Patents

Literature

90results about How to "Increase static electricity" patented technology

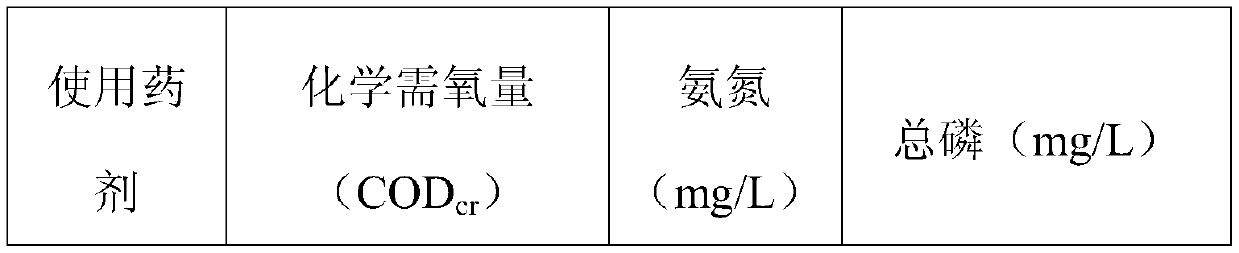

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

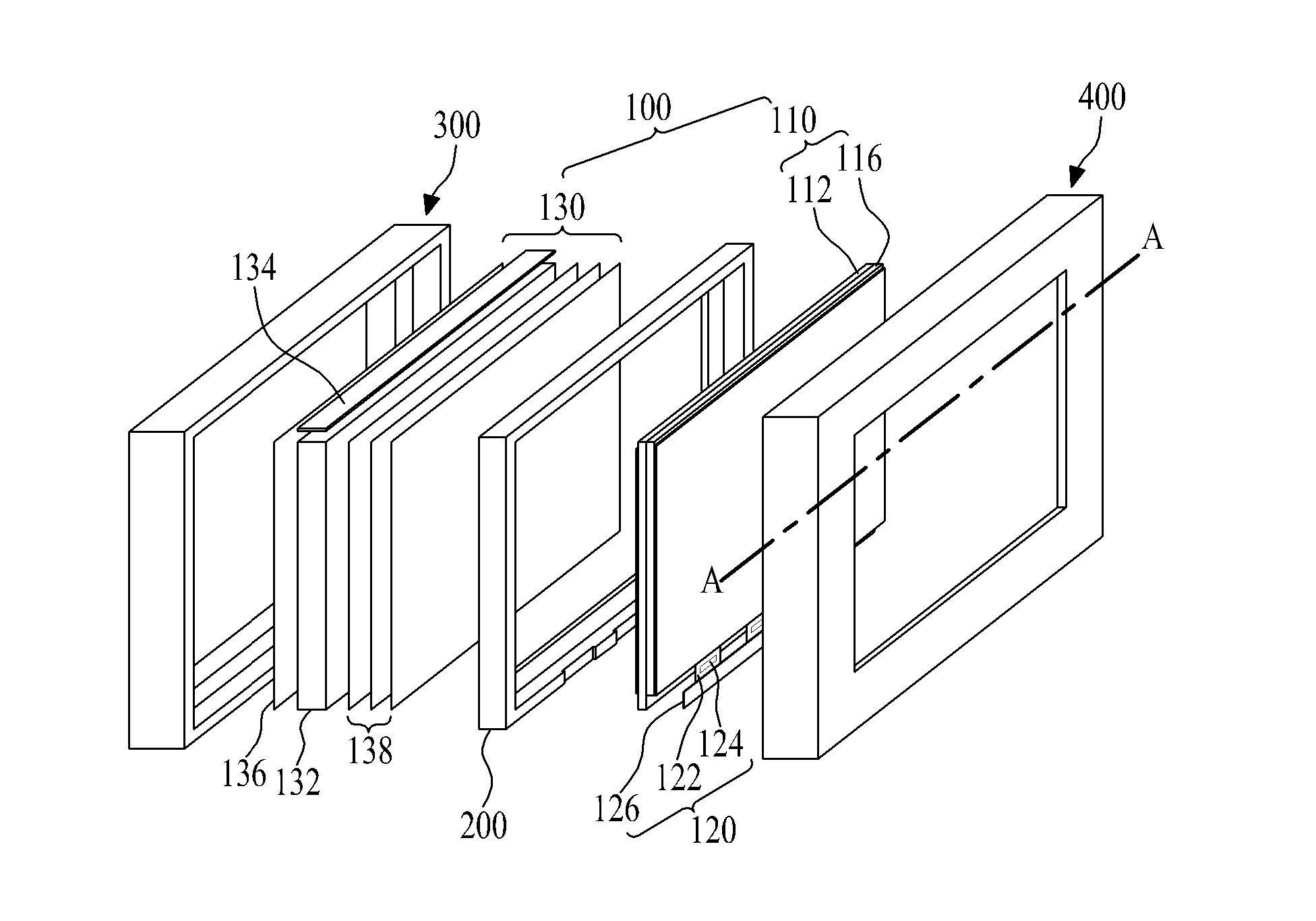

