Organic snow-melting agent and preparation method thereof

A snow-melting agent and organic technology, applied in the field of applied chemistry, can solve the problems of large corrosion and damage of chloride salts, high production cost, environmental pollution, etc., and achieve the effects of small corrosion and damage, saving resources and protecting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

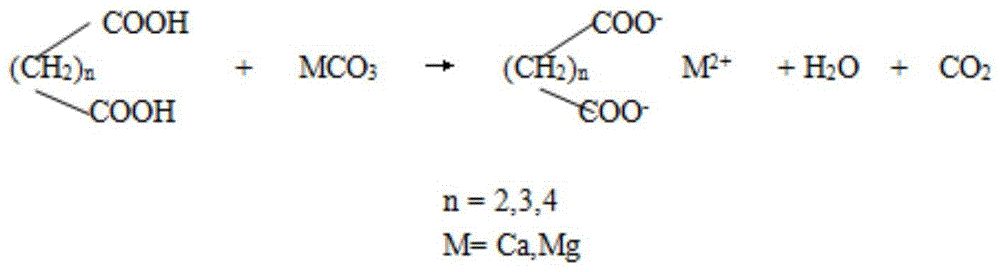

Method used

Image

Examples

Embodiment 1

[0050]An organic deicing agent, the composition is by mass percentage: 8% calcium succinate, 22% magnesium succinate, 14% calcium glutarate, 38% magnesium glutarate, 5% calcium adipate %, magnesium adipate is 13%.

[0051] A kind of preparation method of organic deicing agent, comprises the following steps:

[0052] Step 1, weighing 100g of mixed dibasic acid, mixed with 300g of distilled water, to prepare a mixed dibasic acid aqueous solution with a mass concentration of 25%;

[0053] Step 2, calculate and take by weighing the actual dosage of salinization reagent; Wherein, the composition of salinization reagent, by the percentage of the amount of substance, dolomite powder n 1 : Magnesium carbonate powder n 2 = 50%: 50%;

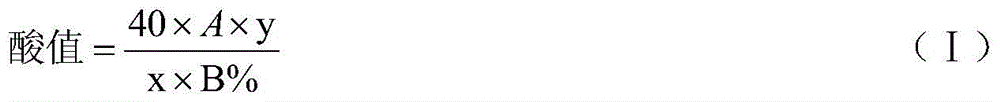

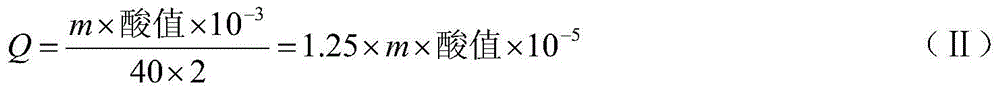

[0054] (1) Calculate the actual dosage W of the salinizing reagent, and calculate according to the formula (I), (II), and (III):

[0055] As can be seen from formula (I), acid value=600 (mgNaOH / g);

[0056] It can be seen from the formula (II) that t...

Embodiment 2

[0070] An organic deicing agent, the composition is by mass percentage: 10% of calcium succinate, 19.5% of magnesium succinate, 18.5% of calcium glutarate, 33.5% of magnesium glutarate, 6.5% of calcium adipate %, magnesium adipate is 12%.

[0071] A kind of preparation method of organic deicing agent, comprises the following steps:

[0072] Step 1, weigh 100g of mixed dibasic acid, mix it with 400g of distilled water, and prepare an aqueous solution of mixed dibasic acid with a mass concentration of 20%;

[0073] Step 2, calculate and take by weighing the actual dosage of salinization reagent; Wherein, the composition of salinization reagent, by the percentage of the amount of substance, dolomite powder n 1 : Magnesium carbonate powder n 2 = 66.7%: 33.3%;

[0074] (1) Calculate the actual dosage W of the salinizing reagent, and calculate according to the formula (I), (II), and (III):

[0075] As can be seen from formula (I), acid value=600 (mgNaOH / g);

[0076] It can be s...

Embodiment 3

[0089] An organic deicing agent, the composition is by mass percentage: 1.5% of calcium succinate, 27% of magnesium succinate, 3% of calcium glutarate, 49.5% of magnesium glutarate, 1% of calcium adipate %, magnesium adipate is 18%.

[0090] A kind of preparation method of organic deicing agent, comprises the following steps:

[0091] Step 1, weigh 100g of mixed dibasic acid, mix it with 350g of distilled water, and prepare a mixed dibasic acid aqueous solution with a mass concentration of 22.2%;

[0092] Step 2, calculate and take by weighing the actual dosage of salinization reagent; Wherein, the composition of salinization reagent, by the percentage of the amount of substance, dolomite powder n 1 : Magnesium carbonate powder n 2 = 10%: 90%;

[0093] (1) Calculate the actual dosage W of the salinizing reagent, and calculate according to the formula (I), (II), and (III):

[0094] As can be seen from formula (I), acid value=600 (mgNaOH / g);

[0095] It can be seen from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com