Antibacterial liquid laundry detergent, preparation method and applications thereof

A technology of laundry detergent and antibacterial agent, which is applied in the field of daily chemicals, can solve problems such as difficult to achieve antibacterial sterilization, unfavorable industrial production, and poor mold inhibition, and achieve high antimicrobial efficiency, low cost, and improved antibacterial activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

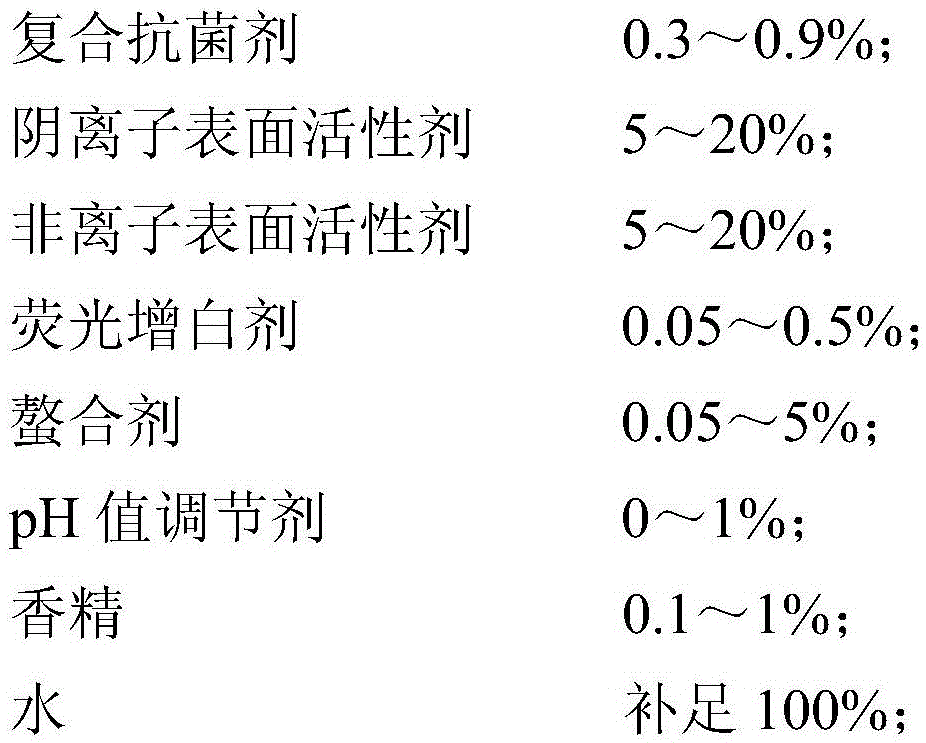

[0033] An antibacterial laundry detergent, comprising the following components by mass percentage:

[0034]

[0035]

[0036] The preparation method of above-mentioned antibacterial laundry detergent, comprises the steps:

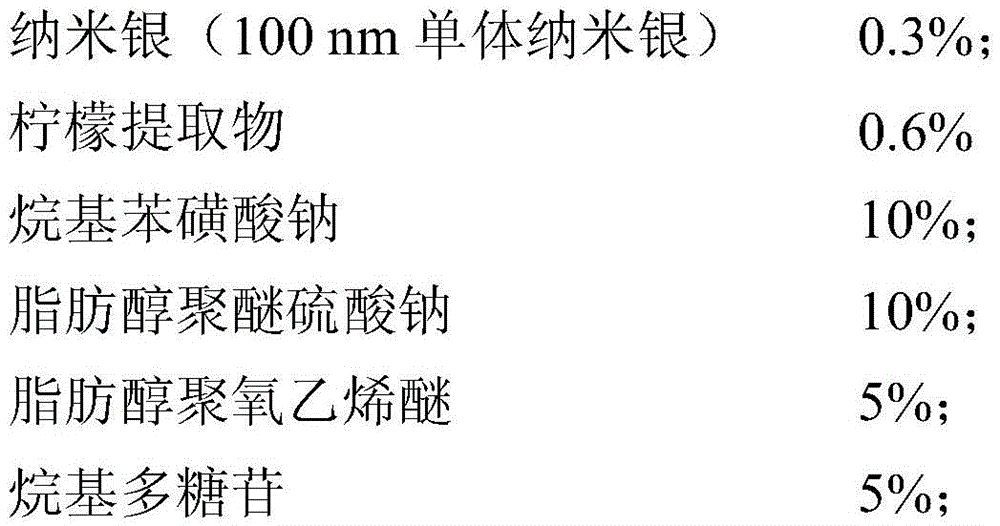

[0037] (1) 0.3% of nano-silver and 0.6% of lemon extract are mixed to obtain a composite antibacterial agent;

[0038] (2) Add 68.5% deionized water into the reaction kettle, heat the temperature to 60°C, add 10% sodium alkylbenzenesulfonate, 10% fatty alcohol polyether sodium sulfate, and 5% fatty alcohol polyoxyethylene ether , 5% alkyl polyglucoside, 0.1% biphenyl whitening agent and 0.1% disodium ethylenediaminetetraacetate, after stirring evenly, adjust the pH value to 7.5 with citric acid, lower the temperature to 30°C, and add 0.3% of essence and 0.9% of compound antibacterial agent are stirred evenly to obtain antibacterial laundry detergent.

