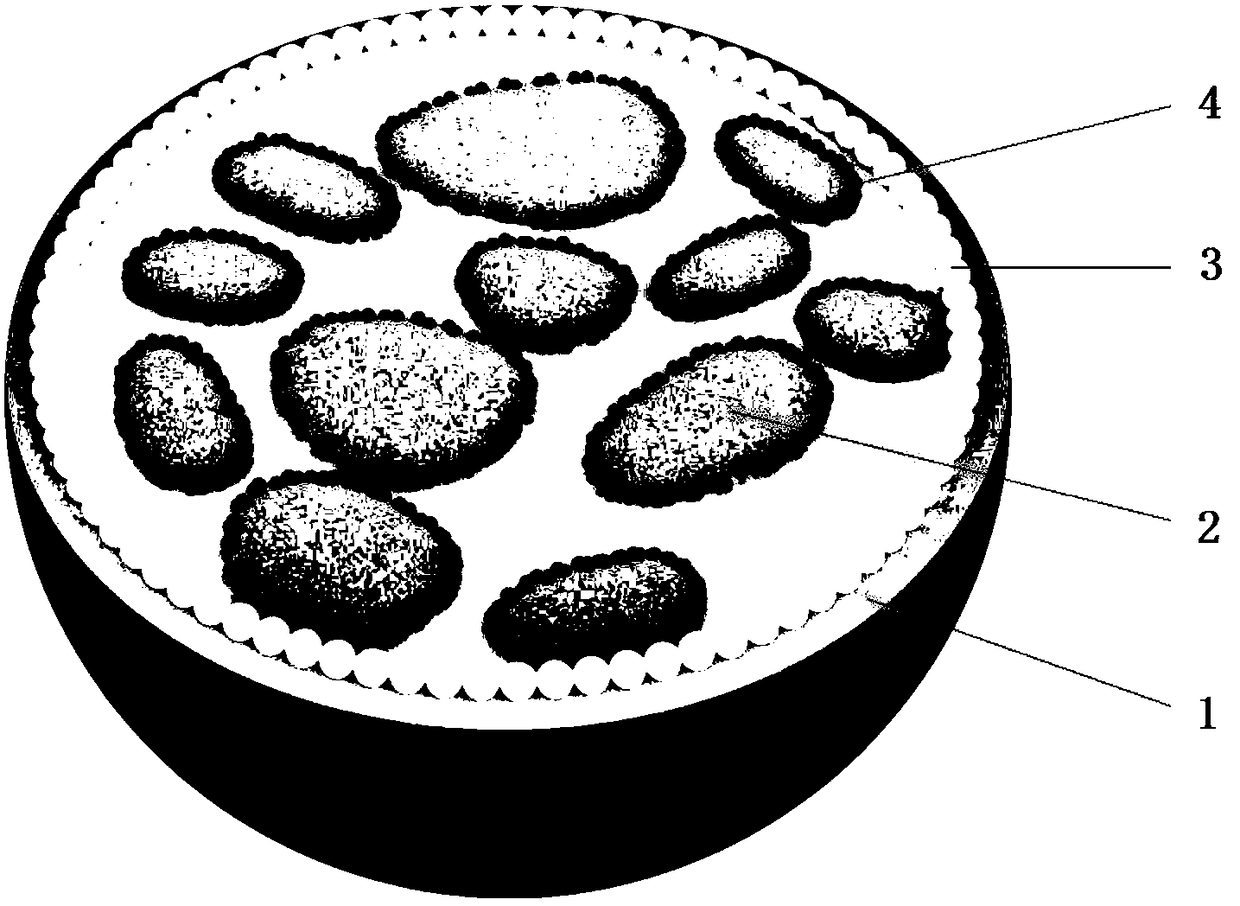

A double-layer coated core-shell negative electrode material for lithium ion battery and a preparation method thereof

A technology of lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of high platform voltage and low specific capacity, and improve conductivity and volume Effects of reduced swelling and excellent long-cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

