Method for preparing instant high-calcium milk powder

A high-calcium, milk powder technology, applied in the direction of milk preservation, milk preparations, separation methods, etc., can solve the problems of poor emulsion stability, easy caking of milk powder, short shelf life, etc., to achieve anti-caking, prolong product shelf life, Good brewing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of this instant high-calcium milk powder specifically comprises the following steps:

[0031] Step 1: Mix milk powder, high-calcium protein powder, white granulated sugar, xanthan gum, maltodextrin, multivitamins and minerals, and stir evenly to obtain a mixed solution. The mixed solution is vacuum concentrated to obtain a concentrated solution, and then in a fluidized bed Spray soybean lecithin on the concentrate in the form of mist, then dry, cool and sieve to obtain the first product;

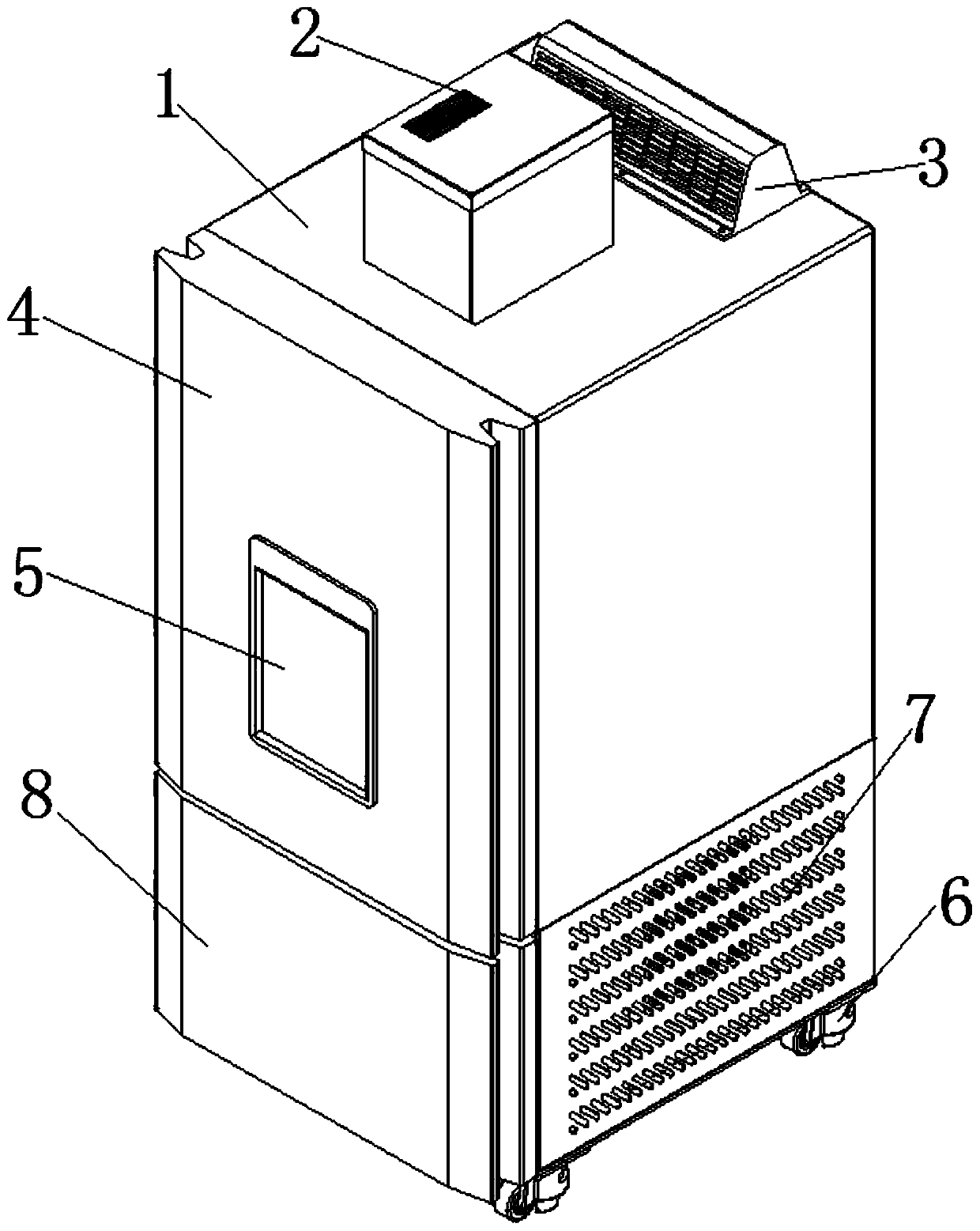

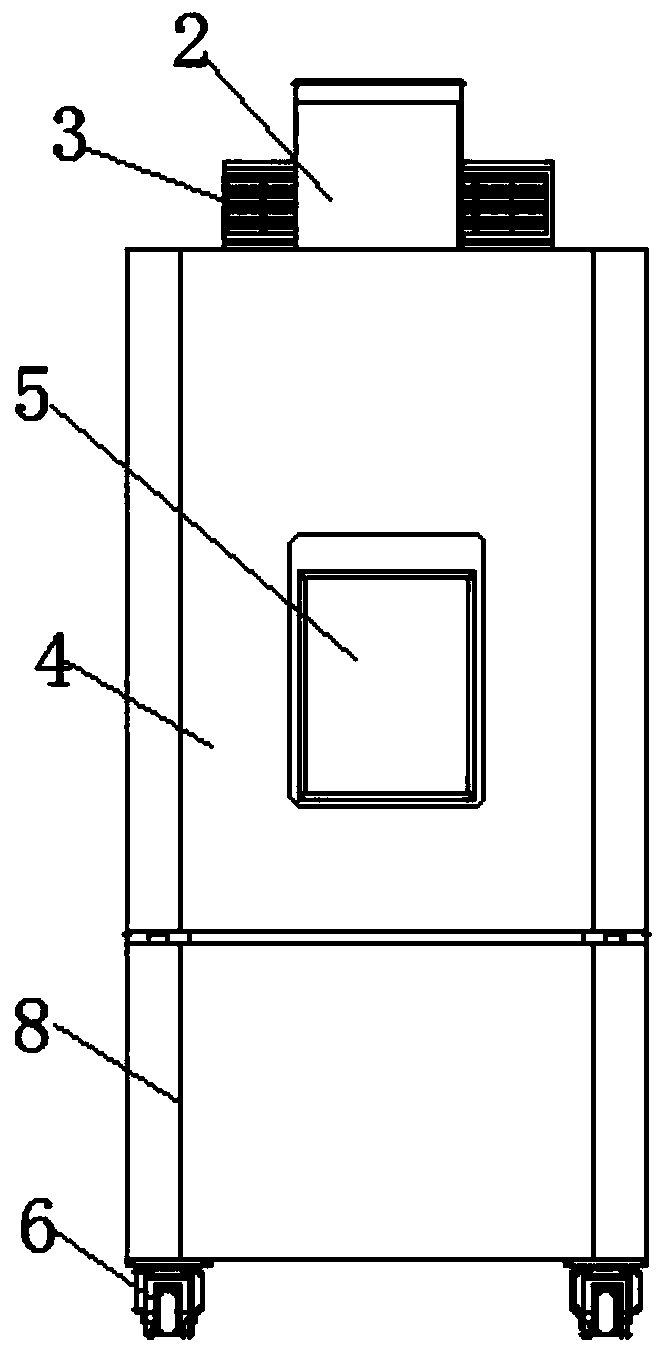

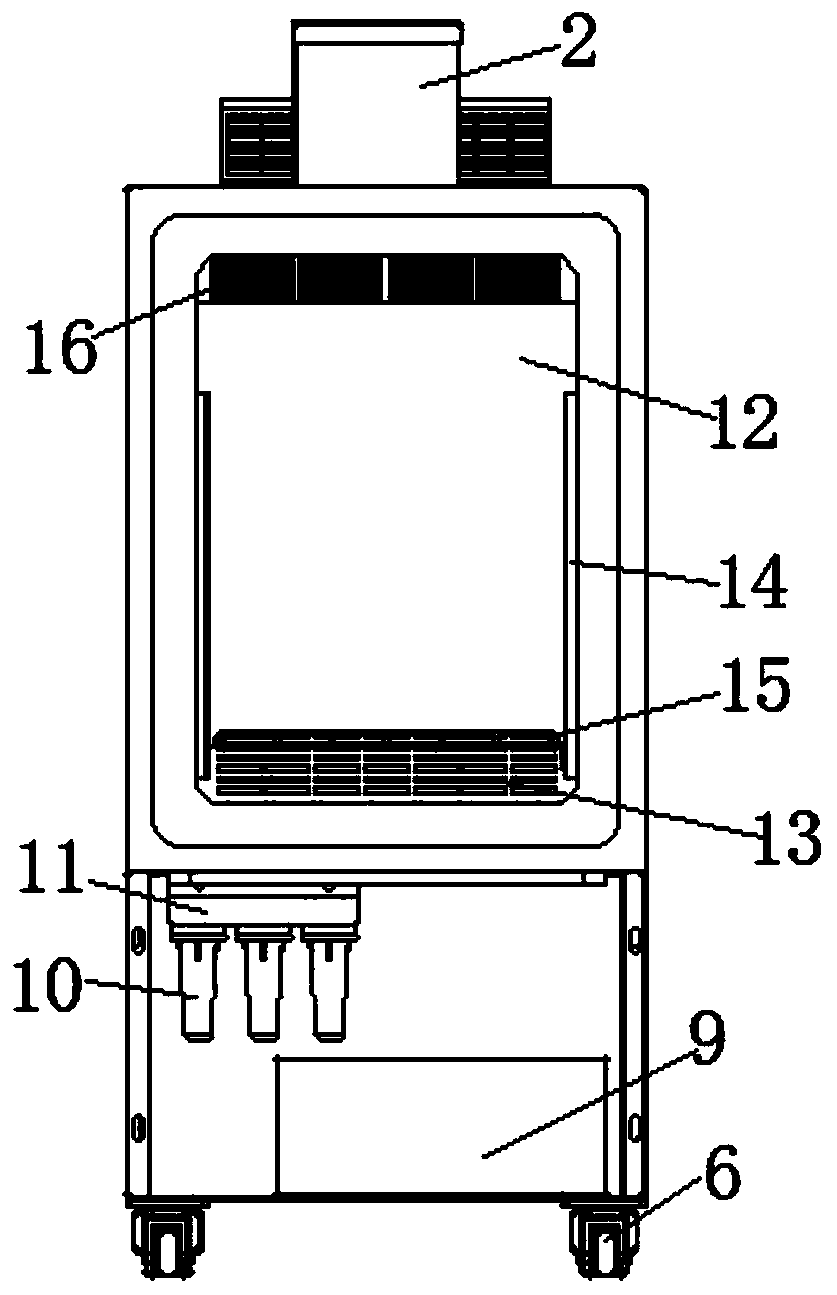

[0032]Step 2: Put the first product into the tray, then put the tray into the surface of the top of the support frame 15 inside the sterilization box, start the fan 24, the outside air first passes through the ventilation hood 3, and then passes through the second filter plate 25 After being filtered, it enters the inside of the box body 1, and then passes through the second orifice plate 16 to exchange heat with the first product, then passes through the first ...

Embodiment 1

[0037] see Figure 1-8 Shown, a kind of preparation method of instant high-calcium milk powder, this instant high-calcium milk powder is produced by the raw material of following parts by weight: milk powder 100 parts, high-calcium protein powder 70 parts, soybean lecithin 15 parts, white granulated sugar 6 parts, yellow 2 parts of raw gum, 3 parts of maltodextrin, 5 parts of multivitamins, and 6 parts of minerals; the multivitamins include vitamin A and vitamin D in a ratio of 1:1, and the minerals include iron sulfate, potassium iodide, sulfuric acid One or more of magnesium and manganese sulfate;

[0038] The preparation method of this instant high-calcium milk powder specifically comprises the following steps:

[0039] Step 1: Mix milk powder, high-calcium protein powder, soybean lecithin, white sugar, xanthan gum, maltodextrin, multivitamins and minerals, stir evenly to obtain a mixed solution, and use a double-effect falling film evaporator to process the mixed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com