Lysine preparing method

A technology for lysine and lysine production, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as low fermentation efficiency, and achieve the effects of improving fermentation efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

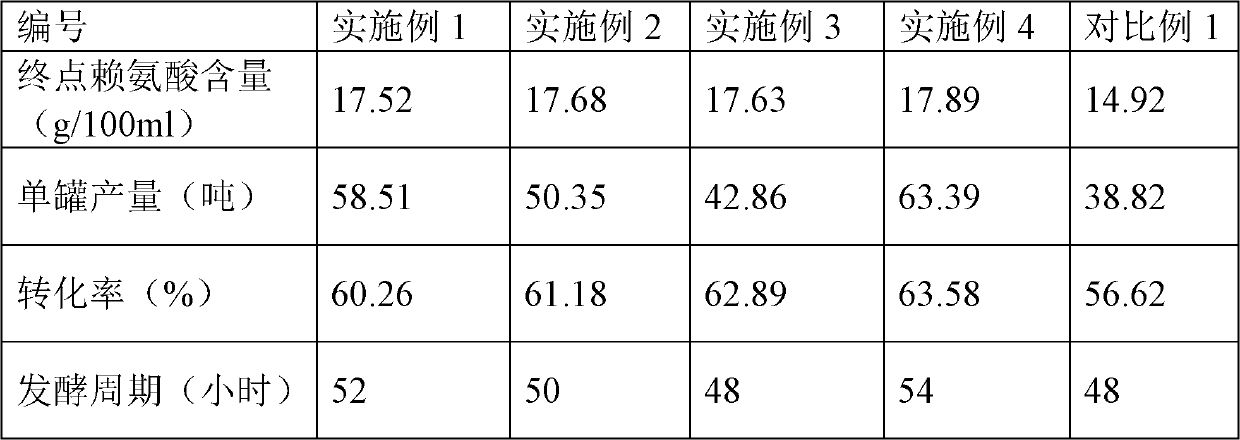

Examples

preparation example Construction

[0010] The invention provides a method for preparing lysine. The method comprises: inoculating lysine-producing microorganisms into fermentation broth and fermenting to produce lysine. During the fermentation process, according to the amount of carbon source and nitrogen source in the fermentation broth , adding carbon source and / or nitrogen source, wherein, the process of fermenting and producing lysine includes: the rising stage of the number of lysine-producing microorganisms, the first decline stage of the number of lysine-producing microorganisms, the increase of the number of lysine-producing microorganisms The maintenance stage and the second decline stage of the number of lysine-producing microorganisms; wherein, in the rising stage of the number of lysine-producing microorganisms, the ventilation rate increases with the increase of the fermentation broth volume; During the first decline phase and the maintenance phase of the lysine-producing microbial population, the a...

Embodiment 1

[0043] This example is used to illustrate the preparation method of lysine provided by the present invention.

[0044] (1) Machining 100 parts by weight of harvested corn to pulverize corn grains, so that the passing rate of corn flour through a 30-mesh sieve is 80%.

[0045] (2) Add water to the pulverized product to 12Be°, add 20 enzyme activity units of amylase (Novozymes, a-amylase) relative to the dry weight of each gram of the pulverized product, and heat it at 85°C, Enzymolysis was carried out for 100 minutes under the condition of pH 5.5 to obtain an enzymolysis product. Wherein, the enzymolysis product is filtered by a hydraulic plate and frame filter press, and the enzymolysis clear liquid (solid content is 20% by weight) is separated; 115 enzyme activity units of glucoamylase (α-1, 4 - Glucose hydrolase, Novozymes), enzymolysis at 60°C and pH 4.5 for 420 minutes to obtain saccharification serum A1 of starchy raw materials.

[0046] (3) Use the starchy raw material...

Embodiment 2

[0050] This example is used to illustrate the preparation method of lysine provided by the present invention.

[0051]Prepare lysine according to the method for embodiment 1, difference is: the initial total volume of fermented liquid is 120 cubic meters, and initial ventilation is 30 cubic meters of air / minute (the unit ventilation is 0.67 cubic meters of air / cubic meter broth / min). The tank pressure is 0.08MPa, the fermentation temperature is controlled at 36°C, and the pH is adjusted with liquid ammonia to maintain it at 6.8. During the fermentation process, the number of lysine-producing microorganisms was measured several times, and the two adjacent values were compared to determine the stage of fermentation (from the 0th hour to the 14th hour, every 30 minutes, and the 14th hour From then on to the 24th hour, check once every 60 minutes, from the 24th hour to the 48th hour, check once every 120 minutes, from the 48th hour to the end of fermentation, check once every 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com