Patents

Literature

100results about How to "Volume expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Experimental device and experimental method for thickened oil pool mixed nano-fluid alternating CO2 microbubble flooding

ActiveCN110130859AReduce oil-water interfacial tension and heavy oil viscosityChange wettabilitySurveyFluid removalOil pullingOil viscosity

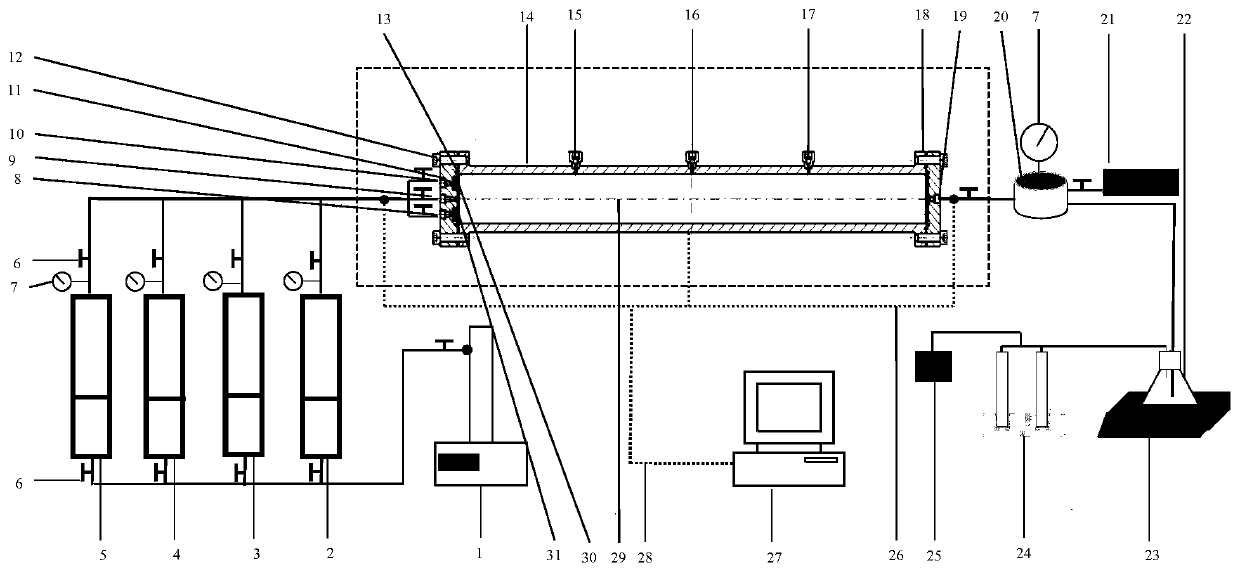

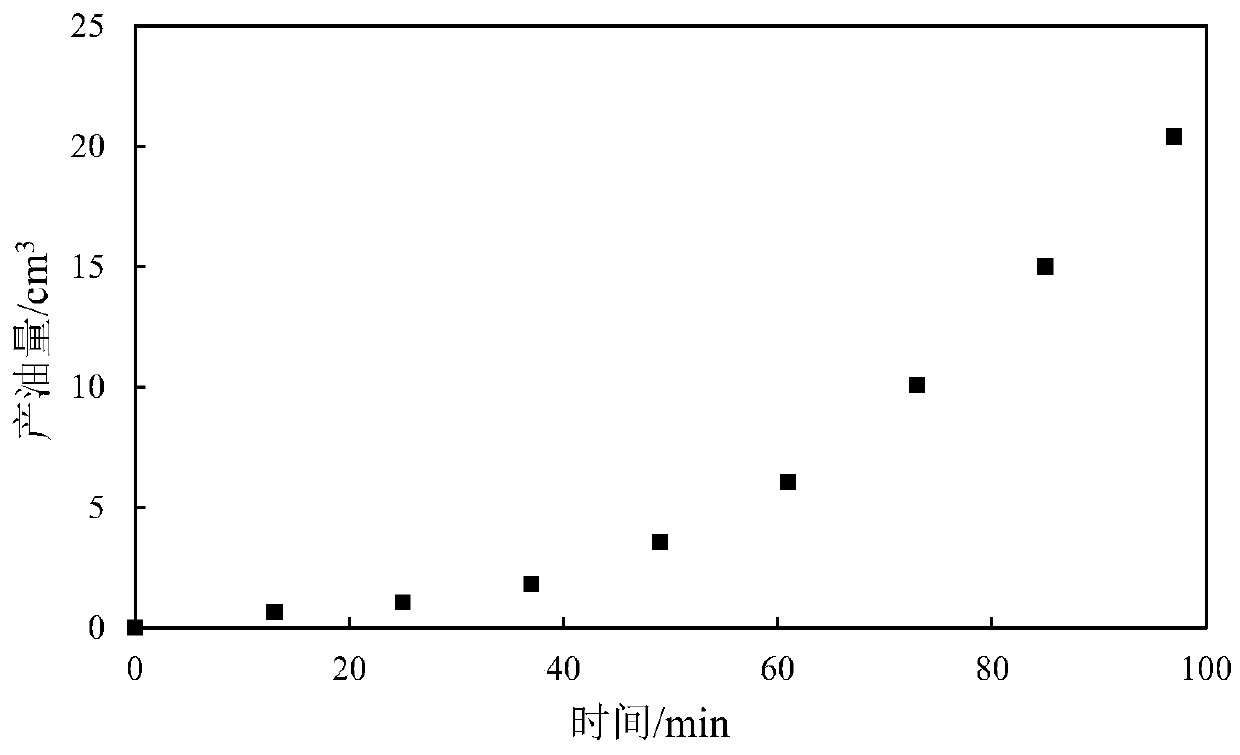

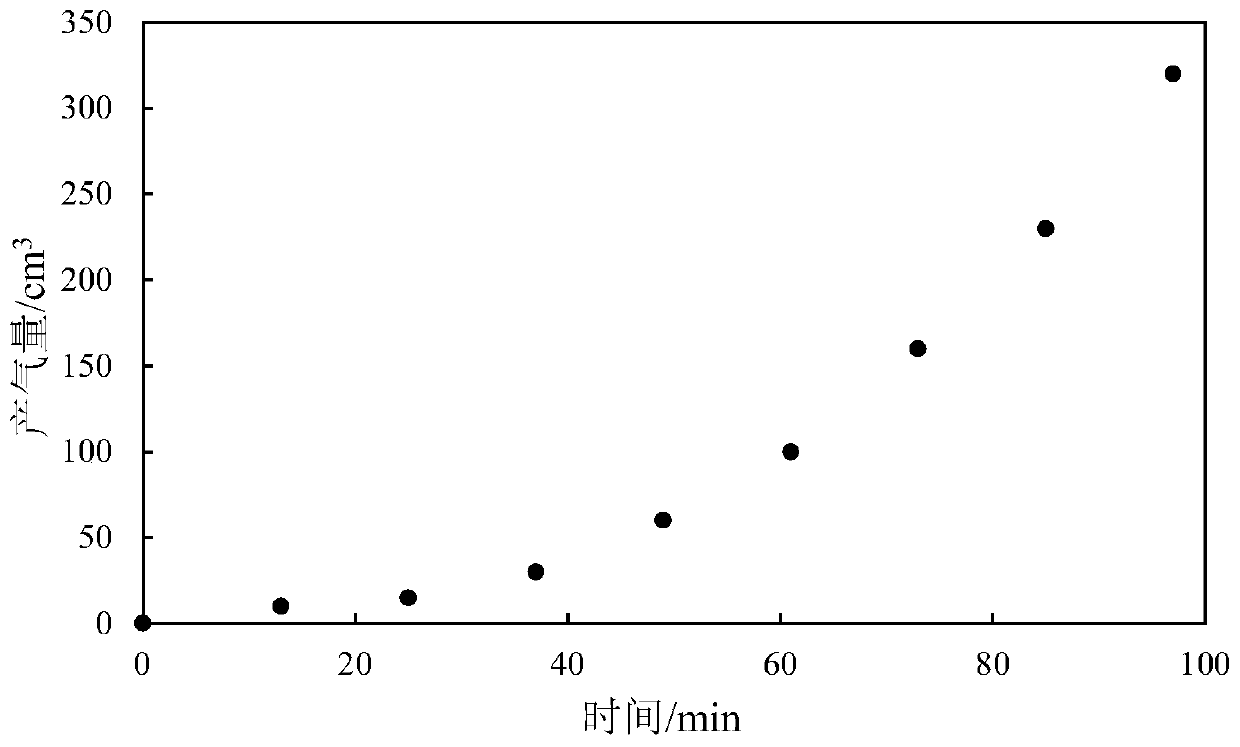

The invention discloses an experimental device and experimental method for thickened oil pool mixed nano-fluid alternating CO2 microbubble flooding. The experimental device and experimental method forthickened oil pool mixed nano-fluid alternating CO2 microbubble flooding introduces mixed nano-particles and combines the advantages of CO2 microbubbles, the phenomena of gas channeling and gravity override of a thickened oil pool occurred during conventional CO2 gas-water alternate flooding can be effectively controlled through a mode of alternating injection, and the recovery efficiency of thethickened oil pool is improved. Compared with CO2 gas, dissolving and diffusing abilities of the CO2 microbubbles are greater in crude oil, buoyancy is smaller, thickened oil viscosity can be better reduced, the volume of thickened oil is expanded, and the sweep coefficient is increased; the mixed nano-fluid can fully combine the advantages of various nano-particles, wettability of oil pull rockscan be changed, the oil-water interfacial tension can be reduced, and the oil washing efficiency is improved; and in addition, the experimental device and experimental method for thickened oil pool mixed nano-fluid alternating CO2 microbubble flooding adopts the method of injecting a mixed nano-fluid slug on the upper part of an oil pool and a CO2 microbubble slug on the lower part, controlling ofthe phenomena of the gas channeling and the gravity override and improvement of the vertical sweep coefficient are helped.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

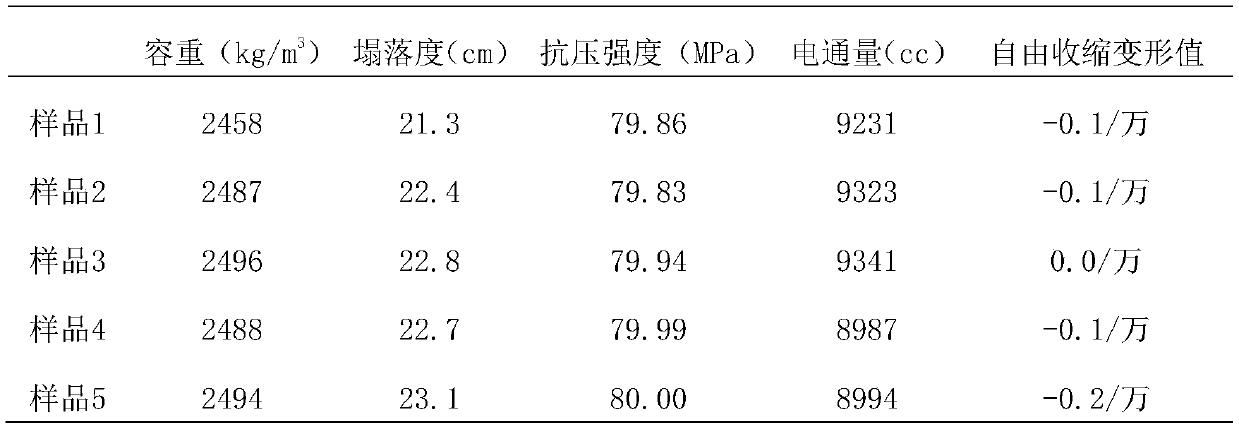

Anti-seepage heat insulating rice husk concrete and preparation method thereof

InactiveCN101857406AHigh porosityLight in massSolid waste managementPermeability coefficientMaterials science

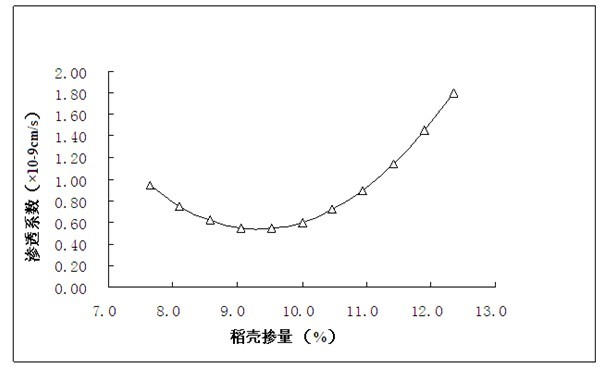

The invention discloses anti-seepage heat insulating rice husk concrete and a preparation method thereof, and the prepared anti-seepage heat insulating rice husk concrete comprises the following raw materials in percentage by mass: 0.6 to 4 percent of rice husk or rice husk powder, 2 to 6 percent of fly ash, 15 to 33 percent of cement, 14 to 27 percent of sand, 26 to 48 percent of stone, 0.15 to 1.2 percent of rice husk coupling agent, 0.11 to 0.29 percent of water reducing agent and the balance of water, and the total mass percentage of the raw materials is 100 percent. The anti-seepage heat insulating rice husk concrete is mainly applied to a concrete lining cannel in a northern irrigation district to prevent frost damage, and tests show the performance of the concrete meets the index requirements of 'Technical Code of Channel Anti-seepage Engineering' on the lining concrete, particularly the heat transfer coefficient of the concrete added with rice husk is only 14 to 20 percent of that of common concrete, and the anti-seepage grade can reach above W4 (the permeability coefficient is less than 0.783*10-8cm / s). Simultaneously, the anti-seepage heat insulating rice husk concrete is applied to non-load-bearing structures or hollow blocks and wall materials in building engineering, is an inexpensive heat insulating material. In addition, the invention opens up a new way for the use of rice husk, and can reduce the harm of combustion to the environment.

