Patents

Literature

48 results about "Calcium magnesium acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

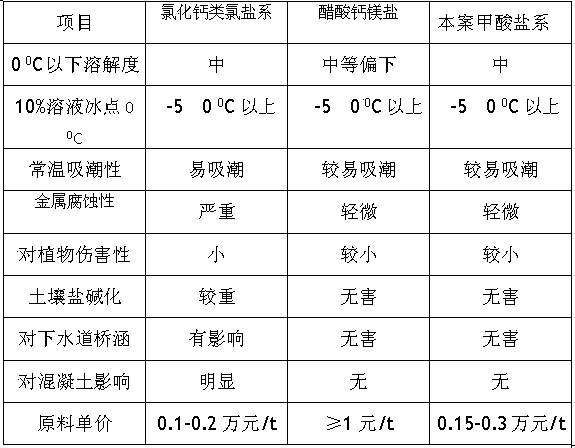

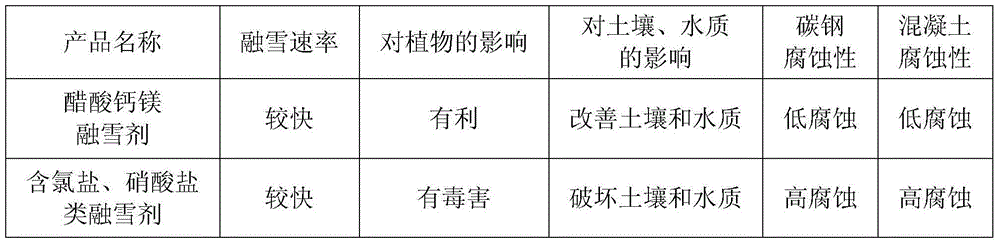

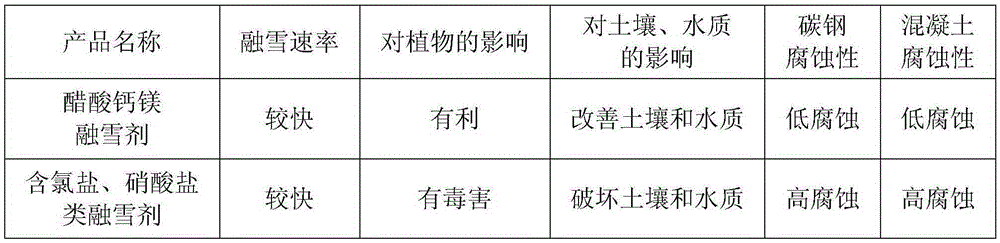

Calcium magnesium acetate (CMA) is a deicer and can be used as an alternative to road salt. It is approximately as corrosive as normal tap water, and in varying concentrations can be effective in stopping road ice from forming down to around −27.5 °C (−17.5 °F) (its eutectic temperature). CMA can also be used as an H₂S capture agent.

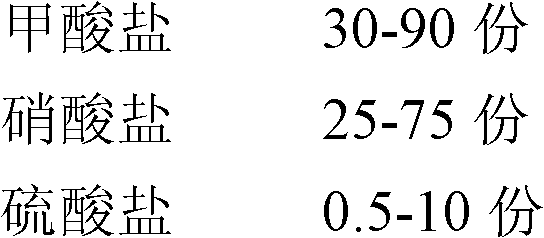

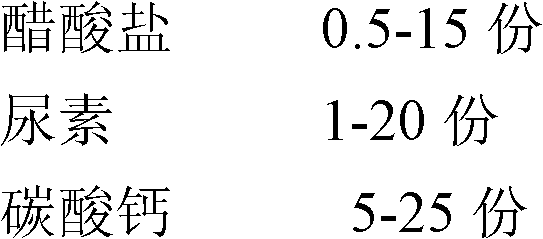

Organic/inorganic composite environment-friendly snow melting agent and preparation method thereof

The invention relates to an organic / inorganic composite environment-friendly snow melting agent. The snow melting agent comprises 30 to 90 parts of formate, 25 to 75 parts of nitrate, 0.5 to 10 parts of sulfate, 0.5 to 15 parts of acetate, 1 to 20 parts of urea and 5 to 25 parts of calcium carbonate. The snow melting agent has a high snow melting speed and a good effect. Compared with the traditional chloride snow melting agent, the snow melting agent has low corrosivity on roads and bridges and low harmfulness on plants. Compared with the traditional calcium magnesium acetate snow melting agent, the snow melting agent is relatively low in cost. A preparation method for the snow melting agent is simple and practicable and applicable to large-scale mechanized operation, and has high popularization and application prospects.

Owner:BEIJING UNIV OF CHEM TECH

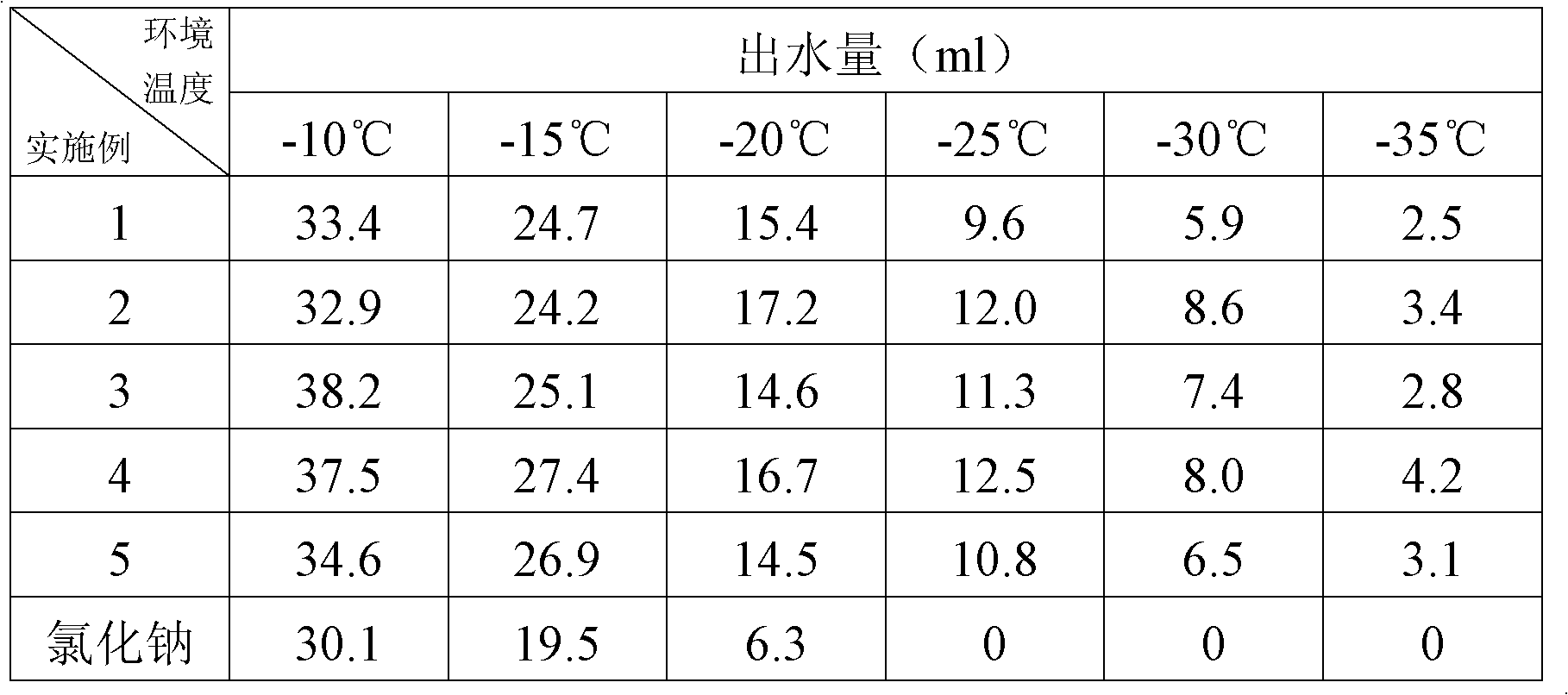

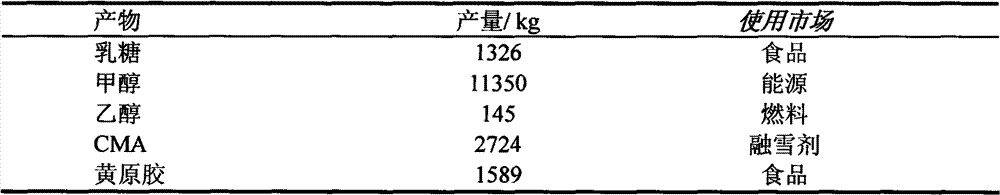

Integrated process of furfural production as well as wastewater, waste slag and waste gas treatment

InactiveCN101481189ACurb emissionsPollution suppressionOrganic chemistryEnergy inputWater vaporDistillation

The invention belongs to the technical field of the chemical production, and relates to a technology for optimizing energy saving and integrating treatment of waste water, waste slag and waste gas in a furfural production process, which is suitable for the energy saving and the three-waste treatment and reformation of furfural production enterprises. The technology is characterized in that limestone and dolomite are used for neutralizing furfural waste water to convert acetic acid into calcium magnesium acetate, and then the water exchanges heat with high-temperature aldehyde gas generated by a hydrolysis kettle to enter an evaporator; high-temperature vapor generated by the vaporization of the waste water enters the hydrolysis kettle to be used as a reaction medium, the residual concentrated liquid is decolorized for extracting calcium magnesium acetate salt, and the residual liquid is used for smoke desulfurization and denitration. After the low-pressure automatic heating and vaporization of high-temperature aldehyde slag for furfural recovery, the high-temperature aldehyde slag is dried at a low temperature to reduce the water content of the aldehyde slag to be lower than 20 percent. The invention has the advantages that the utilization rates of materials and energy are greatly increased, the zero discharge of three wastes is realized without additional energy consumption, and the calcium magnesium acetate salt of high value is also prepared. After the automatic heating distillation and low-temperature drying of the aldehyde slag, the aldehyde slag is used for active carbon and is effectively and cleanly burnt.

