Silicon-based anode material of lithium ion battery and preparation method of silicon-based anode material

A silicon-based negative electrode material and lithium-ion battery technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems that limit the commercialization of silicon materials, structural damage, and loss of lithium intercalation capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

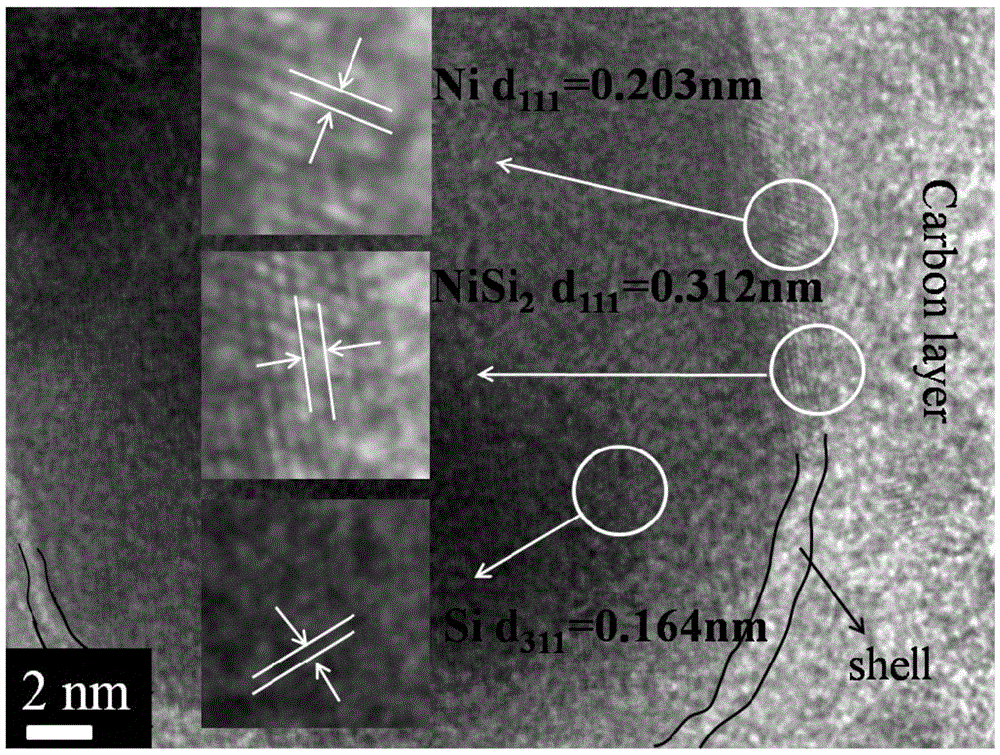

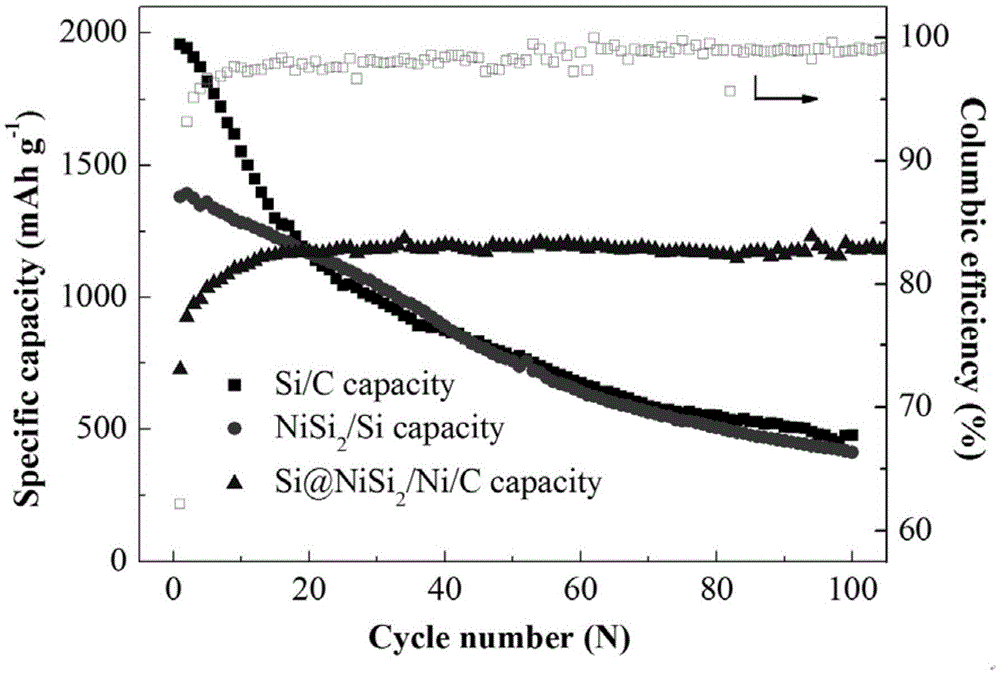

[0054] A Li-ion battery core-shell structure SiNiSi 2 / Ni / C negative electrode material, the silicon-based negative electrode material is a silicon-metal alloy three-layer composite material with a core-shell structure, the core layer is silicon, and the middle layer is an alloy compound NiSi of silicon and metal Ni 2 A mixture of Ni and metal, the outermost layer is pyrolytic carbon.