Owner:NORTHWEST A & F UNIV

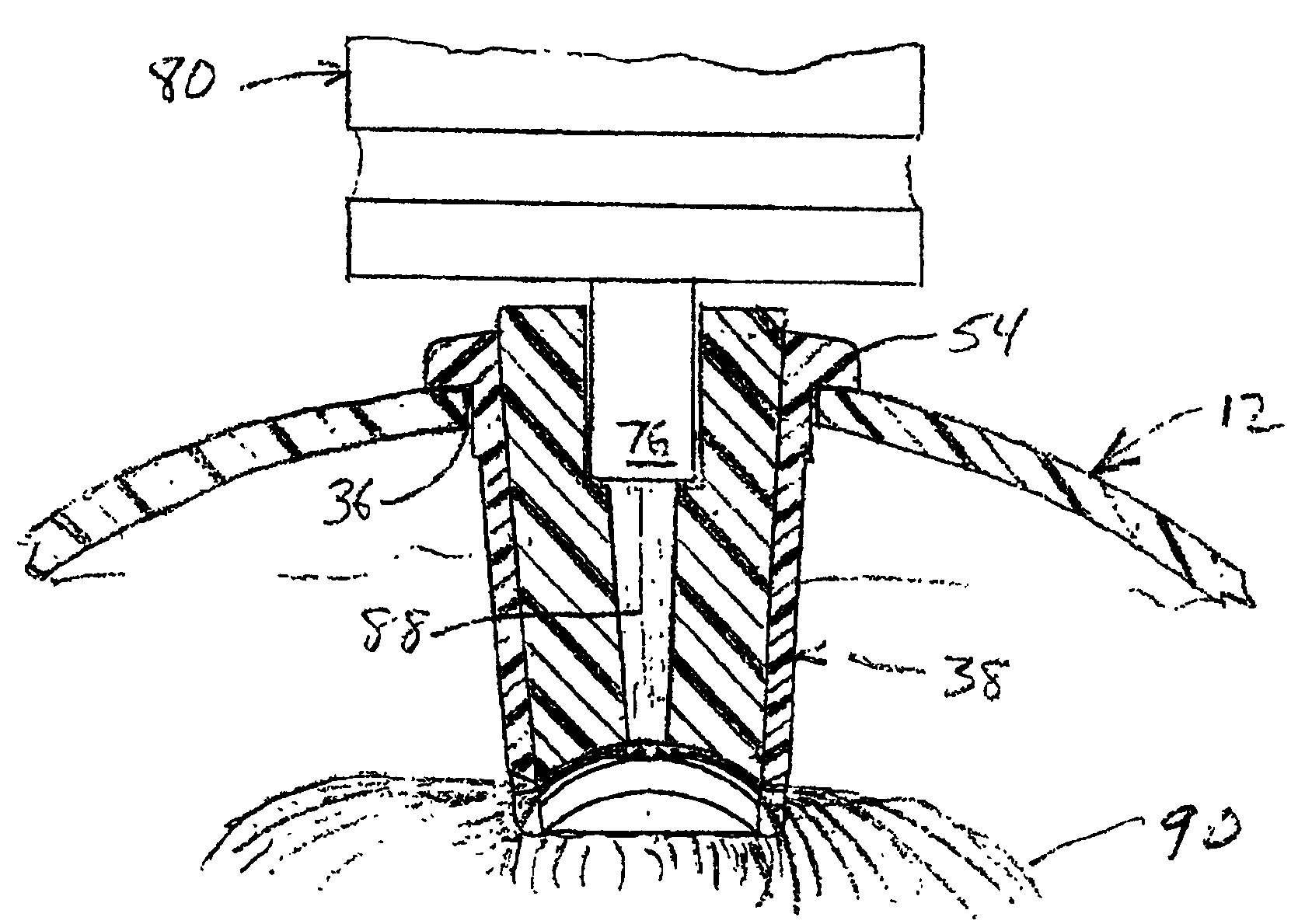

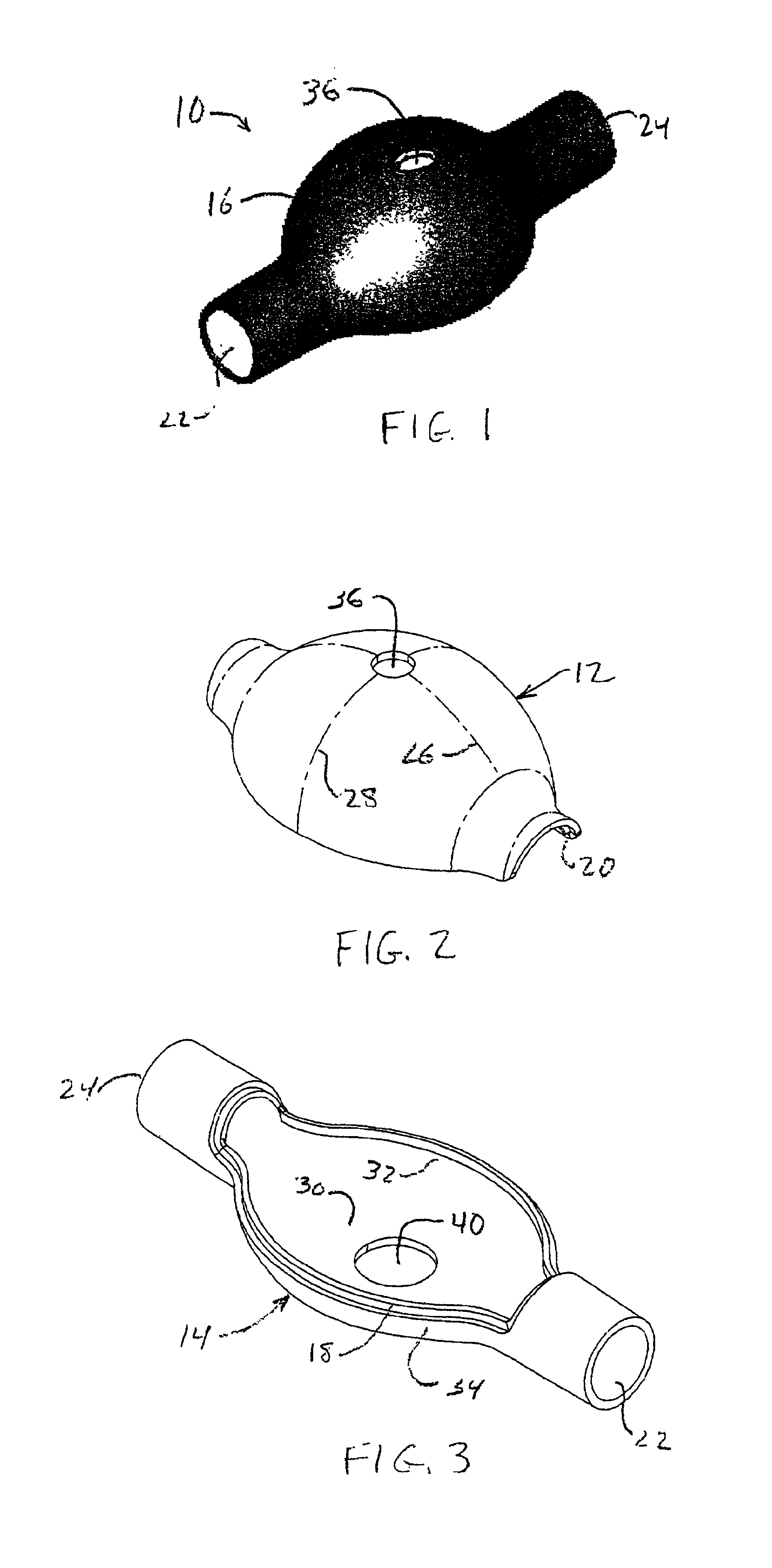

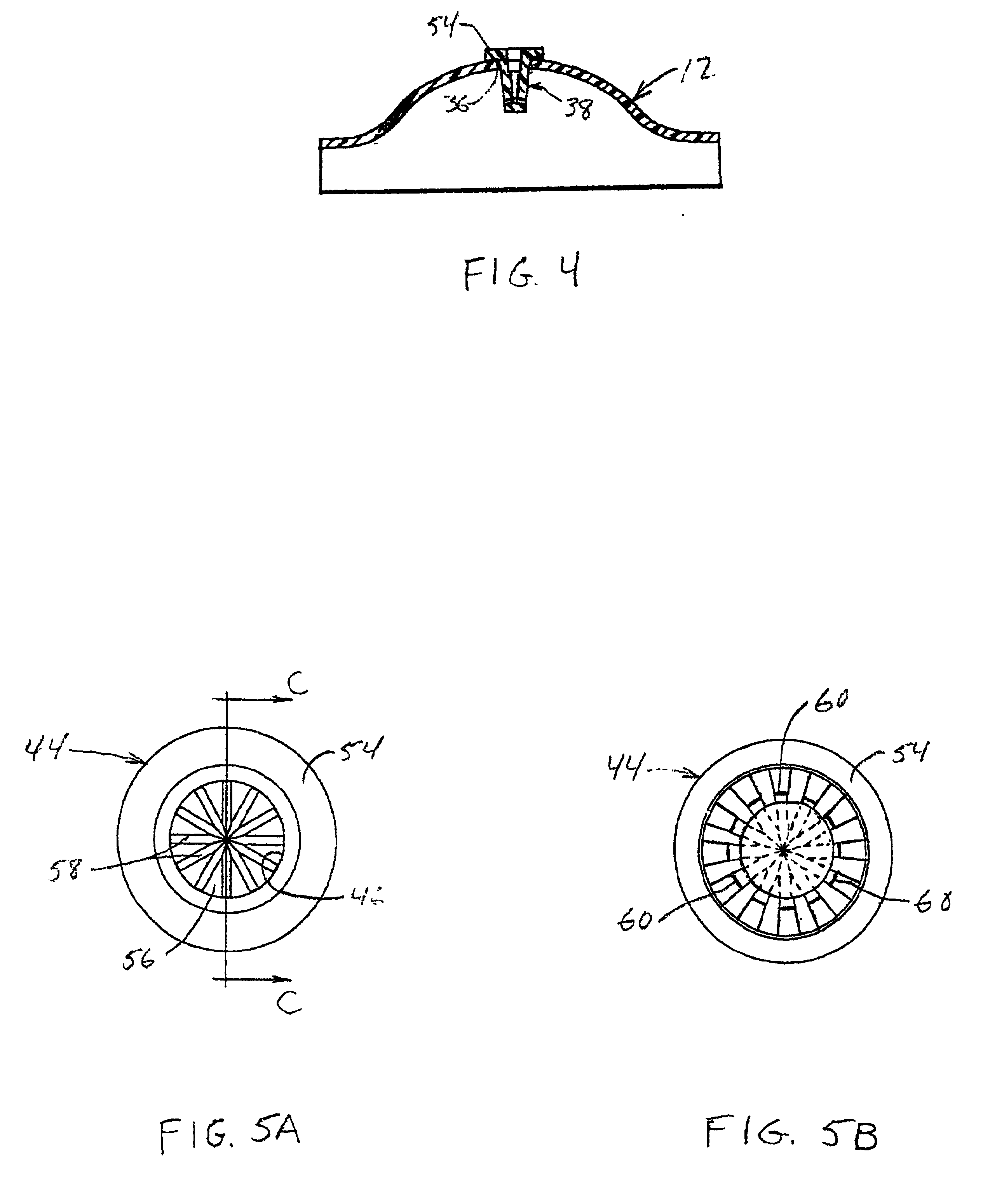

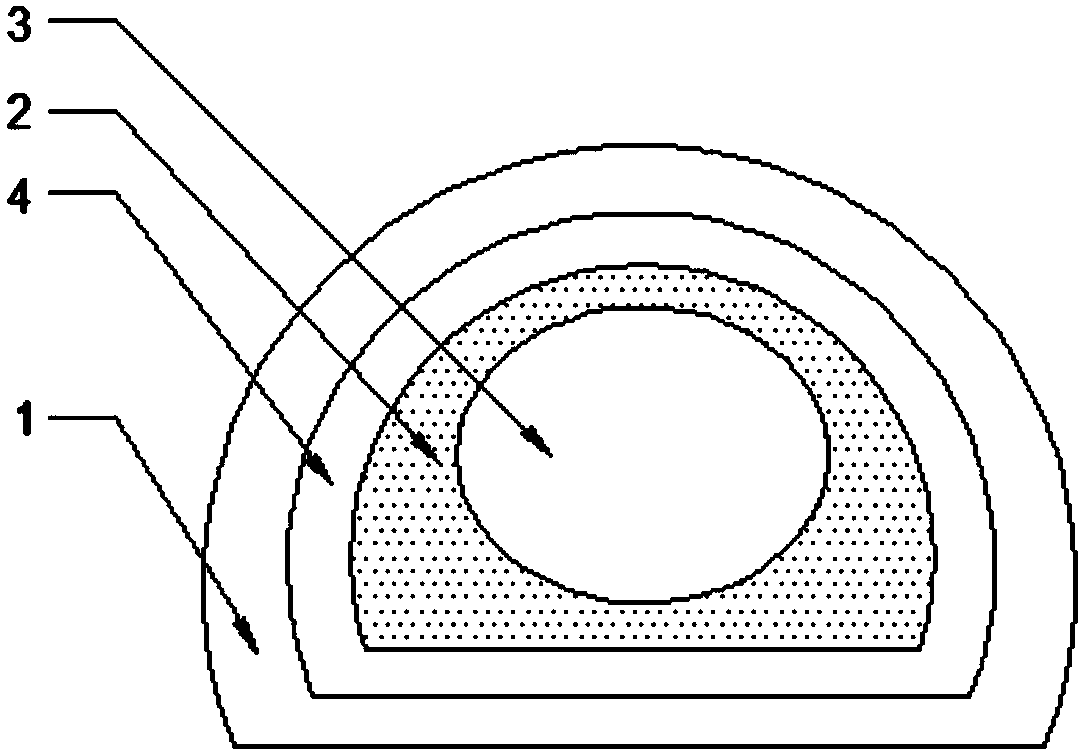

Respiratory equipment spacer assembly

A spacer assembly for a ventilator or other respiratory equipment for dispensing aerosol drugs from metered dose inhaler (MDI) canisters or nebulized drugs from a nebulizer into a respiratory gas stream delivered from a ventilator or other respiratory equipment connected to a patient. The improvements involve optimizing the shape of the spacer assembly body member and providing an efficient MDI nozzle assembly to allow maximal evaporation of the propellant before the propellant droplets impact the walls of the body member while providing a compact volume for directing the output of an MDI canister or a nebulizer into the gas stream.

Owner:SALTER LABS

A kind of method utilizing expander expanded graphite to prepare graphene oxide

The invention discloses a method for preparing graphene oxide by using expanded graphite as an expansion agent. The expandable flake graphite is added to a concentrated sulfuric acid (98%) solution, fuming nitric acid is slowly added, and then dried. After microwave expansion, expanded graphite is obtained; take the above-mentioned expanded graphite, add it to concentrated sulfuric acid, stir and disperse evenly, and slowly add K2S2O8 and P2O5 to obtain pre-oxidized graphite; take pre-oxidized graphite and add it to the expansion agent, according to the expansion coefficient of the expansion agent Depending on the appropriate reaction temperature, pour off the supernatant, centrifuge, wash with water, and wash with 1mHCl three times until the pH is about 6 to obtain a graphene oxide dispersion. The method for preparing graphene oxide from expanded graphite can effectively reduce strong acid waste liquid, reduce pollution, protect the environment, is suitable for large-scale production, and is applied to various fields of industrial production.