Owner:DALIAN UNIV OF TECH

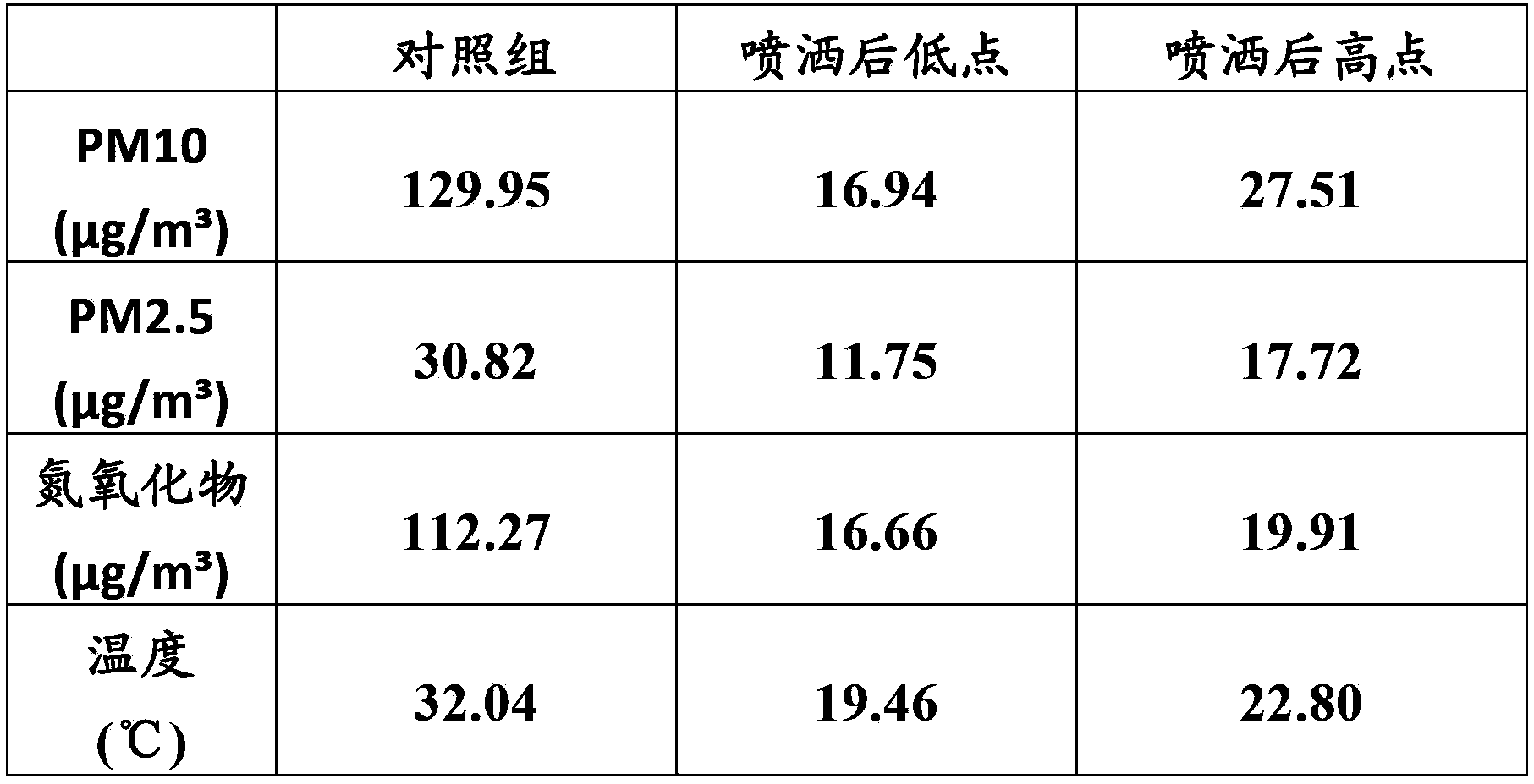

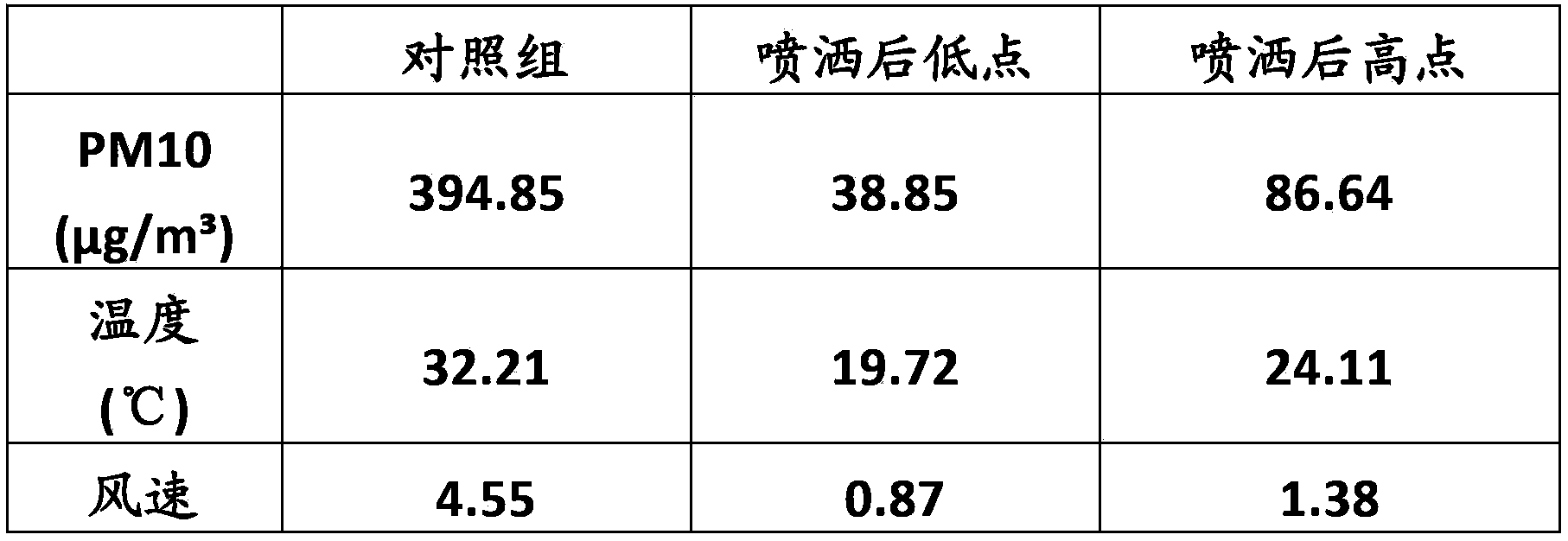

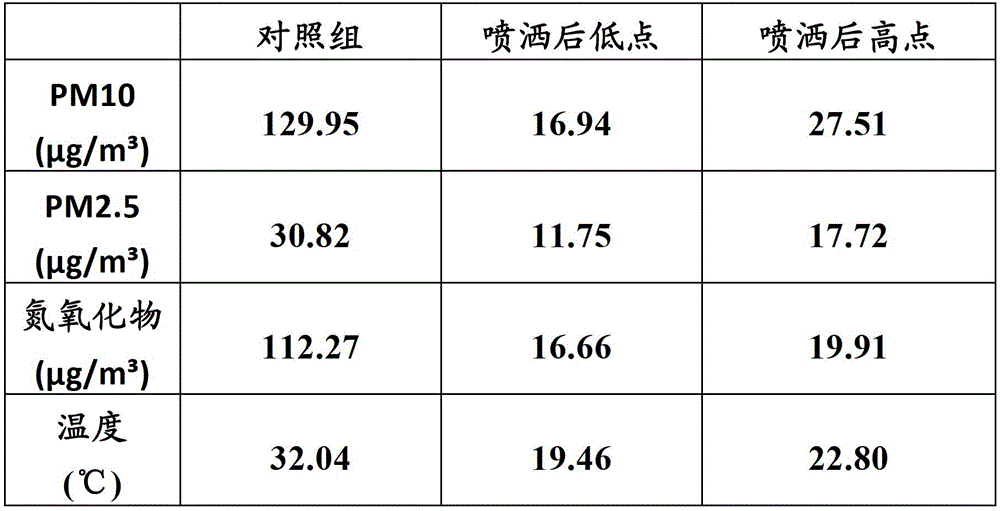

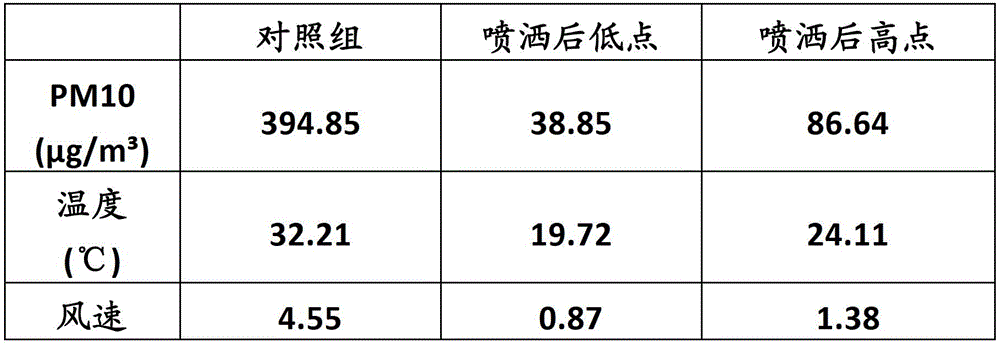

Road dust suppressant for controlling inhalable particles in near-surface air and preparation method

ActiveCN104073222AReduce concentrationWeak corrosiveOther chemical processesDispersed particle separationHazardous substanceAlkylphenol

The invention relates to a road dust suppressant for controlling the inhalable particles in near-surface air and a preparation method thereof. The road dust suppressant comprises the following components in parts by weight: 100-150 parts of calcium magnesium acetate, 0.04-0.2 part of dust suppression aid and 300-1,800 parts of water, wherein the calcium magnesium acetate comprises 0.1-0.9 part of calcium acetate and 0.1-0.9 part of magnesium acetate; and the dust suppression aid is one of surfactants including sodium lauryl sulfate, alkylphenol polyoxyethylene ether TX-10, wetting agent X-405, sodium dodecyl benzene sulfonate, Tween and Span or a mixture of more than one of the surfactants. The road dust suppressant provided by the invention can effectively reduce the inhalable particles and harmful substances such as nitrogen oxides and sulfides on the road, and has the characteristics of environmental friendliness, low corrosion to vehicles and pavement, long-lasting effect and the like.

Owner:北京首创大气环境科技股份有限公司

Method for preparing white snow-melting agent by using pyroligneous liquor and application thereof

InactiveCN103788928APromote meltingMelting snow withoutOther chemical processesSnow meltingCalcium magnesium acetate

The invention discloses a white snow-melting agent prepared by using pyroligneous liquor and a method for preparing white snow-melting agent by using pyroligneous liquor. The method comprises the following steps: distilling pyroligneous liquor under the conditions of a pressure of 0.01+ / -0.005 MPa and a temperature of 68+ / -2 DEG C to obtain a colorless pyroligneous liquor; making the distilled pyroligneous liquor, calcium carbonate and basic magnesium carbonate react for 50-60 min at a temperature of 30-35 DEG C according to a ratio of (4-6):1:1 mol to prepare a colorless CMA (Calcium Magnesium Acetate) liquid snow-melting agent liquid; spraying and drying the colorless CMA liquid snow-melting agent liquid to obtain a CMA white solid snow-melting agent. The snow-melting agent is applied to accumulated snow with excellent effect. The CMA type environment-friendly snow-melting agent is prepared from a biomass effluent, an environment-friendly type snow-melting agent which is low in cost and free from chlorine damage can be provided for road deicing and snow-melting, and the CMA is a good corrosion remover and plays a role in protecting facilities such as roads, bridge facilities, and concrete members. The pyroligneous liquor is from one of byproducts from pyrolysis of the biomass waste through destructive distillation, and is a main energy of a sustainable development energy system.

Owner:TIANJIN UNIV OF COMMERCE

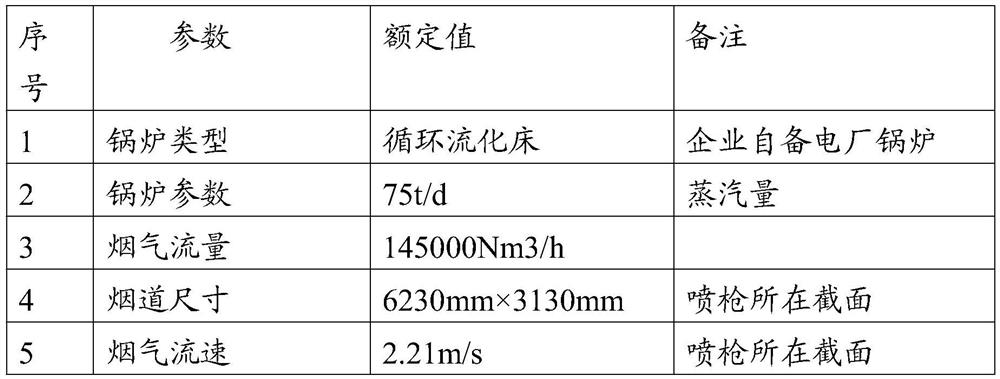

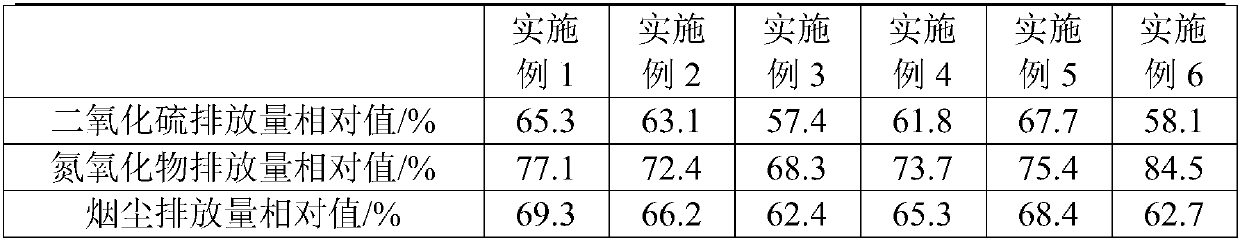

Denitration agent capable of improving SNCR (Selective Non Catalytic Reduction) denitration efficiency and preparation method of denitration agent

InactiveCN103816799AImprove denitrification efficiencyLow investment costDispersed particle separationTreatment fieldNitric oxide

The invention belongs to the treatment field of smoke nitric oxides and in particular relates to a denitration agent capable of improving SNCR (Selective Non Catalytic Reduction) denitration efficiency. The denitration agent is prepared from the following raw materials in parts by weight: 20-30 parts of calcium magnesium acetate, 10-20 parts of ferric oxide, 5-10 parts of titanium oxide, 1-5 parts of manganese dioxide, 0.1-1 part of cerium oxide, 40-65 parts of water and 5-15 parts of hydroxypropyl methyl cellulose. By utilizing catalytic properties of nanoscale oxide catalysts and precipitation property of the calcium magnesium acetate, the denitration agent is added in a reducing agent, thus further improving the denitration efficiency of an SNCR denitration system, enabling the denitration efficiency of the SNCR denitration system to reach more than 85% and greatly reducing the initial investments and the operation cost of owners in denitration treatment of smoke; the invention also provides a preparation method of the denitration agent. The preparation method is reasonable in process, low in cost and easy to produce industrially.

Owner:车均

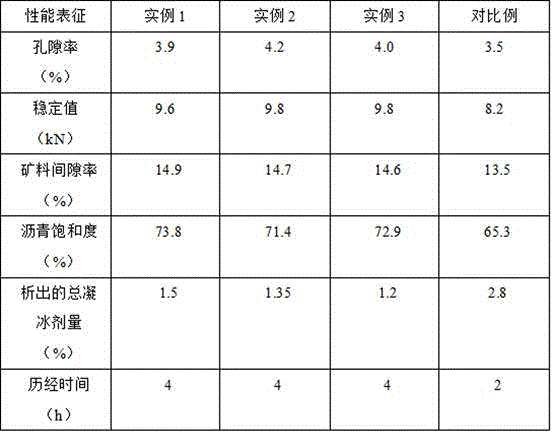

Antifreeze asphalt mixture and preparation method thereof

The invention relates to an antifreeze asphalt mixture and a preparation method thereof and belongs to the technical field of road construction. A calcium acetate melting agent is prepared by the aid of acetylene residues to be loaded on the surface of kieselguhr prior to being subjected to low surface hydrophobic treatment to obtain an antifreezing agent, pavement freezing point can be effectively lowered, icy pavement is prevented, long-term pavement antifreezing effect is achieved, maintenance cost of winter pavement management is lowered, releasing of the calcium acetate melting agent can be effectively alleviated through the kieselguhr, and the antifreezing agent can be evenly released within the range of pavement service life. Basic asphalt aggregate sandstone is prepared as required, rubber particles are tightly embedded between the mixture and the rubber particles as well as the stone material, pavement friction is enhanced, the mixture which is compressed is stable in structure, the rubber particles bear higher pressure, the antifreeze material cannot be destroyed during mixing of the asphalt mixture and paving of the asphalt pavement, and long-term antifreezing performance is achieved.

