Preparation method of environment-friendly snow melting agent

A snow-melting agent and an environmentally friendly technology, which is applied in the field of environmentally friendly snow-melting agent and its preparation, can solve the problems of secondary environmental pollution, high equipment requirements, and high energy consumption, and achieve the effect of reducing the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

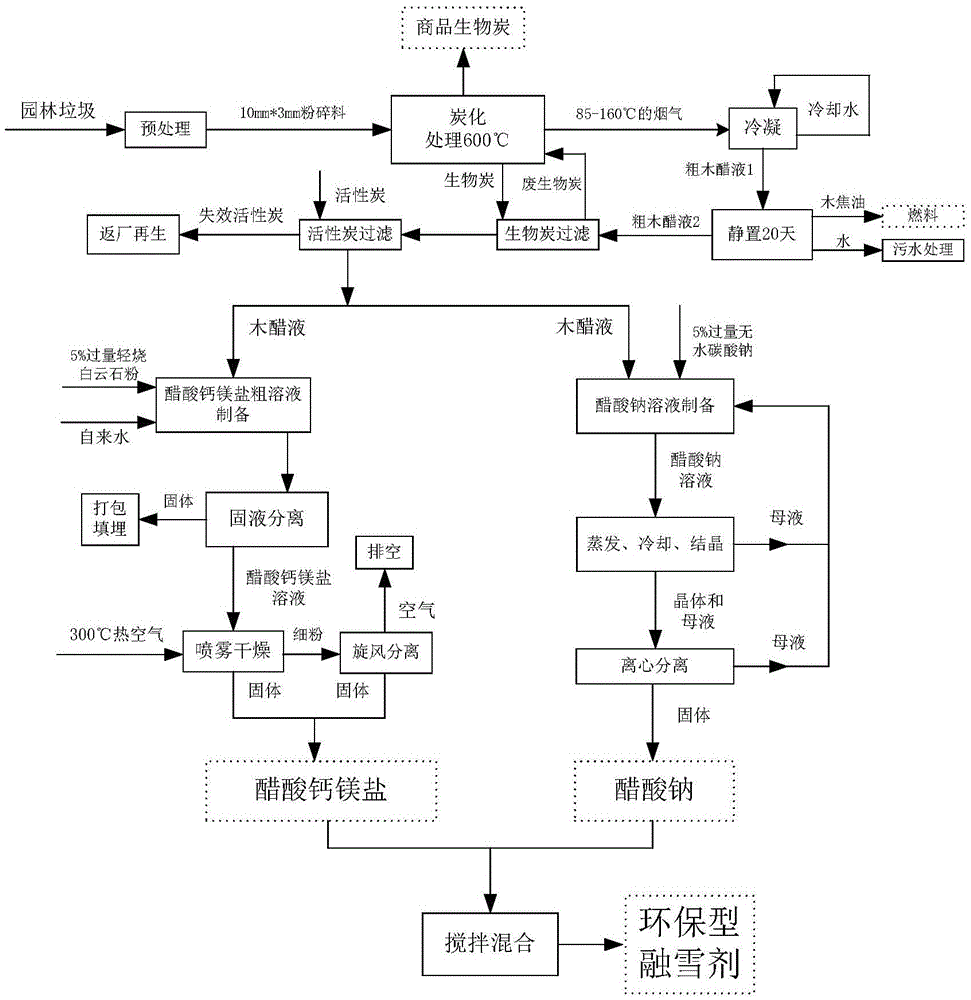

[0049] (1), preparation of wood vinegar

[0050] (a) Pretreatment of garden waste: put the collected garden waste in the storage area for air-drying, and when the moisture content of the garden waste drops below 20%, use a chainsaw to decompose the larger branches into 500mm short branches, and then Sent into the pulverizer for pulverization. The pulverized material is called pulverized material, and the pulverized material is long strip, with a maximum length of 10mm and a maximum diameter of 3mm;

[0051] (b) Collection of crude wood vinegar: put (a) the pretreated pulverized material into a carbonization furnace for carbonization. The carbonization furnace is airtight and the interior is anaerobic. When the temperature in the carbonization furnace reaches 600°C, carbonization is continued for 35 minutes, and the pulverized material is transformed into commercial biochar that can be sold.

[0052] There is a carbonization flue gas condensation collection system on the top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com