and the fermentation periods can be obviously shortened.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Soft measuring method and system for key variables of lysine fermentation process based on PSO-FSVM

InactiveCN106444377AHigh precisionSolve difficult problems that are difficult to detect onlineSpecial data processing applicationsBioinformaticsMeasuring instrumentOptimal control

The invention discloses a soft measuring method and system for key variables of a lysine fermentation process based on PSO-FSVM. The method relies on a hardware platform, a measuring instrument and a computer system software used for intelligent computing. The method includes the following steps: analyzing the technological mechanism of the lysine fermentation process, selecting appropriate auxiliary variables, and establishing a training sample database according to historical pot batch data; mapping a training sample into a high dimensional kernel space, and calculating the fuzzy membership degree corresponding to each sample point in the kernel space; then conducting on-line optimization on a kernel function parameter and a penalty coefficient by a particle swarm algorithm, training the fuzzy training sample by a fuzzy support vector machine, and establishing a soft measurement model; finally, achieving prediction of the key state variables according to the latest to-be-predicted pot batch input vector. The soft measuring method and system achieve the on-line real-time prediction of the key state variables in the lysine fermentation process, and are of great significance for the parameter prediction and the optimal control of the lysine fermentation process.

Owner:JIANGSU UNIV

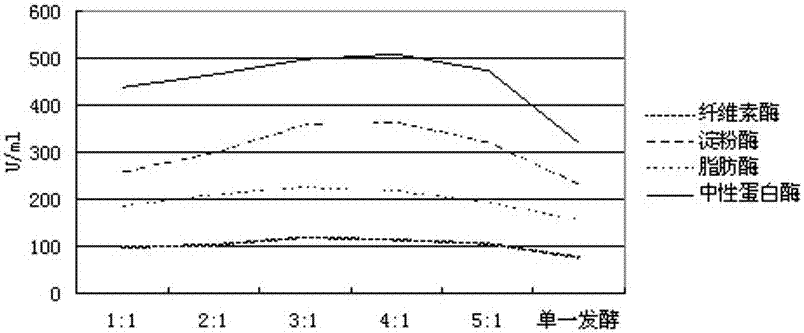

Method for producing high-lysine fermented feed through fermentation of vinegar residue using two-step method

InactiveCN101756012AIncrease added valueIncrease beneficial bacteriaFood processingAnimal feeding stuffTwo stepDigestion

The invention discloses a method for producing a high-lysine fermented feed through fermentation of vinegar residue using a two-step method, comprising the following steps: (1) preparing potato culture medium, inoculating aspergillus niger strains onto the potato culture medium to cultivate; (2) preparing lysine seed culture medium; inoculating corynebacterium glutamicum strains onto the lysine seed culture medium to cultivate; (3) inoculating the aspergillus niger strains onto the vinegar residue to ferment and obtain a pretreatment material through the fermentation of the vinegar residue by the aspergillus niger; (4) inoculating the corynebacterium glutamicum strains onto the pretreatment material which is fermented by the aspergillus niger to ferment and cultivate; and (5) drying at a temperature not higher than 85 DEG C until the water content is below 15% so as to obtain the high-lysine fermented feed through the fermentation of the vinegar residue. The feed produced through the method of the invention has high lysine content and a variety of microbial enzymes, etc. The substances has obvious effects on digestion and absorption, growth and development, and body immunity of animals, and can increase beneficial bacteria in animal intestines and improve intestinal microecology.