Owner:NANJING XINYUE MATERIAL SCI & TECH

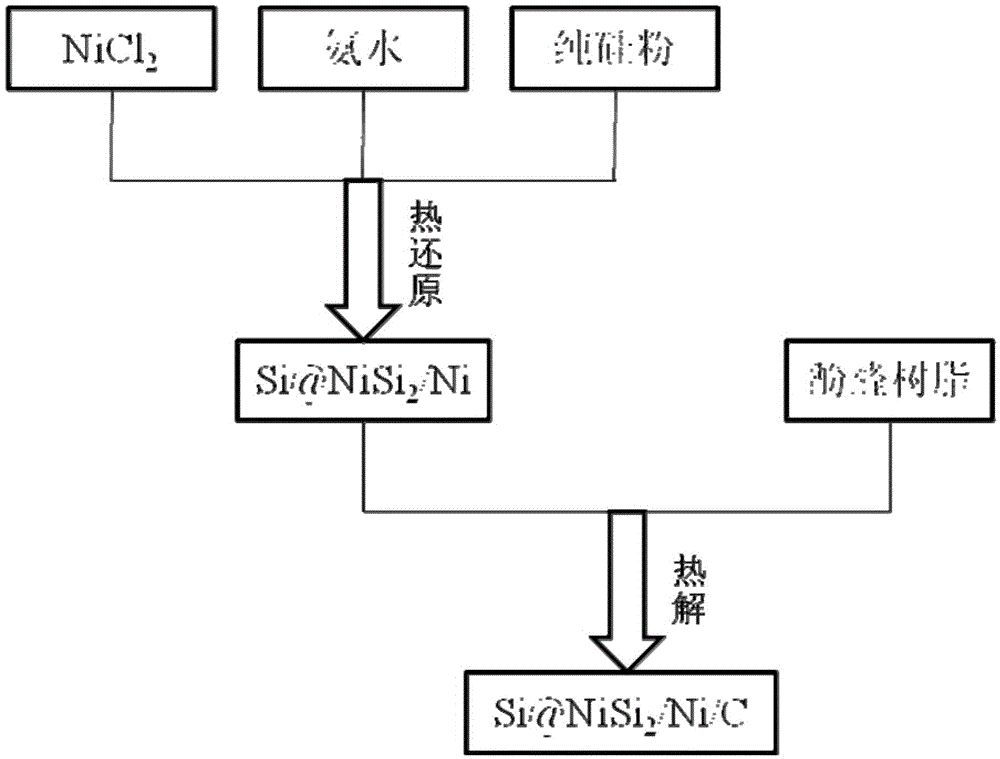

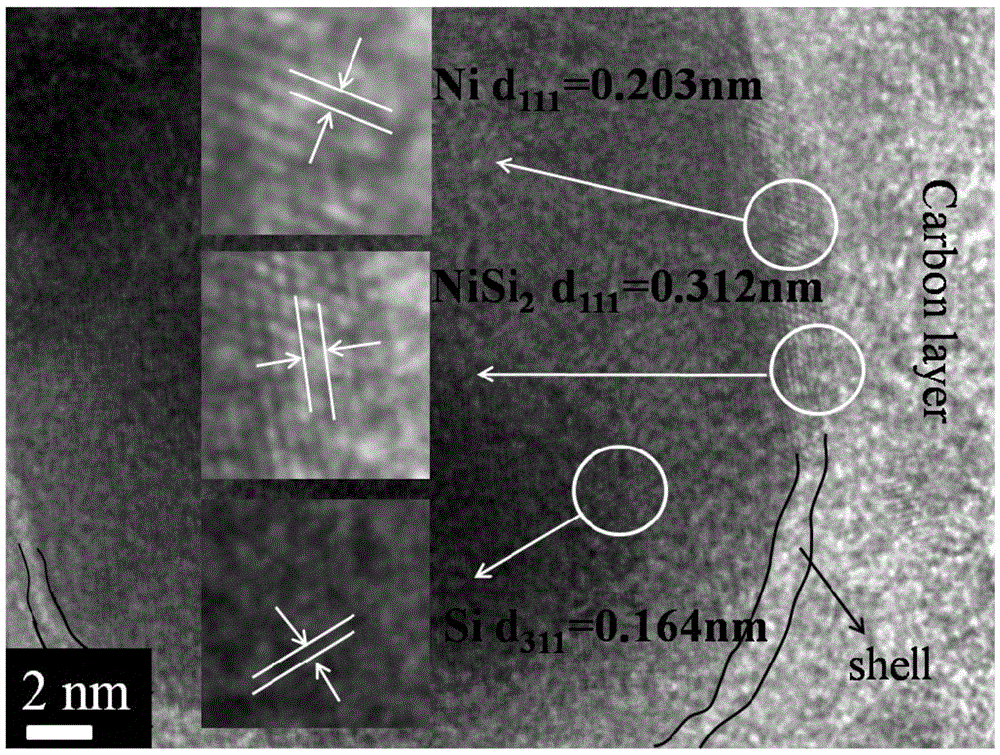

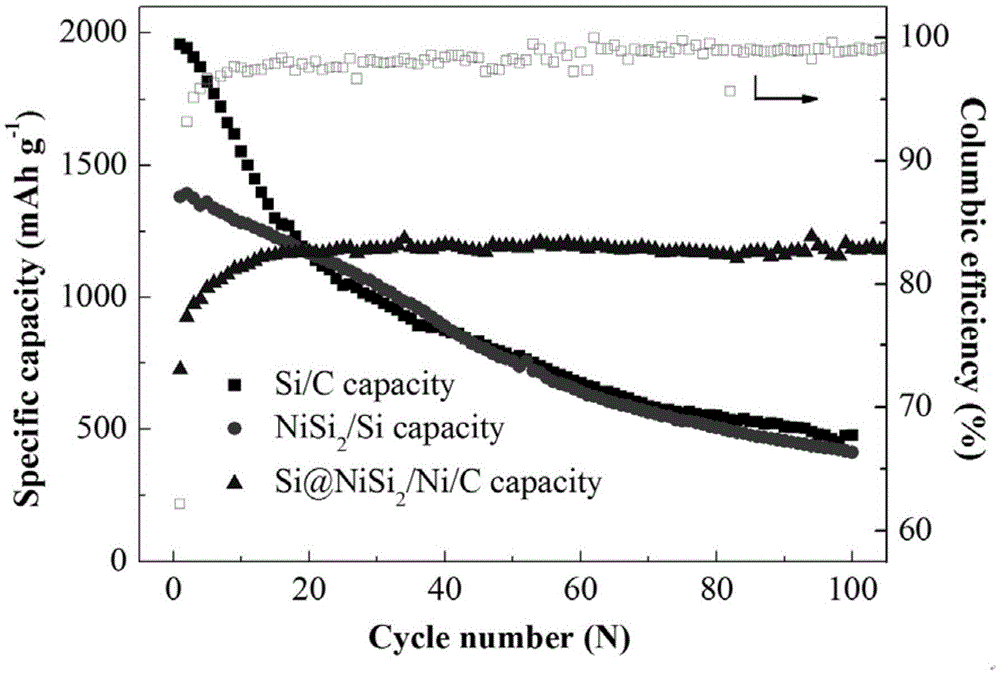

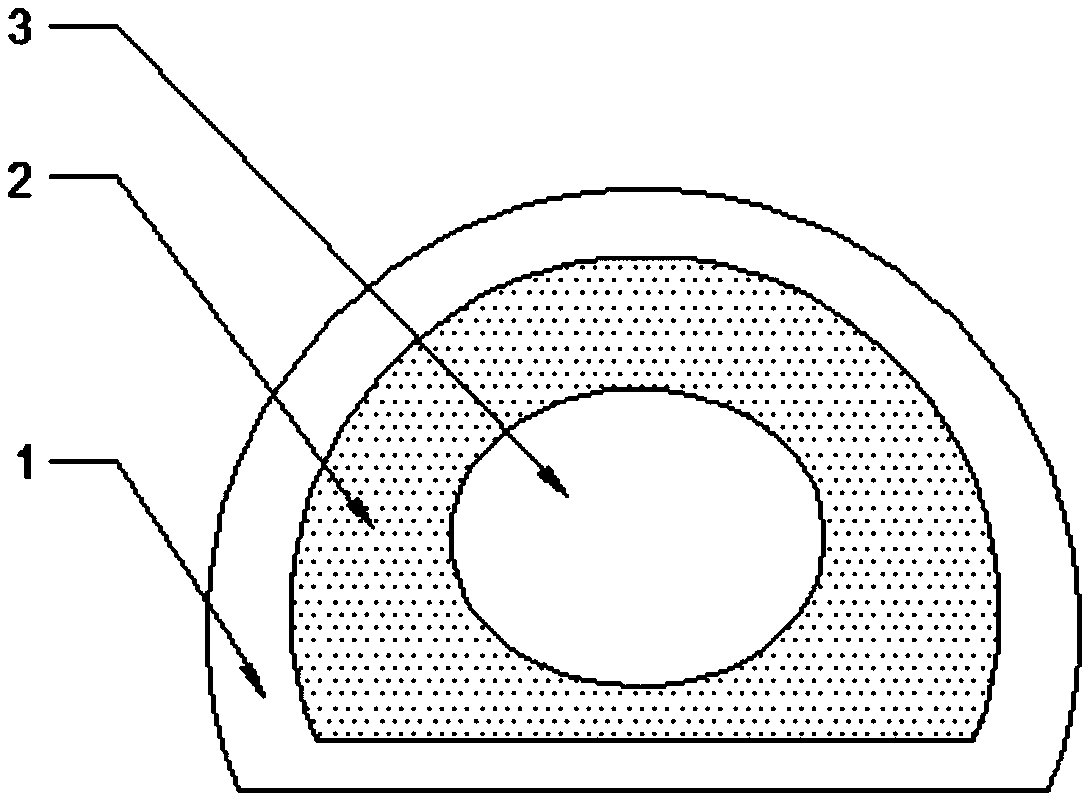

Silicon-based anode material of lithium ion battery and preparation method of silicon-based anode material

InactiveCN105489840AImprove cycle performanceImproved magnification performanceCell electrodesMetal alloyPyrolytic carbon

The invention provides a silicon-based anode material of a lithium ion battery and a preparation method of the silicon-based anode material. The silicon-based anode material of the lithium ion battery is a silicon-metal-alloy three-layer composite adopting a core-shell structure, the core layer comprises silicon, the middle layer comprises the mixture of a silicon and metal X alloy compound and X, the outermost layer comprises pyrolytic carbon, and X is a metal element which is combined with silicon and has a stabile structure in the charging-discharging process. With the adoption of the technical scheme, the cycle performance and the rate capability of silicon powder serving as a lithium ion battery anode material are improved, and the core-shell structure effectively inhibits size expansion of the silicon powder in the charging-discharging process; with the adoption of the pyrolytic carbon, the conductivity of the composite is increased, size expansion of the silicon powder in the charging-discharging process is inhibited, the silicon-based composite has excellent cycle performance and rate capability, the preparation method is simple and low in cost, and raw materials are rich and easy to obtain.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

