Experimental device and experimental method for thickened oil pool mixed nano-fluid alternating CO2 microbubble flooding

A nanofluid and heavy oil reservoir technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of reduced plane and vertical sweep coefficient, poor development effect, high viscosity of heavy oil, etc. To achieve the effect of expanding the longitudinal sweep coefficient, inhibiting gas channeling and gravity overriding, and improving the expansion of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

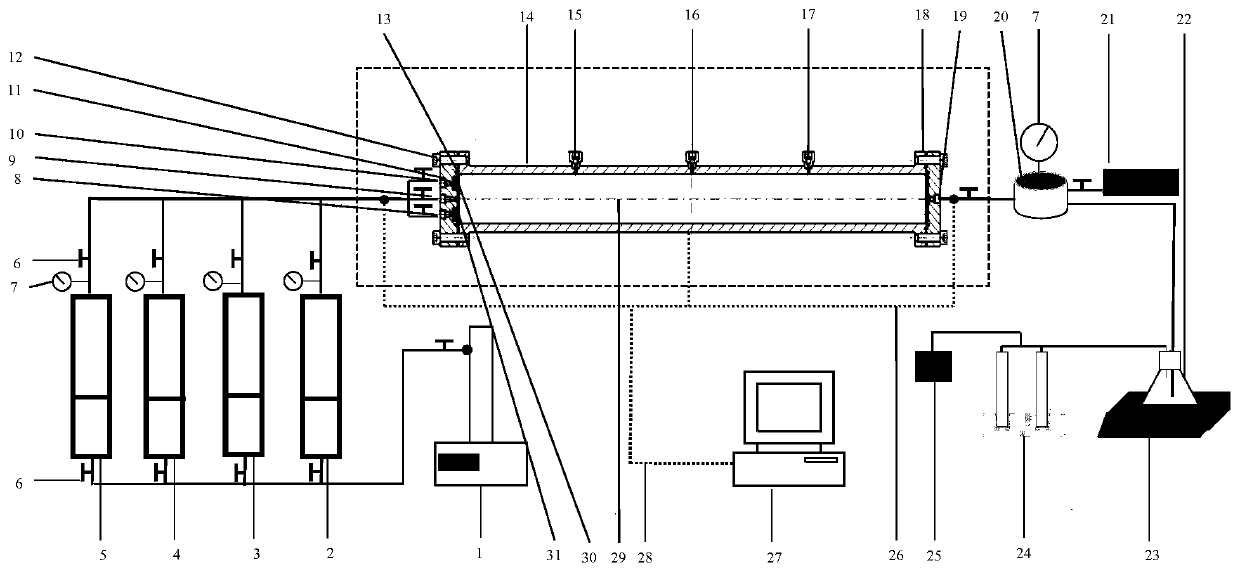

[0086] Such as figure 1 shown.

[0087] A hybrid nanofluid alternating CO in heavy oil reservoirs 2 Microbubble flooding experimental device, including high-precision constant-speed constant-pressure pump (1), CO 2 Container (2), active oil container (3), simulated formation water container (4), mixed nanofluid container (5), control valve (6), pressure gauge (7), lower injection port (8), middle injection port (9), upper injection port (10), inlet cover plate (11), bolt (12), sealing ring (13), outer body (14), first pressure measuring point (15), second pressure measuring point ( 16), the third pressure measuring point (17), outlet cover plate (18), mining outlet (19), back pressure valve (20), back pressure control system (21), gas-liquid separator (22), electronic balance (23), gas metering system (24), vacuum pump (25), constant temperature box (26), computer (27), pressure acquisition system (28), displacement model (29), filter screen (30), CO 2 Microbubble generato...

Embodiment 2

[0097] Mixed nanofluids alternate CO in heavy oil reservoirs as described above 2 The experimental method of the microbubble flooding experimental device comprises the following steps:

[0098] 1) Install and fill the displacement model with quartz sand.

[0099] 2) Prepare fluids for injection, including live oil, simulated formation water, mixed nanofluids and CO 2 gas.

[0100] 3) Empty the air in the displacement model to make the displacement model a vacuum state.

[0101] 4) Inject simulated formation water and live oil, and measure the porosity, permeability and initial oil saturation of the displacement model.

[0102] 5) Heavy oil reservoir depletion production stage: reduce the displacement model pressure to the target reservoir pressure. During the pressure drop process, the oil production, gas production and the pressure of each pressure measuring point are recorded, and the cumulative production gas-oil ratio and recovery degree in the depletion production sta...

Embodiment 3

[0154] Experimental equipment is identical with embodiment 1 in the present embodiment, and the difference of its experimental method and embodiment 2 is:

[0155] In the step 4), the amount of simulated formation water injected into the saturated simulated formation water process is 1108.97cm 3 , so the displacement model porosity is 36.02%.

[0156] The permeability data of simulated formation water at different injection rates are shown in Table 2.

[0157] Permeability under different injection rates in Table 2 Example 3

[0158]

[0159] Then the final permeability of the displacement model is 6.93 μm 2 .

[0160] The original reservoir pressure is 8.7MPa, the injected active oil volume V 油注 and the volume of crude oil produced V 油采 1670.67cm respectively 3 and 639.72cm 3 , so the initial oil saturation is S oi = 92.96%.