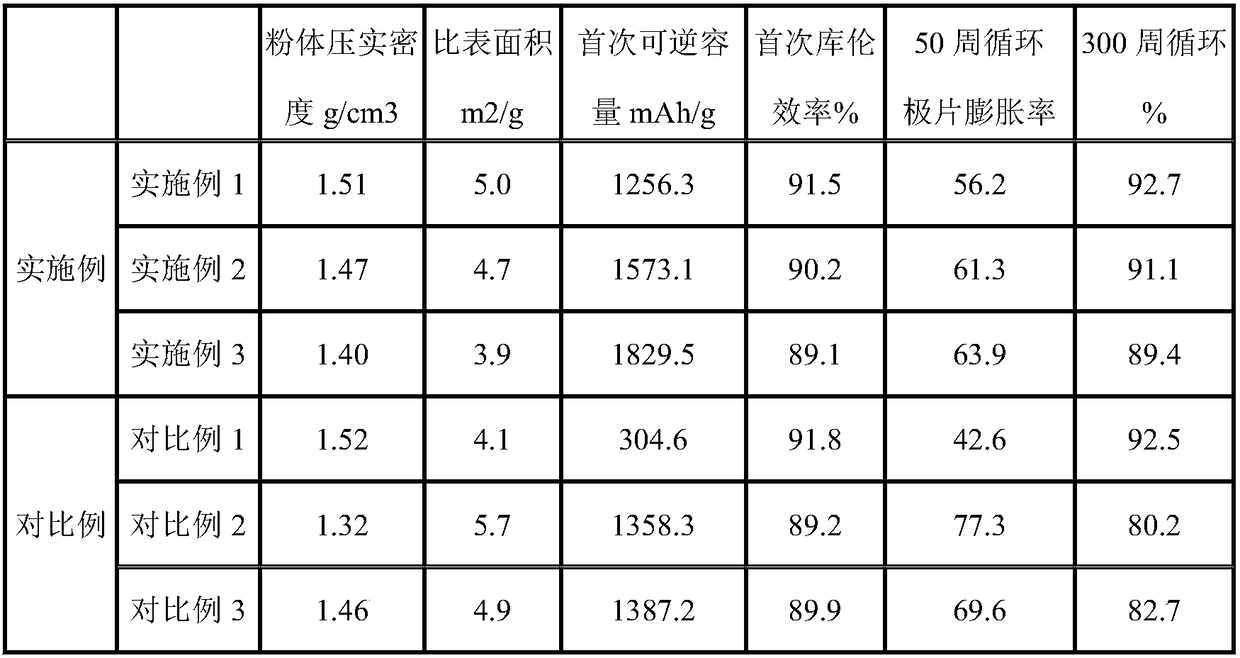

Examples

Embodiment 1

[0023] The preparation method of the double-layer coated core-shell negative electrode material for lithium ion battery described in this embodiment is specifically carried out according to the following steps:

[0024] (1) Take natural graphite particles with a median particle size of 6 μm and place them in the CVD furnace liner, feed nitrogen to remove the air in the CVD furnace until the oxygen content is ≤100ppm, and then raise the temperature to 980°C at a heating rate of 5°C / min , the calcination time is 2h, after the calcination is completed, the silicon tetrachloride gas is introduced into the chemical vapor phase deposition for 1h, the flow rate of the silicon tetrachloride gas is 2L / min, and then sintered at a constant temperature for 4h, the nano-silicon particles are uniformly deposited on the graphite particles, and the negative electrode is obtained material precursors.

[0025] (2) Take titanium dioxide, lithium carbonate and phenolic resin and disperse them in ...

Embodiment 2

[0029] The preparation method of the double-layer coated core-shell negative electrode material for the lithium ion battery described in this embodiment is specifically carried out according to the following steps:

[0030] (1) Take natural graphite particles with a median particle size of 8 μm and place them in the CVD furnace liner, feed nitrogen to remove the air in the CVD furnace until the oxygen content is ≤100ppm, and then raise the temperature to 800°C at a heating rate of 5°C / min , the calcination time is 5h, after the calcination is completed, the silicon tetrachloride gas is fed into the chemical vapor deposition for 2h, the flow rate of the silicon tetrachloride gas is 2L / min, and then sintered at a constant temperature for 4h, the nano-silicon particles are uniformly deposited on the graphite particles, and the negative electrode is obtained material precursors.

[0031] (2) Take titanium dioxide, lithium carbonate and phenolic resin and disperse them in an organic ...

Embodiment 3

[0035] The preparation method of the double-layer coated core-shell negative electrode material for the lithium ion battery described in this embodiment is specifically carried out according to the following steps:

[0036] (1) Take natural graphite particles with a median particle size of 10 μm and place them in the CVD furnace liner, pass nitrogen gas to remove the air in the CVD furnace until the oxygen content is ≤ 100ppm, and then raise the temperature to 700°C at a heating rate of 5°C / min , the calcination time is 5h, after the calcination is completed, the silicon tetrachloride gas is fed into the chemical vapor phase deposition for 4h, the flow rate of the silicon tetrachloride gas is 2L / min, and then sintered at a constant temperature for 4h, the nano-silicon particles are uniformly deposited on the graphite particles, and the negative electrode is obtained material precursors.

[0037] (2) Take titanium dioxide, lithium carbonate and phenolic resin and disperse them ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com