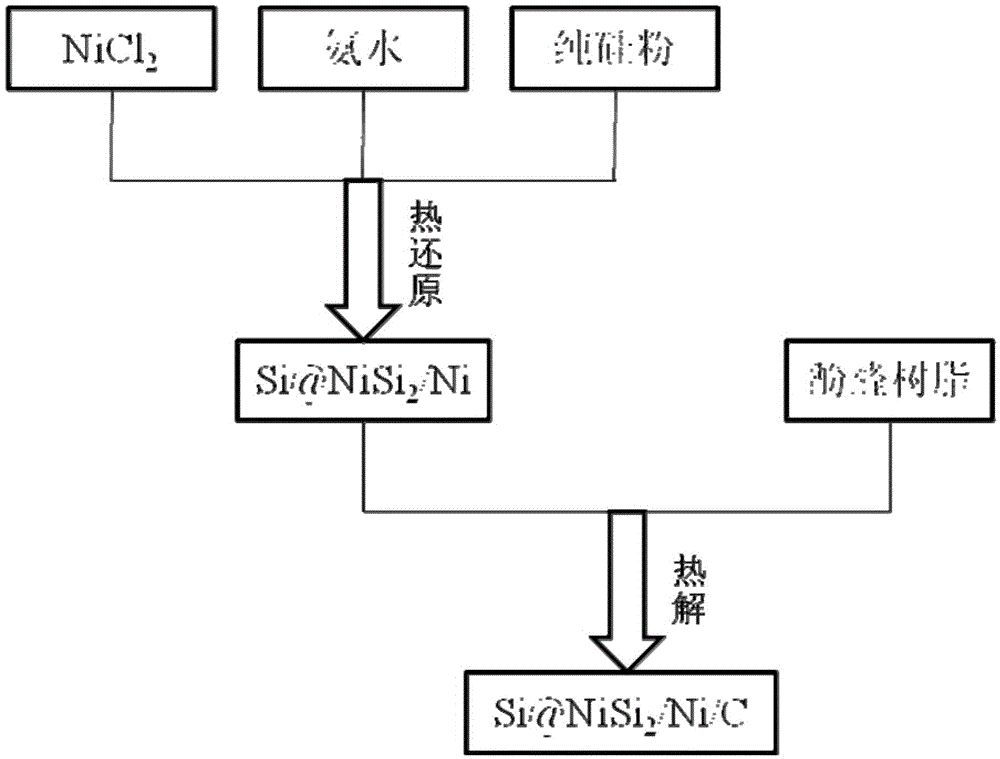

[0055] Prepared by the following steps, the detailed process is as follows figure 1 Shown:

[0056] Step 1: Dissolve nickel chloride in deionized water to obtain nickel chloride solution I, wherein the mass of nickel chloride is m NiCl2 =0.1166g;

[0057] Step 2: After stirring solution I at room temperature for 2 hours, add nano silicon powder, and then continue to stir for 4 hours to obtain solution II, wherein n Si :n Ni 2+ =20:1;

[0058] Step 3: Slowly add ammonia water dropwise to solution II to produce precipitation to obtain Ni(OH) 2 The mixed solution III attached to the surfac...

Embodiment 2

[0069] A Li-ion battery core-shell structure SiNiSi 2 / Ni / C negative electrode material, the silicon-based negative electrode material is a silicon-metal alloy three-layer composite material with a core-shell structure, the core layer is silicon, and the middle layer is an alloy compound NiSi of silicon and metal Ni 2 A mixture of Ni and metal, the outermost layer is pyrolytic carbon.

[0070] Prepared by the following steps, the detailed process is as follows figure 1 Shown:

[0071] Step 1: Dissolve nickel chloride in deionized water to obtain nickel chloride solution I, wherein the mass of nickel chloride is m NiCl2 =0.0778g;

[0072] Step 2: After stirring solution I at room temperature for 2 hours, add nano silicon powder, and then continue to stir for 2 hours to obtain solution II, wherein n Si :n Ni 2+ =30:1;

[0073] Step 3: Slowly add ammonia water dropwise to solution II to produce precipitation to obtain Ni(OH) 2The mixed solution III attached to the surface...

Embodiment 3

[0083] A Li-ion battery core-shell structure SiNiSi 2 / Ni / C negative electrode material, the silicon-based negative electrode material is a silicon-metal alloy three-layer composite material with a core-shell structure, the core layer is silicon, and the middle layer is an alloy compound NiSi of silicon and metal Ni 2 A mixture of Ni and metal, the outermost layer is pyrolytic carbon.

[0084] Prepared by the following steps, the detailed process is as follows figure 1 Shown:

[0085] Step 1: Dissolve nickel chloride in deionized water to obtain nickel chloride solution I, wherein the mass of nickel chloride is m NiCl2 =0.0778g;

[0086] Step 2: After stirring solution I at room temperature for 2 hours, add nano silicon powder, and then continue to stir for 2 hours to obtain solution II, wherein n Si :n Ni 2+ =5:1;

[0087] Step 3: Slowly add ammonia water dropwise to solution II to produce precipitation to obtain Ni(OH) 2 The mixed solution III attached to the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com