Edible food package film and preparation method thereof

A food packaging film, chitosan technology, applied in packaging, wrapping paper, transportation and packaging, etc., to achieve the effects of volume expansion, convenient operation and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

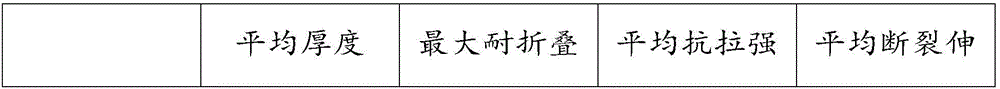

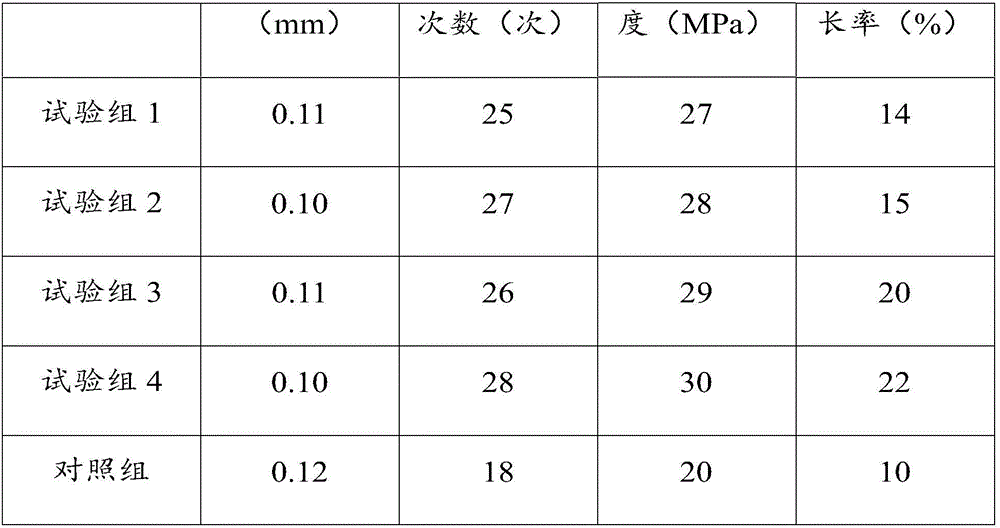

Examples

Embodiment 1

[0024] Crush Mangosteen to get Mangosteen powder, and add 1.5g of Mangosteen powder per 100mL of water to prepare a suspension. The suspension is gelatinized in a hot water bath at 60° C. to obtain a gelatinized solution of Quincinia chinensis powder.

[0025] Take high-molecular-weight sea crab shell chitosan with a weight-average molecular weight of 950KDa and a deacetylation degree of 89% as the chitosan raw material, and add 1g of high-molecular-weight chitosan to every 100mL acidic solution to prepare a chitosan solution . Wherein, the acidic solution includes acetic acid, and the volume percentage of acetic acid in the acidic solution is 1%.

[0026] Mix the gelatinized solution of the above-mentioned phalaetum powder and the chitosan solution in a volume ratio of 30:10, and then add 1 g of the plant essential oil and glycerin mixture to the mixed solution. Next, pass the solution after adding the edible additive through a 180-mesh sieve, and degas the filtrate for 0.5 h...

Embodiment 2

[0028] Crush the seed kernels of Castanopsis chinensis to 40 meshes to obtain the powder of Castanopsis chinensis, which is prepared into a suspension by adding 10 g of Castanopsis chinensis powder per 100 mL of water. The suspension is gelatinized in a hot water bath at 80° C. to obtain a gelatinized solution of the bitter mango powder.

[0029] High-molecular-weight sea prawn chitosan and medium-molecular-weight sea prawn chitosan are used as chitosan raw materials. Wherein the weight-average molecular weight of high molecular weight chitosan is 320KDa and its degree of deacetylation is 92%, accounts for 70% of chitosan weight percentage; Medium molecular weight chitosan is obtained after adopting enzymatic hydrolysis to degrade high molecular weight chitosan, its The weight-average molecular weight is 30KDa and the degree of deacetylation is 90%, accounting for 30% of the chitosan weight percentage. The chitosan solution is formulated at the ratio of adding 5g of chitosan ...

Embodiment 3

[0032] Crush the seed kernels of Castanopsis chinensis to 200 meshes to obtain the powder of Castanopsis chinensis, which is prepared into a suspension by adding 6 g of Castanopsis chondrochia powder per 100 mL of water. The suspension is gelatinized in a hot water bath at 70° C. to obtain a gelatinized solution of Castanopsis chinensis powder.

[0033] The high molecular weight crayfish shell chitosan and the medium molecular weight crayfish shell chitosan are taken together as chitosan raw materials. Wherein the weight-average molecular weight of high molecular weight chitosan is 800KDa and its degree of deacetylation is 85%, accounts for 85% of chitosan weight percentage; Medium molecular weight chitosan is gained after adopting hydrogen peroxide to degrade high molecular weight chitosan, and its weight The average molecular weight is 10KDa and the degree of deacetylation is 83%, accounting for 15% of chitosan by weight. The chitosan solution is formulated at the ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com