Method for improving polyphenol retention rate and antioxidant activity of grains in extruding and pasting

A technology of antioxidant activity and extrusion gelatinization, which is applied in the field of food processing, can solve the problems of unfavorable polyphenol retention, free phenolic acid release, reduction of antioxidant activity of extrudates, loss of polyphenols, etc., to improve antioxidant activity and degree of gelatinization, improving retention and antioxidant capacity, avoiding significant and detrimental losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

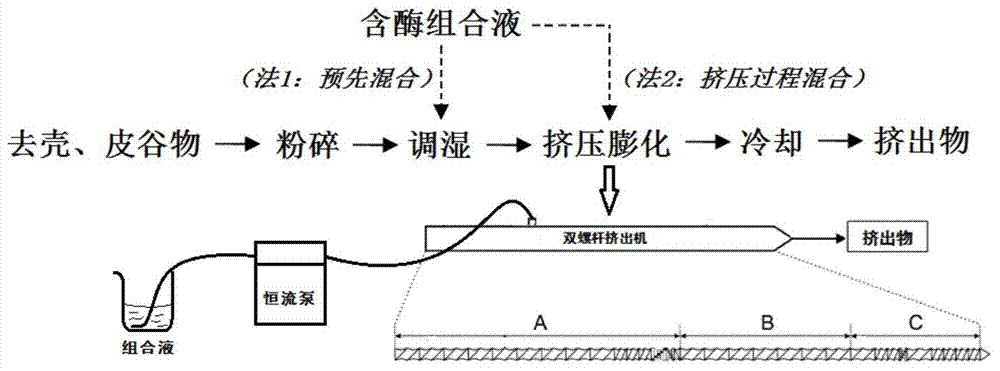

Method used

Image

Examples

Embodiment 1

[0030] Select 1000g of wheat as a grain raw material, shell the wheat, and after crushing and sieving, the water content is about 13.16%, and the starch content is 67.26%. The used combination solution comprises 0.05% of high temperature resistant α-amylase, 0.5% of sodium chloride, 0.05% of sodium acetate, 0.02% of sodium citrate and 0.02% of calcium lactate based on the dry basis of pretreated wheat starch. Wheat raw material after the pretreatment is earlier combined liquid (according to adjusting water content is 30% to add combined liquid, promptly calculates and should add 240.57g combined liquid, wherein amylase, sodium chloride, sodium acetate, sodium citrate, calcium lactate add respectively 0.34, 3.36, 0.34, 0.13, 0.13g, mixed in the combination liquid) and mixed evenly, extruded by twin-screw extrusion system, wherein the temperature of the first sleeve, the second sleeve and the third sleeve They are 45°C, 65°C and 95°C respectively. The screw speed was 50 rpm, an...

Embodiment 2

[0033]Select 1000 g of corn as a raw material of grain, peel the corn, grind it, and sieve it. The moisture content is about 14.54%, and the starch content is 72.63%. The used combination solution comprises 0.05% of high-temperature resistant alpha-amylase, 0.8% of sodium chloride, 0.8% of sodium acetate, 0.02% of sodium citrate and 0.02% of calcium lactate based on the dry basis of pretreated cornstarch. The corn raw material after pretreatment utilizes twin-screw extruding system to extrude and handle, and combined liquid is added as 40% by regulating water content in extrusion process (that is, calculation should add 424.33g combined liquid, wherein amylase, sodium chloride, acetic acid Sodium, sodium citrate, and calcium lactate are 0.36, 5.81, 5.81, 0.14, and 0.14g respectively, mixed in the combination solution), and the temperatures of the first sleeve, the second sleeve, and the third sleeve are respectively 40°C, 60°C and 100°C. The screw speed was 400rpm, and the ex...

Embodiment 3

[0036] Select 1000g of rice as a grain raw material, peel the rice, grind it, and pass through a sieve. Its water content is about 12.62%, and its starch content is 73.18%. The used combination solution comprises 0.3% of medium-temperature alpha-amylase, 1% of sodium chloride, 0.05% of sodium acetate, 0.8% of sodium citrate and 0.02% of calcium lactate based on the dry basis of pretreated rice starch. The rice raw material after pretreatment is mixed with combination liquid in advance (according to adjusting water content is 30% to add combination liquid, promptly calculates and should add 248.29g combination liquid, wherein amylase, sodium chloride, sodium acetate, sodium citrate, calcium lactate add respectively 2.19, 7.32, 0.36, 5.86, 0.14g, mixed in the combination liquid) and mixed evenly, extruded by twin-screw extrusion system, wherein the temperature of the first sleeve, the second sleeve and the third sleeve They are 25°C, 35°C and 60°C respectively. The screw speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com