Owner:谢新昇

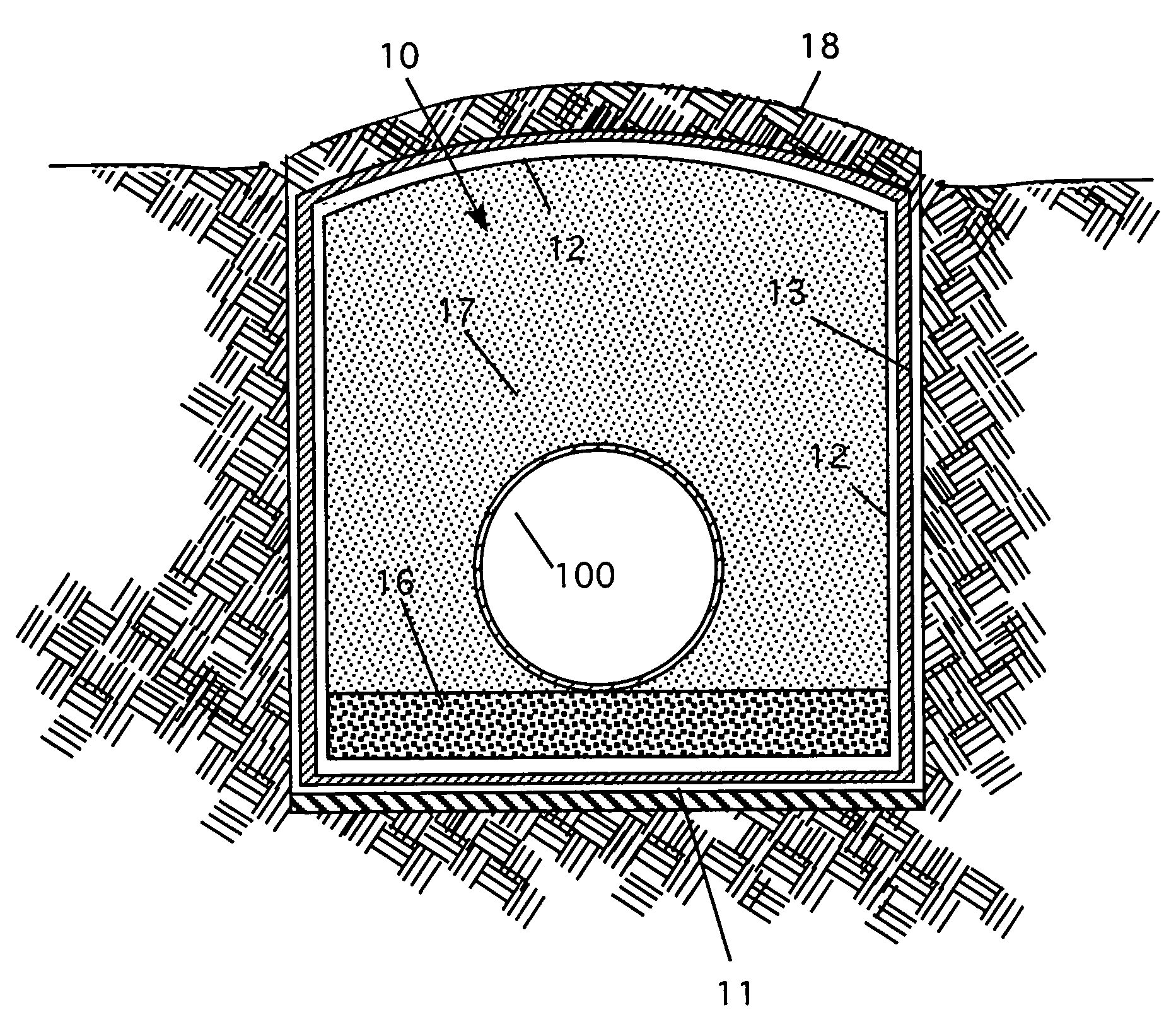

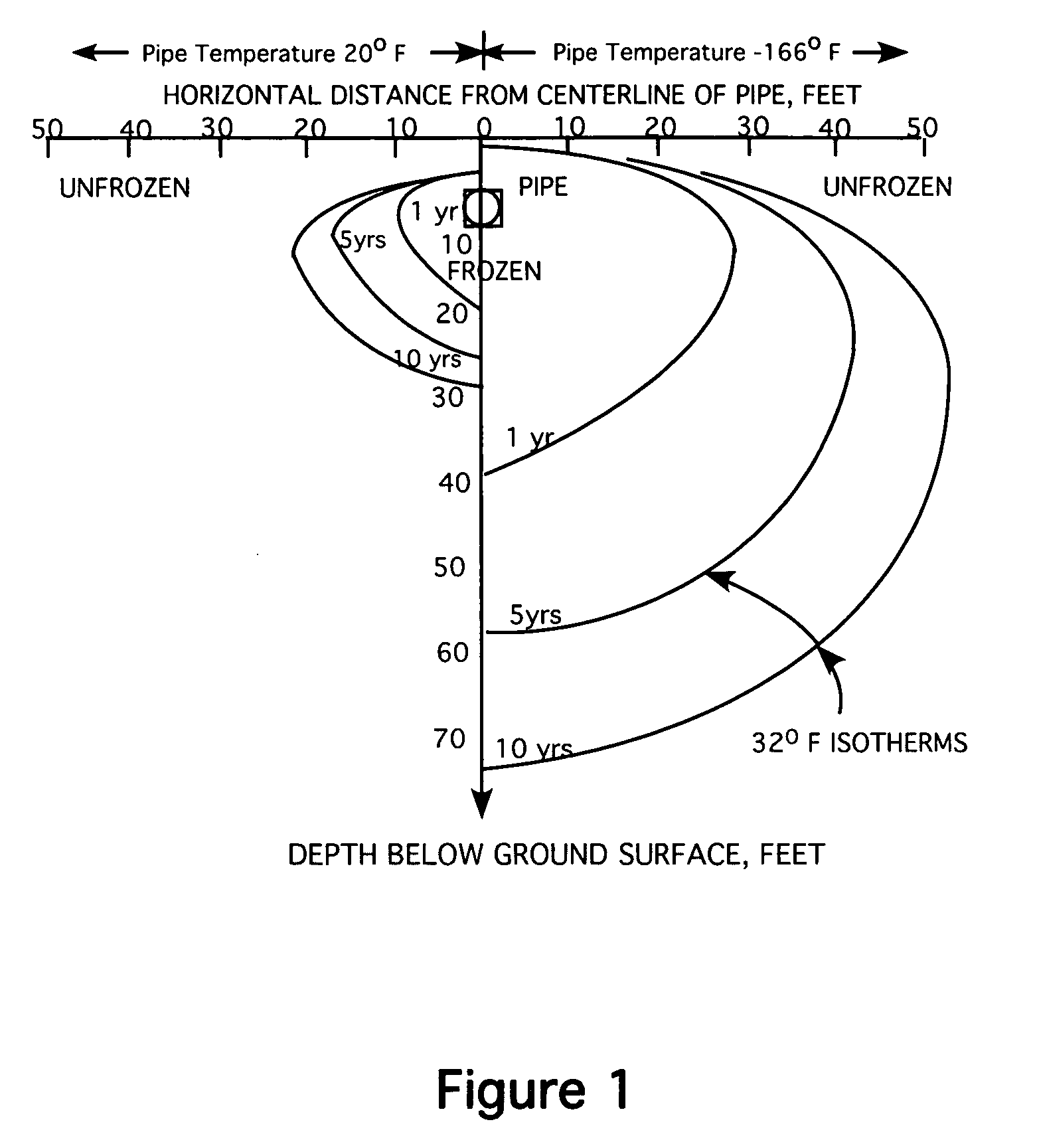

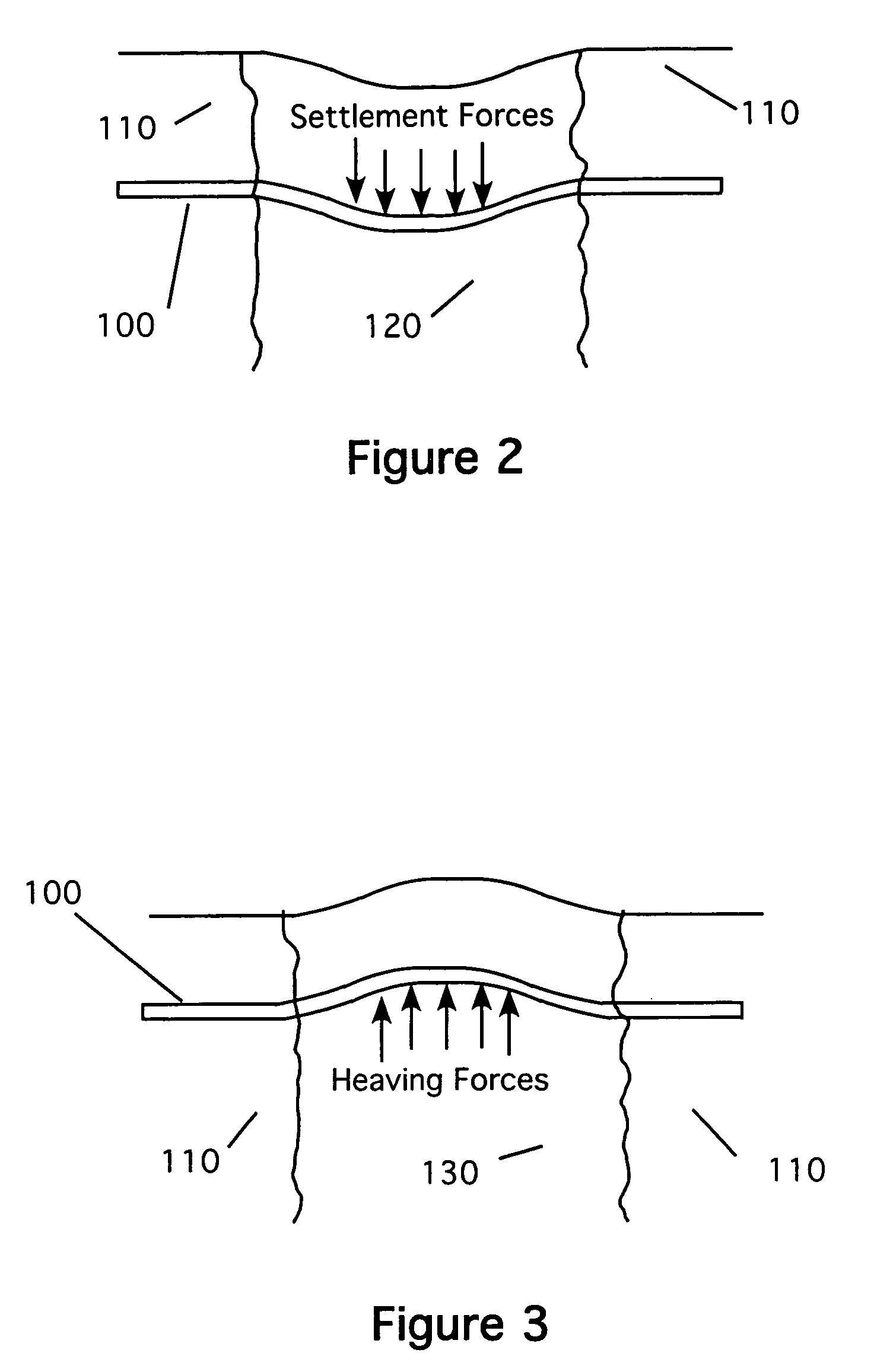

Method of preventing frost heave stress concentrations in chilled buried pipelines

ActiveUS6976809B1Low thermal expansionStabilize the soilPipe supportsPipe laying and repairStress concentrationProduct gas

A method for maintaining a stable soil by surrounding a chilled gas pipe with a material that has an antifreeze component that prevents the soil from freezing. By keeping the soil from freezing, it remains stable at all times. The method calls for excavating a trench, lining it with a geotextile membrane that keeps water from infiltrating into the trench, and then surrounding it with a bed of limestone (calcium carbonate) that is mixed with calcium magnesium acetate (CMA), which acts as an anti-freeze agent. The limestone-CMA mixture surrounds the pipe. The trench is covered by another geotextile membrane to completely seal it. In this way, the pipeline is surrounded by a material that is not subject to freezing. As such, it provides a stable bed for the pipeline to prevent frost heaving.