Owner:TIANJIN SHENGJI GRP CO LTD

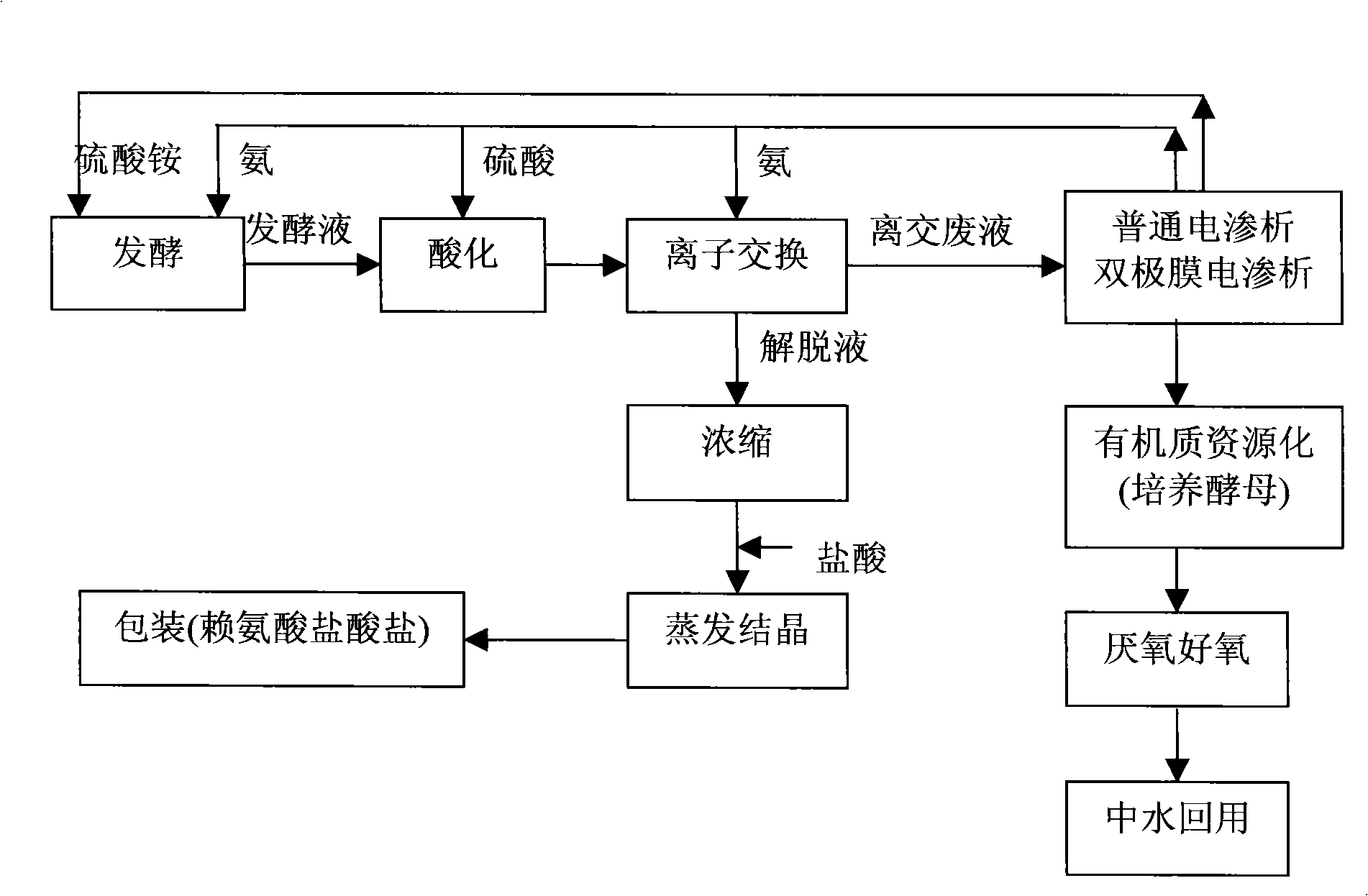

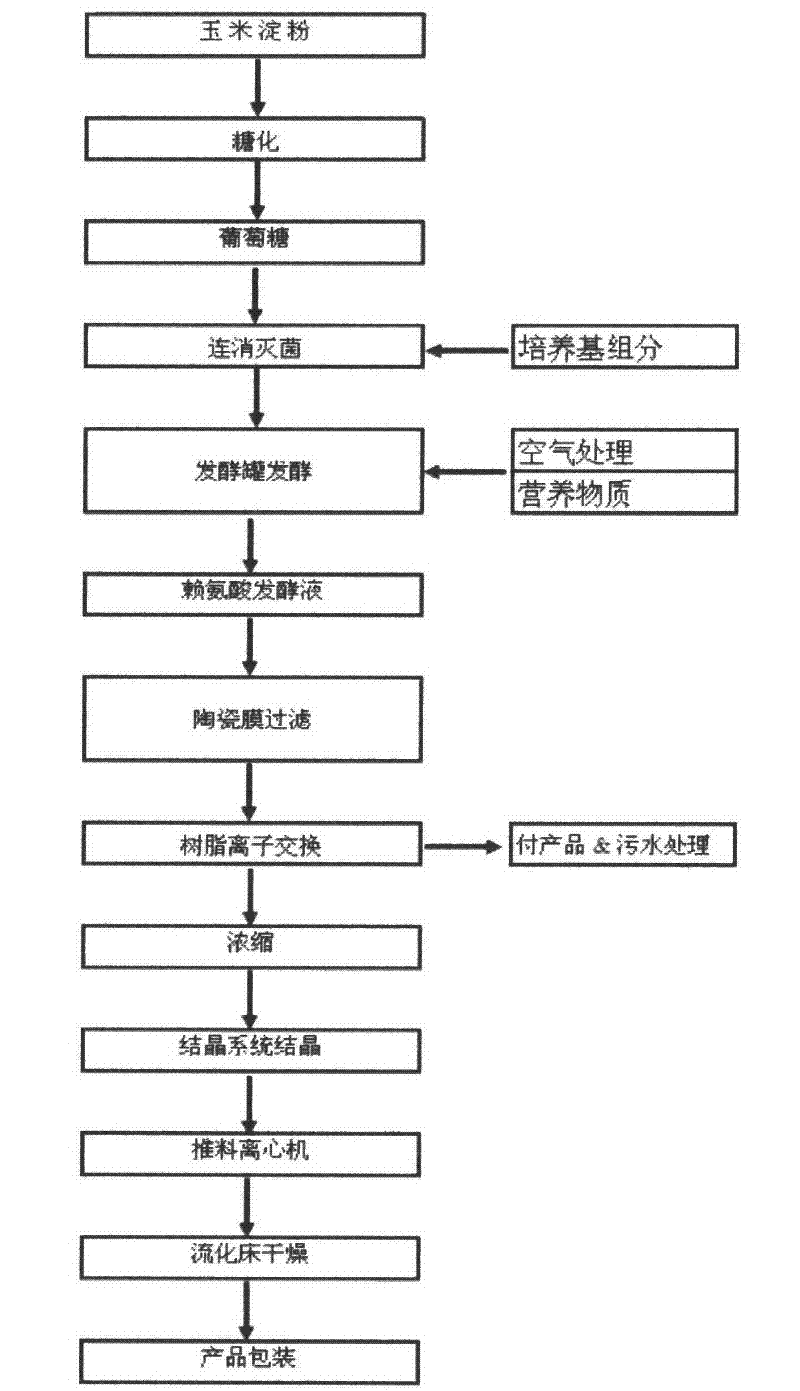

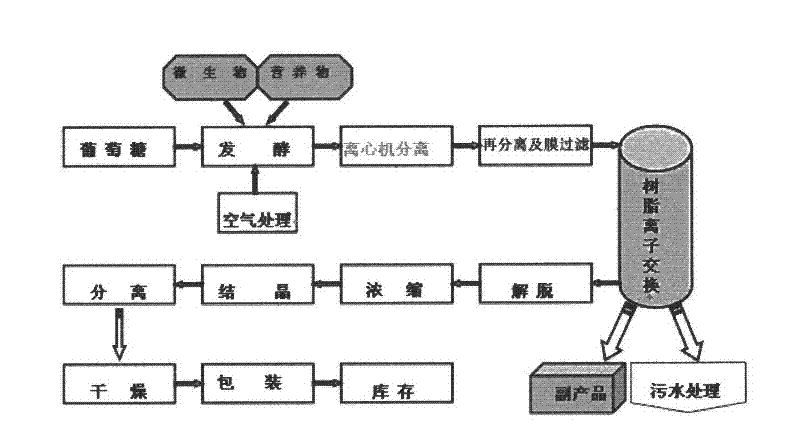

Producing process of lysine

InactiveCN102399833AReduce exchangeOmit enrichmentChemical industryFermentationUltrafiltrationIon exchange

The invention discloses a producing process of lysine, which belongs to the technical field of lysine preparation. The process comprises the following links of saccharifying, fermenting, separating, ion exchanging, concentrating, crystallizing, drying, product packing and the like, wherein the separating and ion exchanging comprise the following steps of: primary separation and reseparation, filtering and resin ion exchange; the steps are specifically as follows: primarily separating the fermented lysine fermenting liquor in a centrifugal machine; accelerating the sedimentation velocity of particles in the liquor; separating and eluting proteins and different precipitates; and then filtering the primarily separated liquor by using an ultrafiltration membrane; and carrying out resin ion exchanging to obtain a side product and separating out of the sewage. According to the invention, compared with the traditional ceramic membrane filtering technology, the membrane filtering link can be used for saving about 60% of sewage and energy consumption; the defect of parking maintenance caused by membrane crack in the ceramic membrane filtering is avoided; simple process, high purity of the prepared product, wide application field, suitability for producing tryptophan, phenylalanine and other amino acids and the like are obtained.