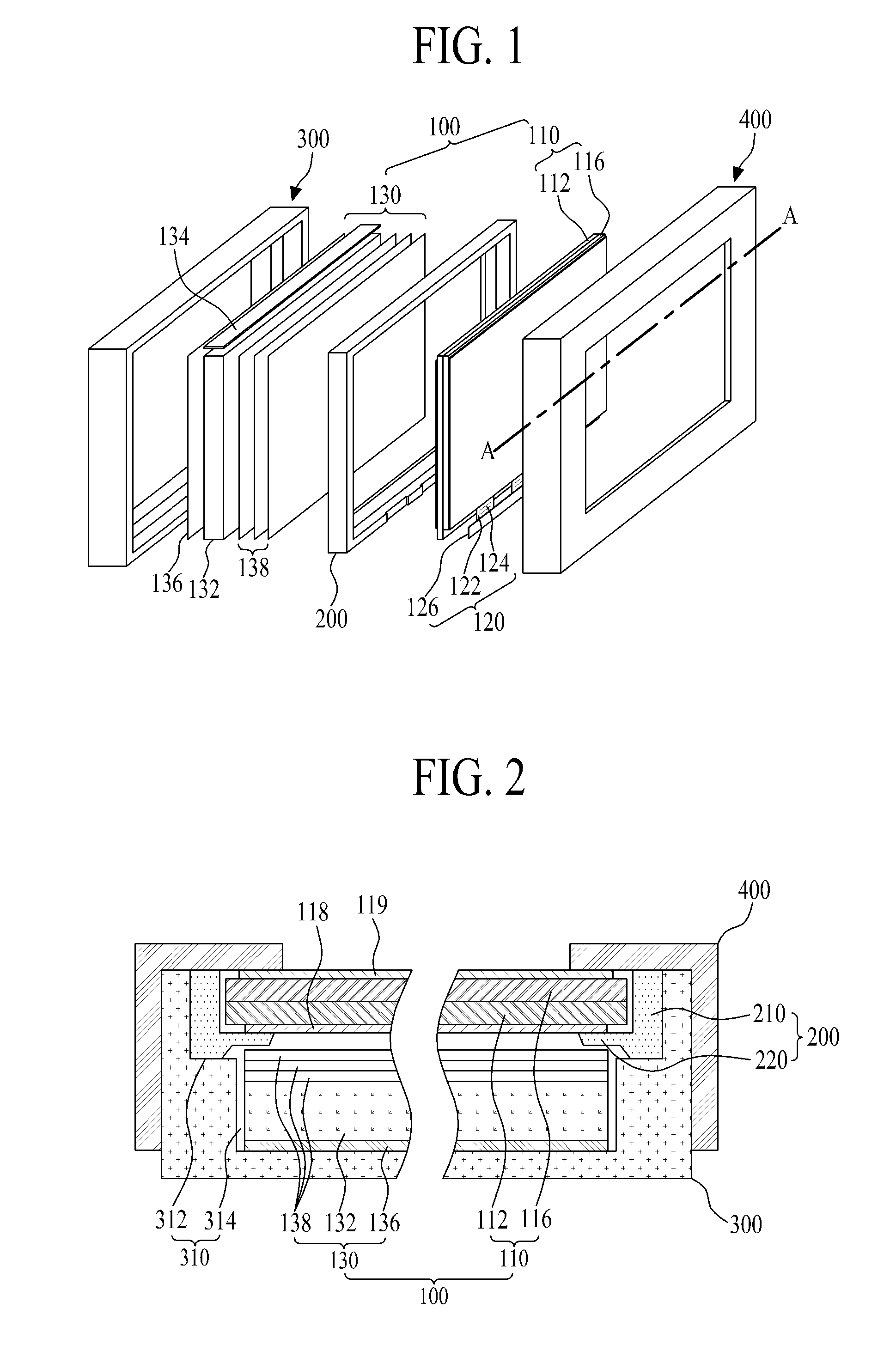

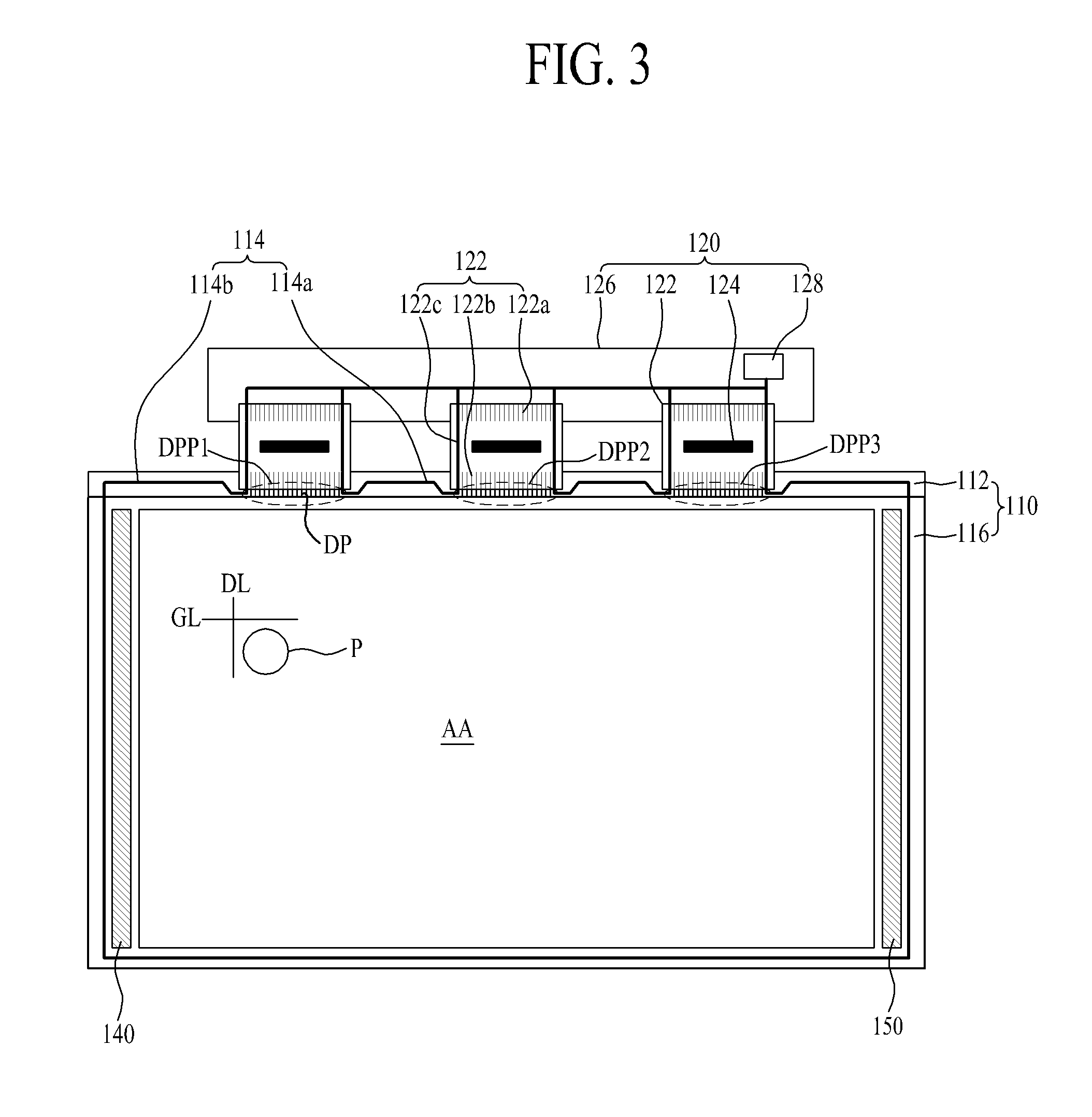

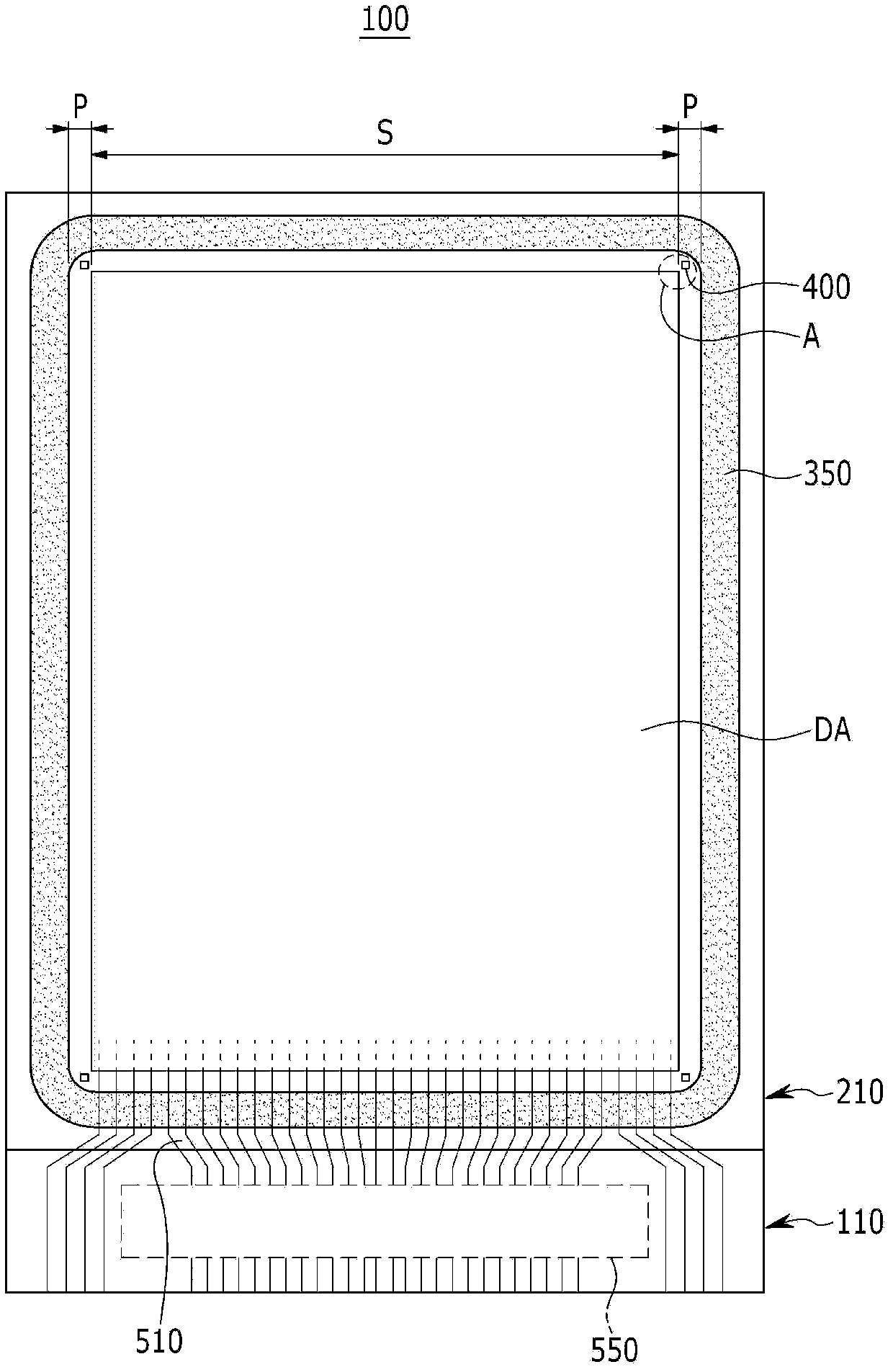

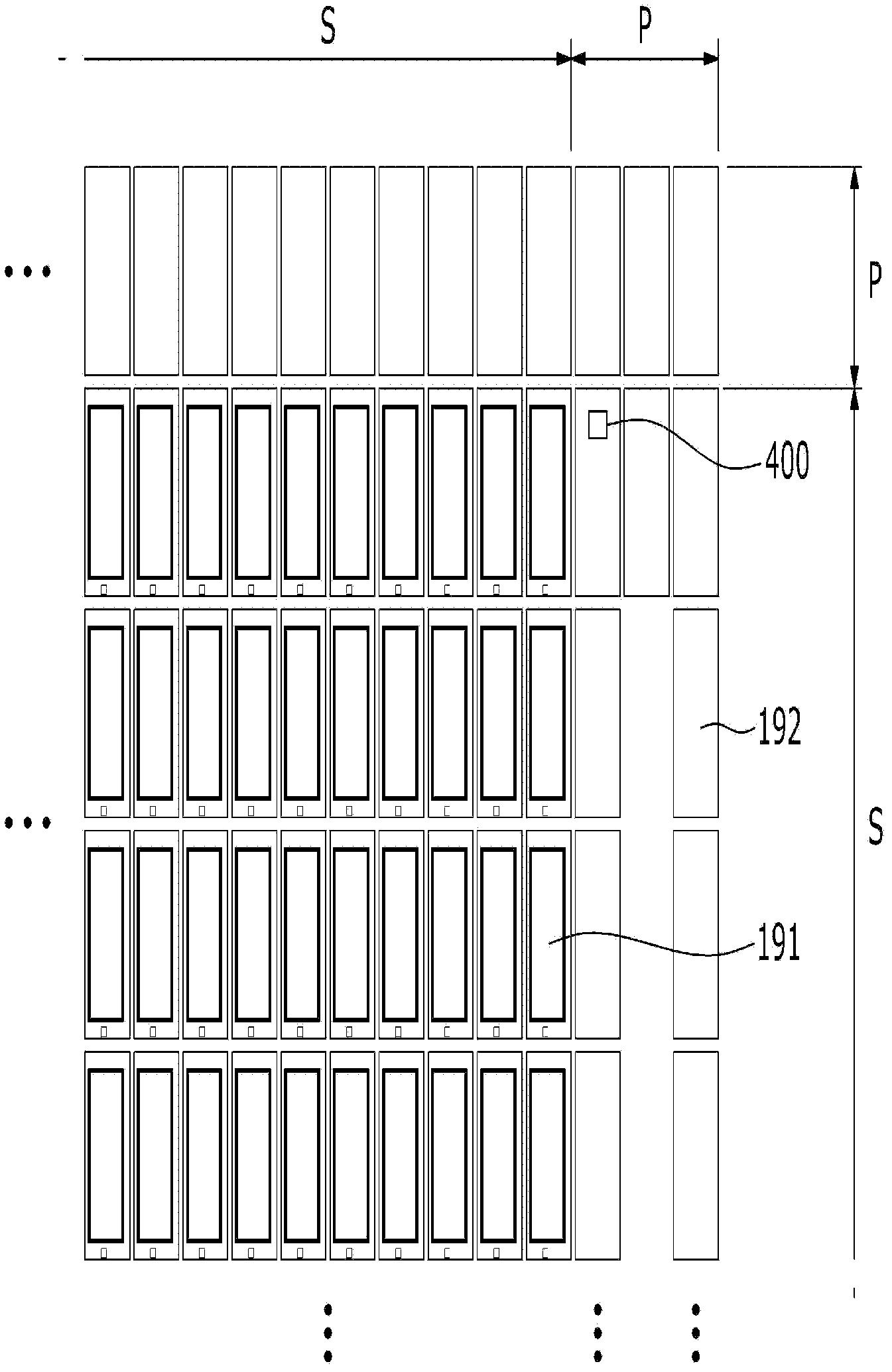

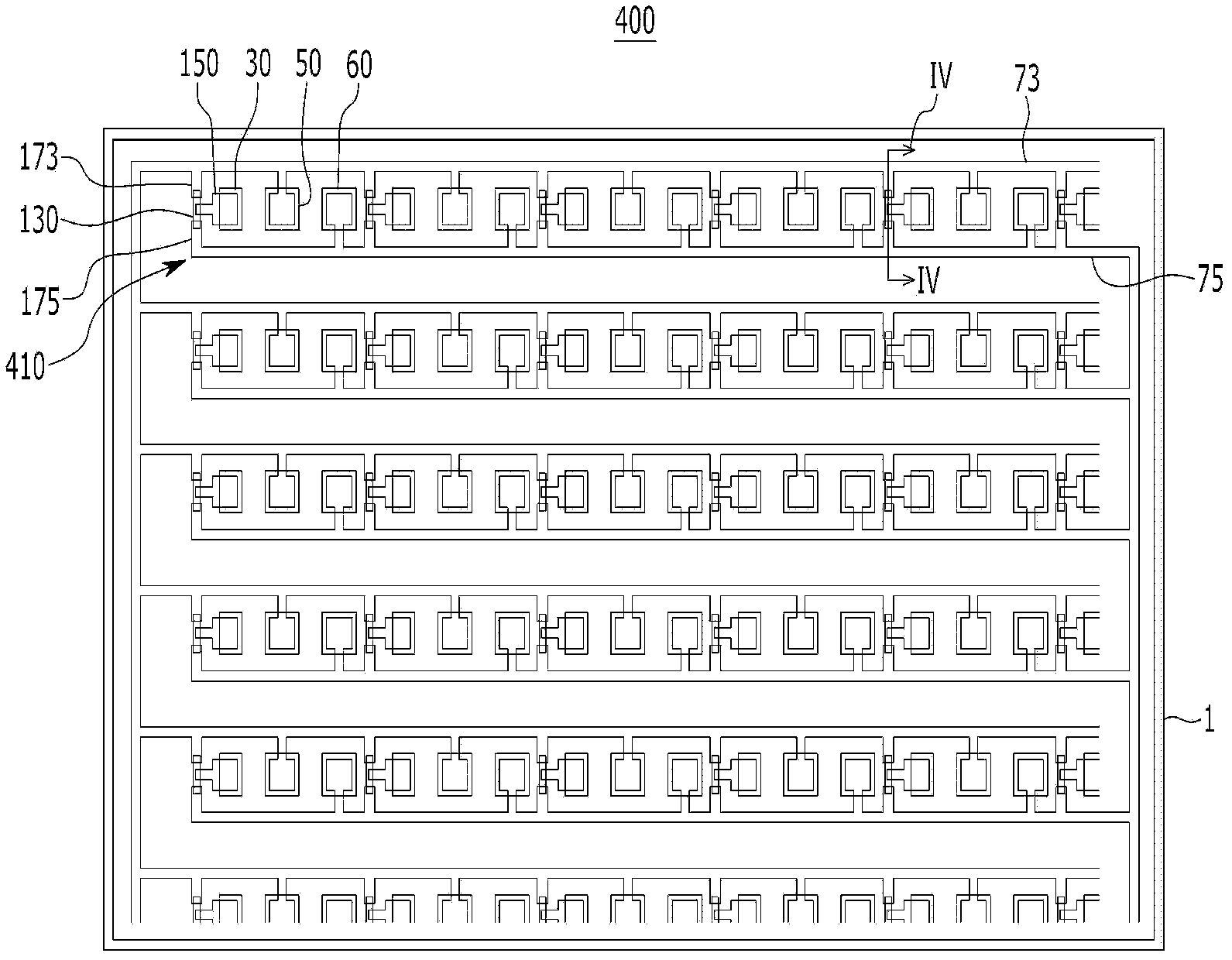

Display panel and display device comprising the same

ActiveUS20110310543A1Improving tolerance against static electricityThickness minimizationDigital data processing detailsElectrical apparatus contructional detailsDisplay deviceGround line

A display panel and a display device having the display panel are discussed. According to an embodiment, the display panel includes a lower substrate provided with a display area and a non-display area; a plurality of data pad portions formed at a side region of the non-display area; an upper substrate bonded to the lower substrate, except for the side region of the non-display area; and at least one ground line supplied with ground power, and formed on the lower substrate of the non-display area to surround in part an outline portion of the display area.