Embodiment 2

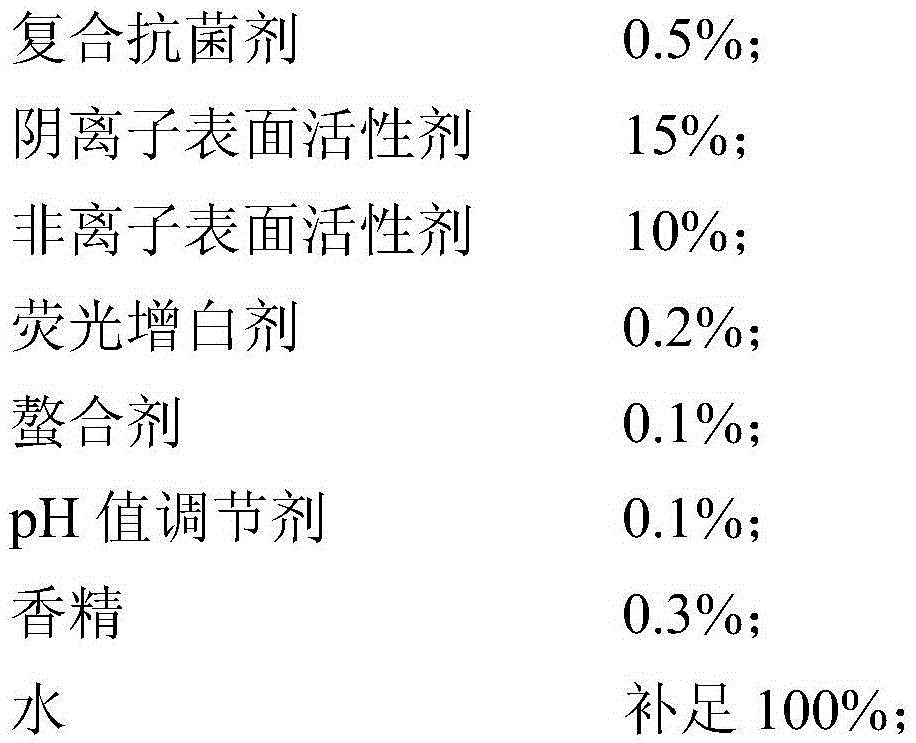

[0040] An antibacterial laundry detergent, comprising the following components by mass percentage:

[0041]

[0042] The preparation method of above-mentioned antibacterial laundry detergent, comprises the steps:

[0043] (1) 0.3% of nano-silver and 0.4% of aloe extract are mixed to obtain a composite antibacterial agent;

[0044] (2) Add 67.9% deionized water into the reactor, heat the temperature to 65°C, add 5% sodium alkylbenzene sulfonate, 10% sodium fatty alcohol polyether sulfate, and 5% sodium fatty acid methyl ester sulfonate in sequence , 5% fatty alcohol polyoxyethylene ether, 5% isomeric alcohol polyoxyethylene ether, 0.1% distyrene-biphenyl type whitening agent and 1% sodium citrate, adjust the pH value to 8.0 after stirring evenly, and reduce When the temperature reaches 35°C, add 0.3% essence and 0.7% compound antibacterial agent, and stir evenly to obtain an antibacterial laundry detergent.

Embodiment 3

[0046] An antibacterial laundry detergent, comprising the following components by mass percentage:

[0047]

[0048] The preparation method of above-mentioned antibacterial laundry detergent, comprises the steps:

[0049] (1) 0.2% of nano-silver and 0.3% of lemon extract are mixed to obtain a composite antibacterial agent;

[0050] (2) Add 68.75% deionized water into the reactor, heat the temperature to 70°C, add 10% sodium alkylbenzenesulfonate, 5% sodium fatty alcohol polyether sulfate, and 5% sodium a-alkenylsulfonate in sequence %, fatty alcohol polyoxyethylene ether 5%, fatty acid methyl ester ethoxylate 5%, bistriazine stilbene derivatives 0.3% and tetrasodium edetate 0.1%, adjust with citric acid after stirring The pH value is 8.5, the temperature is lowered to 40° C., 0.3% of essence and 0.5% of compound antibacterial agent are added, and the antibacterial laundry liquid is obtained after stirring evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com