Owner:DOLE XINGU BIOLOGICAL TECH SHANGHAI

Preparation method of high-lysine fermentation and detoxification cottonseed meal

InactiveCN102805208ASolve two key problems of insufficient lysine contentGood detox effectAnimal feeding stuffBiotechnologyCandida tropicalis

The invention discloses a preparation method of high-lysine fermentation and detoxification cottonseed meal and aims at providing the preparation of high-lysine fermentation and detoxification cottonseed meal, which has the advantages of simultaneously realizing the cottonseed meal detoxification and improving the nutrient substance content in the cottonseed meal, particularly the lysine content. The preparation method has the main technical scheme that the method sequentially comprises the following steps of 1) bacterial strain activation: candida tropicalis, candida utilis and saccharomyces cerevisiae are respectively inoculated to a saccharomycete culture medium, and lactobacilli is inoculated into a culture medium containing liquid lactobacilli; 2) preparation of seeds for production; 3) fermentation substrate preparation; and 4) fermentation substrate inoculation. The preparation method belongs to the technical field of feed preparation.

Owner:XINJIANG XIPU BIOLOGICAL SCI & TECH

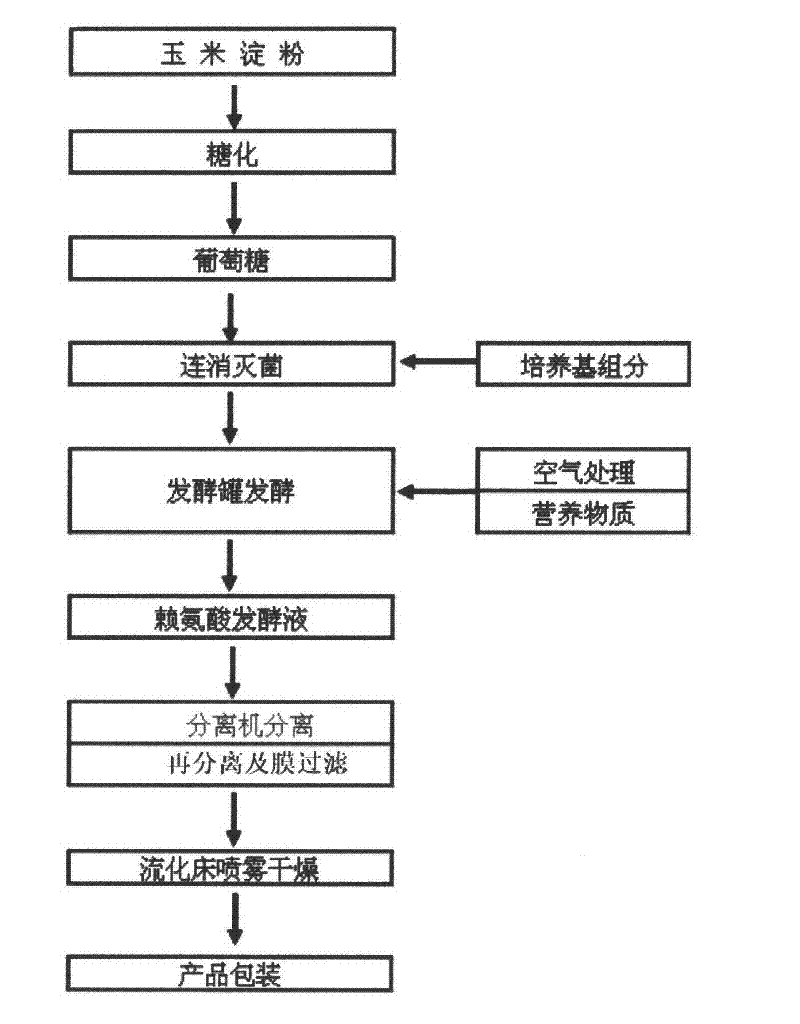

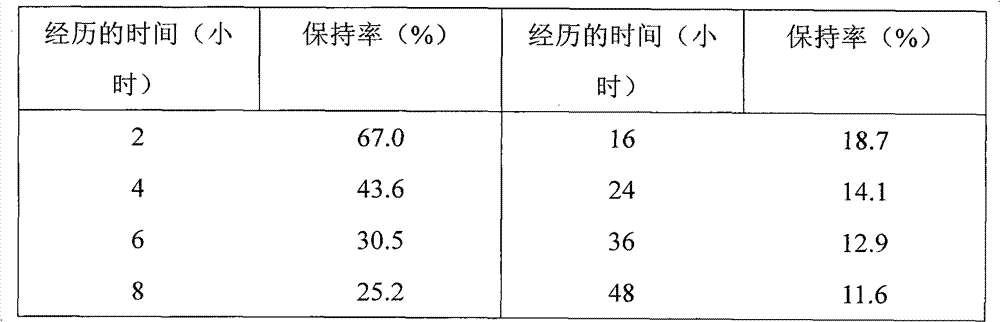

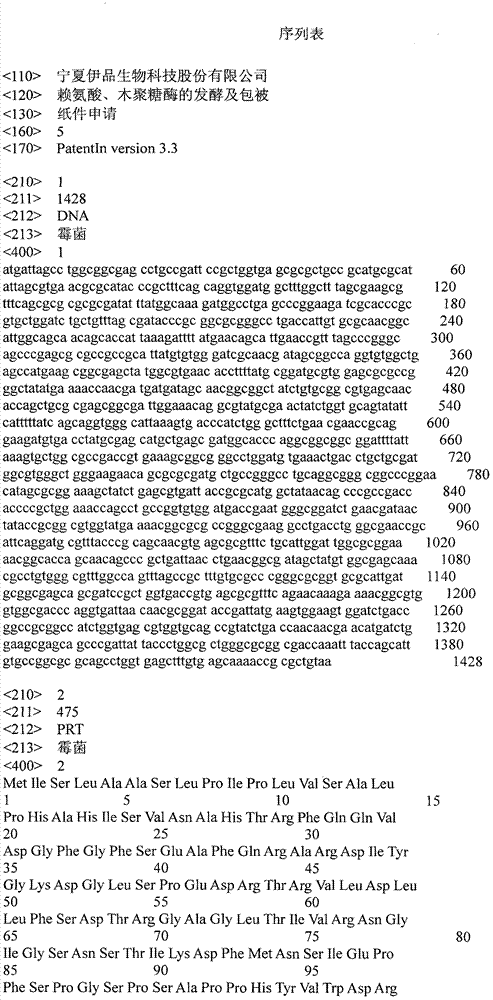

Fermentation and coating of lysine and xylanase

ActiveCN102763771AWith high temperature dehydrationSlow release rateFungiMicroorganism based processesXylanaseLysine fermentation

The present invention provides a fermentation method for preparing an L-lysine product. The method comprises steps of: producing an L-lysine fermentation broth through fermentation; mixing the fermentation broth with high temperature dehydration resistant xylanase which can be obtained by fermentation; and drying the mixture at high temperature, and coating with fat. In addition, the present invention also provides a product produced by the method and high temperature dehydration resistant xylanase, etc.

