TGBAPOPP type matrix resin used for preparing advanced composite and preparation method of TGBAPOPP type matrix resin

An advanced composite material and matrix resin technology, applied in the field of polymer materials and its preparation, can solve the problems of high cost of polyetherimide resin, unfavorable large-scale popularization and application, small linear expansion coefficient, etc., and achieve good comprehensive performance, The effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

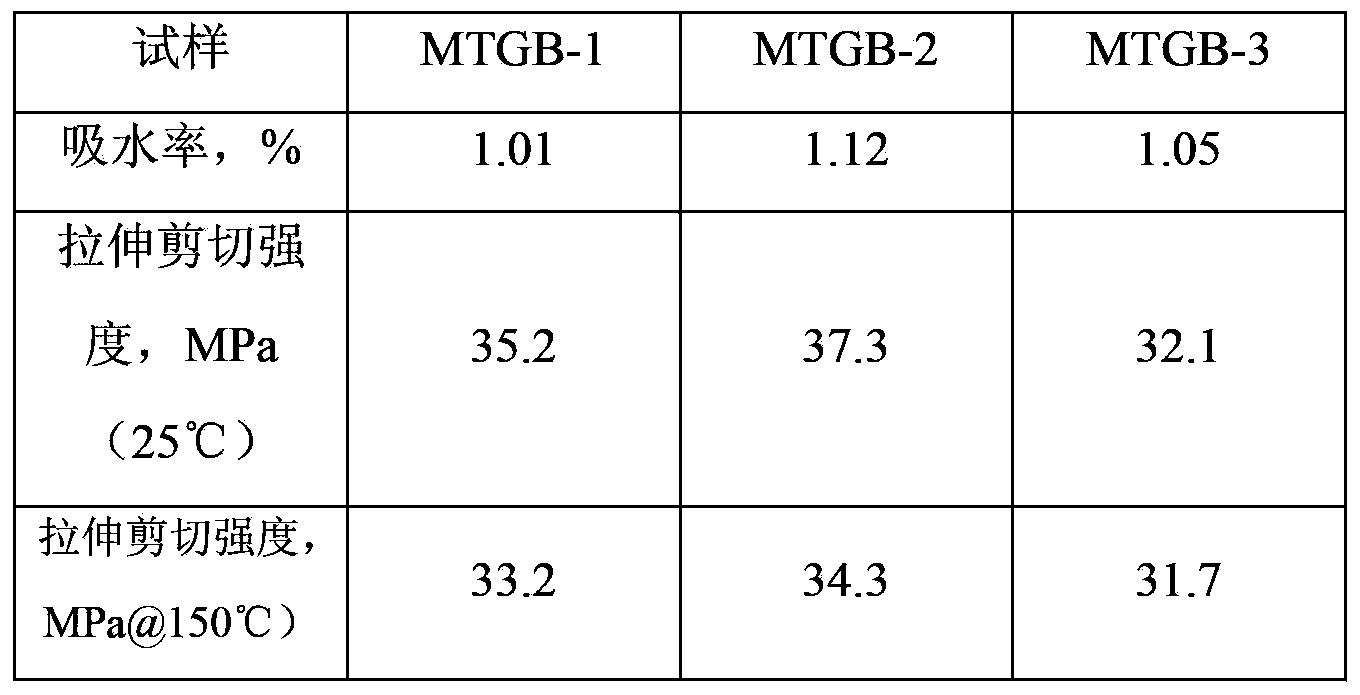

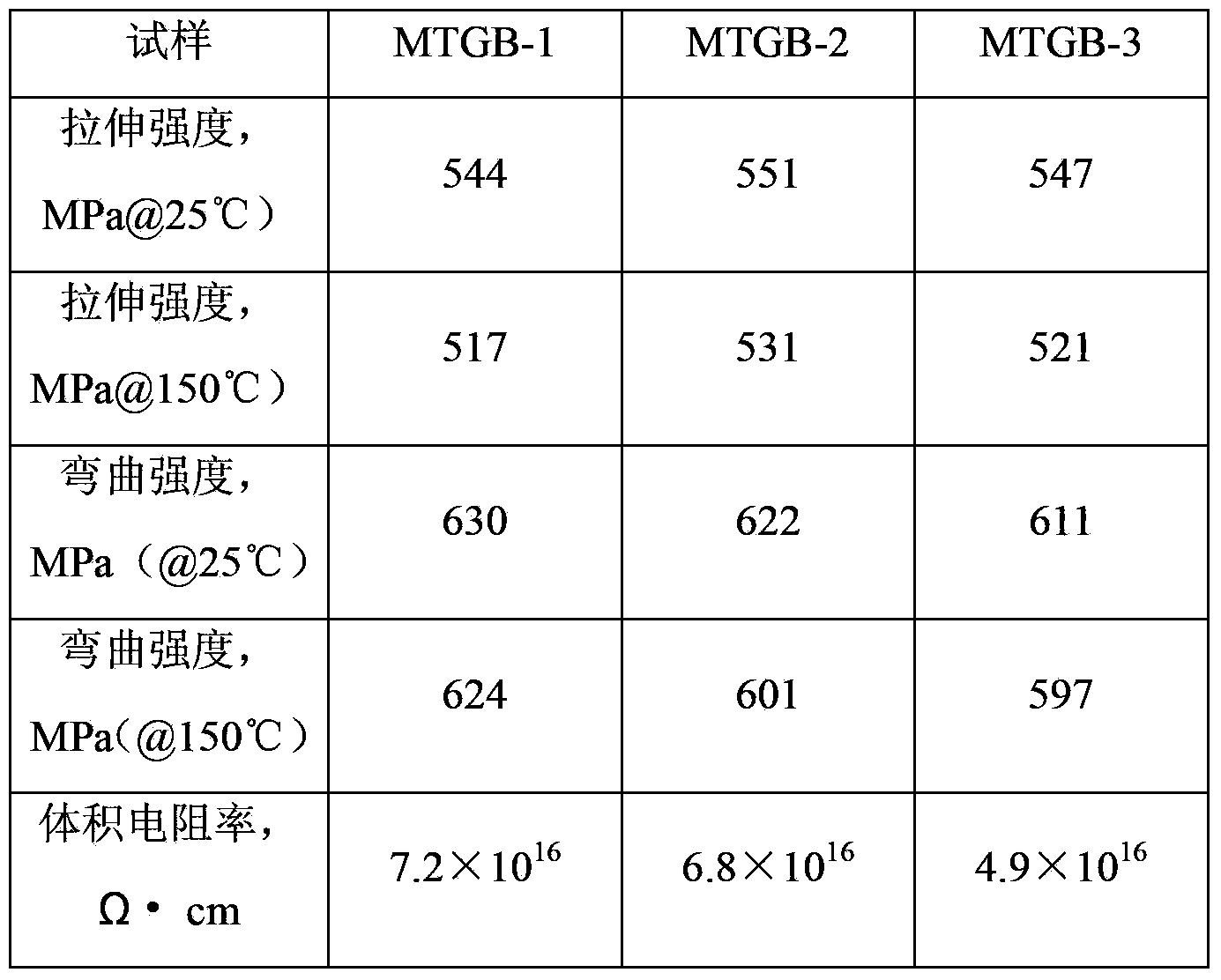

Embodiment 1

[0038] 1000 grams of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane (TGBAPOPP), 500 grams of o-cresol novolac epoxy resin , 150 grams of 2,2-bis[4-(4-maleimidophenoxy)phenyl]propane was put into the reaction kettle, and after reacting at 90°C for 1 hour, 1000 grams of N-iso Propyl-N'-phenyl-p-phenylenediamine solution (20 g N-isopropyl-N'-phenyl-p-phenylenediamine, 250 g dichloromethane and 730 g acetone), 1100 g 2,2,4 - Trimethyl-1,2-dihydroquinoline solution (50 grams of 2,2,4-trimethyl-1,2-dihydroquinoline and 1050 grams of acetone), stir and mix well, add 3900 grams of curing agent Solution (830 g 4,4'-bis(4-aminophenoxy)diphenylsulfone, 100 g 2,4,6-tris(dimethylaminomethyl)phenol and 2970 g N-methyl-2-pyrrolidone ), stirred and mixed evenly to obtain 7650 grams of TGBAPOPP matrix resin for advanced composite materials, denoted as MTGB-1.

Embodiment 2

[0040] 1000 grams of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane (TGBAPOPP), 800 grams of o-cresol novolac epoxy resin , 100 grams of 2,2-bis[4-(4-maleimidophenoxy)phenyl]propane was put into the reaction kettle, and after reacting at 100°C for 0.5 hours, 1100 