Owner:METZ PAUL A +1

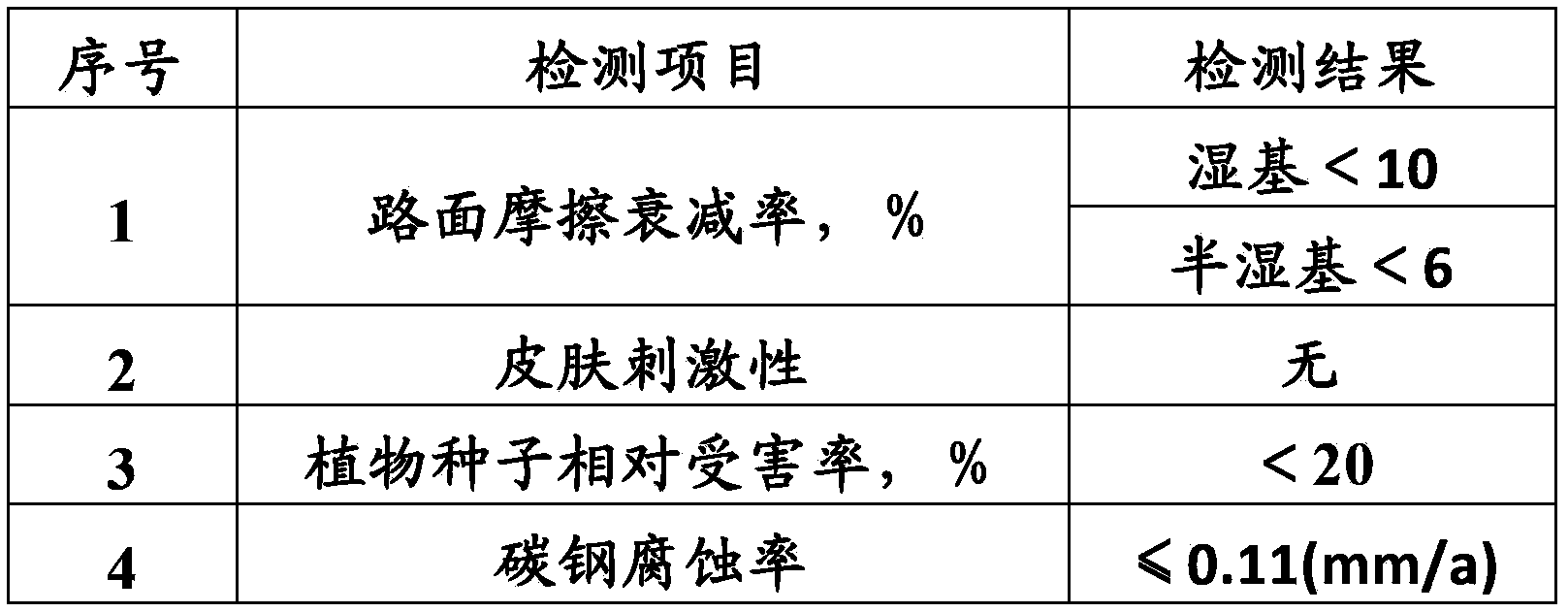

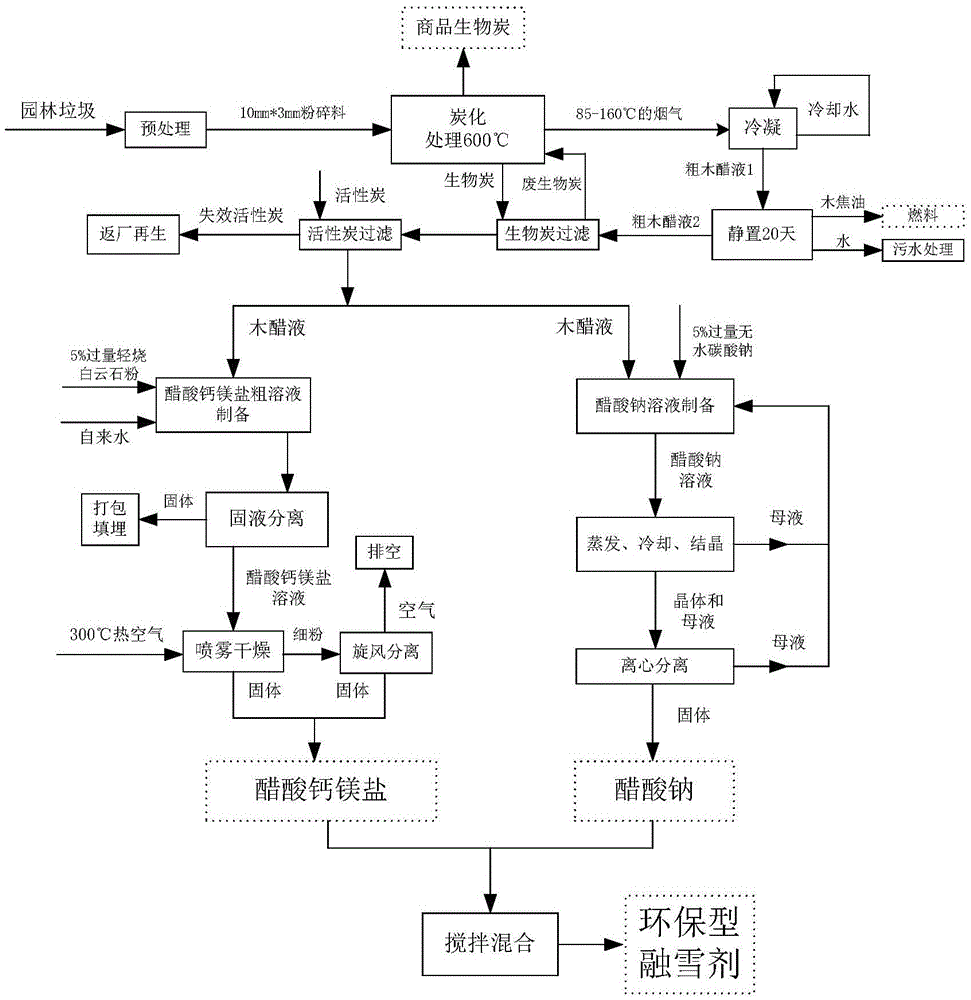

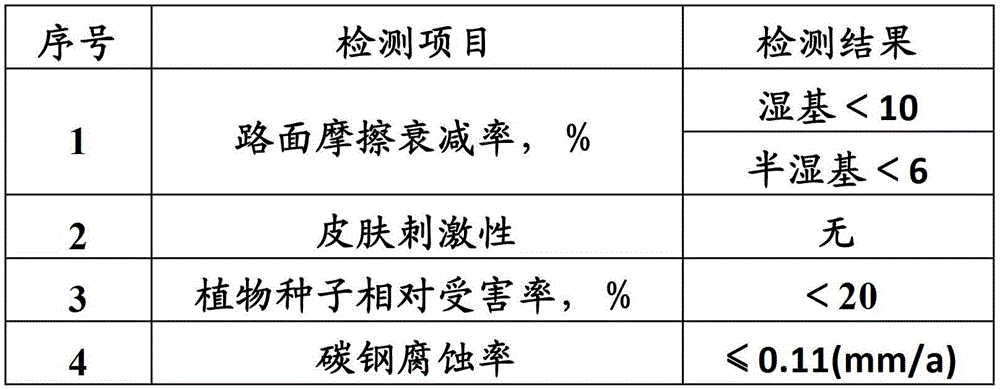

Preparation method of environment-friendly snow melting agent

ActiveCN105567163AReduce manufacturing costNot corrosiveOther chemical processesSodium acetatePlanting seed

The invention provides a preparation method of an environment-friendly snow melting agent. The environment-friendly snow melting agent is prepared from, by weight, 30%-50% of calcium magnesium acetate and 50%-70% of sodium acetate. The environment-friendly snow melting agent is prepared through the following steps that collected garden waste is utilized to prepare pyroligneous liquor; the obtained pyroligneous liquor reacts with commercially-available lightly-roasted dolomite powder to prepare calcium magnesium acetate; the obtained pyroligneous liquor reacts with commercially-available industrial-grade anhydrous sodium carbonate to prepare sodium acetate, the prepared calcium magnesium acetate and sodium acetate are added into a mixer, stirring is performed for 15 minutes to enable the materials to be mixed uniformly, and then the environment-friendly snow melting agent is obtained. According to the method, the preparation cost of the snow melting agent is reduced, the environment-friendly snow melting agent meets the requirements of the Beijing snow melting agent standard (DB11 / T 161-2012) and almost has no corrosiveness on bridges and roads, and the relative damage degree to plant seeds is smaller than 40%.

Owner:田丹 +1

Environment-friendly non-chlorine-salt snow melting and deicing agent and preparation method thereof

InactiveCN104073221AGood water solubilityIce water low freezing pointOther chemical processesSodium metasilicateFormate

The invention provides an environment-friendly non-chlorine-salt snow melting and deicing agent and a preparation method thereof, and belongs to the field of snow melting and deicing. The environment-friendly non-chlorine-salt snow melting and deicing agent is characterized by comprising the following raw materials in percentage by weight: 60-90 percent of main solvent, 2-20 percent of wetting cosolvent and 2-20 percent of corrosion inhibitor, wherein the main solvent is prepared from 60-90 percent by weight of formate and 10-40 percent by weight of sodium metasilicate; the wetting cosolvent is prepared from 40 percent by weight of sodium borate or calcium nitrate and 60 percent by weight of urea or ammonium carbonate; the corrosion inhibitor is prepared from 60 percent by weight of sodium gluconate and 40 percent by weight of zinc sulfate. According to the environment-friendly non-chlorine-salt snow melting and deicing agent, the common problems of high corrosivity, serious impact on soil structures and the like of common inorganic chlorine salt snow melting agents can be effectively solved; after being used, the environment-friendly non-chlorine-salt snow melting and deicing agent can be naturally decomposed under the natural environment, and the cost of the non-chlorine-salt snow melting and deicing agent is lower than that of other organic salt (like acetates including potassium acetate, calcium magnesium acetate and the like) snow melting and deicing agents; therefore, the environment-friendly non-chlorine-salt snow melting and deicing agent is suitable for being used in places like domestic and overseas roads, airport pavements and streets, and has wide popularization and application prospects.

Owner:陕西省建筑材料工业设计研究院有限公司

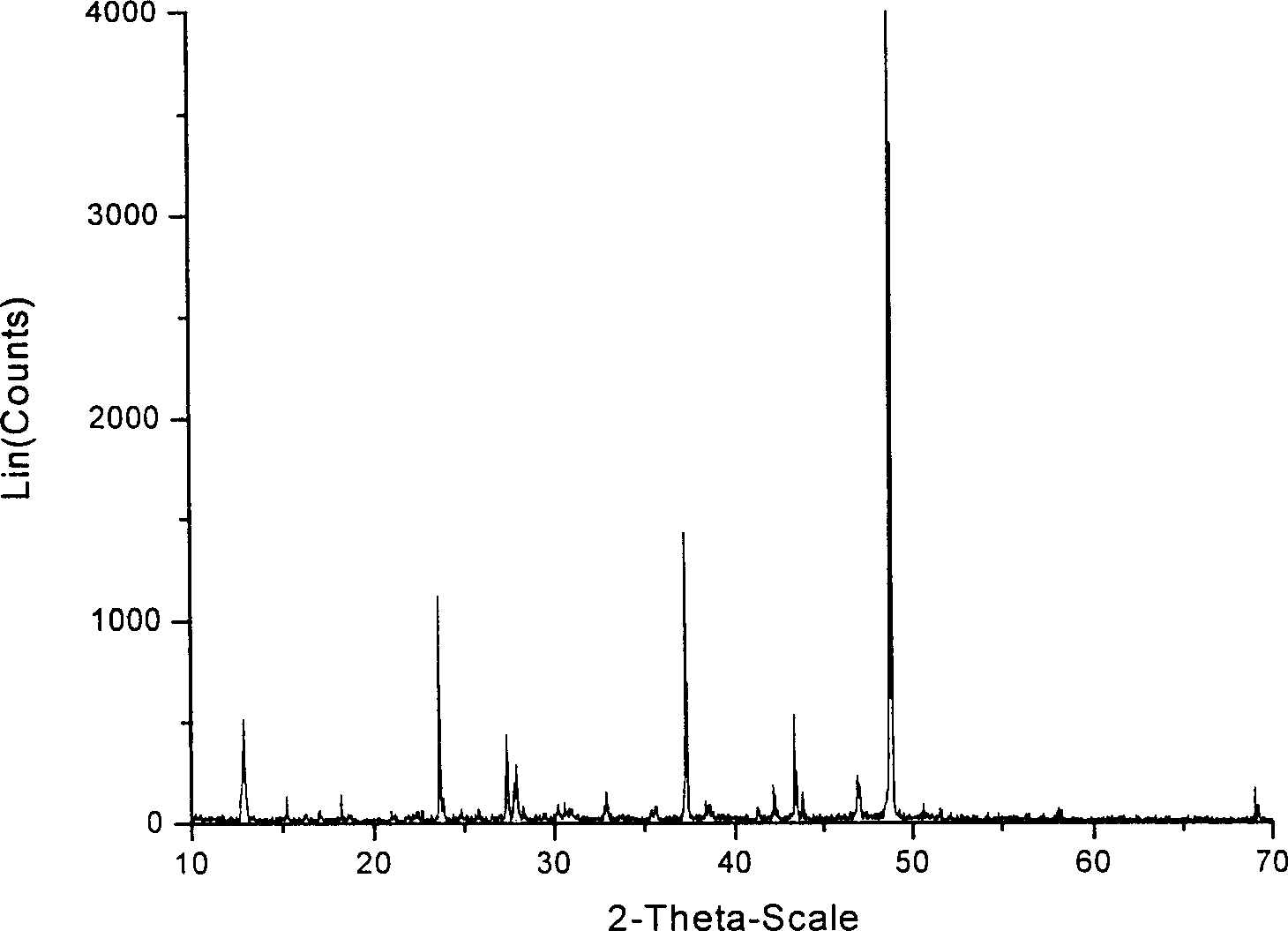

Preparation and apparatus for calcium acetate magnesium salt

InactiveCN101481305AWon't happenAvoid consumptionOther chemical processesCarboxylic acid salt preparationFiltrationMagnesium salt

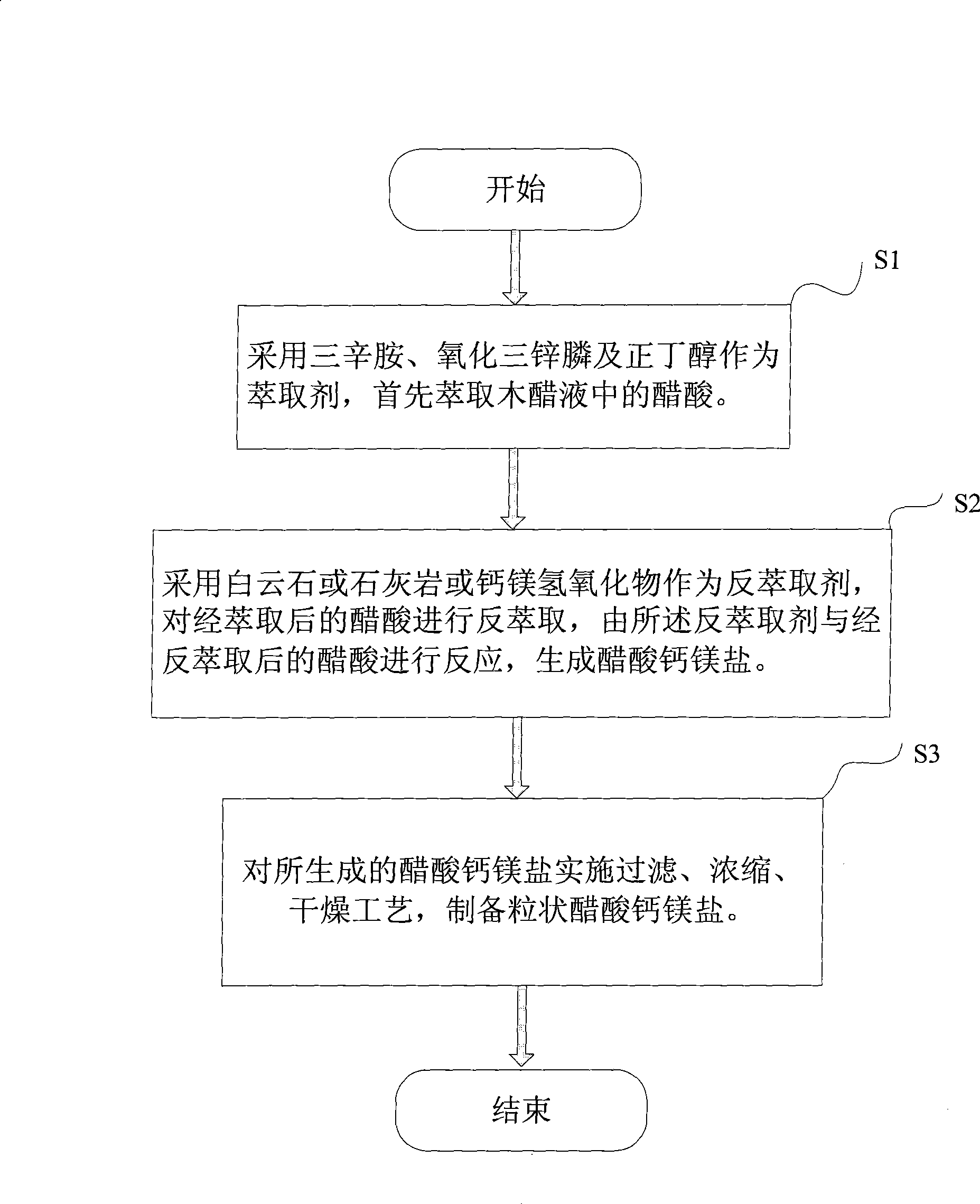

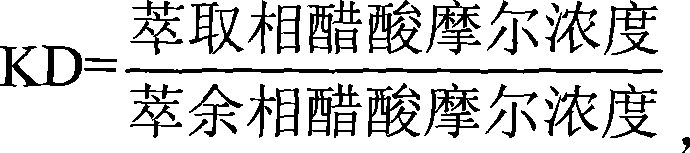

The invention provides a preparation method of calcium magnesium acetate and a device thereof. The preparation method comprises extracting pyroligneous liquor with an organic solvent, and stripping the pyroligneous liquor with dolomite or limestone or calcium magnesium hydroxide to prepare the calcium magnesium acetate, wherein, acetic acid in the pyroligneous liquor and the dolomite or the limestone or the calcium magnesium hydroxide are taken as raw materials. The method comprises the following steps: extraction step S1: taking trioctylamine, trioctylphosphine oxide and n-butyl alcohol as extractants, selecting poly-aluminium sulfate as a demulsifier, and firstly extracting the acetic acid in the pyroligneous liquor; back extraction step S2: taking the dolomite or the limestone as a back extractant, performing back extraction on the extracted acetic acid, and allowing the back-extractant to react with the back-extracted acetic acid to generate the calcium magnesium acetate; and filtering and drying step S3: implementing processes such as filtration, concentration, drying and the like on the obtained calcium magnesium acetate to prepare granular calcium magnesium acetate. The invention develops a method for preparing the calcium magnesium acetate with low cost, and provides a new way for high-value utilization of the pyroligneous liquor.