Owner:NINGXIA EPPEN BIOTECH +1

Recycling method of lysine fermented waste liquid

ActiveCN107164450AIncrease profitIncrease crude protein contentMicroorganism based processesFermentationLiquid wasteMycoprotein

The invention belongs to the technical field of environmental protection, and discloses a recycling method of lysine fermented waste liquid. The method comprises the following steps: 1) regulating pH value; 2) preparing a strain culture solution; 3) preparing composite bacterium liquid; 4) preparing an algae culture solution; 5) preparing an enlarged culture algae solution; 6) preparing a fermentation culture solution; and 7) implementing fermenting and filtering. According to the method provided by the invention, effective utilization of the fermented waste liquid and agricultural wastes can be achieved; water quality is purified while mycoprotein is obtained; load of a sewage treatment device is reduced; and obvious ecological and economic benefits are guaranteed.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

Method for preparing lysine through fermenting

InactiveCN104726510ADoes not affect production capacityReduce consumptionMicroorganism based processesFermentationIon exchangeWastewater

The invention discloses a method for preparing lysine through fermenting. The method is characterized by comprising the steps: inoculating a lysine fermentation strain to a lysine fermentation culture medium under the conditions of producing lysine, and carrying out fermentation culture under the conditions of feeding a carbon source and feeding ammonium chloride, wherein the content of SO4<2-> in an initial culture medium is 10-16g / l. According to the method disclosed by the invention, the lysine fermentation liquor, which is obtained through collecting after the fermentation ends, can be subjected to concentrated crystallization directly after thalli are removed, so as to obtain a lysine finished product, and working procedures, such as ion exchange and deamination, are not required to be carried out, so that an extracting process route is shortened, the consumption of raw and auxiliary materials is lowered, no wastewater is generated, the extracting cost is reduced, and the production capacity of lysine is not affected.

Owner:COFCO BIOTECHNOLOGY CO LTD

Organic matter liquid suitable for being used as leaf fertilizer raw material

InactiveCN103058716AThe promotion effect is obviousAddressing area preparationClimate change adaptationBioloigcal waste fertilisersMonosodium glutamateLysine fermentation

The invention discloses an organic matter liquid suitable for being used as leaf fertilizer raw material. The organic matter liquid is prepared by using yeast culture solution, or residual discharge liquid without saccharomycetes, or lysine fermentation broth, or lysine residual discharge liquid, or glutamic acid fermentation broth, or acid hydrolyzed bean cake amino acid solution, or acid hydrolyzed feather amino acid solution or amino acid solution of enzymolysis fish protein as raw material, wherein the pH value of the organic matter liquid is 3-4, the organic matter content of the organic matter liquid is 2-50%, and the chlorine element content of the organic matter liquid is 1-15%. With the adoption of the organic matter liquid, the organic matter liquid can replace the raw material glutamic acid fermentation mother solution of the traditional leaf fertilizer so as to prepare the leaf fertilizer in the regions in which monosodium glutamate industry is absent, the organic matter liquid provided by the invention is used as the raw material of the leaf fertilizer, the organic matter liquid has the effects of the traditional leaf fertilizer, and further facilitates the growth of the plants well.

Owner:GUANGXI SUINING CHEM IND GRP +1

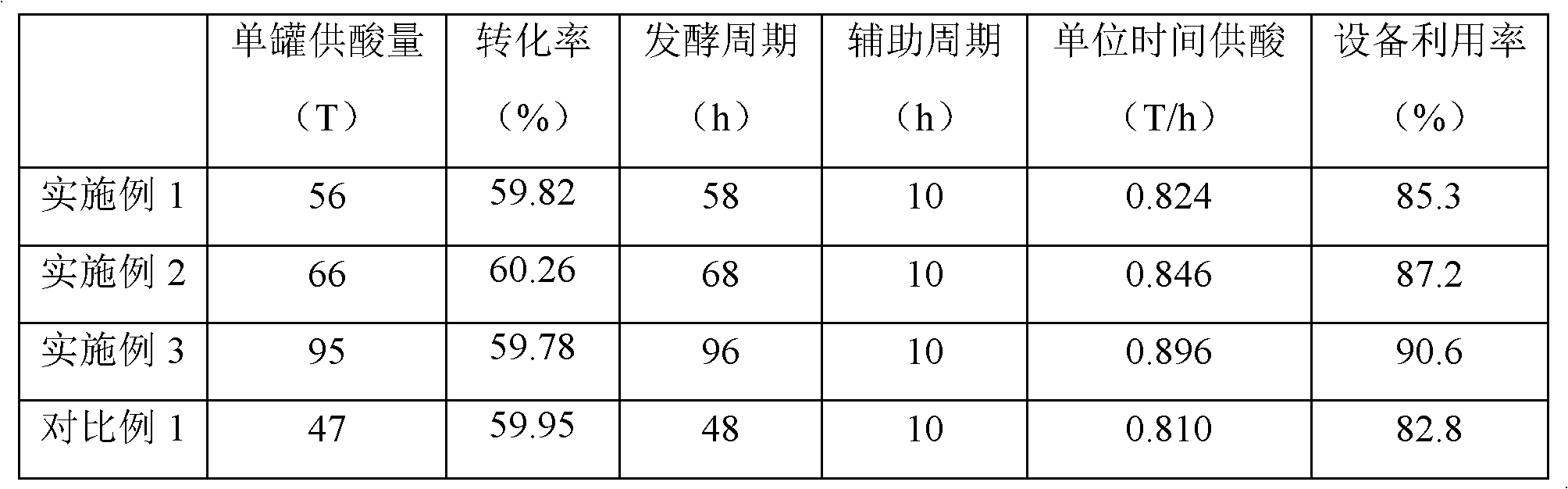

Production method of lysine

InactiveCN102533890ATake advantage ofProlong fermentation timeMicroorganism based processesFermentationEconomic benefitsNitrogen source

The invention discloses a production method of lysine. The method comprises the step of inoculating lysine fermentation strains into lysine fermentation media for fermentation culture under the condition of feeding a carbon source and a nitrogen source. The method is characterized by refilling lysine fermentation strains into fermentation liquor within 30-48 hours of fermentation culture. The method has the following advantages: the fermentation time can be lengthened and the content of final lysine, the acid supply quantity per tank and the conversion rate can be improved, thus lowering the production cost and improving the economic benefits; and by adopting the optimized embodiment, namely refilling the lysine fermentation strains extracted from the emptied fermentation liquor within 15-40 hours of fermentation culture, the lysine fermentation strains in the emptied fermentation liquor can be fully utilized, thus further lowering the production cost and improving the economic benefits.

