Cleaning method for semiconductor materials

A semiconductor and post-cleaning technology, which is applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, detergent compounding agents, etc., can solve the problem of rapid failure of solution cleaning ability, increase the surface roughness of silicon wafers, and environmentally unfriendly chemical reagents etc. to achieve the effect of effectively removing metal ions, promoting saponification reaction, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Alkaline degreasing washes for silicon, quartz, ceramic semiconductor materials:

[0044] Potassium hydroxide 3%, potassium carbonate 3.6%, dipotassium dihydrogen pyrophosphate 2.1%, potassium tripolyphosphate 2%, acetal acetal 4.5%, sodium dodecyl diphenyl ether disulfonate 1.8%, H-662.5 % (Dow Chemical TRITON H-66), aliphatic amine polyoxyethylene ether 2%, and the balance is water; all percentages are calculated by mass and volume percentage, the same below. Immerse several silicon product samples (quartz wafers after etching, silicon wafers, polished silicon wafers, silicon machined surfaces, quartz machined surfaces, respectively P-type monocrystalline silicon, polycrystalline silicon, etc.) Ultrasonic immersion cleaning, the temperature is controlled at 35-50 ℃, cleaning is about 15-20 minutes, and deionized water is rinsed after cleaning. After cleaning, there is no grease residue from the appearance of the product, and there is no obvious foreign matter at 1000...

Embodiment 2

[0048] Alkaline degreasing washes for silicon, quartz, ceramic semiconductor materials:

[0049] Potassium hydroxide 3%, potassium carbonate 4%, dipotassium dihydrogen pyrophosphate 3%, potassium tripolyphosphate 2.8%, acetone acetal 5.2%, sodium dodecyl diphenyl ether disulfonate 1.6%, H-662 %, aliphatic amine polyoxyethylene ether 1.6%, and the balance is deionized water; immerse several silicon product samples (same as Example 1) in the above-mentioned alkaline degreasing lotion, soak and clean with ultrasonic waves, and control the temperature at 35-50 ° C , Clean for about 15-20 minutes, rinse with deionized water after cleaning.

