Method for preparing 1,5-pentanediamine

A technology for the fermentation of pentamethylenediamine and lysine, which is applied in directions such as fermentation to achieve the effects of simple process, cost saving and reduction of purification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0048] Preparation Example 1. Preparation of lysine fermentation stoste

[0049] Prepare lysine fermentation stock as follows

[0050] (1) Slope: use LB medium

[0051] LB medium: containing 1% peptone, 0.5% yeast powder, 1% sodium chloride, pH 7.0.

[0052] (2) Seed cultivation

[0053] The corynebacterium slant with lysine production ability was inoculated in 200 ml of liquid medium (broth medium: beef extract 1%, peptone 1%, yeast extract 0.5%, sodium chloride 0.5%, pH 7.0 ) in a 500ml seed bottle at 33°C and 200rmp shaker for 10-15 hours.

[0054] (3) Lysine fermentation

[0055] In a 10L fermenter, add 5L of fermentation medium. Insert above-mentioned seed liquor and start to ferment. The fermentation medium of the fermenter contains: glucose 8%, molasses 1.2%, corn steep liquor 1%, ammonium sulfate 0.6%, dipotassium hydrogen phosphate 2%, magnesium sulfate heptahydrate 0.08%, iron sulfate heptahydrate 0.002%, sulfuric acid tetrahydrate Manganese 0.002%, the balanc...

preparation Embodiment 2

[0059] Preparation Example 2. Preparation of Lysine Decarboxylase Fermentation Broth

[0060] The lysine decarboxylase fermentation broth was prepared as follows:

[0061] (1) Seed cultivation

[0062] Inoculate the liquid medium (LB medium containing 1% of peptone, 0.5% of yeast powder, and 1% of sodium chloride) with 100 ml of liquid liquid culture medium (LB medium, containing 1% of peptone) by inoculating the glycerol-preserved bacterial liquid of haffney genetically engineered bacteria expressing lysine decarboxylase , pH7.0) in a 500ml seed bottle at 35°C, 170rmp shaker for 15 hours.

[0063] (2) Lysine decarboxylase fermentation

[0064] In a 5L fermenter, add 3 liters of LB medium, and start fermentation by inserting the above seed liquid after sterilizing at 121°C for 20 minutes (the formula of the fermentation medium is LB medium: peptone 1%, yeast powder 0.5%, sodium chloride 1%, pH7.0), start fermentation at 30°C and 300 rpm, control the air flow rate to 0.3...

Embodiment 1

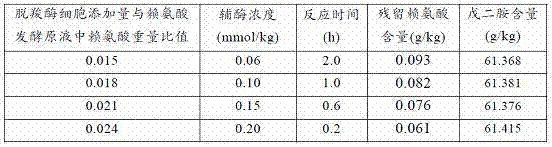

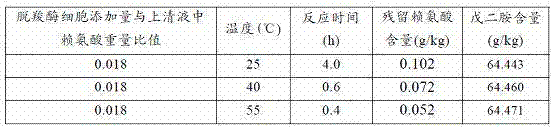

[0065] Embodiment 1. Lysine decarboxylase catalyzes lysine fermentation stoste

[0066] The lysine fermentation stoste that takes a certain amount of Preparation Example 1 method to obtain joins in the 500ml Erlenmeyer flask, and the lysine content is 11%; SO in the lysine fermentation stoste 4 2- The concentration is about 0.23mol / kg, which also contains sugar and free NH 4 + , total sugar content 350ppm, free NH 4 +The content is 0.032mol / kg. Add lysine decarboxylase cells (obtained by the method of Preparation Example 2, the same below) and coenzyme (5'-pyridoxal phosphate) to this lysine fermentation stoste, and shake the reaction for a certain period of time at a stirring speed of 200rpm, The reaction temperature was set at 38°C; the weight ratio of lysine decarboxylase in the reaction system to the weight ratio of lysine in the lysine fermentation stock solution, the coenzyme concentration (the ratio of the coenzyme added to the weight of all reaction materials exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com