Preparation process of 1,5-pentamethylene diamine

A technology of pentamethylenediamine and seeds, which is applied in the field of preparation of 1,5-pentamethylenediamine, can solve the problems of short fermentation period, toxicity of pentamethylenediamine microbial strains, etc., and achieve short production period, low cost and reduced toxicity impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 prepares lysine fermented liquid

[0040] (1) Inclined surface: use LB medium

[0041] LB medium: peptone 1%, yeast extract 1%, sodium chloride 0.5%, pH 7.2.

[0042] (2) Primary seed medium (shake flask seed medium)

[0043] The lysine producing strain used is Escherichia coli (Escherichia coli) ELa6116 (preservation number: CCTCCNO: M 2018736).

[0044] Get a ring of Escherichia coli (Escherichia coli) ELA6116 slant bacterial classification, inoculate in 100 milliliters of liquid culture medium (broth culture medium: beef extract 1%, peptone 1%, yeast extract 0.5%, sodium chloride 0.5%, pH Value 7.0) in the 500 milliliter seed bottle, at 33 ℃, 200rmp shaker culture 15-20 hour, obtain lysine primary seed liquid.

[0045] (3) Lysine fermentation conditions

[0046] In a 500mL Erlenmeyer flask, add 100mL of fermentation medium, insert 4mL of the above-mentioned lysine primary seed solution, and start fermentation at a temperature of 33°C and a shaker spe...

Embodiment 2

[0048] Embodiment 2 prepares the seed liquor of producing lysine decarboxylase bacterial strain

[0049] The strain used: Hafnia alvei strain Am607 (deposit number: CCTCC NO: M2018737).

[0050] Method: Take 200uL of the glycerol-preserved bacterial solution of the strain, inoculate it into a 500mL seed bottle filled with 100mL liquid seed medium, and culture it on a shaker at 35°C and 170rmp for 15 hours to obtain the seed solution of the lysine decarboxylase-producing strain. After testing, the content of lysine decarboxylase in the seed liquid is no more than 20U / mL.

[0051] LB medium: peptone 1%, yeast powder 0.5%, sodium chloride 1%, pH 7.0.

[0052] If no special instructions, following examples and comparative example adopt embodiment 1,2 method to prepare lysine fermented liquid and produce the seed liquid of lysine decarboxylase bacterial strain.

Embodiment 3

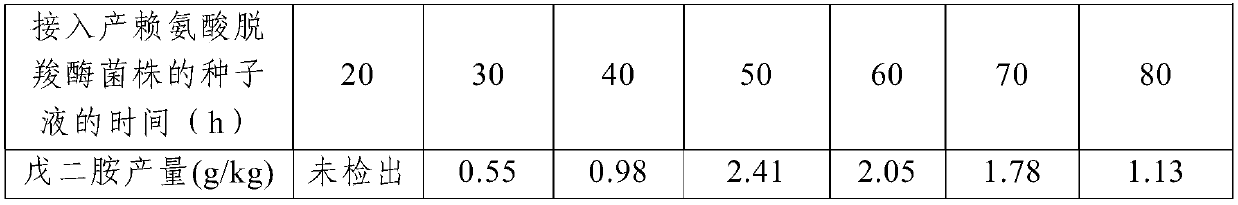

[0054] Take 1mL of the seed liquid of the lysine decarboxylase-producing strains cultured for 15 hours, respectively, and transfer them into the lysine fermentation broth fermented to 20h, 30h, 40h, 50h, 60h, 70h and 80h, without controlling the pH value of the fermentation process. Shake culture at 200rpm at 35°C. When the content of pentamethylenediamine no longer increases, it is judged that the fermentation is over. The actual incubation time is 20h, and the content of pentamethylenediamine in the fermentation broth is measured at the end of the fermentation. The results are shown in Table 1.

[0055] Table 1

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com