Owner:COFCO BIOTECHNOLOGY CO LTD

Method for preparing fermented high-lysine high-protein feed

InactiveCN102178038AIncrease contentMeet needsFood processingAnimal feeding stuffProcessing costLysine fermentation

The invention discloses a method for preparing a fermented high-lysine high-protein feed. The method comprises the following steps of: preparing a lysine fermented material and a yeast fermented material; and crushing the lysine fermented material, the yeast fermented material, bean pulp and corn protein powder, and mixing to obtain a finished product. The processing cost is low, and the method is convenient to operate; the content of lysine and protein in the feed is increased, the experiment proves that the feed prepared by the method has the crude protein content of more than or equal to 40 percent and the lysine content of more than or equal to 8 percent, and the demand of animals on the lysine and the protein is met; moreover, the absorption effect of the animals is high, and the breeding benefit is improved.

Owner:河南宏翔生物科技有限公司

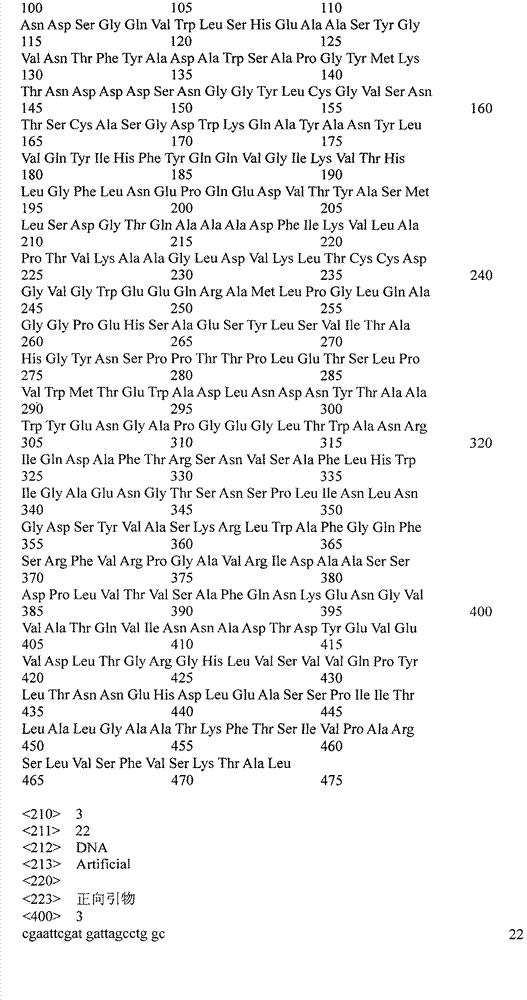

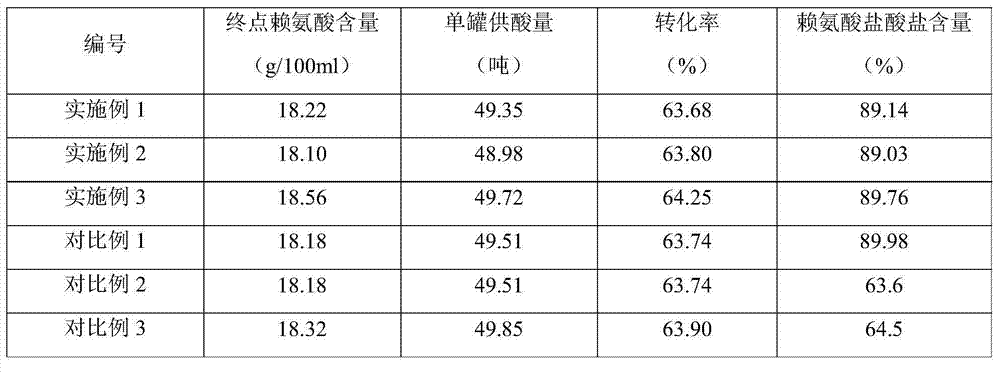

Method for preparing lysine

InactiveCN102399834AImprove conversion rateIncrease the acid supply of a single tankMicroorganism based processesFermentationBiotechnologyNitrogen source

The invention provides a method for preparing lysine. The method comprises the following steps of: inoculating lysine fermentation strains into lysine fermentation culture solution, and performing fermentation culture under the condition of a feeding carbon source and a feeding nitrogen source. The method is characterized in that the lysine fermentation strains contain strains which are subjected to the fermentation culture for 8 to 30 hours under the condition of the fermentation culture of the lysine. By the method, the conversion rate and single-tank acid supply amount are improved substantially, the production can be performed continuously, the production capacity is improved, and the production cost is reduced.

Owner:COFCO BIOTECHNOLOGY CO LTD

Lysine preparing method

ActiveCN102559794AEasy to produceImprove filtration efficiencyMicroorganism based processesFermentationSugarLysine fermentation

The invention provides a lysine preparing method which ferments the lysine through the product of dry sugar manufacturing, divides the fermenting process into four steps, namely, increasing step of the number of lysine-producing microbe, first decreasing step of the number of lysine-producing microbe, retaining step of the number of lysine-producing microbe and second decreasing step of the number of lysine-producing microbe, adopts respective ventilation control, so as to enable the lysine-producing microbe to better produce the lysine, improve the fermenting efficiency of the lysine, and reduce the production cost of the lysine. Furthermore, as the control of the fermentation process is adjusted, the product of the dry sugar manufacturing can effectively ferment, so as to highlight the low cost of the dry sugar manufacturing, and integrally improve the economy of the preparing technology of the lysine.

Owner:COFCO BIOTECHNOLOGY CO LTD

Production method of lysine

ActiveCN102533891AIncrease production capacityIncrease end-point lysine contentMicroorganism based processesFermentationSulfateEconomic benefits

The invention discloses a production method of lysine. The method comprises the step of inoculating lysine fermentation strains into lysine fermentation media for fermentation culture under the condition of feeding a carbon source and a nitrogen source. The method is characterized by feeding nutrient salts into fermentation liquor after fermentation culture for 15 hours, wherein the nutrient salts comprise potassium chloride, magnesium sulfate and manganese sulfate. The production method has the following advantages: the content of final lysine, the acid supply quantity per tank and the conversion rate can be improved, namely improving the yield of lysine, thus improving the economic benefits.