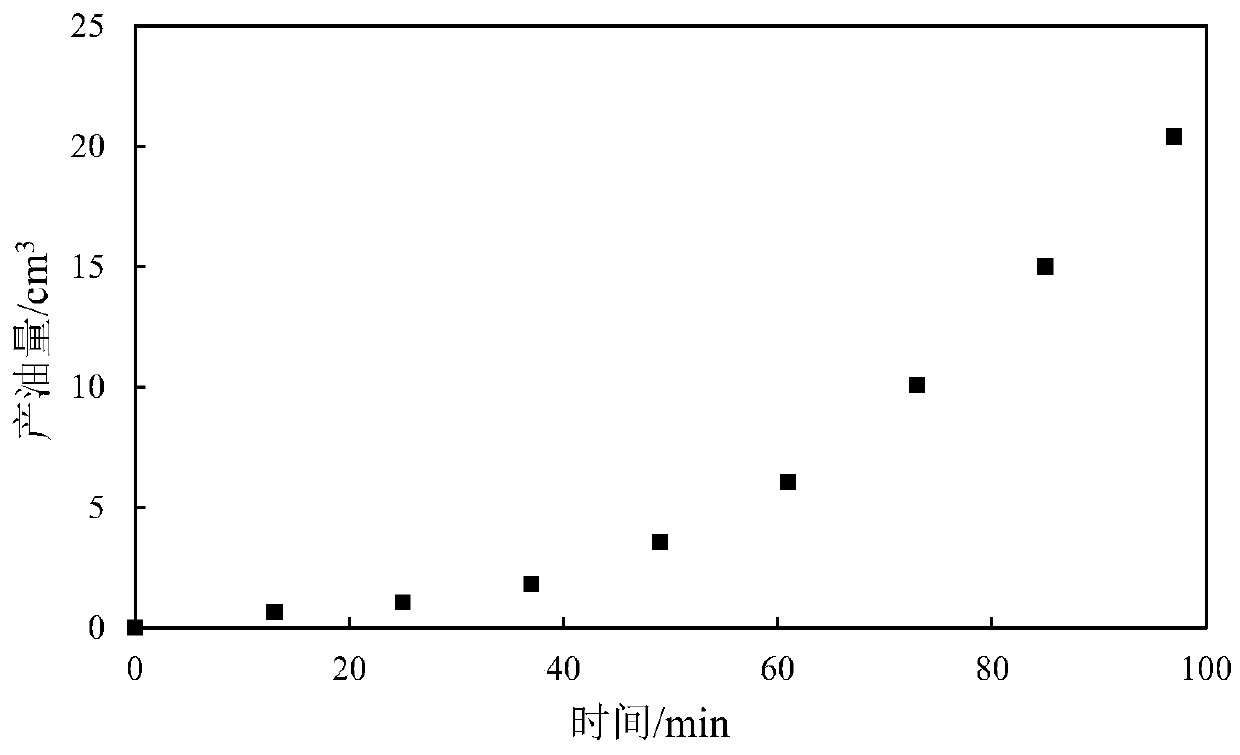

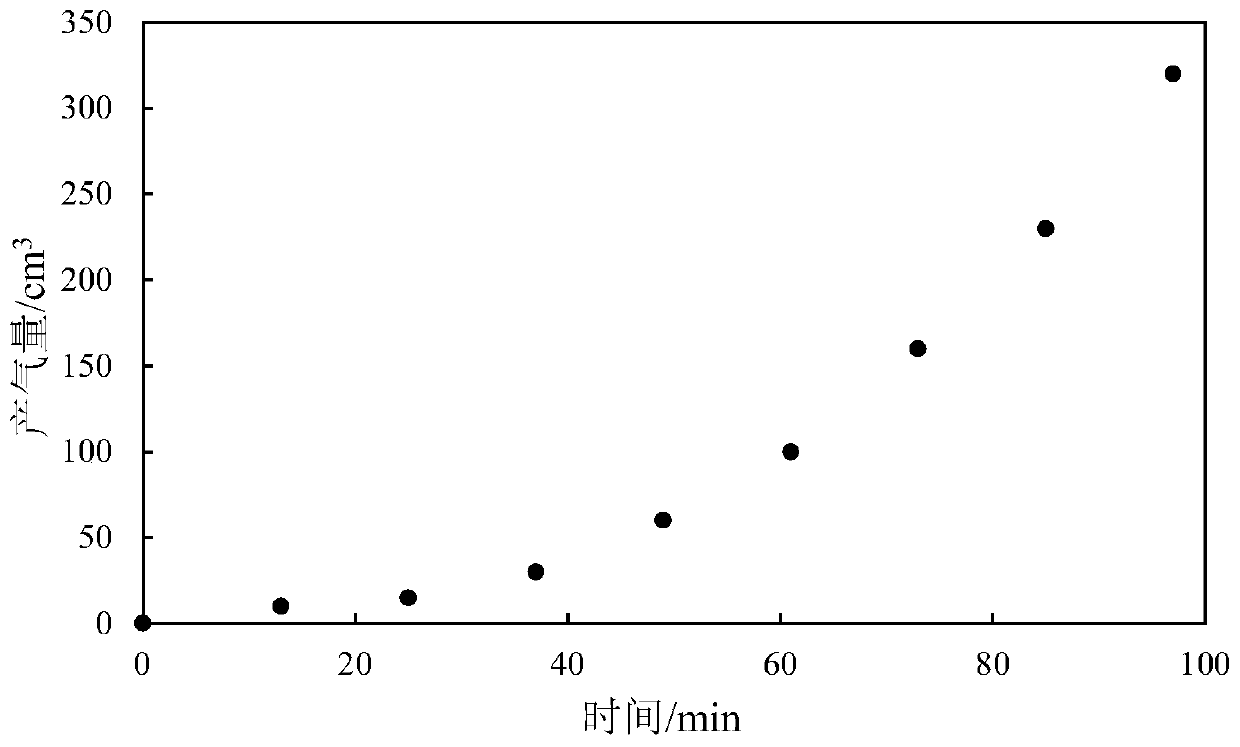

[0161] In the step 5), the target reservoir pressure is 6MPa. During the pressure drop process, the oil production, gas production and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com