Lightweight foaming casting nylon material and its preparation method and application

A casting nylon and lightweight technology, which is applied in the field of lightweight foaming and casting nylon materials and its preparation, can solve the problems of difficult control of foaming and poor mechanical properties, and achieve the effects of uniform cells, light weight and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of lightweight foaming cast nylon material of the present invention, it comprises the following steps:

[0036] S1. Add the above-mentioned amide monomers in parts by weight to the reaction kettles A and B of the casting nylon material equipment at a ratio of 1:1, evacuate to 0.1Mpa, heat and melt, and dehydrate at 120-150°C for 5 ~30min;

[0037] S2. Add the above-mentioned catalyst to the reaction kettle A, keep the temperature of the melt in the kettle constant at 120-140°C, and vacuumize for 10-30 minutes; to obtain the active material A; at the same time, add the co-catalyst to the reaction kettle B in turn , toughening agent, maintain the melt temperature in the kettle at 120-140°C, vacuumize for 10-30min, and obtain active material B;

[0038] S3. Spray and mix active material A and active material B, add foaming agent during the spray mixing process, spray cast into a mold that has been preheated to 140-180°C, and perform magnetic stirrin...

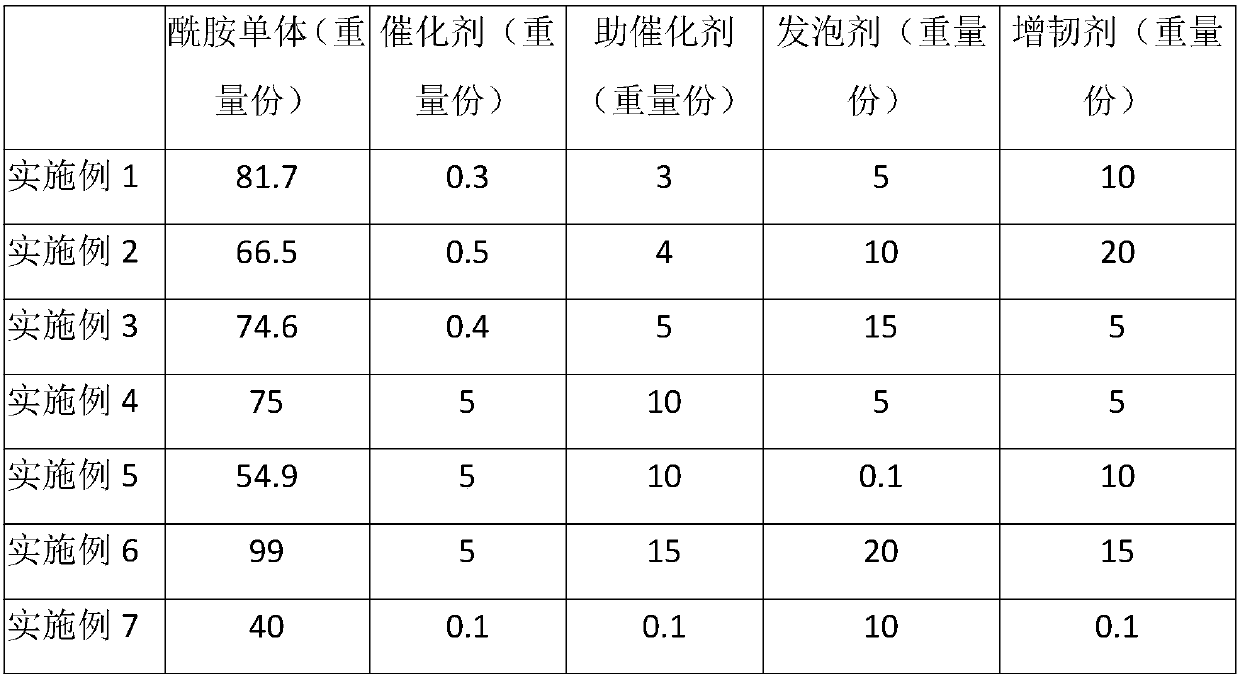

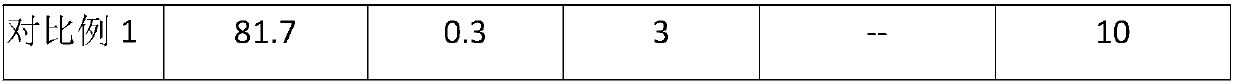

Embodiment 1

[0041] (1) Lightweight foamed cast nylon material

[0042] The lightweight foamed cast nylon material of this embodiment is prepared from the raw materials and proportions in Table 1. Wherein, the amide monomer is caprolactam, the catalyst is sodium hydroxide, the cocatalyst is isocyanate MDI, the foaming agent is sodium carbonate, and the toughening agent is polyether polyol.

[0043] (2) Preparation method of lightweight foamed cast nylon material

[0044] The preparation method of the lightweight foamed cast nylon material of the present embodiment comprises the following steps:

[0045]S1. Add 81.7 parts by weight of caprolactam to the A and B reaction kettles of the casting nylon equipment respectively according to the weight part of 1:1, vacuumize to 0.1MPa, heat and melt, dehydrate at 120°C for 30min, stop vacuuming, and feed Nitrogen protection;

[0046] S2. Add 0.3 parts by weight of sodium hydroxide to reactor A, maintain the melt temperature in the reactor at 120...

Embodiment 2

[0049] (1) Lightweight foamed cast nylon material

[0050] The lightweight foamed cast nylon material of this embodiment is prepared from the raw materials and proportions in Table 1. Wherein, the amide monomer is caprolactam, the catalyst is sodium hydroxide, the cocatalyst is TDI, the foaming agent is AC foaming agent, and the toughening agent is isoprene.

[0051] (2) Preparation method of lightweight foamed cast nylon material

[0052] The preparation method of the lightweight foamed cast nylon material of the present embodiment comprises the following steps:

[0053] S1. Add 66.5 parts by weight of caprolactam into reaction kettles A and B of the casting nylon equipment respectively in parts by weight 1:1, evacuate to 0.1MPa, heat and melt, dehydrate at 140°C for 5 minutes, stop vacuuming, and feed Nitrogen protection;

[0054] S2. Add 0.5 parts by weight of sodium hydroxide to reactor A to maintain the melt temperature in the reactor at 140°C for 10 minutes; at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com