Recycling method of lysine fermented waste liquid

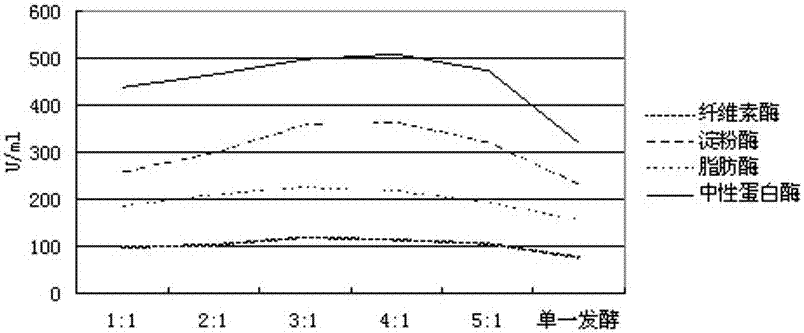

A technology for lysine fermentation and fermentation waste liquid, which is applied in microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve the problems of limited use of wastewater and high cost of medium raw materials, and achieves high utilization rate and crude oil. The effect of high protein content and enhanced enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for recycling lysine fermentation waste liquid, comprising the steps of:

[0031] Step 1) Adjust the pH: add a sulfuric acid solution with a concentration of 2M to the fermentation waste liquid, and adjust the pH of the fermentation waste liquid to 6.8;

[0032] Step 2) Prepare strain culture medium: take 1L as an example, take glucose 90g, yeast powder 30g, MgSO 4 12g, K 2 HPO 4 5g, KH 2 PO 4 5g, FeSO 4 1g and CaCO 3 1g, add to the fermentation waste liquid obtained in step 1), adjust the pH to 6.8, and set the volume to 1L;

[0033] Step 3) Preparation of compound bacterial liquid: Bacillus subtilis seed liquid (1×10 8 individual / ml) and Bacillus licheniformis seed solution (1×10 8 per ml) were mixed according to the volume ratio of 3:1, and then transferred to the strain culture solution according to the volume ratio of 6%, and cultivated at 32°C for 12 hours to obtain the composite bacterial solution;

Embodiment 2

[0040] A method for recycling lysine fermentation waste liquid, comprising the steps of:

[0041] Step 1) Adjust the pH: add a sulfuric acid solution with a concentration of 3M to the fermentation waste liquid, and adjust the pH of the fermentation waste liquid to 6.8;

[0042] Step 2) Prepare strain culture medium: take 1L as an example, take glucose 90g, yeast powder 30g, MgSO 4 12g, K 2 HPO 4 5g, KH 2 PO 4 5g, FeSO 4 1g and CaCO 3 1g, add to the fermentation waste liquid obtained in step 1), adjust the pH to 6.8, and set the volume to 1L;

[0043] Step 3) Preparation of compound bacterial liquid: Bacillus subtilis seed liquid (1×10 8 individual / ml) and Bacillus licheniformis seed solution (1×10 8 per ml) were mixed according to the volume ratio of 4:1, and then transferred to the strain culture solution according to the volume ratio of 6%, and cultivated at 32°C for 12 hours to obtain the composite bacterial solution;

[0044] Step 4) Prepare algae culture sol...

Embodiment 3

[0050] The lysine fermentation waste liquid used in the present invention is the raffinate after extracting lysine and bacteria from the fermentation liquid, and the content of each main component is: sugar 15-20g / L, fatty substance 3-5 g / L L. Crude protein 20-30g / L, COD 1500-2000mg / L, ammonia nitrogen 200-300mg / L and SS 150-200mg / L.

[0051] Taking Example 1 as an example, the components in the fermented liquid obtained in the analysis step 7) are: COD is 27 mg / L, ammonia nitrogen is 11 mg / L and SS is 18 mg / L; It can reach more than 100mg / L, and at the same time, the level of pollutants in the liquid is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com