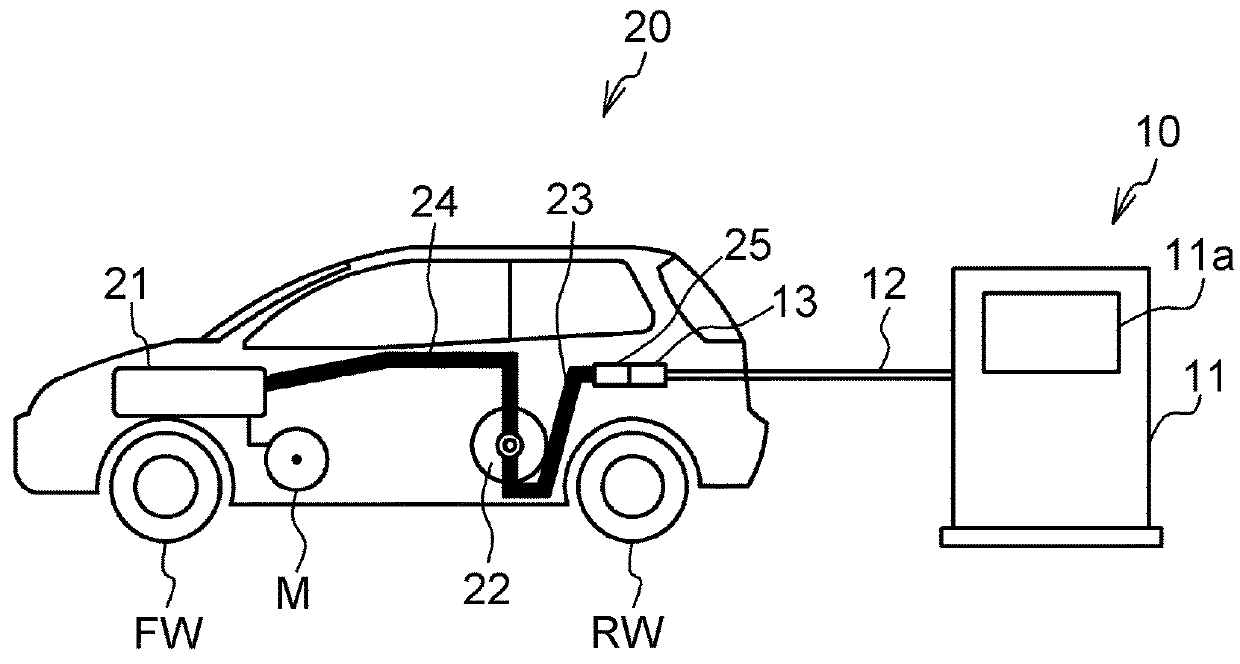

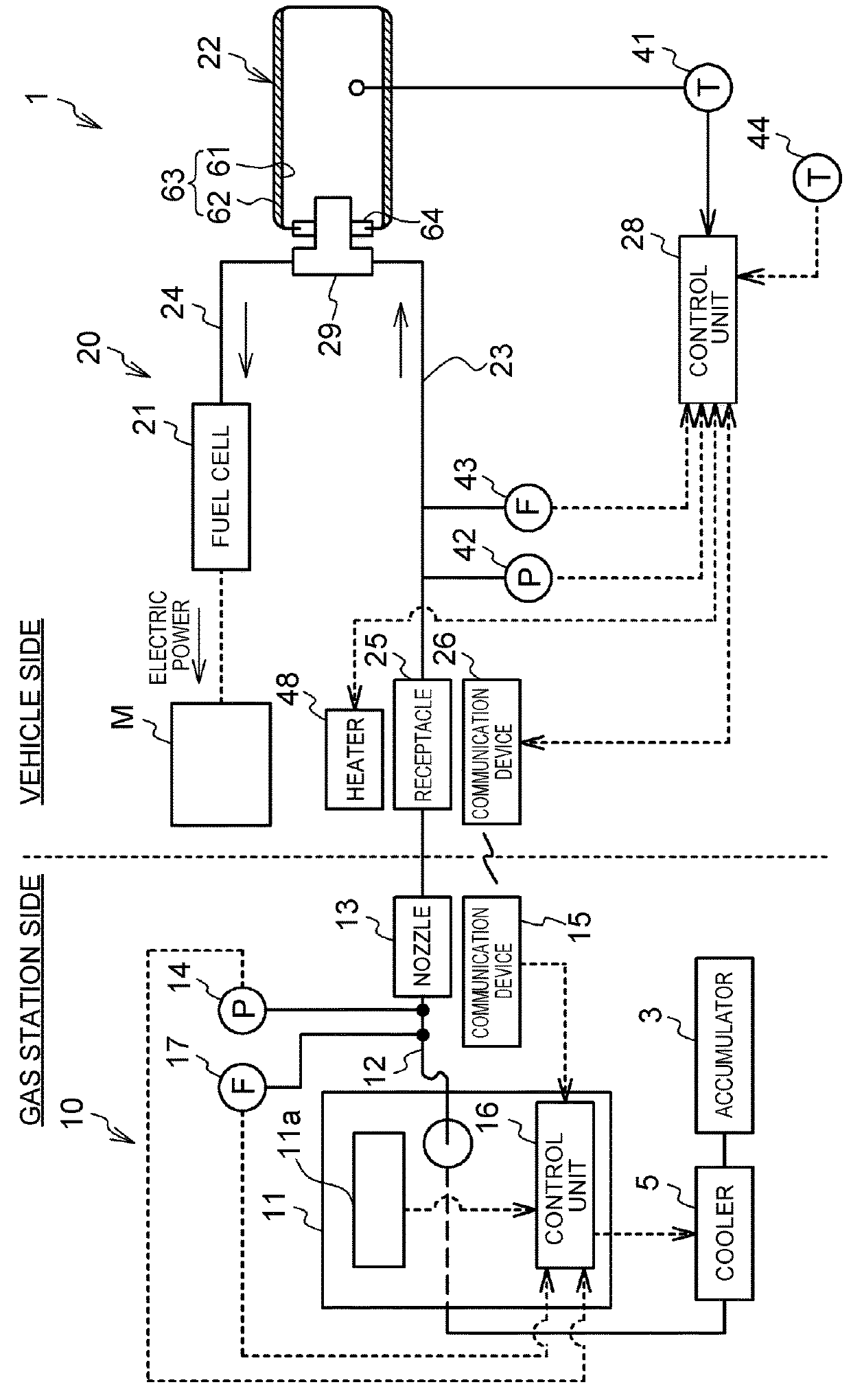

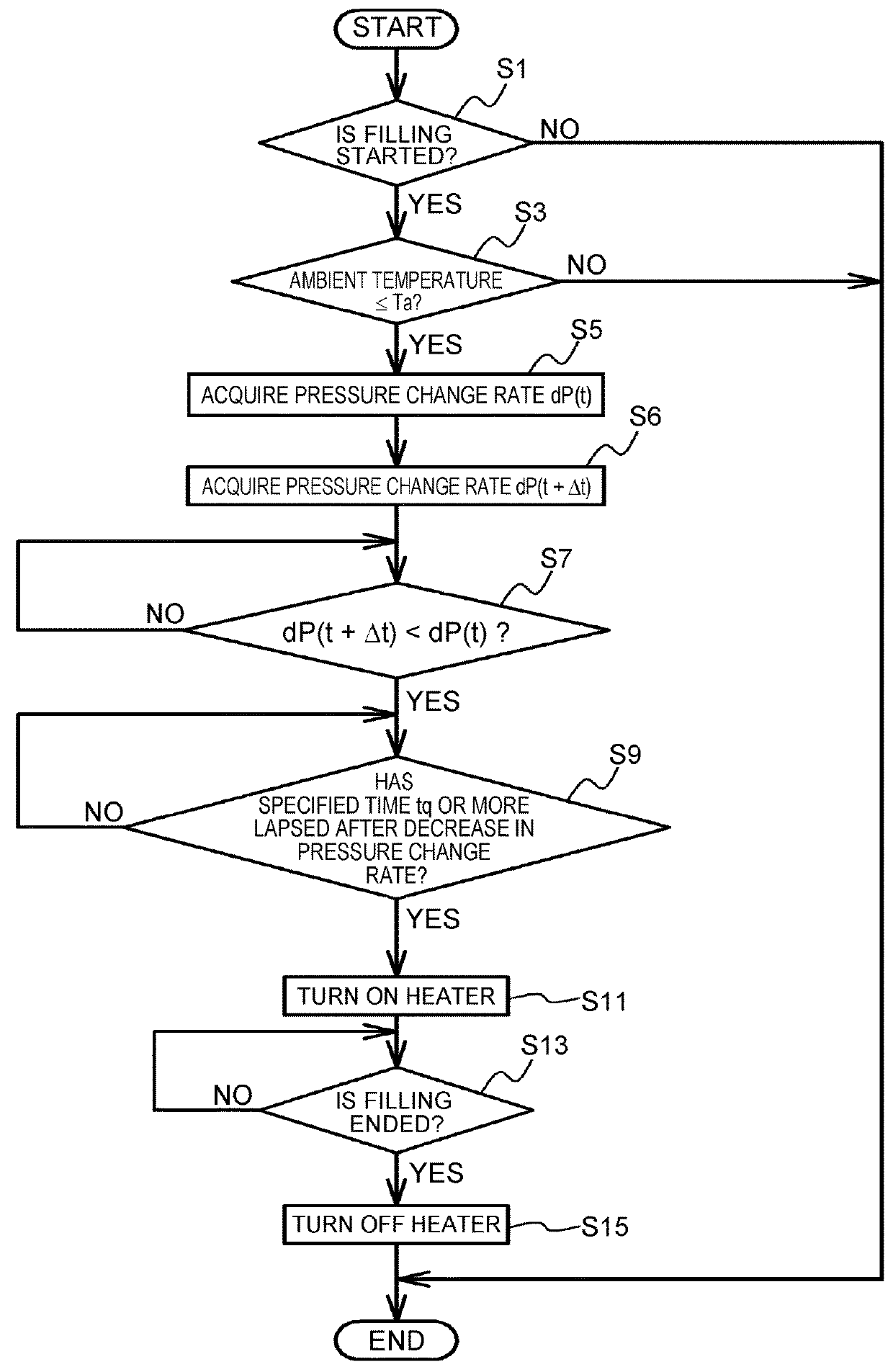

Vehicle and method for filling fuel gas

ActiveUS20180266633A1Suppress decrease in amount of fuelReduce power consumptionReactant parameters controlGas handling applicationsProduct gasProcess engineering

A vehicle including: a tank configured to be filled with fuel gas; a receptacle configured to be connected to a nozzle included in a fuel gas filling apparatus; a filling passage configured to provide communication between the receptacle and the tank; a heating unit configured to heat the receptacle; a determination unit configured to determine whether or not a parameter value, correlated with a filling speed of the fuel gas filled into the tank from the fuel gas filling apparatus, indicates decrease in the filling speed during filling of the fuel gas into the tank; and a control unit configured to, when the determination unit determines that the parameter value indicates decrease in the filling speed during filling of the fuel gas into the tank, to cause the heating unit to start heating of the receptacle during filling of the fuel gas into the tank.

Owner:TOYOTA JIDOSHA KK

Production method for alginate specialized for welding

ActiveCN103360510AReduce contentEliminate decalcification processWelding/cutting media/materialsSoldering mediaSulfurCalcification

The invention relates to a production method for alginate specialized for welding. In the production method, alginic acid is formed by an acidification method; then a secondary washing process is employed in a washing process after the alginic acid is formed by acidification; and a compound washing liquid is selected to wash again after the alginic acid is conversed into alginate by neutralization in a solid phase. The above improvements can effectively reduce the content of phosphorus, sulfur and chlorine in a finished product of the alginate. Acidification treatment is used to form alginic acid in the preparation method. Compared with a conventional calcification method, the production method provided by the invention omits a decalcification process, shortens a production period, and reduces working time. Besides, compared once washing in the prior art, the secondary washing process is employed after acidification, so that the content of phosphorus, sulfur and chlorine can be effectively reduced. The compound washing liquid is selected to wash the alginate after neutralization in the solid phase, so that the concentrations of inorganic ions such as phosphorus, sulfur and chlorine are reduced and the volume of the obtained alginate expands, thereby facilitating subsequent smashing. The particle size can easily reach below 75 [mu]m when the alginate is smashed, with little loss.

Owner:青岛海之林生物科技开发有限公司

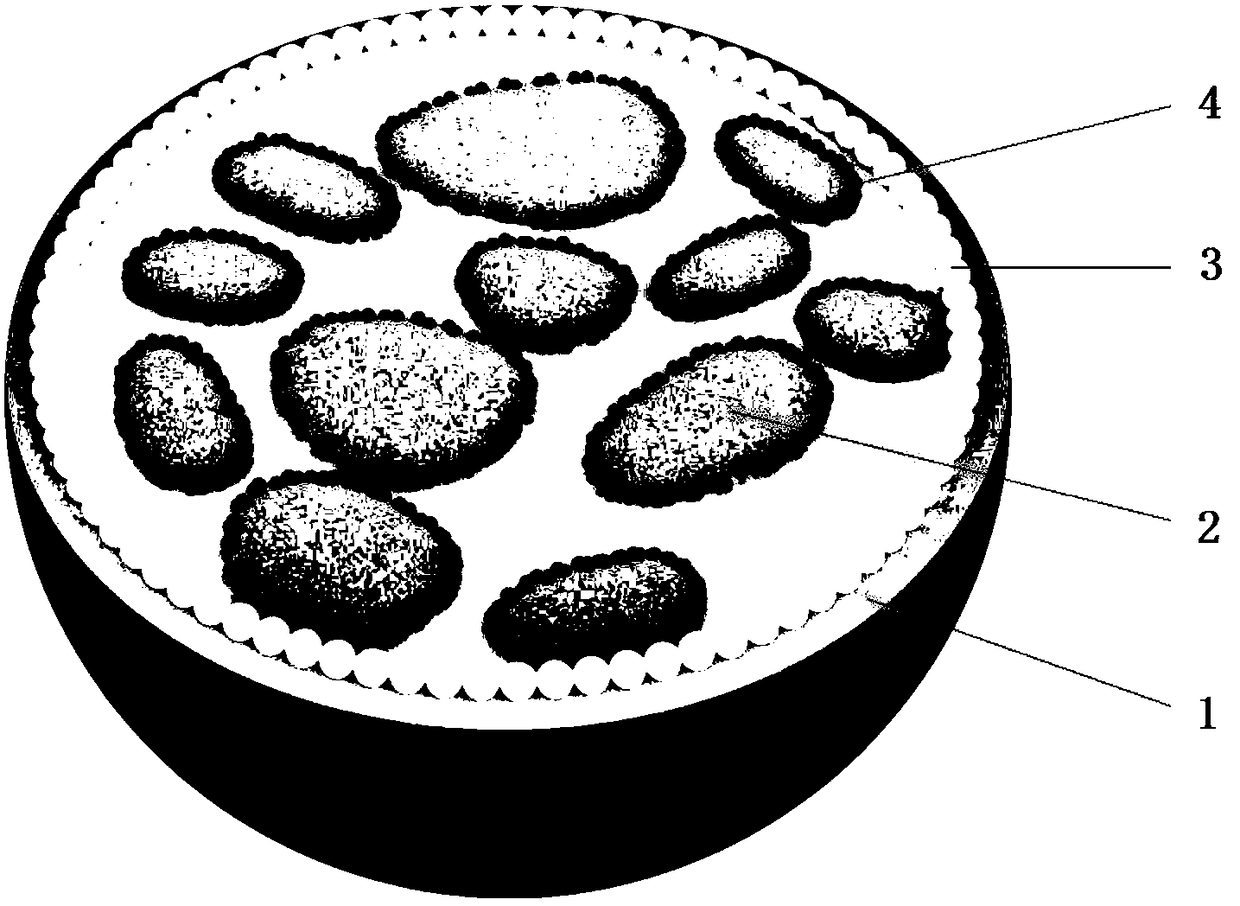

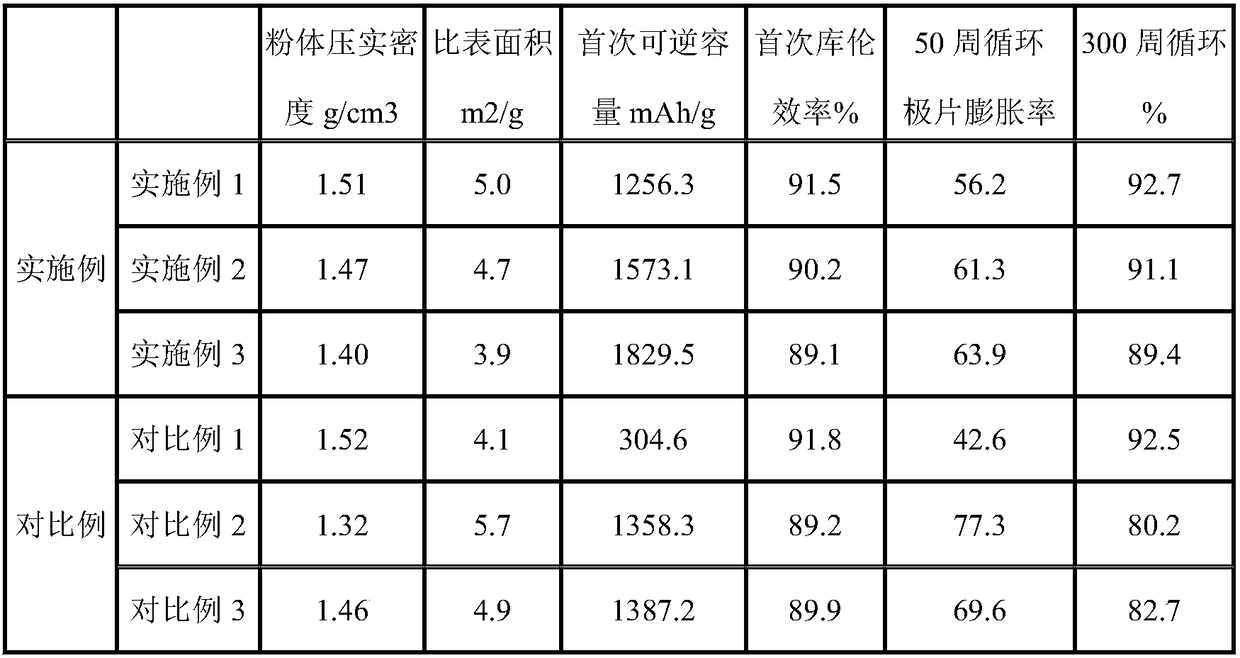

A double-layer coated core-shell negative electrode material for lithium ion battery and a preparation method thereof

InactiveCN109119618AHigh magnificationExcellent long cycle performanceMaterial nanotechnologyCell electrodesHigh rateSodium-ion battery

The invention discloses a double-layer coated core-shell negative electrode material for lithium ion battery and a preparation method thereof. A CVD deposition method is used for depositing nano silicon on that graphite particle to obtain a precursor of a negative electrode material; The titanium dioxide, the lithium carbonate and the organic pyrolysis carbon source are dispersed in an organic solvent to prepare a gel; the precursor of anode material was added into the gel, and the core-shell structure anode material was prepared by low temperature treatment, homogeneous dispersion and high temperature reaction. The core of double-layer coated core-shell negative electrode material for the lithium ion battery is nano silicon and graphite, the nano silicon is deposited on the surface of graphite particles, the outer shell is an organic pyrolytic carbon layer, and the inner shell is formed by attaching lithium titanate to the inner wall of the organic pyrolytic carbon layer. The core-shell negative electrode material has high capacity, high rate and excellent cycling performance, and the preparation process is simple, green and pollution-free, suitable for large-scale production.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD

Composite powder for improving scouring resistance of carbon-containing refractory material and preparation method of composite powder

The invention belongs to the technical field of preparation of carbon-containing refractory material, and mainly relates to composite powder for improving scouring resistance of a carbon-containing refractory material and a preparation method of the composite powder. The provided composite powder for improving the scouring resistance of the carbon-containing refractory material is compounded from zirconium carbide particles and nano zirconium oxide, wherein the mass ratio of the nano zirconium oxide to the zirconium carbide particles in the composite powder is 0.5:1 to 1:0.5; the particle size of the zirconium carbide particles is 200-400 meshes, and the zirconium carbide particles are positioned in the center of the composite powder; the nano zirconium oxide is part of stable zirconium oxide of which the particle size is less than 30nm; the nano zirconium oxide is uniformly dispersed and is enwrapped on the outer surface of the zirconium carbide particles; and the particle size of the composite powder is between 80 meshes and 150 meshes. The composite powder provided by the invention ensures that zirconium oxide has strong adhesive force on the surface of zirconium carbide, and meanwhile, and the composite powder is crushed after drying to obtain an appropriate particle size, and finally obtain the nano zirconium oxide coated zirconium carbide composite powder.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

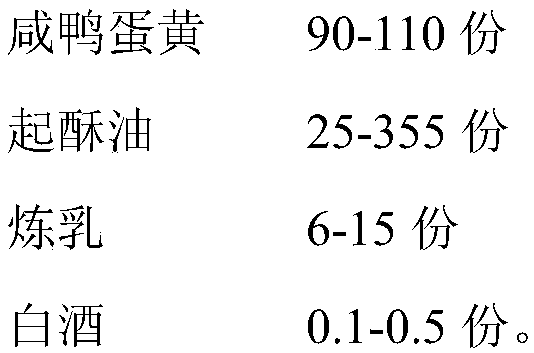

Egg-yolk puff and preparation method thereof

InactiveCN109077093ADistinct tasteThe taste is sweet and softDough treatmentBakery productsFlavorYolk

The invention relates to a food production process, in particular to egg-yolk puff and a preparation method thereof. The egg-yolk puff comprises a skin material layer, a Daifuku skin layer and a egg-yolk stuffing core layer which are coated sequentially from outside to inside, the skin material layer comprises an oil crisp layer wrapping the outer surface of the Daifuku skin layer and an oil skinlayer wrapping the outer surface of the oil crisp layer, and the weight ratio of the oil crisp layer to the oil skin layer is 0.7-1.0:0.8-1.0. The egg-yolk puff and the preparation method thereof havethe advantages that the egg-yolk puff is clear in layering sense and bright yellow in color and luster when being eaten, by adopting the Daifuku skin layer, the taste is soft, waxy, fragrant and sweet, the softness is high, the elasticity is high, the oil content and materials in egg-yolk stuffing can be prevented from permeating outward, it is avoided that the egg-yolk stuffing and outer layer materials are penetrate each other to affect the taste and layering sense of the egg-yolk puff, it is ensured that the unique flavor of salted duck egg yolk is not easy to lose, so that the produced egg-yolk puff is fragrant and sweet in taste, crisp in the outer layer, fragrant and soft but not sweet and greasy in the inner layer and rich in taste and has clear layers, and the egg-yolk puff can bemore in line with the edible pursuit of modern people.