Owner:北京联合创业环保工程股份有限公司

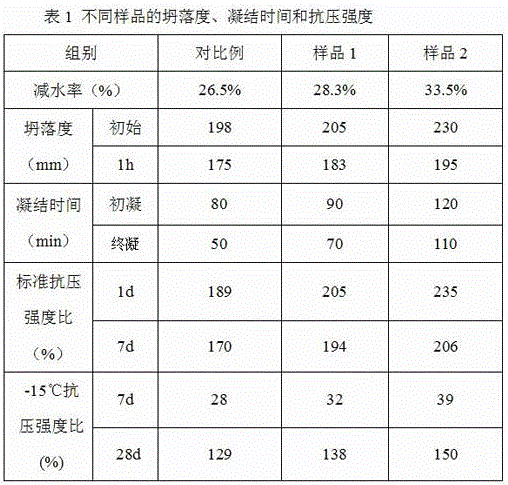

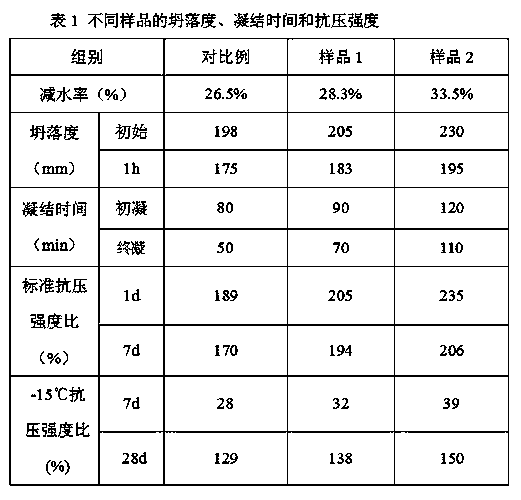

Antifreezing water reducing agent and preparation technique thereof

The invention relates to an antifreezing water reducing agent and a preparation technique thereof. The antifreezing water reducing agent is composed of a main material and an antifreezing agent which accounts for 10 wt% of the main material. The main material is composed of the following components in parts by mass: 100-120 parts of aliphatic water reducing agent, 150-180 parts of sodium metaphosphate and 10-20 parts of early-strength admixture. The antifreezing agent is composed of the following components in parts by weight: 0.5-1.5 parts of air entraining agent, 3-8 parts of calcium magnesium acetate, 1-8 parts of sodium 2-mercaptoethane sulfonate, 2-5 parts of tetrapolyethyleneglycol monooctyl ether, 10-15 parts of nano diatomite and 5-10 parts of rigid fiber. By adding the antifreezing agent and pine wood extract, the antifreezing water reducing agent has the advantages of favorable water-reducing effect, higher slump0retaining strength, bleeding prevention, favorable antifreezing effect and strong slow-release effect, increases the strength of concrete and saves the enterprise cost.

Owner:平顶山奥思达科技有限公司

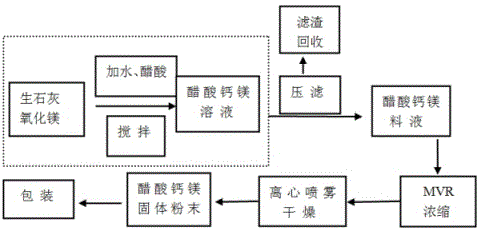

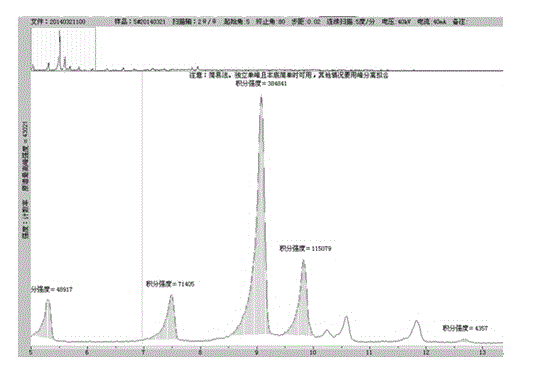

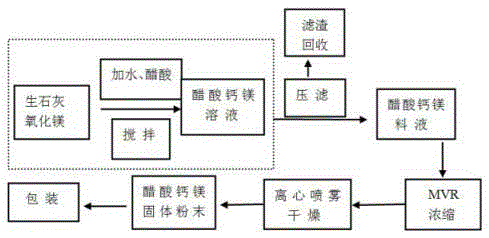

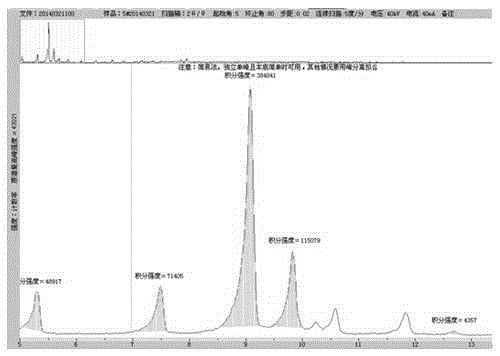

Preparation process and application of calcium magnesium acetate

ActiveCN104355984AGood water solubilityLow eutectic point of iceOrganic compound preparationOther chemical processesFiltrationSnow melting

The invention discloses a preparation process and an application of calcium magnesium acetate. The preparation process comprises the following processing steps: preparing a calcium acetate solution, and performing press filtration, MVR concentration and centrifugal spray-drying. The preparation process disclosed by the invention is simple in technical process, easy to operate, easy in raw material acquisition, free from emission of three wastes in an overall production process, high in production efficiency, high in yield, low in equipment investment, wide in application and remarkable in economic benefits. The calcium magnesium acetate prepared by the process disclosed by the invention has the functions of melting snow, deicing, resisting dust, preventing dust and controlling atmospheric pollution; as a snow melting agent, the calcium magnesium acetate is higher in snow melting capability and enables accumulated snow and ice layers to be loose so that the snow and the ice layers can be removed more easily; as a dust resisting agent, the calcium magnesium acetate can be used for removing NOx and SO2 generated by combustion of coal and HCl generated by combustion of PVC (Polyvinyl Chloride) so as to control the atmospheric pollution; moreover, the calcium magnesium acetate causes quite low corrosion to metals and causes no toxic or side effects to human, soil and plants.

Owner:LAIZHOU LAIYU CHEM CO LTD

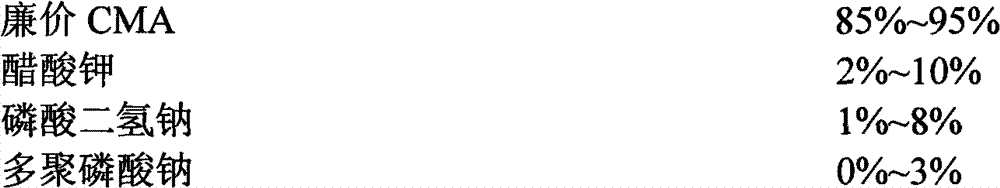

Novel environment-friendly snow-melting agent and preparation method thereof

InactiveCN102775959ANot corrosiveAvoid Decomposition DefectsOther chemical processesSnow meltingDolomite

The invention discloses a low-cost environment-friendly snow-melting agent, and a preparation method and an application of the low-cost environment-friendly snow-melting agent. The low-cost environment-friendly snow-melting agent is prepared by mixing 85 to 95% of low-cost CMA, 2 to 10% of potassium acetate, 1 to 8% of sodium dihydrogen phosphate, and 0 to 3% of polyphosphoric acid. The environment-friendly snow-melting agent is low in cost, has no corrosion, and is harmless to soil. The low-cost CMA is the low-cost CMA granular product which is manufactured by mixing calcium magnesium acetate which is produced by the reaction between a biologically fermented by-product emulsion produced by producing cheese through milk and served as the raw material and calcium-magnesium oxide and the calcium magnesium acetate produced by the reaction between glacial acetic acid and dolomite (Ca / MgO) or limestone (Ca / MgCO3) based on a certain ratio; the potassium acetate can increase the snow-melting frequency, and the potassium can improve the fertility of the soil; the sodium dihydrogen phosphate served as the neutralizer can ensure that the pH value of an aqueous solution prepared by mixing is 7; and with the polyphosphoric acid serving as the preservative, the prepared snow-melting agent has low corrosion or has no corrosion.

Owner:深圳市科中大交通建材有限公司

Process for preparing calcium magnesium acetate by vacuum distillation method

InactiveCN1379012AIncrease concentrationEasy to dehydrateCarboxylic acid salt preparationReaction temperatureAcetic acid solution

A process for preparing calcium magnesium acetate includes such steps as mixing Ca and Mg compound (the mole ratio of Ca:Mg is 3-4:6-7) with solution of acetic acid, to form a solution with concentration of (3-5) mol / L, reaction at 40-90 deg.C for 1-3 hr, filtering, vacuum distilling concentration at 45-90 deg.C and under -0.08-0.1 MPa for 1-5 hr, and drying. Its advantages are simple process, low reaction temp. and high purity of product.

Owner:TSINGHUA UNIV

Fluoride solidifying agent for treating fluorine pollution caused by burning coal and preparation method and application method thereof