Owner:COFCO BIOTECHNOLOGY CO LTD

Method for preparing bio-organic fertilizer by utilizing corn steep liquor and lysine fermentation waste liquid

InactiveCN109305831AAvoid wastingIncrease incomeBio-organic fraction processingBacteriaDecompositionWaste treatment

Owner:SHOUGUANG GOLDEN FAR EAST MODIFIED STARCH CO LTD +3

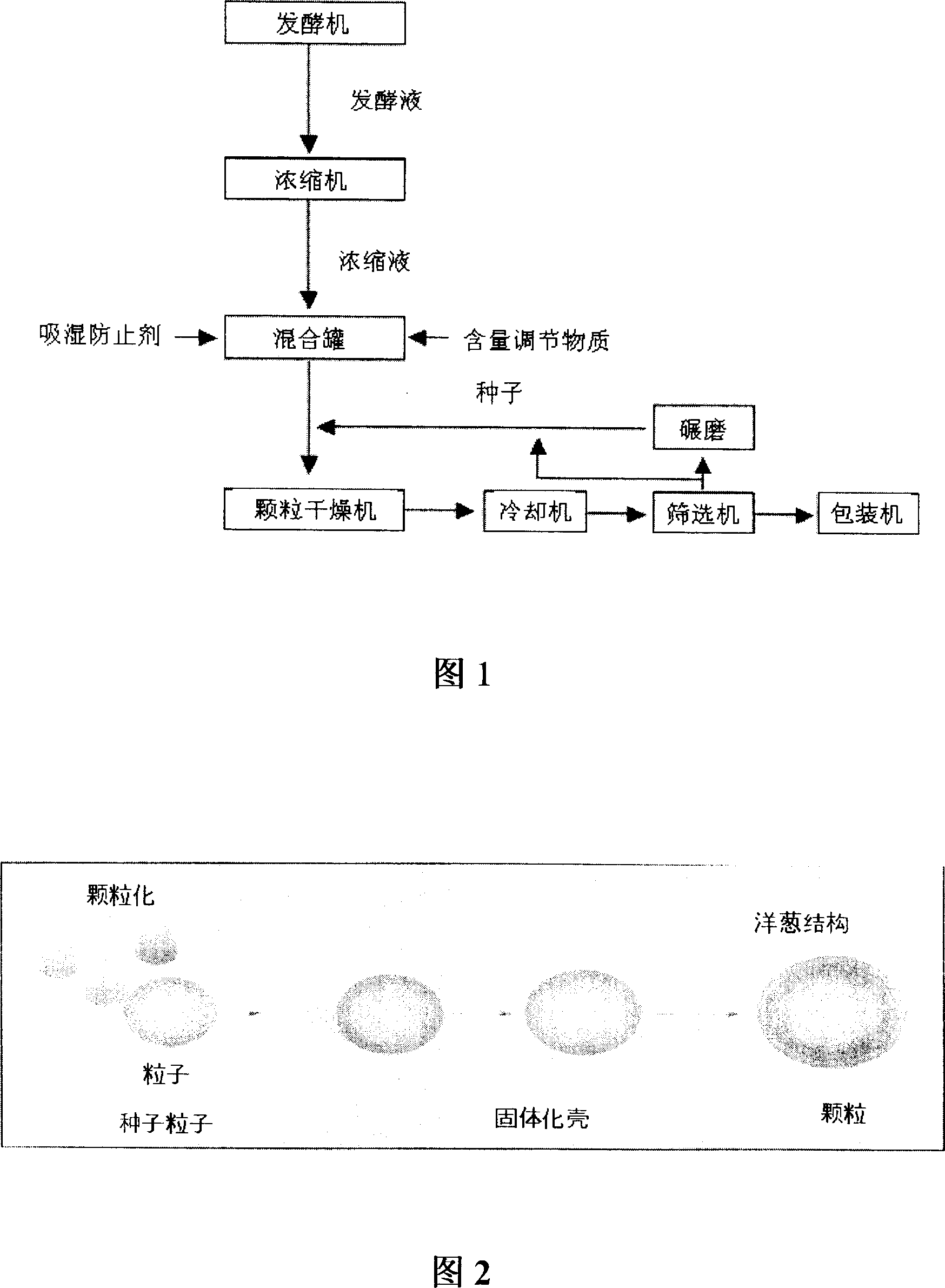

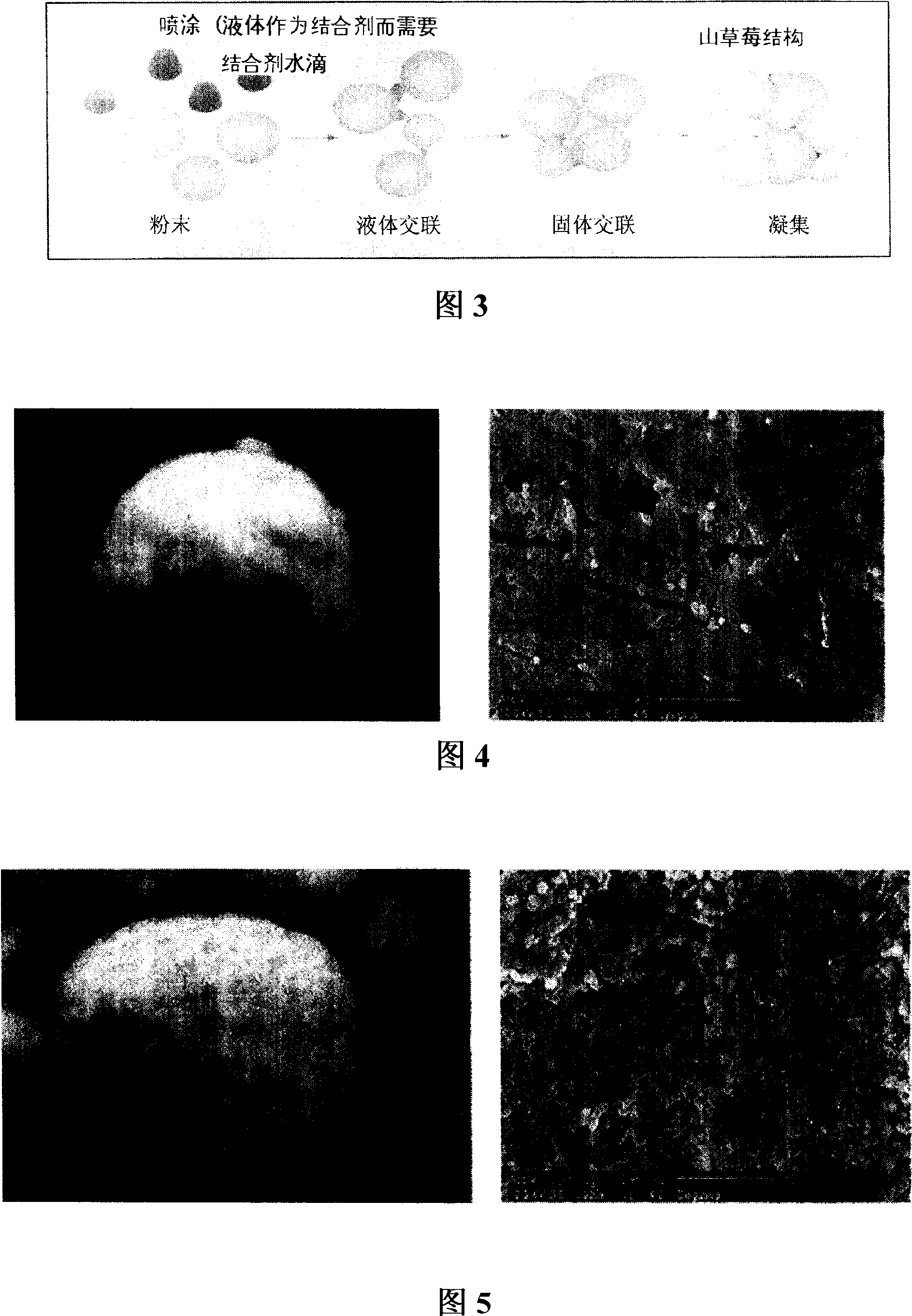

Animal feed additives based on fermentation broth and production process thereof by granulation

ActiveCN100998370AIncrease surface densityThe production process is simpleAnimal feeding stuffAccessory food factorsSolid componentFodder

A process for the production of animal feed additives from fermentation broth containing L-lysine is disclosed. The process does not require filtering of biomass in order to remove the biomass and produces granulated lysine of controllable lysine purity with a high bulk density, low viscosity, and a low hygroscopic property which does not require the addition of an anti-absorptive substance. In this process, a lysine fermentation broth produced after slant culture, flask culture, seed process, and cultivation process is concentrated to a solid content of about 44-52%. A product with low hygroscopicity, high bulk density, and the intended amount of purity is produced after being mixed with substances for controlling the amount of purity and granulated by coating the surface of the seeds. This process enables a production of animal feed additives having a lysine-HCl purity of at least 65%, a water content of at most 3%, and a bulk density of 670 + 50kg / D.

Owner:CJ CHEILJEDANG CORP

Fermentation and coating of lysine and compound enzyme

