Lysine fermentation process feeding prediction control system and method based on fuzzy neural network

A technology of fuzzy neural network and lysine fermentation, applied in general control system, control/regulation system, adaptive control, etc., can solve problems such as poor loop coupling and inability to adapt to the dynamic characteristics of the fermentation process, etc. The effect of strong generalization ability, enhanced adaptive ability, and strong reasoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

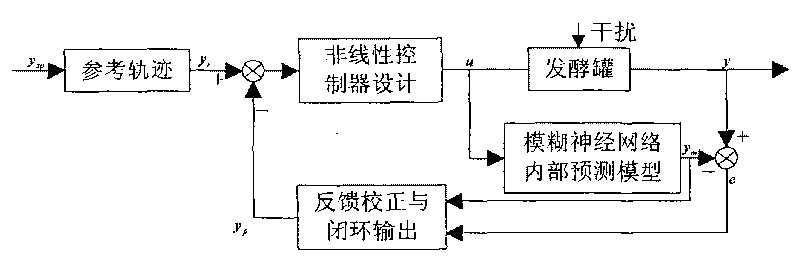

[0028] follow below figure 1 The basic framework shown is described in detail.

[0029] 1. Establish a nonlinear prediction model based on fuzzy neural network

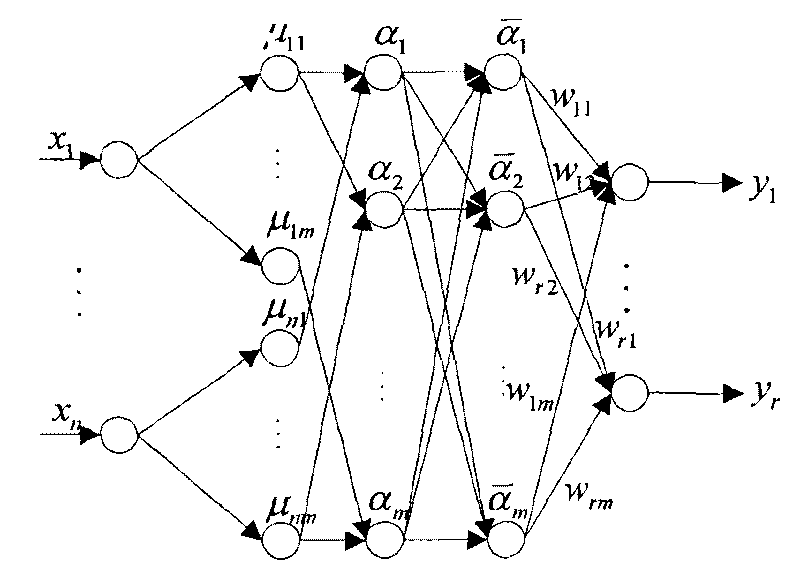

[0030] Model Neural Network (FNN) is a five-layer adaptive neural network that introduces fuzzy operations, and combines the advantages of fuzzy logic and neural networks. The input and output relationship of fuzzy neural network is as follows: figure 2 shown.

[0031] Wherein the first layer is the input layer, and each node of this layer is directly connected with each component of the input vector, which plays a role of input value=[x 1, x 2 ,...,x n ] to the next layer, the number of nodes in this layer is N 1 = n; the second layer is the membership function layer, and each node in this layer completes the function of a Gaussian membership function, for the jth node of the i variable in this layer:

[0032] μ ij ( x i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com