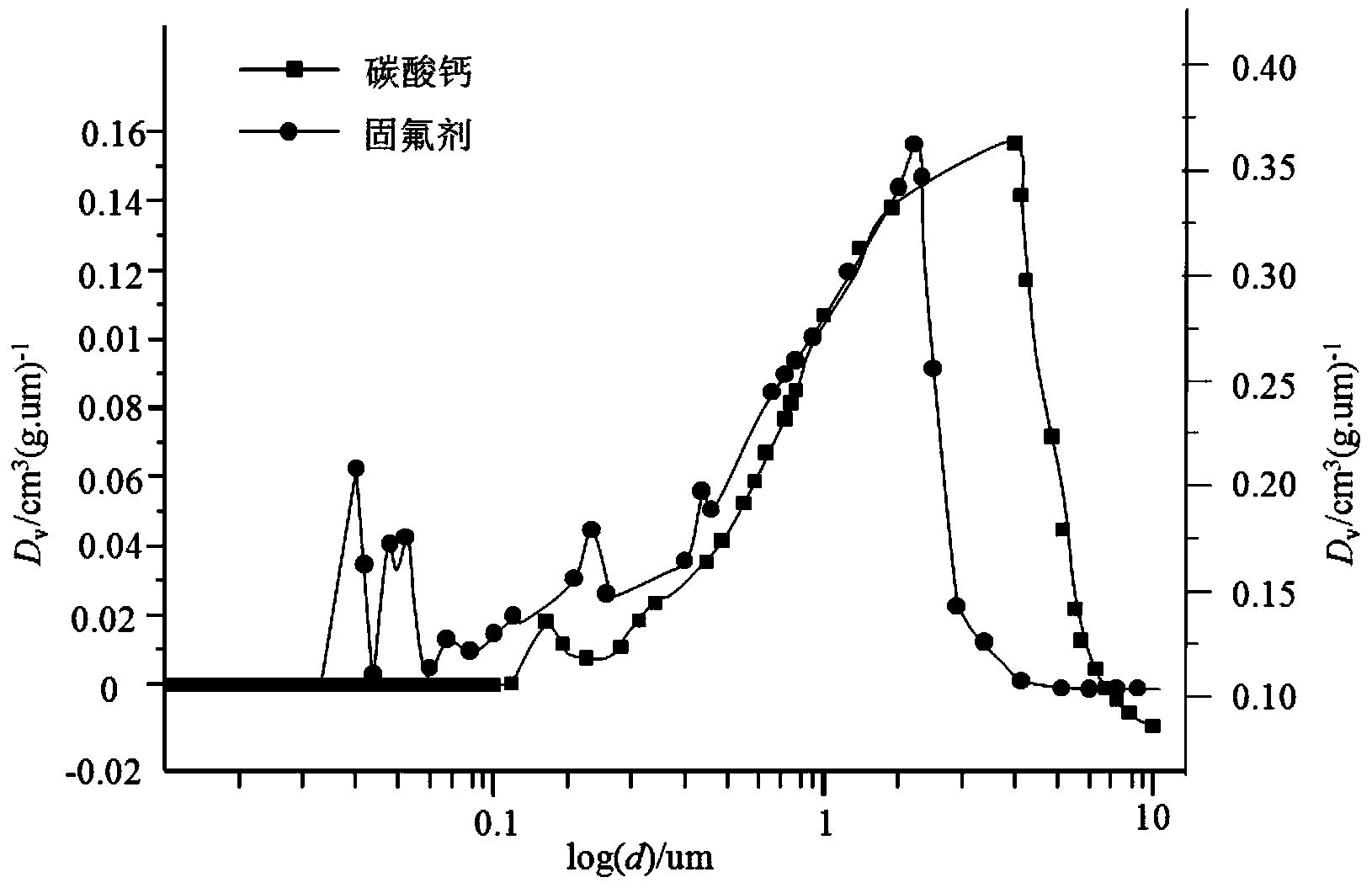

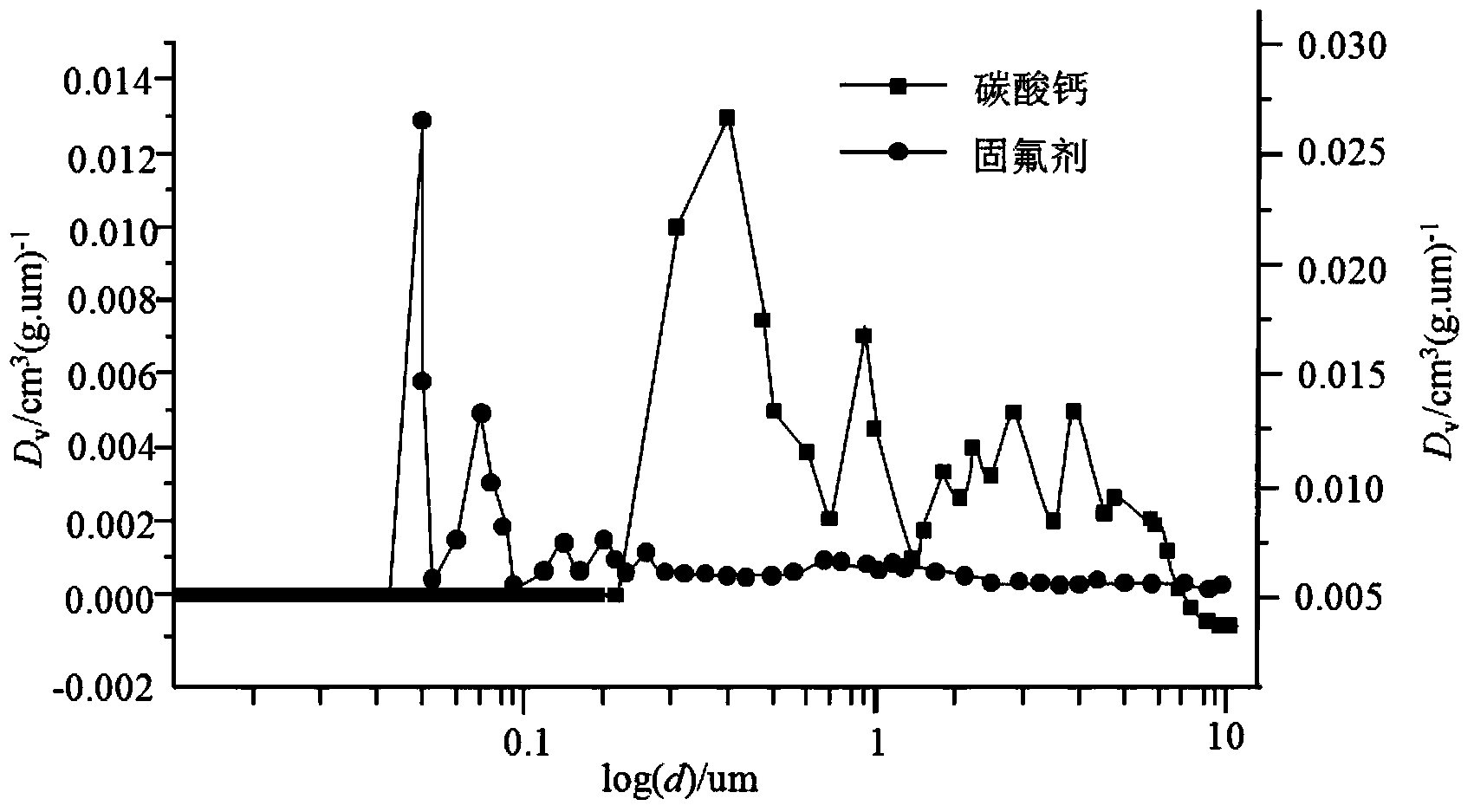

ActiveCN103923721AImprove microscopic void structureLarge hole volumeSolid fuelsPorosityPotassium carbonate

The invention discloses a fluoride solidifying agent for treating fluorine pollution caused by burning coal. The fluoride solidifying agent is prepared by the following steps of respectively weighing calcium magnesium acetate, aluminum sulfate, sodium carbonate and potassium carbonate according to the molar ratio of ca2+, Al3+, Na+ to K+, wherein the molar ratio is 30: 1.5: 3: 2-4.5; evenly mixing the calcium magnesium acetate, the aluminum sulfate, the sodium carbonate and the potassium carbonate; grinding the mixture through a 180 mesh-300 mesh screen; adding water with the weight 6-12 times that of the mixture into the mixture; heating the mixture to the temperature of 70 DEG C-90 DEG C; stirring the mixture for two to six hours; drying the mixture at the temperature of 100 DEG C-120 DEG C; grinding the mixture through the temperature of 70 DEG C-90 DEG C. Compared with the calcium carbonate serving as the traditional fluoride solidifying agent, porosity and specific surface area of the fluoride solidifying agent are increased greatly, fluoride can be solidified effectively during coal burning, and fluoride content in high-temperature smoke is reduced effectively. Compared with the calcium magnesium acetate serving as the fluoride solidifying agent independently, effect in removing fluoride in high-temperature smoke is more remarkable. Furthermore, the preparation method of the fluoride solidifying agent is simple, and raw material price and production cost are low. The method for solidifying fluoride during coal burning by utilizing the fluoride solidifying agent is easy to implement.

Owner:沃德费默循环经济科技发展(北京)有限公司

Solid desulfurization and denitrification agent

PendingCN112403529AEasy to removeImprove adsorption capacityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationPtru catalystEthylic acid

The invention discloses a solid desulfurization and denitrification agent, and belongs to the technical field of catalyst preparation. The catalyst comprises the following raw materials: iron oxide, manganese dioxide, urea, calcium magnesium acetate, titanium oxide, kaolin and calcium carbonate. By further optimizing formula components of the solid denitrification agent, the technical effect of denitrification while desulfurization is achieved, specifically, the adsorption and removal capacity of calcium carbonate is enhanced through modification, the desulfurization and denitrification effects are good, the denitrification rate reaches 80% or above, and the desulfurization effect reaches 97% or above.

Owner:宜兴市禄洪环保科技有限公司

Method of applying calcium magnesium acetate to affect growth of unwanted broadleaf weeds in lawn grasses

The new art of the present invention is use of calcium magnesium acetate to affect broadleaf weeds, as a result of exposure. The method enhances the speed of effectiveness of elimination of certain broadleaf weeds. The non toxic substance can help protect the environment. The optional method of using a binding liquid to cause a better adhering of the granular form of calcium magnesium acetate to the leaves of an unwanted plant in lawn grasses and less rolling off of the grains when applied to the leaves. Grinding to smaller micron grains even as small as dust and then applying to the leaves to affect unwanted weeds wherein by reduction of weight which the standard sized grains add to the leaf, the grinding helps limit grain roll off and weight added to the leaf. The optional method of converting the calcium magnesium grains to a liquid form, then applying to the broadleaf weed, is an option. Any of the mentioned methods provides a fast elimination of the violet weed plants in desirable lawn grasses, with the intent of using these in my personal business practices as a lawn care professional.

Owner:SCHULTZ SR SHANE BLAKE

Road dust suppressant for controlling inhalable particulate matter in near-surface air and preparation method thereof

ActiveCN104073222BReduce concentrationWeak corrosiveOther chemical processesDispersed particle separationHazardous substanceAlkylphenol

The invention relates to a road dust suppressant for controlling the inhalable particles in near-surface air and a preparation method thereof. The road dust suppressant comprises the following components in parts by weight: 100-150 parts of calcium magnesium acetate, 0.04-0.2 part of dust suppression aid and 300-1,800 parts of water, wherein the calcium magnesium acetate comprises 0.1-0.9 part of calcium acetate and 0.1-0.9 part of magnesium acetate; and the dust suppression aid is one of surfactants including sodium lauryl sulfate, alkylphenol polyoxyethylene ether TX-10, wetting agent X-405, sodium dodecyl benzene sulfonate, Tween and Span or a mixture of more than one of the surfactants. The road dust suppressant provided by the invention can effectively reduce the inhalable particles and harmful substances such as nitrogen oxides and sulfides on the road, and has the characteristics of environmental friendliness, low corrosion to vehicles and pavement, long-lasting effect and the like.

Owner:北京首创大气环境科技股份有限公司

Modification method of brick-making material

InactiveCN102442793ANo corrosionReduce energy consumptionOther chemical processesLiquid productBrick

The invention discloses a modification method of a brick-making material. the method provided by the invention is characterized by comprising the following steps of: adding a modification treatment fluid into the brick-making raw material, carrying out high-speed dispersion, stirring, reacting, waiting or adjusting pH value to a stable range, followed by pumping filtration to obtain a solid product A and a liquid product B; drying the solid product A to obtain the modified brick-making material; heating and concentrating the liquid product B, refining, filtering and drying to obtain a by-product snow-melting agent. By the adoption of the modification method of the brick-making material, on one hand, the brick-making material containing calcium and magnesium, the content of which does not exceed standard, can be obtained; on the other hand, the calcium magnesium acetate environment-friendly snow-melting agent can be obtained. Thus, no corrosion, low energy consumption, high selectivityand high value can be realized. The modification method is a novel low-cost method of treating waste with waste. In the meantime, the modification method of the brick-making material has scientific and simple flows, is convenient to operate and is easy to realize large-scale production.

Owner:DALIAN UNIV OF TECH +1

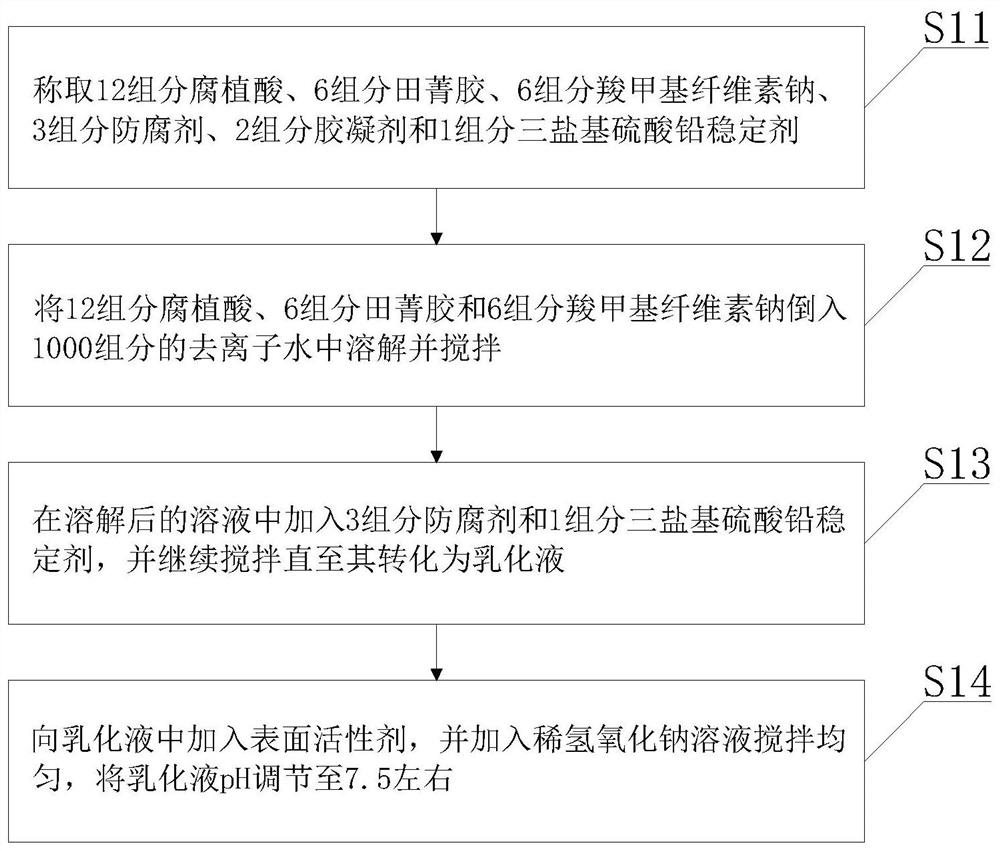

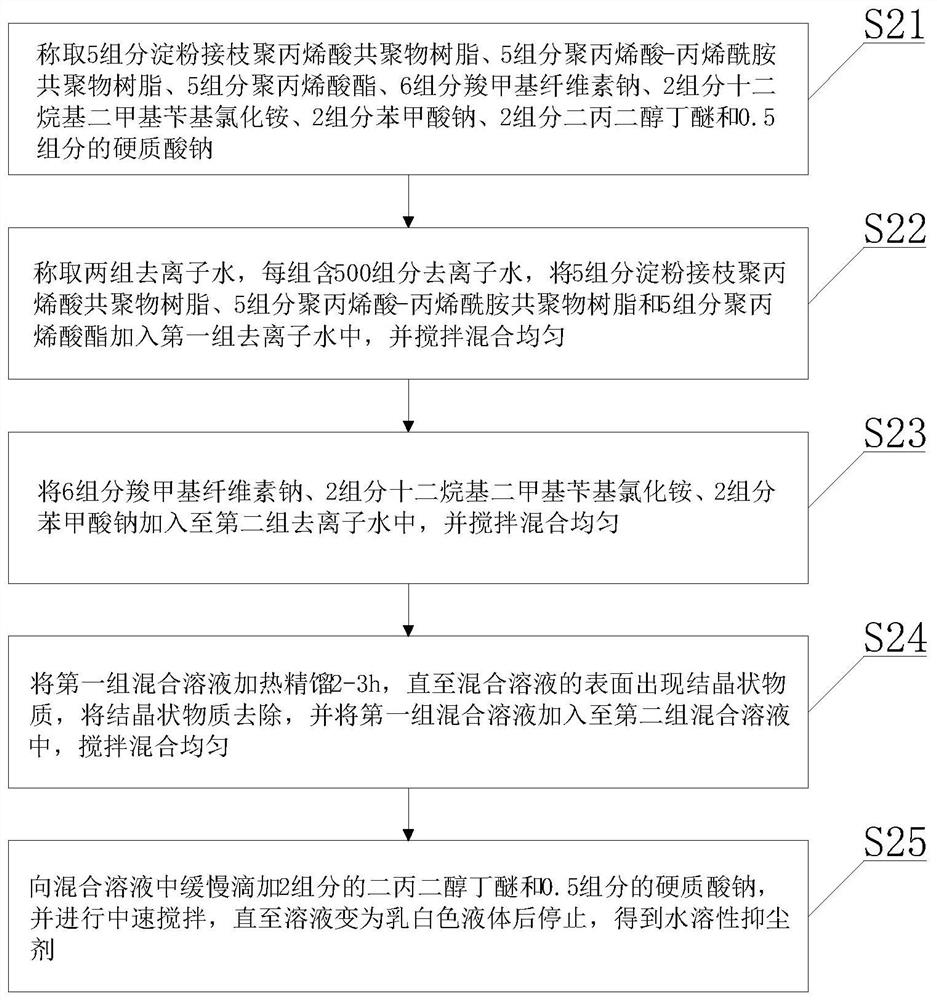

Preparation method for dust inhibitor with photocatalytic activity and spraying construction method

InactiveCN108192568APhotocatalytically activeImprove photocatalytic activityPhysical/chemical process catalystsOther chemical processesAdhesiveMagnesium acetate

The invention relates to a preparation method for a dust inhibitor with photocatalytic activity and a spraying construction method. The preparation method for the dust inhibitor comprises the following steps: preparing sol A and a solution B, namely, stirring anatase type nano titania powder with water, performing ultrasonic treatment, leaving to stand, collecting supernate, and adding a 0.2-5% adhesive so as to obtain sol A, wherein the particle size of the nano titania powder is 1-100nm; sufficiently mixing 0.1-0.9 part by weight of calcium acetate and 0.1-0.9 part by weight of magnesium acetate with 300-100 parts by weight of water so as to obtain a calcium acetate magnesium solution, and putting 0.04-0.2 part by weight of dust inhibition aids into the calcium acetate magnesium solutionso as to obtain the solution B. By adopting the preparation method provided by the invention, a nano TiO2 / CMA composite material with an efficient pollutant degradation property can be prepared, andthe composite material has a very good dust inhibition and adsorption property and photocatalytic activity under light radiation and is harmless to the environment.