The invention provides a method for preparation of an L-lysine product by fermentation. An L-lysine fermentation solution is produced by fermentation; the L-lysine fermentation solution is mixed with high temperature-resistant dehydrated compound enzyme obtained by fermentation; and the mixture is dried and is coated by fat. The invention also provides a product and an enzyme obtained by the method.

Owner:NINGXIA EPPEN BIOTECH

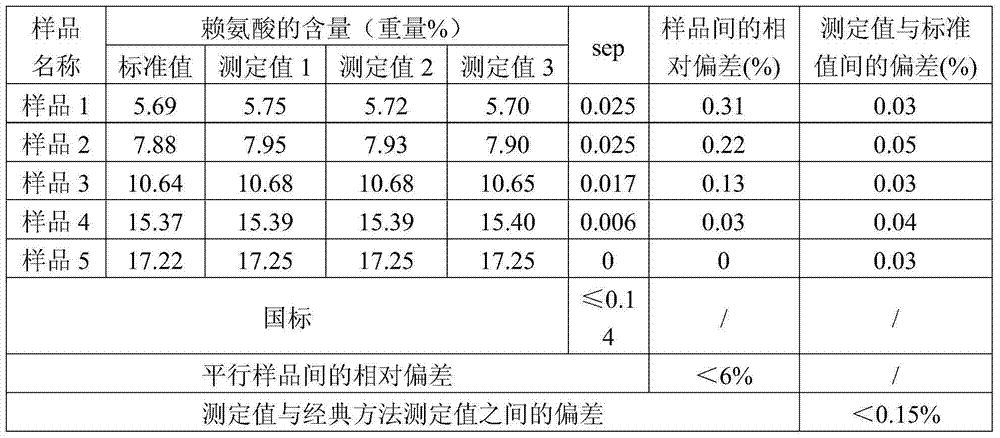

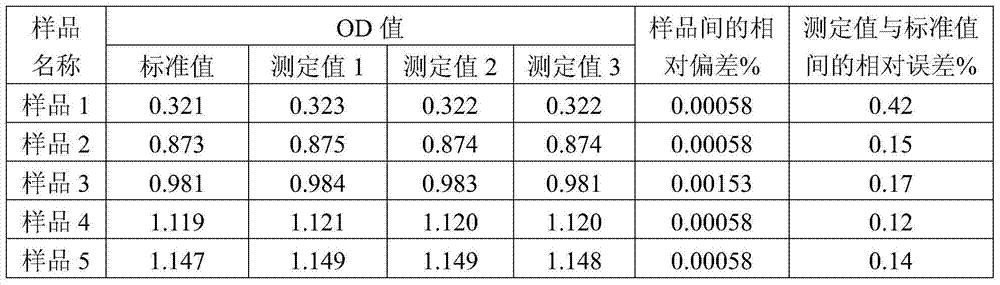

Analysis method of lysine fermentation liquid

ActiveCN103487398ASimultaneous determinationSynchronous contentMaterial analysis by optical meansTest sampleNitrogen

The invention discloses an analysis method of a lysine fermentation liquid. The lysine fermentation liquid contains lysine, fermentation strains, reducing sugar and amino nitrogen. The method comprises the steps as follows: near-infrared spectrograms of multiple standard samples of the lysine fermentation liquid are acquired; the content of the lysine, OD (optical density) values of the fermentation strains, the content of the reducing sugar and the content of the amino nitrogen in the multiple standard samples are obtained respectively; multiple linear regression equations of the content of the lysine, the OD values of the fermentation strains, the content of the reducing sugar and the content of the amino nitrogen as well as respective corresponding near infrared absorbance values are obtained respectively; and the content of the lysine, the OD values of the fermentation strains, the content of the reducing sugar and the content of the amino nitrogen in to-be-tested samples of the lysine fermentation liquid are calculated. According to the technical scheme, the purpose of synchronous, quick and safe measurement of the content of the lysine, the OD value of the fermentation strains, the content of the reducing sugar and the content of the amino nitrogen in the lysine fermentation liquid is achieved.