Owner:东莞市食滋源食品有限公司

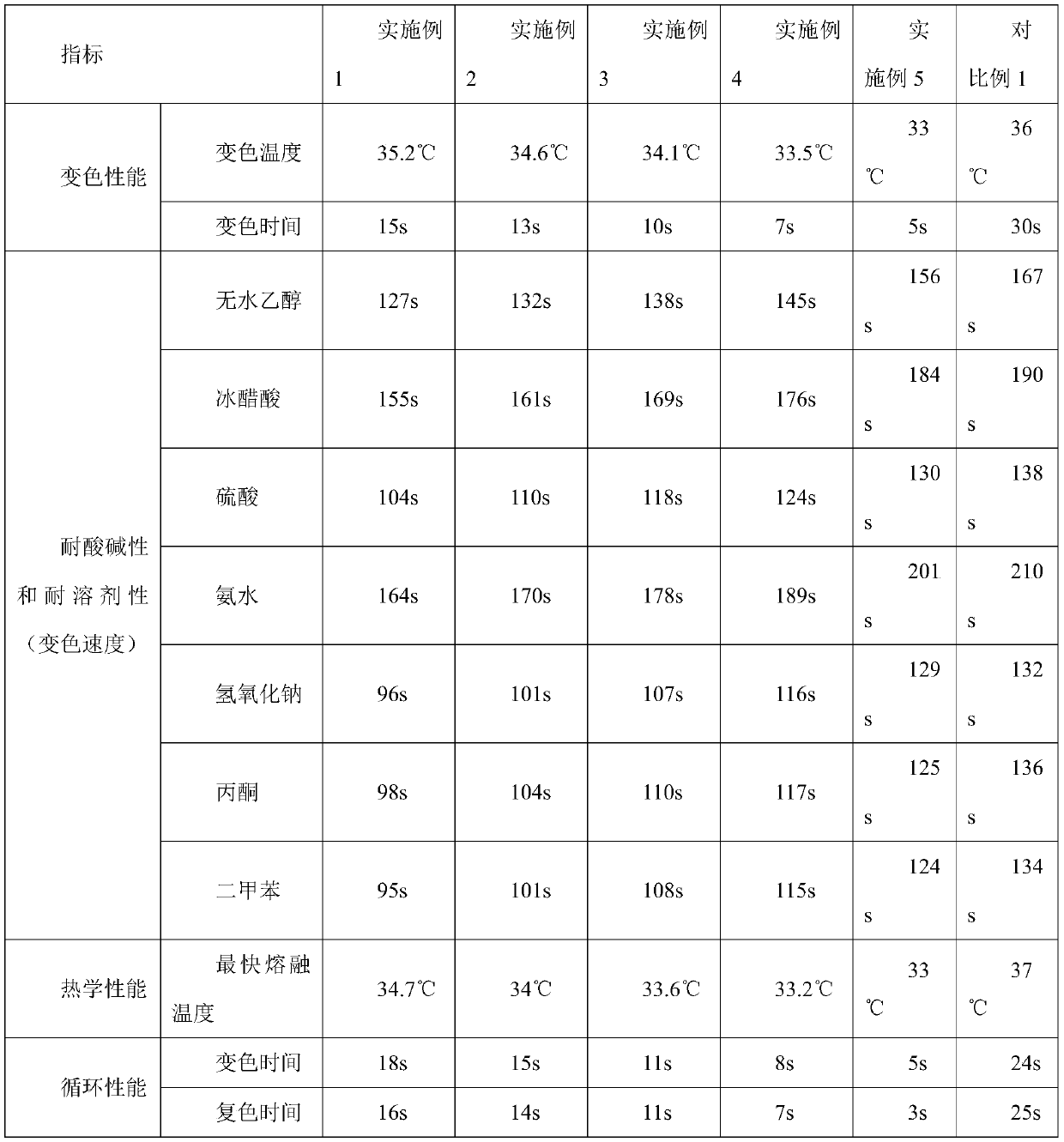

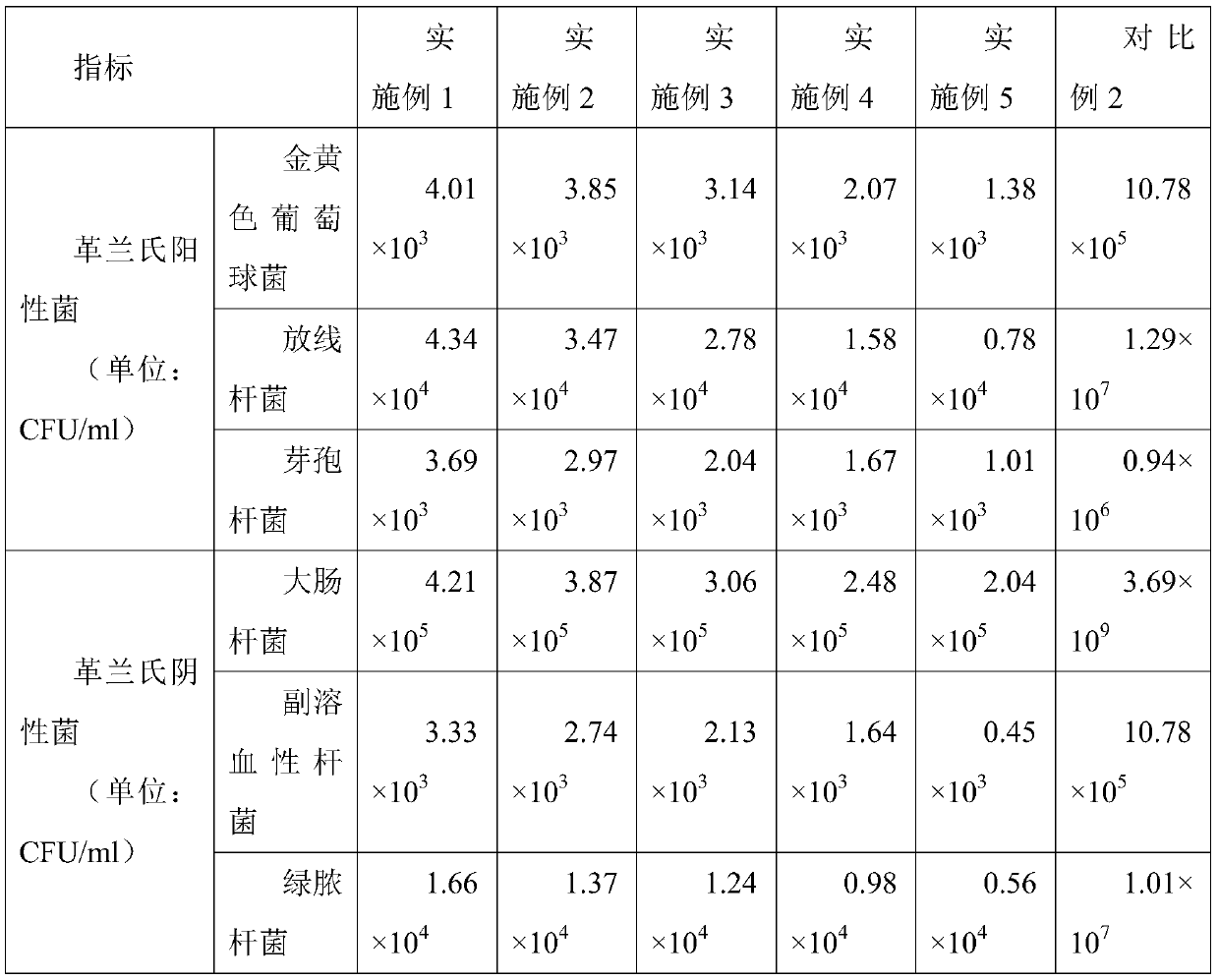

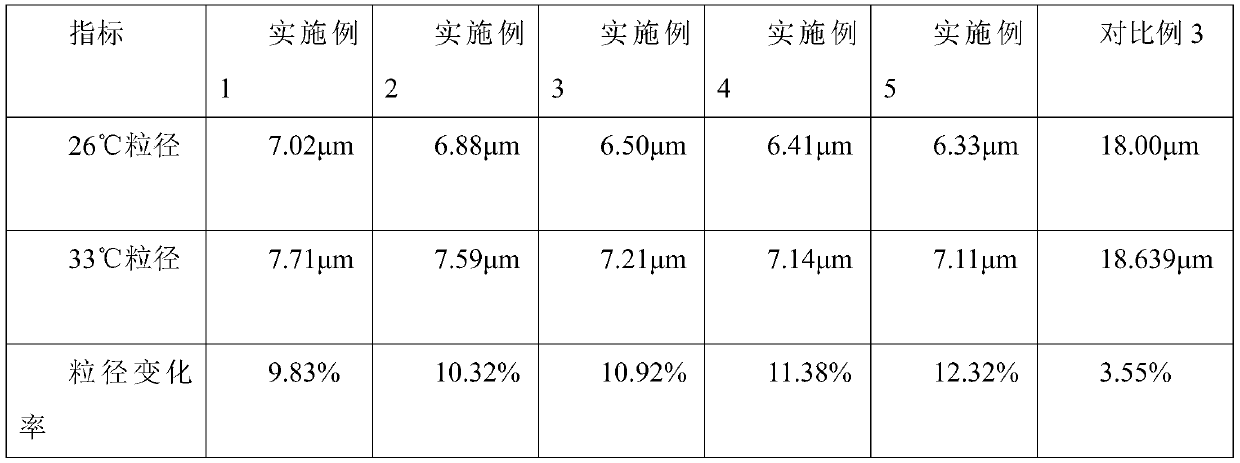

Male urinal thermochromic mark material and manufacturing method thereof

ActiveCN111394089AImprove protectionImplementing a Hierarchical Shell-Core StructureUrinalsBiocideMedicineEngineering

The invention discloses a male urinal thermochromic marking material and a manufacturing method thereof. The material is of a shell-core microcapsule structure and comprises a shell and a core, the core comprises an inner core body and an outer core body, the inner core body is an antibacterial temperature-sensitive network hydrogel material, the outer core body is a thermosensitive reversible color-changing microcapsule, the shell is a water-swelling polymer copolymer, and the weight ratio of the shell to the outer core body to the inner core body is 1: 1: 8 to 2: 1: 1.5. The antibacterial temperature-sensitive network hydrogel material is prepared from silver nitrate and antibacterial plant extract effective components; the thermosensitive reversible color-changing microcapsule comprisesa color former, a color developing agent, a solvent and a semi-synthetic polymer material effective component. The mark can change color after making contact with urine with the human body temperature when a user uses the mark, antibacterial active substances are released in the using process and after the user uses the mark to maintain sanitation of a urinal, the using interestingness is improved, meanwhile, the attention of the user is improved, urine splashing is reduced, the enjoyment of the user is improved, and the environment refreshing atmosphere is improved.

Owner:杭州传一科技有限公司

Whey protein solid beverage

InactiveCN107258927AHigh organic ferrous contentPromote decompositionWhey manufactureSolubilityAdditive ingredient

The invention discloses a whey protein solid beverage. The whey protein solid beverage is prepared from the following raw materials: concentrated whey protein powder, inulin, resistant dextrin, a flavoring agent, vitamin A acetate, vitamin C, vitamin E acetate, thiamine hydrochloride, riboflavin, pyridoxine hydrochloride, vitamin B12, folic acid, calcium pantothenate, ferrous fumarate, zinc sulfate, maltodextrin, natural strawberry essence, silicon dioxide and stevioside. According to the whey protein solid beverage disclosed by the invention, the raw materials have high protein content and contain various types of vitamins, so that the absorption of proteins can be accelerated, the water solubility is relatively high and the mouthfeel is more fine and smooth. The whey protein solid beverage disclosed by the invention has the effects of supplementing physical ability, nutrients and various types of the vitamins, protecting eyesight and the like. The whey protein solid beverage has simple and reasonable raw material composition, natural components and a proper proportion; when being brewed with water, the whey protein solid beverage is more uniformly dispersed and is convenient for oral administration; the whey protein solid beverage is a solid beverage suitable for people.

Owner:深圳瑞森健康科技有限公司

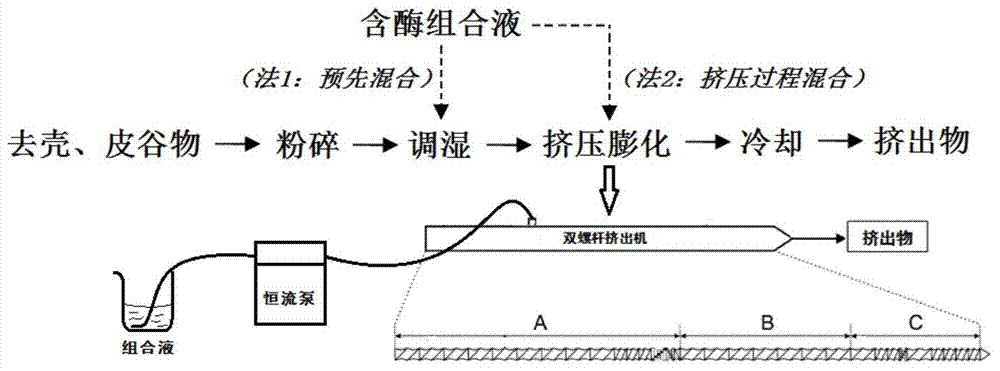

Method for improving polyphenol retention rate and antioxidant activity of grains in extruding and pasting

ActiveCN104738403AImproves antioxidant activityImprove completenessFood shapingFood preparationAntioxidant capacitySolubility

The invention provides a method for improving polyphenol retention rate and antioxidant activity of grains in extruding and pasting. The method is characterized in that enzyme-containing combined liquid is added to pre-processed grains; the gains are extruded and pasted through a twin-screw extruding system; the extruded products are cooled for later use; the enzyme-containing combined liquid can be added before extruding and pasting or during extruding and pasting. By virtue of the method, polyphenol content can be remained to the maximum, the antioxidant activity of the extruded products can be improved, and meanwhile, the moisture absorption, water solubility, viscosity and other physicochemical properties of ripened grains can be improved; the method is applicable to starch syrup preparation, alcohol or wine-like fermenting industry.

