Waste and old road asphalt regenerating agent and preparation method thereof

A technology of road asphalt and regenerant, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of high volatility of regenerant, insufficient service life of regenerated asphalt, increased source of petroleum products and difficulty in obtaining them, and achieves Improve the performance of waste asphalt, good anti-aging performance, and realize the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

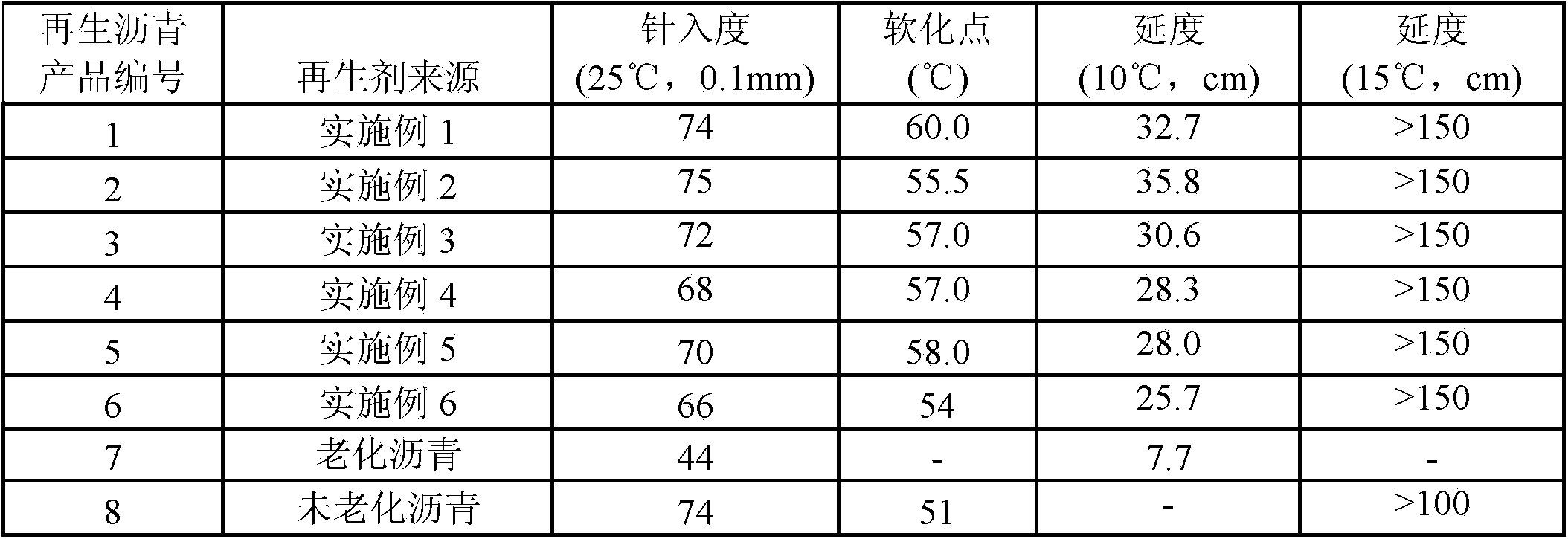

Embodiment 1

[0037] Mix 100g of petroleum asphalt, 250g of aromatic oil, and 50g of biomass pyrolysis oil at 120°C for 15 minutes, then add 150g of disproportionated rosin and 25g of styrene-butadiene rubber, and shear at 160°C for 30 minutes at a shear rate of 4000r / min.

Embodiment 2

[0039] Mix 125g of petroleum asphalt, 250g of aromatic oil, and 50g of biomass pyrolysis oil at 120°C for 15 minutes, then add 50g of disproportionated rosin and 25g of styrene-butadiene rubber, and shear at 160°C for 40 minutes at a shear rate of 4000r / min.

Embodiment 3

[0041] Mix 165g of petroleum asphalt, 225g of aromatic oil, and 40g of biomass pyrolysis oil at 120°C for 15 minutes, then add 50g of disproportionated rosin and 20g of styrene-butadiene rubber, and shear at 150°C for 40 minutes at a shear rate of 4000r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com