Owner:北京首创大气环境科技股份有限公司

Coal additive and preparation method thereof

The invention discloses a coal additive which comprises, by weight, 10-15 parts of potassium permanganate, 3-5 parts of potassium perchlorate, 3-5 parts of iron chloride, 3-8 parts of alumina, 5-10 parts of calcium magnesium acetate, 5-10 parts of barium succinate, 3-5 parts of lauryl alcohol polyoxyethylene ether, 3-5 parts of laurate diethanolamide, 3-8 parts of calcium hydroxide, 1-5 parts of sodium hydroxide, 1-3 parts of polyoxyethylene, 1-3 parts of catalyst, 1-3 parts of swelling agent, 1-3 parts of dispersant, 1-3 parts of foamer and 30-40 parts of water. The coal additive has the advantages that the coal additive can reduce generation of sulfur dioxide, nitrogen oxide and dust during coal burning at the same time, so that the objective of environment protection is achieved.

Owner:宁波敬业控股集团有限公司

Preparation technology and application of calcium magnesium acetate

ActiveCN104355984BGood water solubilityLow eutectic point of iceOrganic compound preparationOther chemical processesFiltrationSnow melting

The invention discloses a preparation process and an application of calcium magnesium acetate. The preparation process comprises the following processing steps: preparing a calcium acetate solution, and performing press filtration, MVR concentration and centrifugal spray-drying. The preparation process disclosed by the invention is simple in technical process, easy to operate, easy in raw material acquisition, free from emission of three wastes in an overall production process, high in production efficiency, high in yield, low in equipment investment, wide in application and remarkable in economic benefits. The calcium magnesium acetate prepared by the process disclosed by the invention has the functions of melting snow, deicing, resisting dust, preventing dust and controlling atmospheric pollution; as a snow melting agent, the calcium magnesium acetate is higher in snow melting capability and enables accumulated snow and ice layers to be loose so that the snow and the ice layers can be removed more easily; as a dust resisting agent, the calcium magnesium acetate can be used for removing NOx and SO2 generated by combustion of coal and HCl generated by combustion of PVC (Polyvinyl Chloride) so as to control the atmospheric pollution; moreover, the calcium magnesium acetate causes quite low corrosion to metals and causes no toxic or side effects to human, soil and plants.

Owner:LAIZHOU LAIYU CHEM CO LTD

A kind of antifreeze type water reducer and its preparation process

The invention relates to an antifreezing water reducing agent and a preparation technique thereof. The antifreezing water reducing agent is composed of a main material and an antifreezing agent which accounts for 10 wt% of the main material. The main material is composed of the following components in parts by mass: 100-120 parts of aliphatic water reducing agent, 150-180 parts of sodium metaphosphate and 10-20 parts of early-strength admixture. The antifreezing agent is composed of the following components in parts by weight: 0.5-1.5 parts of air entraining agent, 3-8 parts of calcium magnesium acetate, 1-8 parts of sodium 2-mercaptoethane sulfonate, 2-5 parts of tetrapolyethyleneglycol monooctyl ether, 10-15 parts of nano diatomite and 5-10 parts of rigid fiber. By adding the antifreezing agent and pine wood extract, the antifreezing water reducing agent has the advantages of favorable water-reducing effect, higher slump0retaining strength, bleeding prevention, favorable antifreezing effect and strong slow-release effect, increases the strength of concrete and saves the enterprise cost.

Owner:平顶山奥思达科技有限公司

Economic environment-friendly snow melting agent and preparation method thereof

InactiveCN105385415ALess destructiveLess corrosiveOther chemical processesCarboxylic acid salt preparationSnow meltingCalcium magnesium acetate

The invention discloses an economic environment-friendly snow melting agent and a preparation method of the economic environment-friendly snow melting agent. The economic environment-friendly snow melting agent is characterized by being mainly prepared from the following raw materials of acetate, low-corrosivity chloride and an anticorrosive which are taken as main raw materials, wherein the main raw materials are prepared from the following components in percentage by weight: 40 to 45 percent of calcium magnesium acetate, 20 to 25 percent of magnesium acetate and 10 to 25 percent of calcium acetate by adding 5 to 8 percent of calcium chloride in a certain proportion and 2.5 to 3.5 percent of anticorrosive. The economic environment-friendly snow melting agent and the preparation method of the economic environment-friendly snow melting agent, disclosed by the invention, have the advantages that the deicing performance is good, the freezing point is low, the corrosivity on materials such as metal and concrete of municipal infrastructures is small, the destructiveness on farmland and greening vegetation is extremely low, and the production technology is simple; due to the adoption of the preparation method for producing calcium acetate, magnesium acetate and calcium magnesium acetate by using waste acetic acid, the cost is effectively reduced, and the preparation method is suitable for being widely promoted.

Owner:南京简氏环保技术有限公司

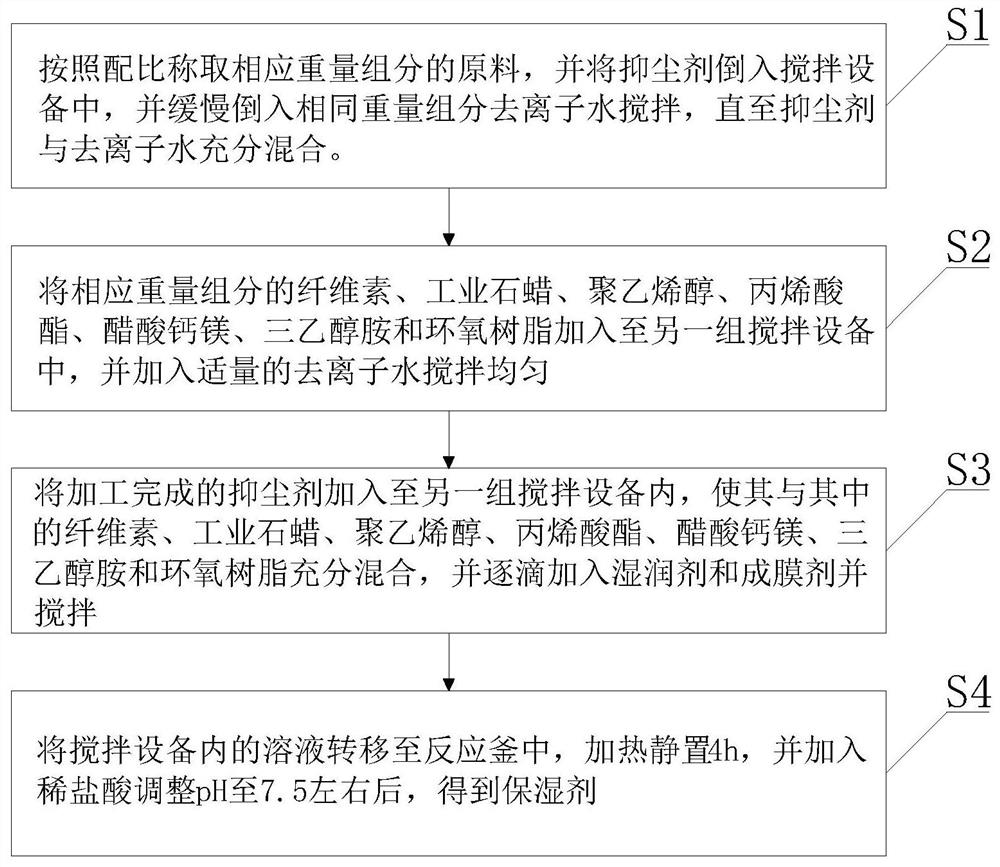

Humectants for inhibiting flying dust of calcium carbonate and preparation method of humectants

PendingCN111690374AGuaranteed ContaminationQuality improvementOther chemical processesEpoxyPolyvinyl alcohol

The invention discloses humectants for inhibiting flying dust of calcium carbonate. The humectants comprise a crusting dust suppressant, a water-soluble dust suppressant, a wetting agent, a film-forming agent, industrial paraffin, polyvinyl alcohol, acrylate, calcium magnesium acetate, triethanolamine and epoxy resin. The crusting dust suppressant is added in the preparation process of a first humectant, spraying is performed in a space with relatively high flying dust in a workshop, moisture in the air can be quickly combined, and the outer side of the dust is wrapped to form a film, so the quality of dust is improved, dust is settled to the ground; in the preparation process of a second humectant, the water-soluble dust suppressant is added, and after spraying, other types of dust in theair can be wrapped and dissolved and are finally settled to the ground; the crusting dust suppressant and the water-soluble dust suppressant are respectively added into a third humectant, dust in theair can be wrapped and form a film, and dust impurities are directly dissolved in the settling process; the humectant can be compatible with space moisture retention of most powder products includingcalcium carbonate powder production, and the production cost is effectively saved.