Owner:JIANGNAN UNIV

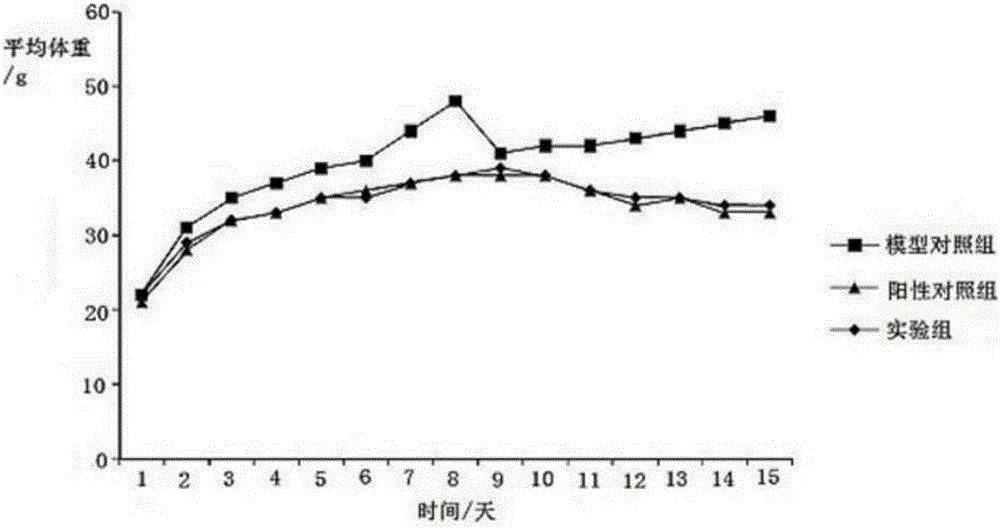

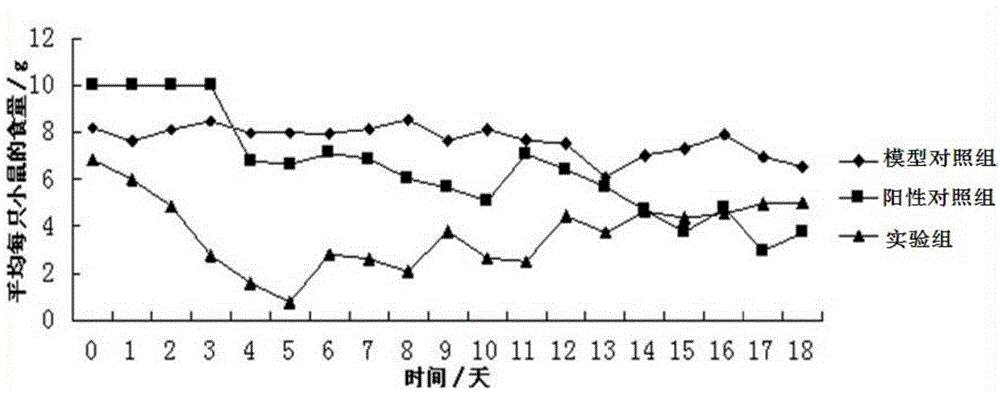

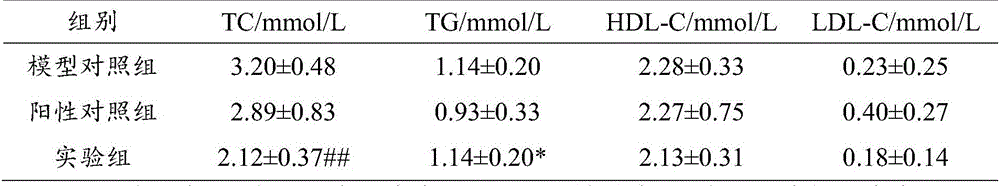

Composition with weight losing and blood fat reducing functions and preparing method and application thereof

ActiveCN105727205AEnhance memoryAnti agingMetabolism disorderKetone active ingredientsDietary fiberSide effect

The invention relates to a composition with weight losing and blood fat reducing functions and a preparing method and application thereof.The composition is prepared from, by weight, 5-17 parts of white kidney bean extract, 2-12 parts of agaricus bisporus extract, 2-12 parts of dietary fibers, 0.5-7 parts of green tea extract and 0.5-7 parts of radix curcumae longae extract.According to the composition, raw material composition and matching between all the raw materials are fully considered, all the raw materials are matched and take effect in cooperation under a specific matching ratio, and the functions of losing weight and reducing blood fat are achieved; the composition has the remarkable weight losing and blood fat reducing functions, and is small in toxic and side effect, high in safety, simple in composition and low in cost as the composition only comprises five raw materials.

Owner:ZHANGZHOU PIEN TZE HUANG PHARM

High-strength micro-expansive heat preservation material

The invention provides a high-strength micro-expansive heat preservation material comprising the following components in parts by weight: 20-60 parts of flint clay, 5-15 parts of andalusite, 2-12 parts of kyanite, 3-20 parts of alumina hollow balls, 2-15 parts of perlite, 1-6 parts of alumina micro powder, 1-4 parts of silicon dioxide micro power and 1-6 parts of high-alumina cement. The heat preservation material provided by the invention is high in strength and good in heat preservation performance under normal temperature and after being sintered, and is micro-expansive in volume after being sintered under high temperature. The heat preservation material can be tightly adhered to a furnace shell after being constructed on a liner of a high-temperature cylinder part such as a rotary kiln, a hot air pipeline and the like under the condition of drying and high-temperature sintering, so that the furnace lining structure damage caused by a gap formed between the liner and the furnace shell after the liner is shrunk can be reduced, the heat preservation effect of a furnace lining can be improved, and the service life of the furnace lining can be prolonged.

Owner:WUHAN IRON & STEEL (GROUP) CORP

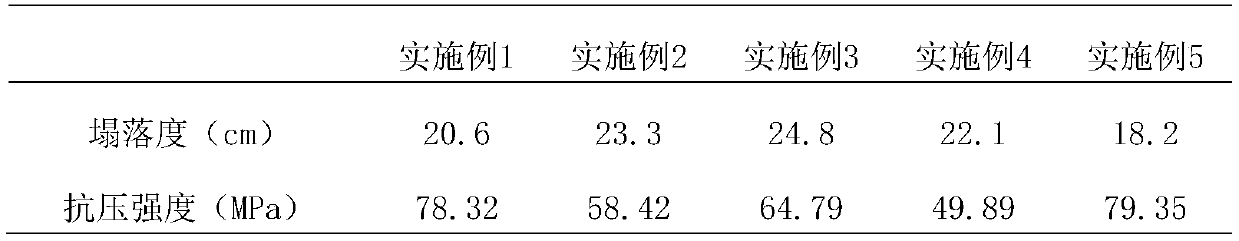

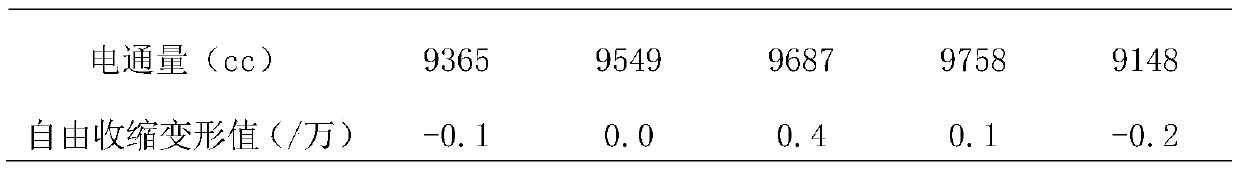

Non-shrinkage cementing material made of phosphogypsum and preparation method of non-shrinkage cementing material and concrete

The invention relates to the technical field of comprehensive utilization of phosphogypsum, in particular to a non-shrinkage cementing material made of the phosphogypsum and a preparation method of the non-shrinkage cementing material and concrete. The phosphogypsum, coal ash or phosphorous slag, water quenching slag and steel slag are compounded to form a mixed material, the non-shrinkage cementing material is prepared by adding ordinary Portland cement, high-value comprehensive utilization of the phosphogypsum is achieved, sulfate in the phosphogypsum is used as an activator to activate theactivity of the coal ash, the phosphorous slag, the water quenching slag, the steel slag and the like, and reacts with the coal ash, the phosphorous slag, the water quenching slag, the steel slag, Al2O3 in the cement and hydrated product of the cement Ca(OH)2 to form ettringite Aft, capillary pore in the concrete is filled and blocked, the quality percentage control of raw materials is combined, the performance of the cementing material is improved, thus when the cementing material is applied to the concrete, the compactness of the concrete is improved, volume expansion is generated, the non-shrinkage high-performance concrete is obtained, at the same time, the hydration heat of the cement is lowered, cement consumption is saved, and the production cost of the concrete is lowered.

Owner:赵源 +2

Lithium alginate production process

The invention provides a lithium alginate production process.The lithium alginate production process includes steps: (1) performing alkali digestion of brown algae to prepare alginic acid; (2) adding the alginic acid and a certain quantity of a composite lithium salt into a neutralization reactor to react for 50-70min until the alginic acid and the composite lithium salts are completely neutralized to form lithium alginate, wherein neutralization reaction includes solid-phase neutralization reaction and liquid-phase neutralization reaction with ethyl alcohol serving as a medium; consumption of the composite lithium salt is 7-15% of that of the alginic acid; the composite lithium salt is composed of lithium carbonate and lithium acetate, and a ratio of the lithium carbonate to the lithium acetate is 80-90:10-20; (3) performing centrifuging, plunger extruding granulation, drying and grinding to obtain lithium alginate in required meshes.The lithium alginate prepared according to the process is 100-2000mPa.s in viscosity, 40-320 in mesh number, 6.0-8.0 in pH value, smaller than or equal to 15.0% in moisture content and 14-28% in ash content.In addition, the lithium alginate production process can be implemented under the condition of existing sodium alginate solid-phase and liquid-phase neutralization production technology.

Owner:青岛海之林生物科技开发有限公司

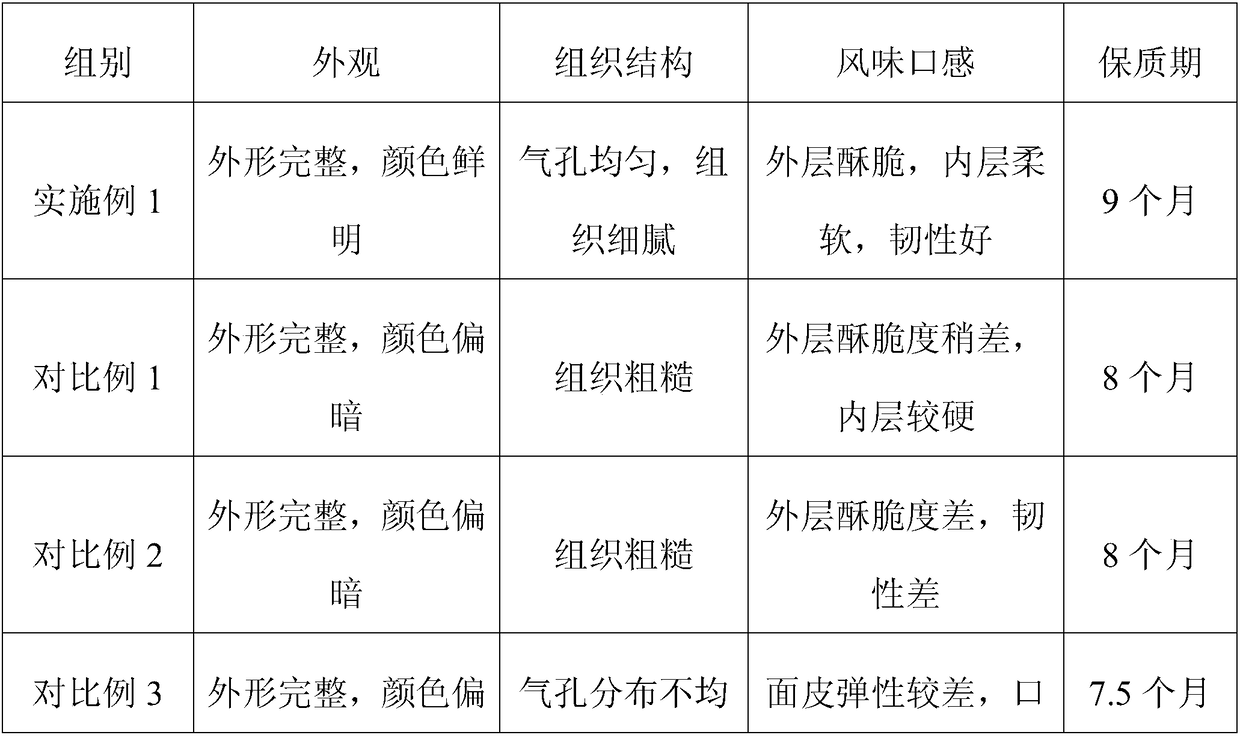

Quick-frozen pan-fried pork buns and making method thereof

InactiveCN109480184AIncrease surface areaCrispy tasteFood freezingYeast food ingredientsGlutenBaking powder

The invention discloses quick-frozen pan-fried pork buns. The wrappers of the pan-fried pork buns comprise the following raw materials in parts by weight of 95-105 parts of medium-gluten flour, 0.15-0.35 part of yeast, 0.8-1.3 parts of white sugar, 0.3-0.5 part of baking powder, 0.8-1.3 parts of emulsified oil, 2-5 parts of lard, 0.2-0.4 part of a wrapper modifier and 51-54 parts of water. The wrapper modifier is added to the wrappers, so that the mouth feel of the wrappers can be notably improved, the stability can be improved, and the quality guarantee period can be prolonged. The inventionalso provides a making method of the quick-frozen pan-fried pork buns. Dough leavening is performed in a freezer, fermentation is performed in the freezer of 0-5 DEG C for one night, on the next day,the effect of half-leavened dough can be achieved, and the wrappers of the pan-fried pork buns can be tenacious and cannot retract; and dough is put in a pork bun making machine for shaping, secondaryleavening is not used, the pan-fried pork buns are directly put in a tunnel for quick-freezing, the technology is simplified and controllable, and the production efficiency is greatly improved.

Owner:河南创新研霖食品科技有限公司

High tear-resistant cable sheath material

The invention discloses a high tear-resistant cable sheath material. The high tear-resistant cable sheath material is prepared from the following raw materials in parts by weight: 53 to 69 parts of nitrile rubber, 18 to 32 parts of polypropylene, 10 to 18 parts of butadiene styrene rubber, 6 to 12 parts of polyurethane elastomer, 1 to 3 parts of black carbon N330, 18 to 27 parts of organophosphate ester modified nanometer clay, 2 to 5 parts of calcium carbonate, 4 to 10 parts of polyester fiber, 0.5 to 2 parts of sulfur powder, 2 to 4 parts of accelerant DM, 1 to 3 parts of accelerant TT, 1 to 5 parts of active zinc oxide, 1 to 3 parts of main antioxidant, 0.5 to 1 part of auxiliary antioxidant, 1 to 3 parts of main ultraviolet absorbing agent, 0.5 to 1 part of auxiliary ultraviolet absorbing agent, 5 to 12 parts of paraffin oil, 2 to 6 parts of trioctyl trimellitate, 3 to 5 parts of tributyl citrate, and 1 to 3 parts of lubricating agent. The high tear-resistant cable sheath material has the advantages that the tear-resistant property, tensile strength and other mechanical property are excellent, the flame-retardant property is good, and the anti-aging property is realized.