Owner:LG DISPLAY CO LTD

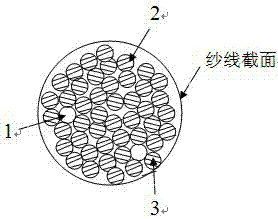

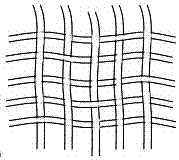

Flame-retardant antistatic yarn and fabric thereof

ActiveCN106948052AGood flame retardant and antistatic effectFunction increaseElectroconductive/antistatic filament manufactureFibre mixingYarnPolymer science

The invention relates to a flame-retardant antistatic yarn, formed by weaving 2-5 wt% grapheme-dacron complex fibers [1], 60-65% dacron flame-retardant fibers [2], and 30%-38 wt% Yasaier fibers [3]. The grapheme-dacron complex fibers [1] are obtained by a grapheme-dacron spinning complex liquid through a wet spinning method, and the involved grapheme is modified grapheme. The flame-retardant antistatic yarn has advantages of good flame-retardant antistatic effect, lasting functions, good wearability, and low production cost. The grapheme-dacron complex fiber has good conductivity, radiation protection and anti-acne performance, and functionality of the yarn is improved. The Yasaier fiber can improve moisture regain, improve electrostatic phenomenon, and has high strength, and can effectively ensure physical properties of a blended yarn. The flame retardant property of the flame-retardant dacron is good, and strength of the flame-retardant dacron is high, weather resistance is good, and the flame-retardant dacron ensures endurance of the yarn.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

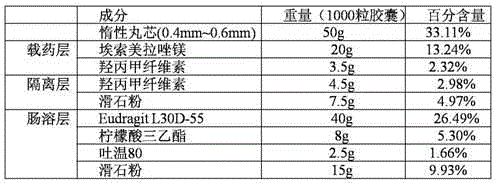

Enteric-coated micropellet containing esomeprazole magnesium

ActiveCN104414978APrevent Mutual AggregationAvoid being sucked by the wall of the fluidized cylinderOrganic active ingredientsDigestive systemMethacrylic acid-ethyl acrylate copolymerStearic acid

The invention relates to an enteric-coated micropellet containing esomeprazole magnesium. The enteric-coated micropellet comprises an inert pellet core, a medicament-loaded layer, an isolation layer and an enteric-coated layer, wherein the enteric-coated layer contains a methacrylic acid / ethyl acrylate 1: 1 copolymer, glyceryl monostearate, Tween 80 and talcum powder, wherein the methacrylic acid / ethyl acrylate 1: 1 copolymer is preferably Eudragit L30D-55. The enteric-coated micropellet containing esomeprazole magnesium, provided by the invention, can give consideration to acid resistance, release rate and stability of a product for a long time in the placement process, can meet or exceed existing preparation quality standards; and furthermore, the enteric-coated micropellet is prepared by simple process steps, is suitable for a relatively large pellet core (0.3mm-1mm), has the characteristic of low production cost, and is more suitable for large-scale industrialized production.