Owner:COFCO BIOTECHNOLOGY CO LTD

Method for preparing lysine fermentation culture medium by utilizing mycoprotein

InactiveCN110885863APromote fermentationPromote accumulationBacteriaMicroorganism based processesBiotechnologyMycoprotein

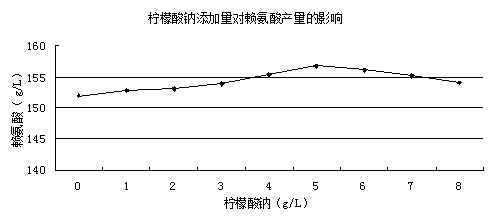

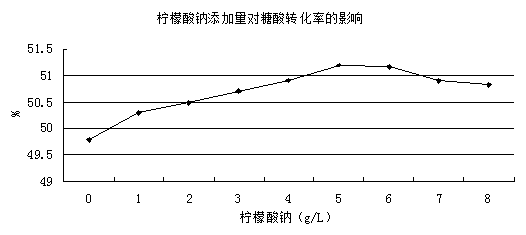

The invention belongs to the technical field of amino acid fermentation. The invention discloses a method for preparing a lysine fermentation culture medium by utilizing mycoprotein. The method comprises the steps of 1) taking the following raw materials: mycoprotein vinasse combined hydrolysate, glucose, molasses, ammonium sulfate, sodium citrate, monopotassium phosphate, magnesium sulfate heptahydrate, manganese sulfate tetrahydrate, ferrous sulfate heptahydrate, vitamin B1 and biotin; and (2) sequentially adding the raw materials into water, uniformly stirring, adjusting the pH value to 7.8by using a NaOH aqueous solution, and sterilizing for 10 minutes at 115 DEG C. According to the method disclosed by the invention, the lysine fermentation culture medium is prepared by using mycoprotein and vinasse as main raw materials, so that the cost is greatly reduced.

Owner:齐齐哈尔龙江阜丰生物科技有限公司

Method for enhancing fermentation yield of lysine

InactiveCN104498554ALow priceIncrease productionMicroorganism based processesFermentationMinor elementGlucose polymers

The invention provides a novel method for enhancing fermentation yield of lysine, which comprises the following steps: by using Corynebacterium glutamicum as a lysine fermentation strain, converting the glucose in the seed tank culture medium and fermentation tank culture medium into equivalent cassava liquefaction solution, and carrying out fermentation culture under the conditions of feeding a carbon source, a nitrogen source and minor elements. The cheap accessible cassava is used as the raw material, and the liquefaction substance of the cassava is used as the carbon source instead of the glucose in the lysine seed tank and fermentation tank culture medium, thereby enhancing the lysine yield, increasing the conversion rate, reducing the raw material expenses and further lowering the cost.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

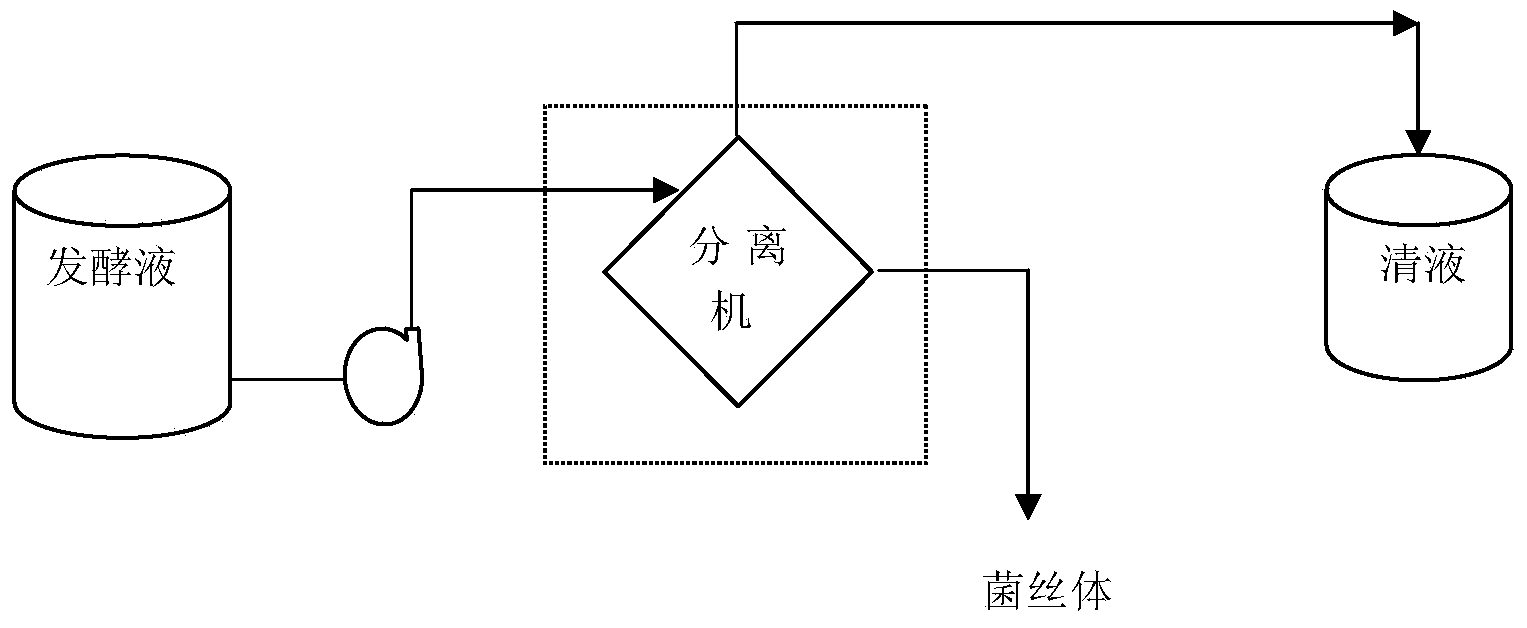

Extraction process of lysine fermentation liquor

InactiveCN103450041ALess investmentHigh yieldOrganic compound preparationChemical industryControl systemLysine fermentation

The invention provides a new process of extracting lysine fermentation liquor by adopting a separator in a lysine production process. The technical process for the extraction of the lysine fermentation liquor comprises two stages as follows: a first stage for treating fermentation liquor; and a second stage for extracting lysine from the materials (which are treated in the first stage) through a process control system, wherein mycelia formed by separating are discharged from the bottom of the separator through a screw pump; and clear liquor is discharged from the top of the separator through a centripetal pump. The extraction process of the lysine fermentation liquor has the advantages of low investment, high benefit, high device efficiency, energy-saving and the like.

Owner:长治市金泽生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com