Owner:天长市康宁甘油科技有限公司

Production technology of magnesium alginate

The invention provides production technology of magnesium alginate. The production technology comprises the following steps: (1) preparing alginic acid from brown algae via alkali digestion; (2) adding alginic acid and a certain amount of composite magnesium salt into a reactor, and reacting for 50-75 min till alginic acid and composite magnesium salt are neutralized and are completely converted to magnesium alginate, wherein the neutralization reaction comprises a solid-phase neutralization reaction and a liquid-phase neutralization reaction taking alcohol as a medium; (3) using the composite magnesium salt with the amount being 7-15% of that of alginic acid; (4) taking magnesium chloride and basic magnesium salt, the ratio of which is 10-20:80-90, to prepare the composite magnesium salt, wherein (5) the basic magnesium salt comprises one or more of magnesium bicarbonate, magnesium hydroxide, magnesium carbonate, magnesium oxide, magnesium acetate, and magnesium silicate; and (6) performing centrifugation, plunger extruding granulation, drying, and pulverizing to prepare magnesium alginate with a required mesh size. Magnesium alginate prepared in the invention has the viscosity in a range of 100-2000 mPa.s, the mesh size in a range of 40-320 mesh, the pH value in a range of 6.0-8.0, a water content no more than 15.0%, and an ash content in a range of 14-28%. The production technology can be realized in a condition of conventional solid-phase, and liquid-phase neutralization production technology of algin.

Owner:青岛海之林生物科技开发有限公司

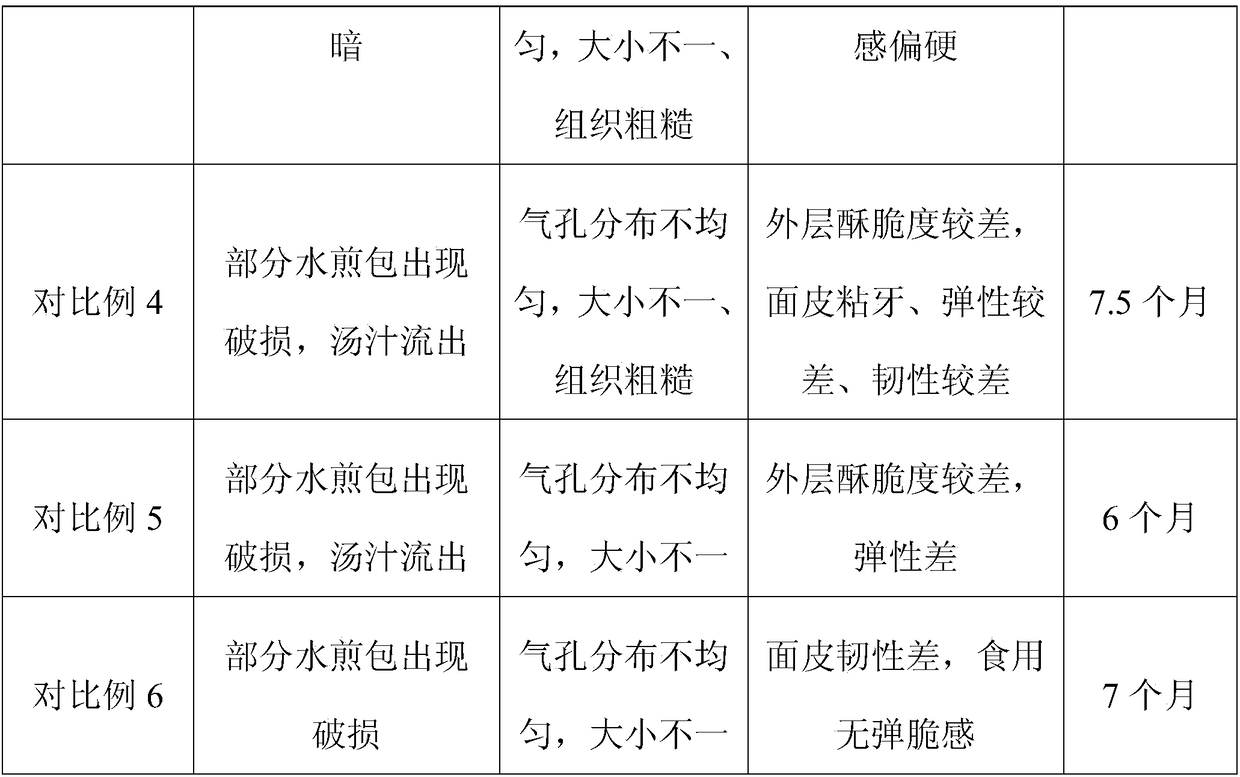

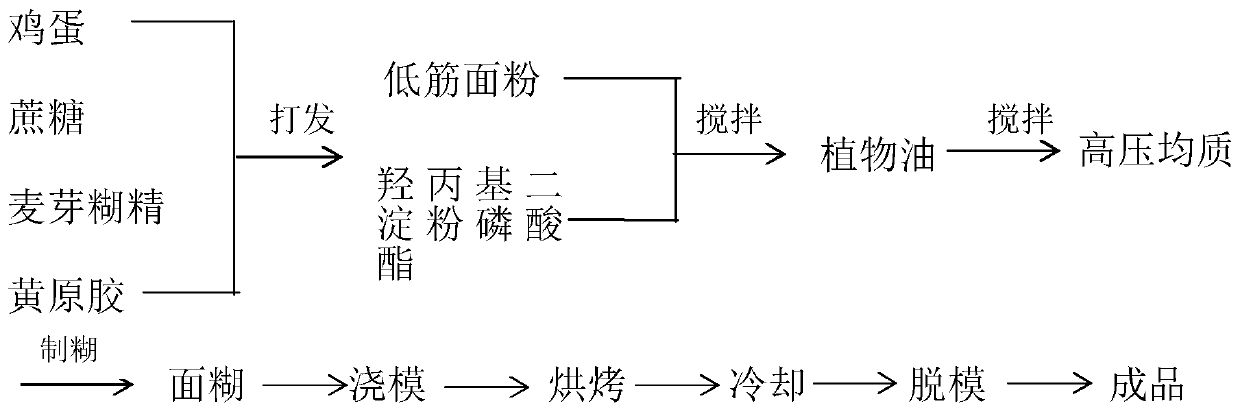

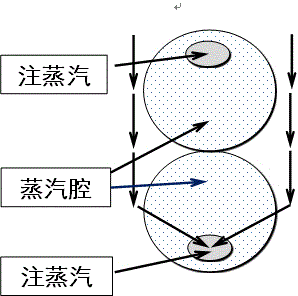

Making method of low-temperature resistant ageing resistant cakes

InactiveCN109699708ANot easy to retractStable structureDough treatmentModified nutritive productsCooking & bakingVegetable oil

The invention discloses a making method of low-temperature resistant ageing resistant cakes. The making method comprises the steps of (1) uniformly mixing maltodextrin with xanthan gum in proportion to obtain a maltodextrin and xanthan gum mixture, weighing cane sugar, egg liquid and the maltodextrin and xanthan gum mixture, performing placing in a stirrer, and performing stirring, to obtain milkywhite foam; (2) adding low-gluten flour and hydroxypropyl distarch phosphate, and performing whipping to obtain paste, so that the flour and egg paste are thoroughly mixed; (3) adding vegetable oil to the stirred cake paste, and performing whipping to obtain paste emulsified for the first time; (4) brushing a layer of the vegetable oil to a cake mold, and then pouring the paste into the cake mold; (5) putting the mold loaded with the paste in an oven for baking; and (6) taking out the thoroughly-cooked cakes, performing natural cooling to room temperature, and performing removing from the mold, so as to obtain cake products. According to the making method, the low-temperature storage properties of the made cakes are improved, the ageing resistance is improved, the cakes are good in tissuestructure stability, the mouth feel of the cakes is improved, and the specific volume of the cakes is increased.

Owner:ZHEJIANG XINDIJIAHE FOOD CO LTD

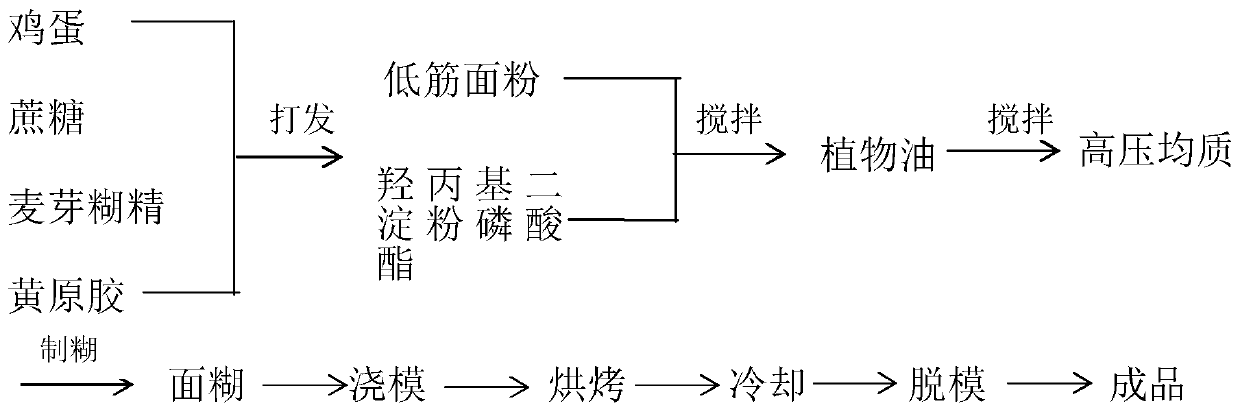

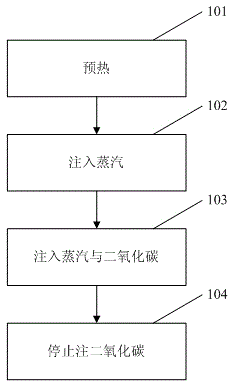

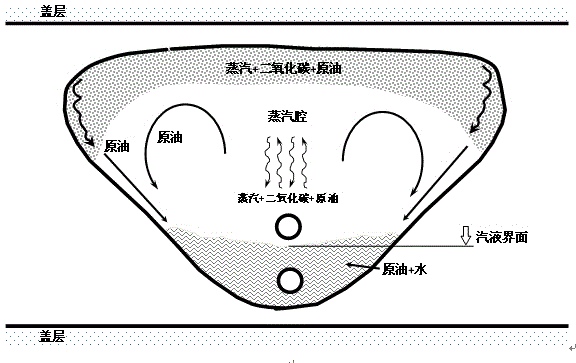

Steam-carbon dioxide assisted gravity oil drainage oil production method

InactiveCN104975834AEnhanced overall recoverySlow down condensationFluid removalHorizontal wellsHeat losses

The invention provides a steam-carbon dioxide assisted gravity oil drainage oil production method, which comprises the following steps of: 1, preheating two horizontal wells in parallel distribution; 2, injecting steam into the upper part horizontal well, and maintaining the original formation pressure in the lower part horizontal well for production; 3, simultaneously injecting the steam and carbon dioxide into an oil layer through the upper part horizontal well, and maintaining the original formation pressure in the lower part horizontal well for production; and 4, stopping the carbon dioxide injection, continuously injecting the steam into the upper part horizontal well, and continuously performing production in the lower part horizontal well. The steam-carbon dioxide assisted gravity oil drainage oil production method has the advantage that through a steam assisted gravity oil discharge technology for reducing the crude oil viscosity, reducing the shaft heat loss and improving the steam enthalpy through adding the carbon dioxide, the recovery ratio of a super-heavy oil reservoir can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of special flour for fried bread stick

The invention discloses a processing method of special flour for fried bread stick, which is characterized by: (1) selection and purchase of the raw material (wheat): selecting 3-4 kinds of wheat for mixing and processing, with the hardness rate being 60-70 percent, the content of wet gluten being more than or equal to 30 percent, the water absorption rate being higher than or equal to 60 percent, the stabilizing period being more than or equal to 6 minutes, the ductility being more than or equal to 150mm, the tensile resistance being 400-500BU and other indicators in line with the second-grade requirements in the national standard; (2) cleaning process: removing various impurities, and ensuring that the impurity content in the wheat to be milled satisfies the national standard; and (3) milling process: completely milling and screening to reduce the floating impurities and the ash content in the flour; adopting the milling process of removing husks five times, removing cores eight times, removing slag twice and removing residues twice, purifying 5-6 times, using the coproduction technology so that the extraction proportion of the special flour for the fried bread stick reaches 12-15 percent, and extracting during the preceding husk milling, residue milling and rescreening. The fried food produced with the special flour for the fried bread stick of the invention can reduce the oil absorption rate of the product, and has an enlarged size, a fine and uniform structure, a crispy taste and a golden color.

Owner:ZHANGJIAGANG FLOUR FOOD

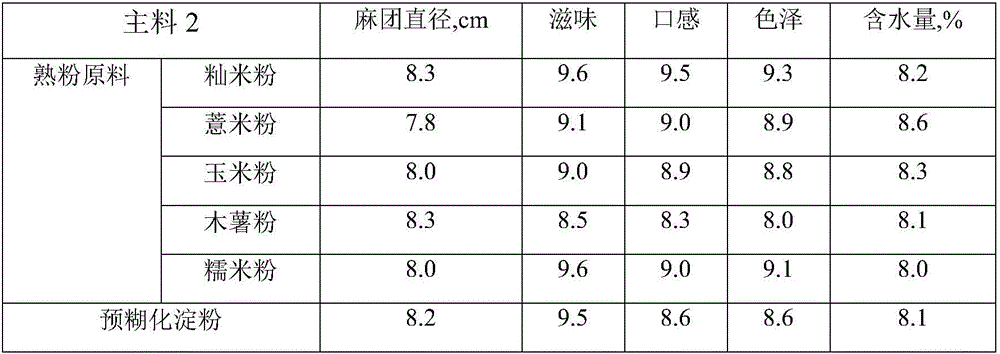

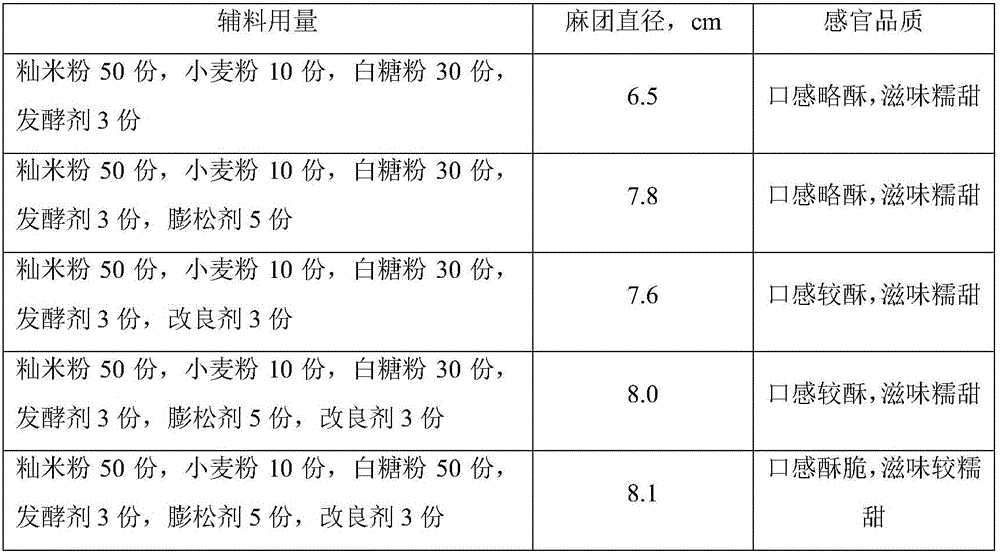

Special flour for fried glutinous rice balls with sesame seeds, as well as making method and application of special flour

InactiveCN106386951AEasy to useImprove volume expansionDough treatmentDough/pre-mixesBiotechnologyTriticum turgidum

The invention belongs to the field of food processing, and relates to special flour for fried glutinous rice balls with sesame seeds, as well as a making method and an application of the special flour. The special flour for the fried glutinous rice balls with sesame seeds is made from, in parts by weight, a main material 1 such as 100 parts of raw glutinous rice flour, a main material 2 such as 50-300 parts of cooked flour and auxiliary materials such as 5-100 parts of long-shaped rice flour, 1-20 parts of wheat flour, 10-100 parts of white sugar powder and 0.1-3 parts of a fermenting agent. The making method comprises the following step of pasting the raw material of the main material 2. When the special flour for the fried glutinous rice balls with sesame seeds disclosed by the invention is used, only an appropriate amount of water needs to be added, and the special flour is convenient to use.