Owner:SICHUAN GOWELL PHARMA

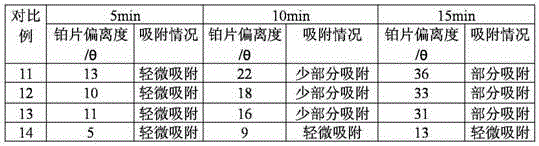

Power electronics assembly with cooling element

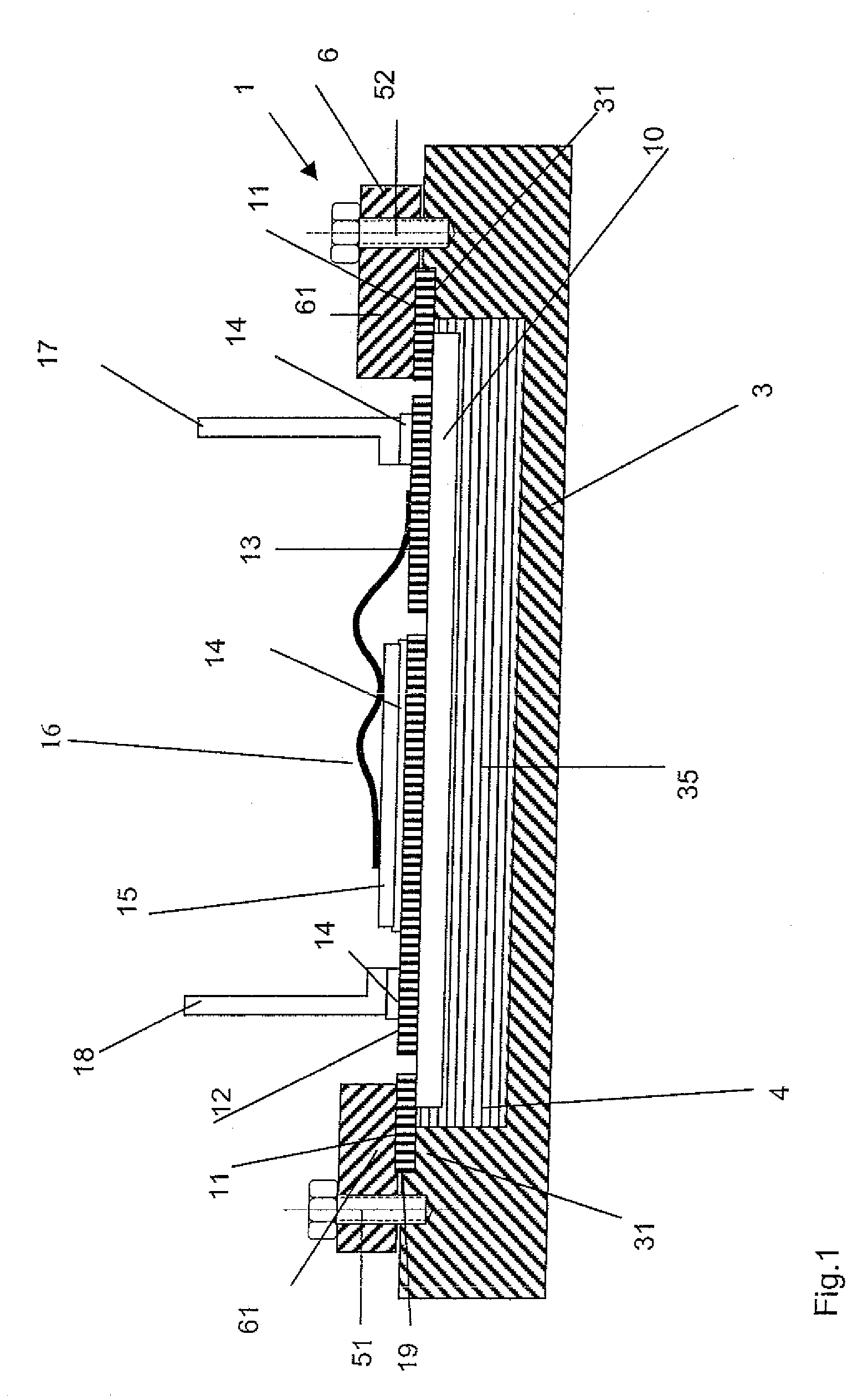

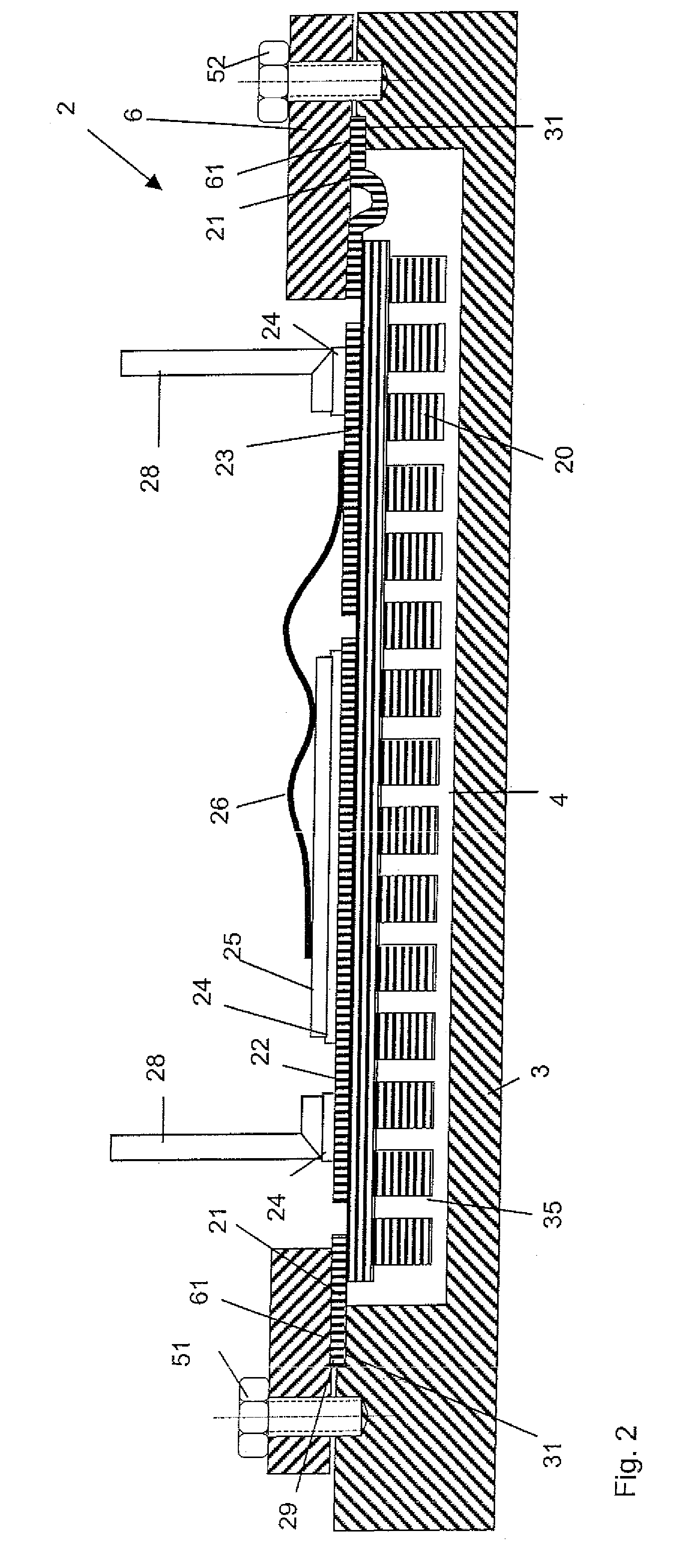

InactiveUS7800220B2Simple structureImprove the level ofSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

The invention concerns a power electronic arrangement comprising an insulating substrate, a cooling element arranged beneath the insulating substrate and one or more power electronic components disposed on a respective metallization surface of the insulating substrate. Disposed on the surface of the insulating substrate is a metal layer portion which projects beyond the insulating substrate at all sides. The region of the metal layer