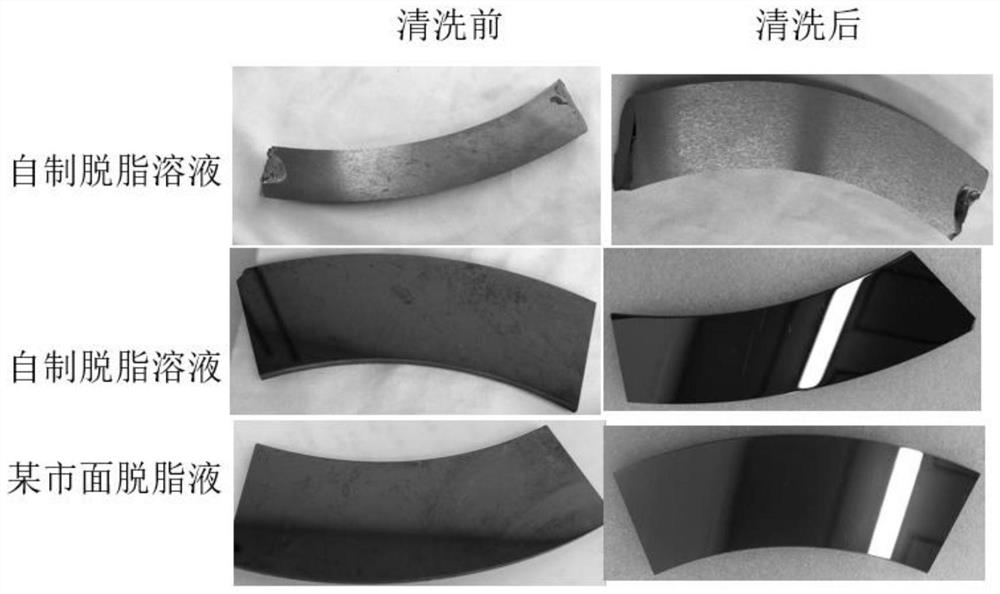

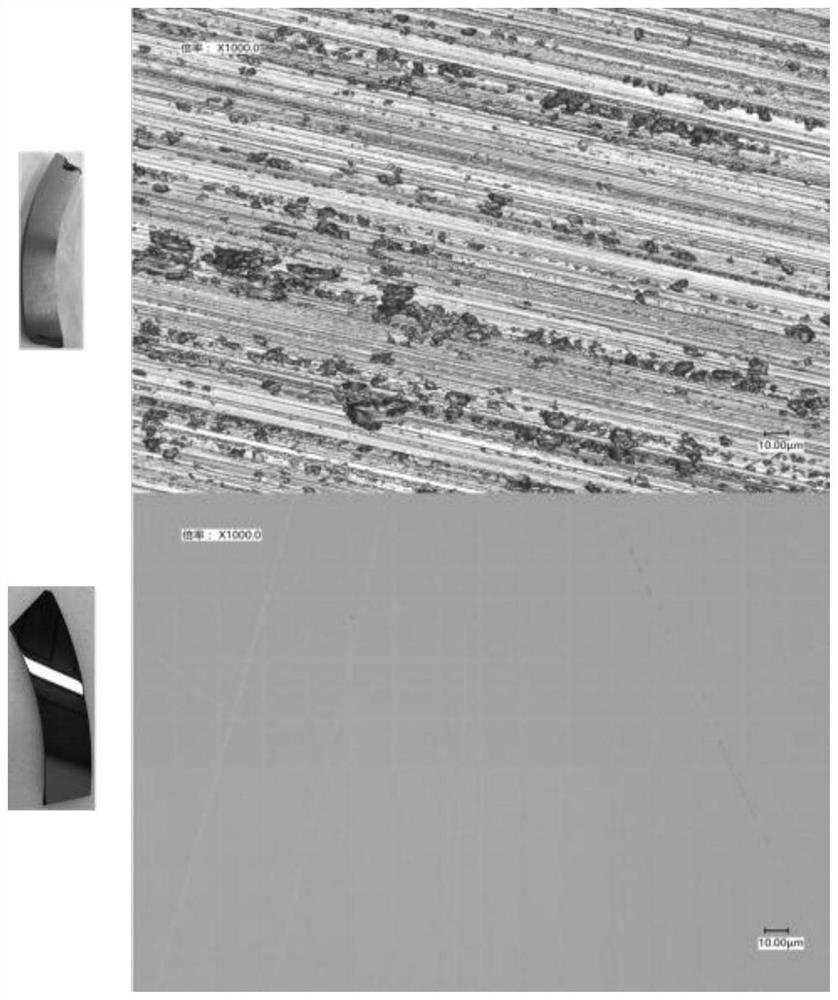

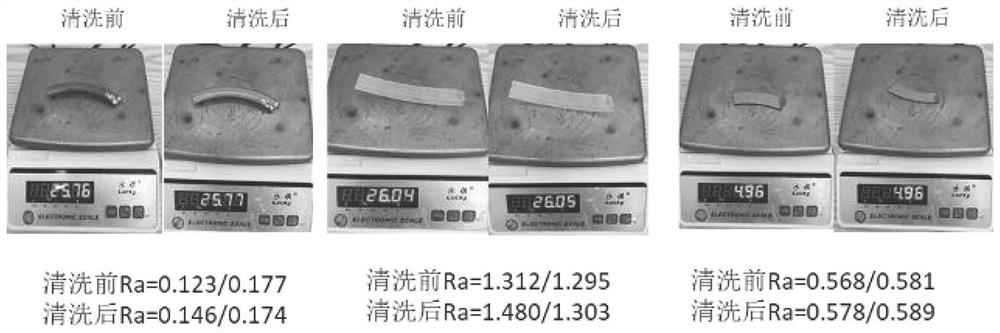

[0050] The samples after the degreasing treatment of Example 1 and Example 2 were detected, figure 1 The appearance diagrams of 2 silicon wafer samples before and after degreasing and cleaning are shown, and the third row is a comparison diagram of a market degreasing solution under the same conditions. figure 2 It is a 1000x high-definition...

Embodiment 3

[0053] Metal ion cleaning solution suitable for silicon, quartz and ceramic semiconductor materials, including acid A cleaning solution, neutral cleaning solution, and acid B cleaning solution, which can treat metal elements on the surface of samples, including 30 metal elements required by the semiconductor industry Metal elements, specifically Al, Sb, As, Ba, Be, Bi, B, Cd, Ca, Cr, Co, Cu, Ga, Ge, Fe, Pb, Li, Mg, Mn, Mo, Ni, K, Na , Sr, Sn, Ti, W, V, Zn, Zr.

[0054] The sample is first soaked and cleaned with acid A lotion at room temperature, the cleaning time is about 15-20 minutes, and then rinsed with deionized water; Clean for about 15-20 minutes, rinse with deionized water after cleaning; finally put it in acid B lotion for immersion cleaning, control the temperature at room temperature, clean for about 15-20 minutes, and rinse with deionized water after cleaning. Among them, the acid A washing solution is: ammonium fluoride 3.9%, fluorosilicic acid 2%, H-951.2% (Ger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com