grams of N-iso Propyl-N'-phenyl-p-phenylenediamine solution (50 g of N-isopropyl-N'-phenyl-p-phenylenediamine and 1050 g of acetone), 1100 g of 2,2,4-trimethyl-1 , 2-dihydroquinoline solution (20 grams of 2,2,4-trimethyl-1,2-dihydroquinoline and 1080 grams of acetone), stir and mix well, add 5500 grams of curing agent solution (200 grams of 2, 2-bis[4-(4-aminophenoxy)phenyl]propane, 200 grams of 3,4'-diaminodiphenyl ether, 100 grams of p-phenylenediamine, 130 grams of 2,4,6-tris(di Methylaminomethyl) phenol and 3070 gram N-methyl-2-pyrrolidone, 1800 gram dichloromethane), stir and mix uniformly, obtain 9600 gram advanced composite material TGBAPOPP type matrix resin, denote as MTGB-2.

Embodiment 3

[0042] 1000 grams of N,N,N',N'-tetraglycidyl-2,2-bis[4-(4-aminophenoxy)phenyl]propane (TGBAPOPP), 1000 grams of o-cresol novolac epoxy resin , 300 grams of 2,2-bis[4-(4-maleimidophenoxy)phenyl]propane was put into the reactor, and after reacting at 100°C for 1 hour, 1300 grams of N-iso Propyl-N'-phenyl-p-phenylenediamine solution (50 g N-isopropyl-N'-phenyl-p-phenylenediamine and 1250 g acetone), 1400 g 2,2,4-trimethyl-1 , 2-dihydroquinoline solution (50 grams of 2,2,4-trimethyl-1,2-dihydroquinoline and 1350 grams of acetone), stir and mix well, add 6000 grams of curing agent solution (150 grams of 2, 2-bis[4-(4-aminophenoxy)phenyl]propane, 250 g 1,3-bis(3-aminophenoxy)benzene, 300 g 3,3'-dimethyl-4,4 '-Diaminodiphenylmethane, 180 g 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane, 120 g 2,4,6-tris(dimethylaminomethyl)phenol and 3,000 grams of N-methyl-2-pyrrolidone, 2,000 grams of N,N-dimethylformamide), and stir and mix evenly to obtain 11,000 grams of TGBAPOPP matrix re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com