Owner:安徽雪城超细碳酸钙有限公司

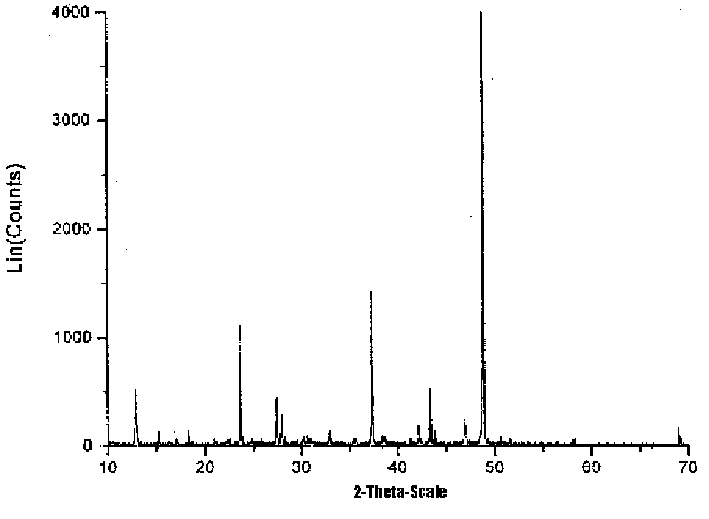

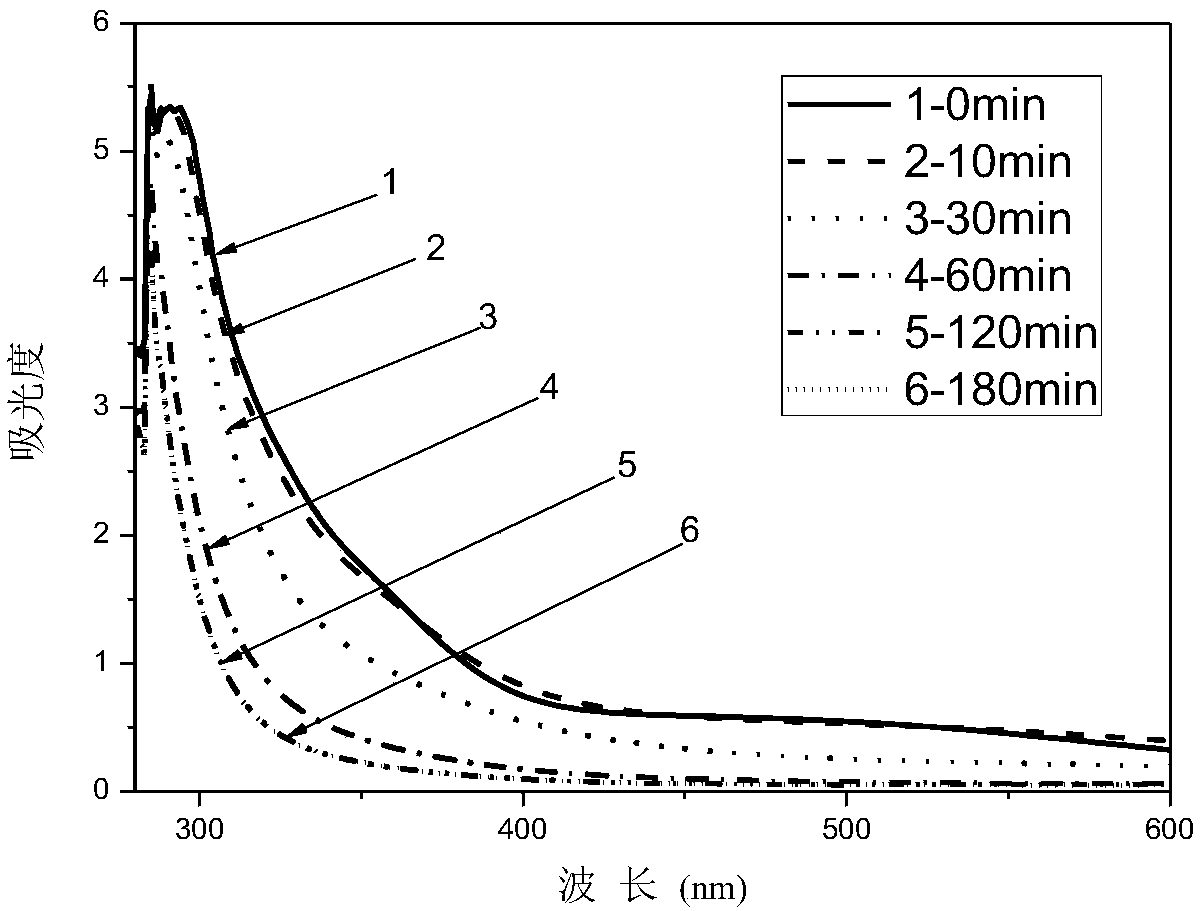

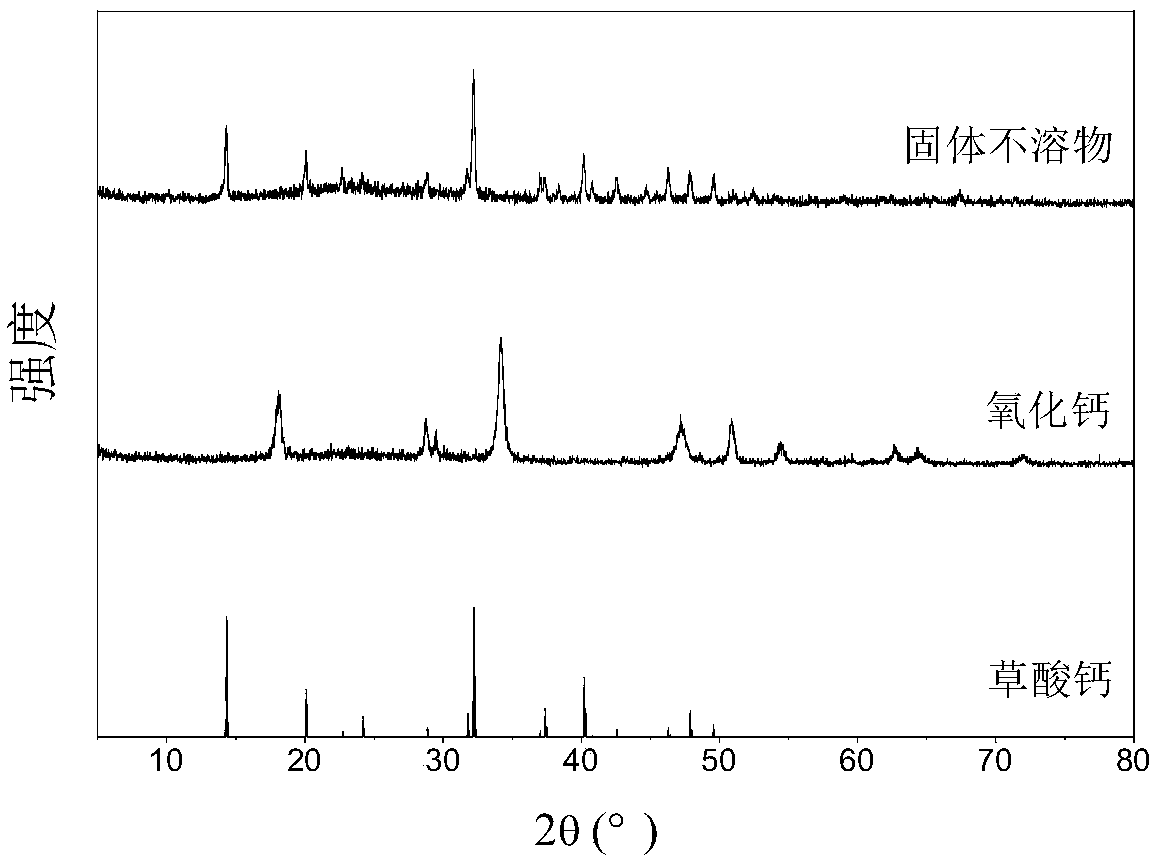

Method for decolorization of pyroligneous liquor and preparation of calcium magnesium acetate based on catalytic ozonation

ActiveCN109569442AHigh reactivitySimple production processOther chemical processesMagnesiaFiltrationCarboxylic salt

Disclosed is a method for decolorization of pyroligneous liquor and preparation of calcium magnesium acetate based on catalytic ozonation. The method mainly includes (1), adding solid bases which comprise calcium or magnesium oxides and hydroxides in pyroligneous liquor, and reacting at the room temperature for 1-2 hours while keeping the pH value within 7-8; (2), filtering to extract dark-brown pyroligneous liquor transfer solution; (3), adding the same solid bases as the step (1) in the dark-brown pyroligneous liquor transfer solution by the volume of 1-10g / L,while keeping the pH valve to be8-11; (4), introducing ozone to the treated pyroligneous liquor transfer solution obtained in the step (3), reacting for 3-5 hours, with the concentration of O3 being 90-120mg / L and the flow rate being 200-1000mL / min; (5), after decolorization, regulating the pH value of the pyroligneous liquor transfer solution to be similar to neutral, performing suction filtration to extract low-carbon calciummagnesium carboxylate solution, and atomizing the low-carbon calcium magnesium carboxylate solution; (6), calcining solid precipitates filtered out in the step (5) at the temperature of 800 DEG C. The method is simple in process, low in cost, short in time for decolorization and high in comprehensive utilization rate, and is energysaving, efficient and free of secondary pollution.

Owner:CHINA CATALYST HLDG CO LTD

Method for preparing calcium-magnesium acetate by utilizing steel slag

InactiveCN103864599ARealize automatic meltingSimple recipeOrganic compound preparationOther chemical processesSlagAcetic acid solution

The invention belongs to the technical field of civil engineering and in particular relates to a method for preparing calcium-magnesium acetate by utilizing steel slag. Calcium-magnesium acetate is prepared through reaction between an acetic acid solution and the steel slag, wherein the mass ratio of the steel slag to acetic acid is (1-3):1. The aim of automatically melting ice and snow can be achieved by directly spraying the calcium-magnesium acetate product (water aqua or solid powder) onto roads, bridges, airfield runways and the like. The method is simple in formula and production process and is easy to popularize and apply.

Owner:福建源鑫环保科技有限公司

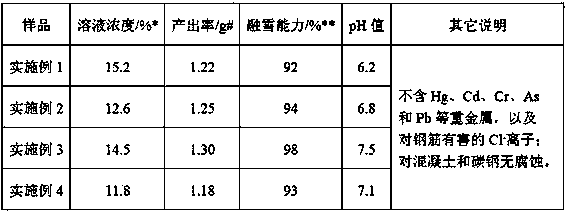

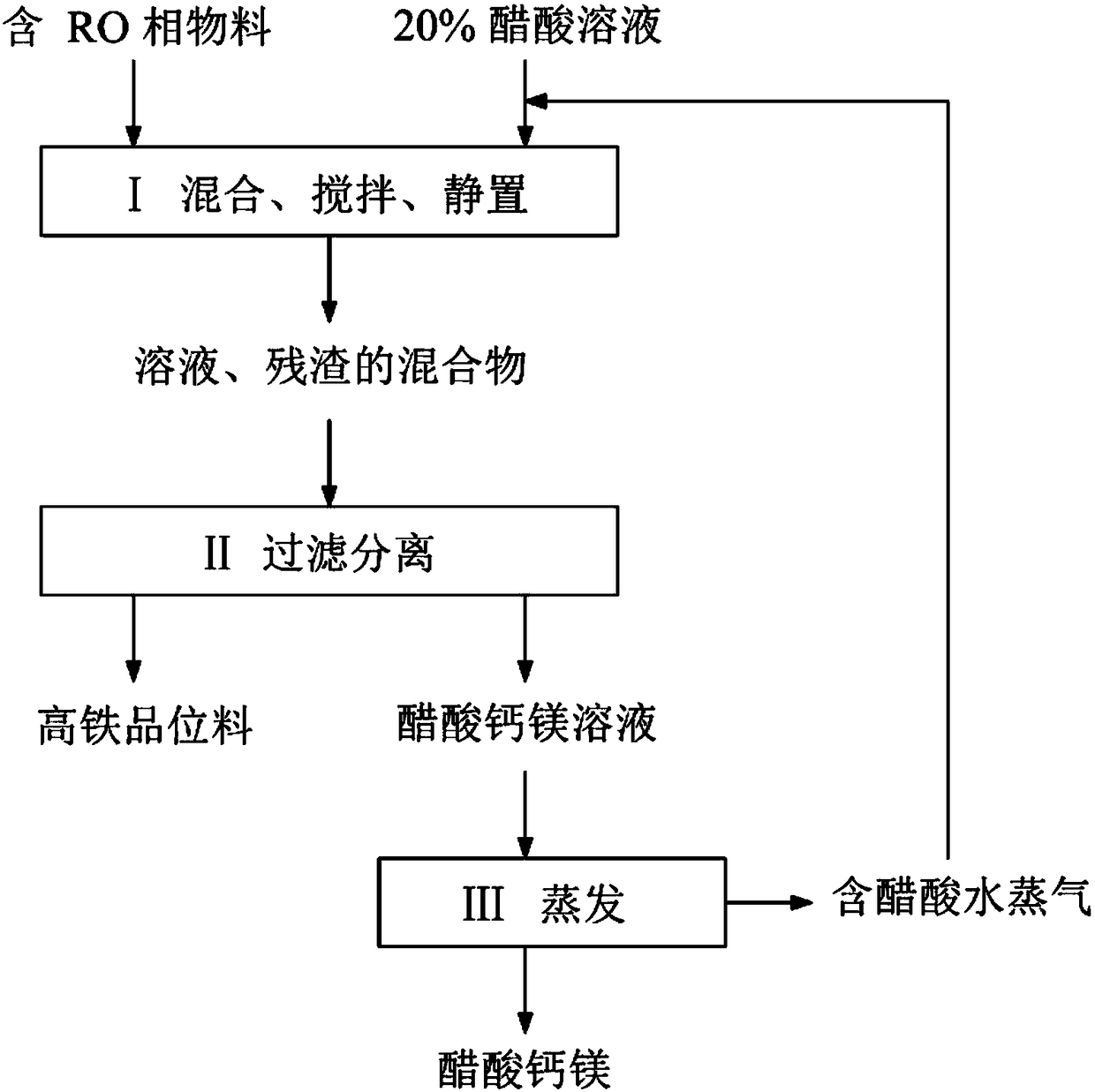

Production process for preparing high-iron-grade product and calcium magnesium acetate from RO-phase-containing material

InactiveCN108298594ASolve the problem of low difficulty to useHigh market demandOrganic compound preparationFerrous oxidesSlagDistillation

The invention provides a production process for preparing a high-iron-grade product and calcium magnesium acetate from an RO-phase-containing material. The RO-phase-containing material is added into an acetic acid solution; stirring reaction is performed, so that non-FeO ingredients in the RO phase and hydrated active minerals in the steel slag are sufficiently dissolved; still standing is performed so that the non-dissolved residue is sufficiently settled, and the solution layers; supernate is extracted to obtain the calcium magnesium acetate solution containing acetic acid; settled materialsare subjected to extraction filtering and dewatering to obtain the high-iron-grade material which can be used as iron making concrete powder making or heavy medium powder for coal dressing; the calcium magnesium acetate solution containing acetic acid is heated to 1 to 50 DEG C to obtain the calcium magnesium acetate powder dried by distillation; the calcium magnesium acetate powder can be used as a desulphurization and denitrogenation agent for fire coal or environment-friendly snow-melting agent. The selective dissolution effect of the acetic acid solution on the RO phase ingredient is used; the MgO, CaO and MnO ingredients in the RO-phase-containing material are dissolved out; the high-grade iron concretes are obtained; a new technology is provided for the steel slag resource utilization; the operation of the technical process is easy; waste gas, waste water and industrial slag cannot be generated; the operation cost is low.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

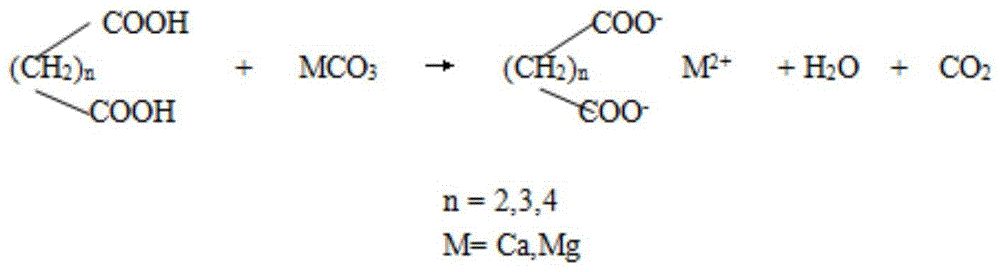

Organic snow-melting agent and preparation method thereof

ActiveCN105778864ACorrosion damage is smallSave resourcesOther chemical processesEvaporationSnow melting

The invention discloses an organic snow-melting agent and a preparation method thereof and belongs to the technical field of applied chemistry.The organic snow-melting agent is prepared from, by mass, 1.5-15% of calcium succinate, 15-30% of magnesium succinate, 3-25% of calcium glutarate, 25-50% of magnesium glutarate, 1-10% of calcium adipate and 10-20% of magnesium adipate.The preparation method of the organic snow-melting agent comprises the following steps of 1, preparing a mixed diacid aqueous solution; 2, calculating and weighing the actual adding volume of salinization reagent; 3, conducting mixing; 4, conducting filtering; 5, conducting decolouration treatment; 6, conducting evaporation for separation.The prepared novel non-chlorine-salt type organic snow-melting agent is mixed with diacid calcium and magnesium and is applicable to snow melting and deicing of places with the temperature being 15 DEG C or above, compared with snow-melting agents of the same type, namely calcium acetate and magnesium acetate, which are commonly used on the market, the applicable temperature range is broadened by about 5 DEG C, and the corrosion damage effect is extremely small; a new path is opened up for recycling of a byproduct, namely mixed diacid, in the nylon production industry, resources are saved, and the environment is protected.

Owner:辽宁省交通科学研究院有限责任公司

Fire coal clean assistant and preparation method thereof

ActiveCN109609241AImprove thermal stabilityEffective absorptionSolid fuelsEnvironmental resistanceCombustion

The invention relates to a fire coal clean assistant and a preparation method thereof. The fire coal clean assistant comprises: 8-15 weight parts of water, 1-5 weight parts of calcium oxide, 2-4 weight parts of calcium magnesium acetate, 1-3 weight parts of urea, 0.5-1.5 weight parts of titanium dioxide, 0.5-1.5 weight parts of a catalyst and 0.5-1.5 weight parts of a composite binder. The fire coal clean assistant provided by the invention is environment-friendly and pollution-free, the used raw materials are clean and non-toxic, the preparation method is simple, therefore the fire coal cleanassistant can be produced in large batches and applied to the market, especially is very effective for low non-point source pollution caused by civil bulk coal combustion, lowers environmental pollution and reduces resource waste. Moreover, the assistant provided by the invention can also be used for general coal combustion areas without organized emission, solves the hazards of fire coal to theenvironment from the source, and does not produce secondary pollution problem.

Owner:北京首创大气环境科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com