Owner:HUAZHONG AGRI UNIV

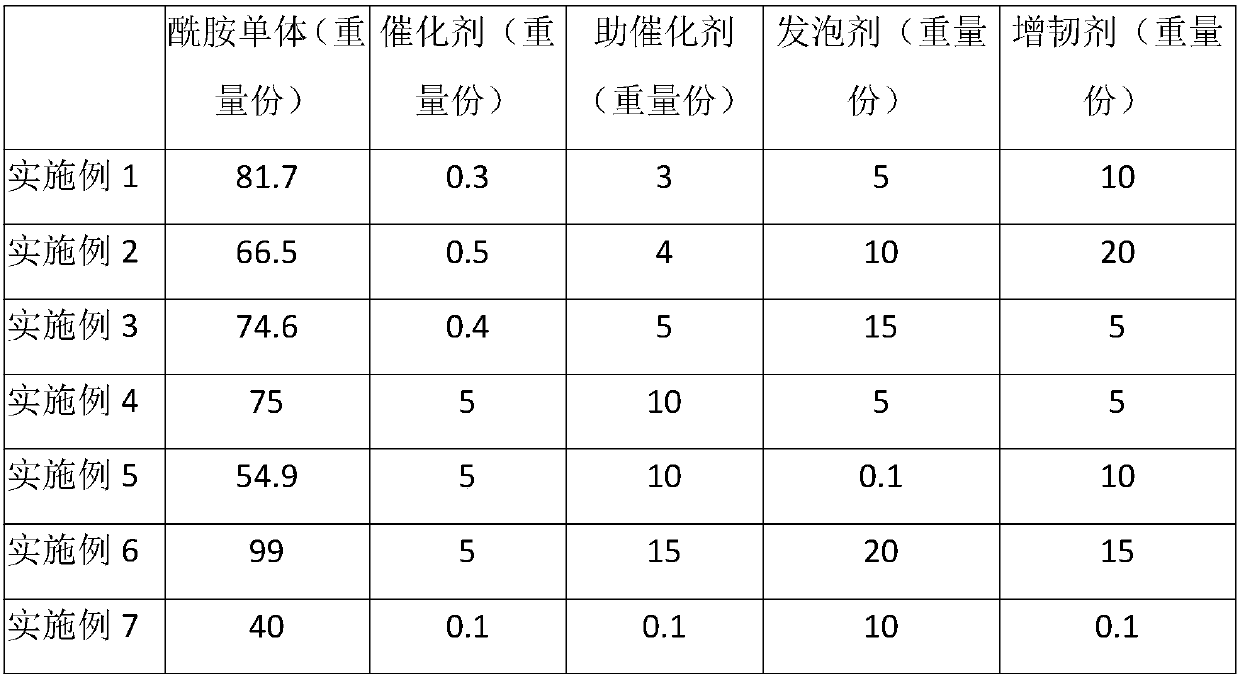

Lightweight foaming casting nylon material and its preparation method and application

The invention discloses a lightweight foaming casting nylon material, which is prepared from, by weight, 40-99.6 parts of amide monomer, 0.1-5 parts of catalyst, 0.1-15 parts of promoter, 0.1-20 partsof foaming agent, and 0.1-20 parts of flexibilizer. The lightweight foaming casting nylon material aims to solve the shortcomings of uncontrollable foaming and poor mechanical performance during theprocess of the existing foaming and casting production. By compounding the foaming agent with the flexibilizer and adjusting the MCPA6 formula technique, the foaming agent is foamed in a MCPA6 monomermelt, so as to further polymerize and shape. The lightweight foaming casting nylon material solves the problem of shaping and contraction of MCAP6. The invention further provides a preparation technique of the lightweight foaming casting nylon material; the foaming technique of the material is stable and the material is good in mechanical performance. The lightweight foaming casting nylon material can be widened to its application domain, and applied to lightweight, shock reduction and noise reduction of an automobile.

Owner:HUNAN UNIV OF TECH

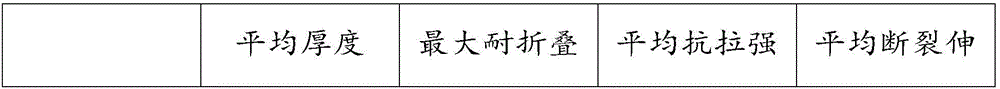

Edible food package film and preparation method thereof

InactiveCN106805248AHigh antibacterial activityHigh bactericidal activityFlexible coversWrappersFood packagingMechanical property

The invention belongs to the field of food packaging and relates to an edible food package film and a preparation method thereof. The preparation method includes: adding, by weight, 30-80 parts of castanopsis sclerophylla powder into water to obtain a suspension, and gelatinizing the suspension to obtain castanopsis sclerophylla powder gelatinized liquid; dissolving, by weight, 10-60 parts of chitosan into acid solution to obtain chitosan solution; mixing the castanopsis sclerophylla powder gelatinized liquid with the chitosan solution, adding, by weight, 1-60 parts of edible additives, and filtering to obtain filtrate; subjecting the filtrate to reduced-pressure debubbling, injection molding and drying to obtain the edible food package film. The preparation method is simple in step and convenient and quick in operation, and the edible food package film prepared according to the method is excellent in mechanical property, water resistance, antibacterial performance and freshness preservation and is foldable repeatedly. In addition, the package film is edible and degradable after being discarded, thereby being green and environmental friendly.

Owner:HUBEI ENG UNIV

Lightweight foam composite material having high water storage capacity and achieving continuous water supply

ActiveCN108207604AImprove water storage capacitySustainable water supplyAgriculture gas emission reductionCultivating equipmentsCelluloseFiber

The invention relates to a building or wall material suitable for plant growth, in particular to a lightweight foam composite material having the high water storage capacity and achieving continuous water supply. The components of the material comprise two or more of polymer, hydrogel particles, cellulose and hard fiber, and the material is obtained by mixing and foaming all the components; holesformed through material foaming and hydrogel or cellulose swelling after water absorption form water channels; after water absorption, the whole volume expansion ratio of the material is smaller than5%. The material is high in water storage capacity, high in strength, small in contour expansion after water absorption, good in water mobility and suitable for plant growth.

Owner:邬瑛 +5

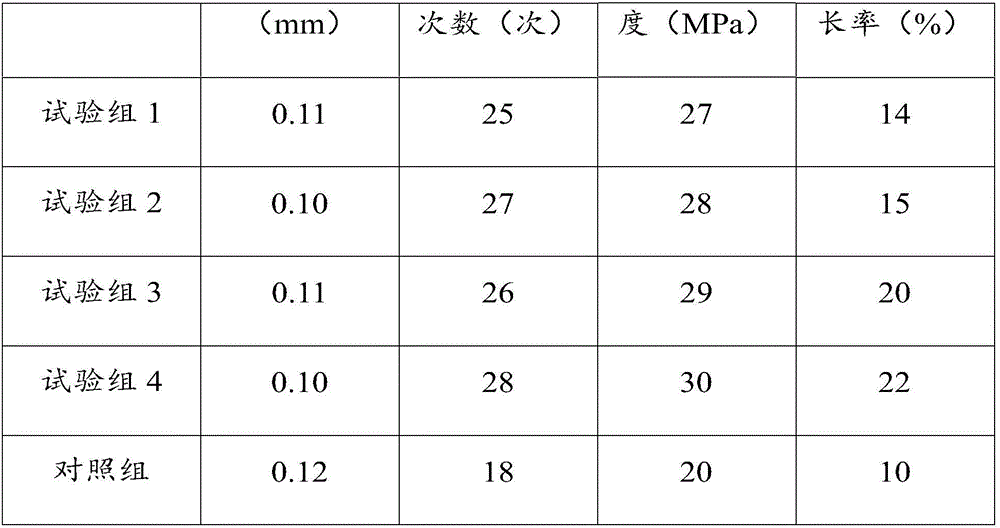

Water-retaining planting method for Millettia specisoa Champ in sloping land

InactiveCN108476896ANo pollution in the processLarge specific surface areaSuperphosphatesBioloigcal waste fertilisersBiologyBiomass

The invention belongs to the technical field of agricultural planting, and specifically relates to a water-retaining planting method for Millettia specisoa Champ in a sloping land. The water-retainingplanting method comprises the following steps: (1) preparationof the sloping land; (2) seedling raising and transplanting; and (3) water and nutrient management. The water-retaining planting method provided by the invention has the following steps: biomass charcoal and a water-retaining fertilizer are spread onto the sloping land during ploughing and buried into soil after ploughing, have good water-retaining effect, can rapidly absorb and slowly release water, realize water retention for the sloping land, and have good water-retaining effect, so the Millettia specisoa Champ can vigorously grow on the sloping land, and the yield of the Millettia specisoa Champ on the sloping land is increased.

Owner:东兰县委荣村伟造林下药材种植合作社

Waxy wheat fried food and preparation method thereof

The invention relates to a waxy wheat fried food and a preparation method thereof. The waxy wheat fried food comprises the following raw materials in percentage by weight: 50-100 percent of main material and 0-50 percent of auxiliary material. The preparation method comprises the following steps of: preparing dough; pressing billets; frying; and packaging. The food prepared by the method keeps the original wheat aroma and nutrition, is ready to enjoy when opened, has scrip mouthfeel, and is a featured healthy leisure food. The method has the advantages of simple formula, easiness and convenience in operation, safety and suitability for industrial production; and a successful approach is provided for effective utilization of the waxy wheat.

Owner:JIANGSU LIXIAHE REGION AGRI RES INST

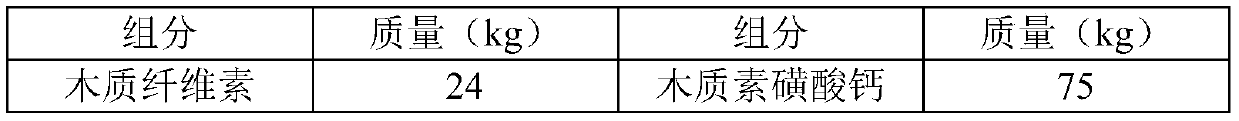

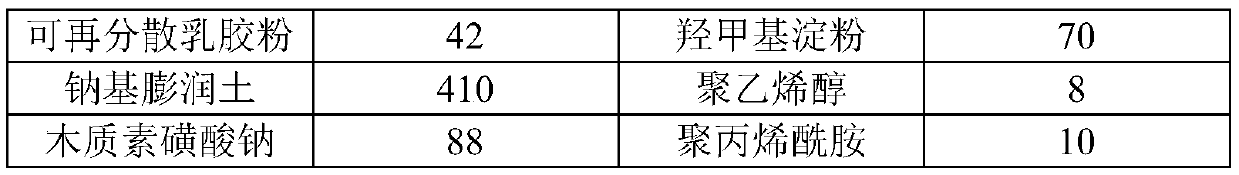

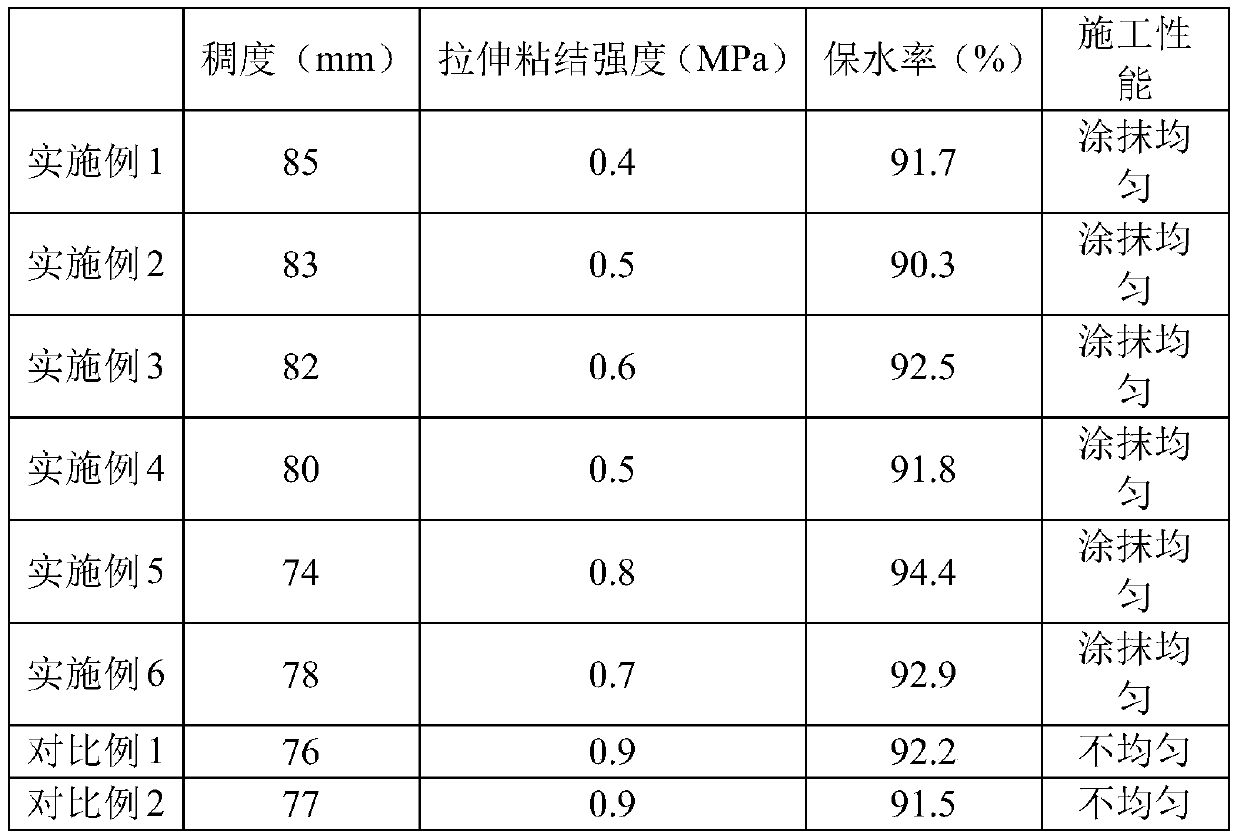

Thickening powder for dry-mixed mortar and preparation method of thickening powder

The invention relates to thickening powder for dry-mixed mortar and a preparation method of the thickening powder. The invention relates to the technical field of dry-mixed mortar. The thickening powder particularly includes the following components: 20-30 kg / t of cellulose, 30-45 kg / t of redispersible latex powder, 380-430 kg / t of bentonite, 80-100 kg / t of sodium lignosulphonate and 60-80 kg / t ofcalcium lignosulphonate. The thickening powder also comprises 50 to 70 kg / t of hydroxymethyl starch, 5 to 10 kg / t of polyvinyl alcohol, and 10 to 15 kg / t of polyacrylamide. The thickening powder prepared by the invention is added into the dry-mixed mortar, so that the consistency of the mortar can be ensured, and the binding power between the mortar and a wall body can be improved.

Owner:宁波新广亿建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com