portion, that projects beyond the insulating substrate, forms a metal flange which borders the insulating substrate. The cooling element, on its side towards the insulating substrate, beneath the insulating substrate, has one or more recesses, whereby a cavity delimited by the insulating substrate and wall surfaces of the one or more recesses is formed beneath the insulating substrate for receiving a liquid cooling agent. The metal flange is further connected to the cooling element.

Owner:ECPE ENG CENT FOR POWER ELECTRONICS

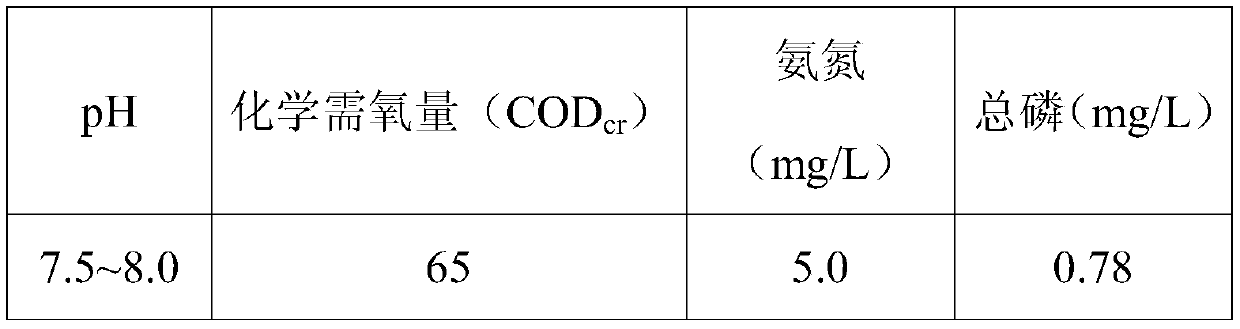

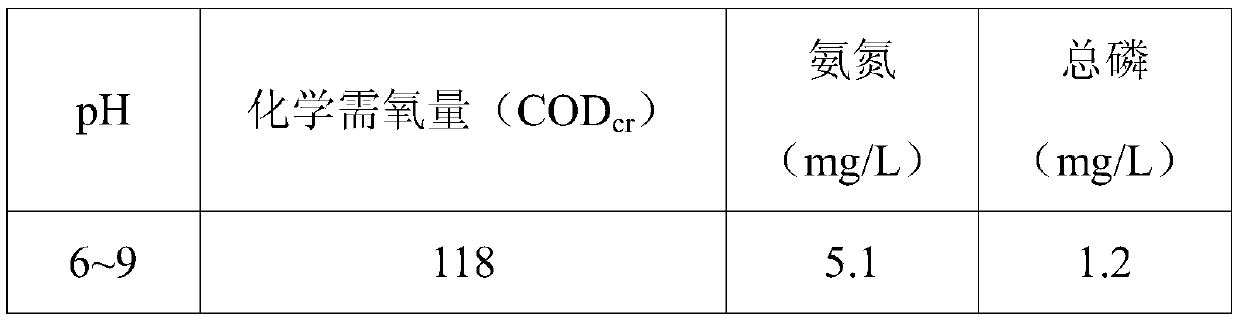

Composite wastewater treatment medicament and preparation method thereof

ActiveCN109748374ALarge specific surface areaStrengthen the void structureWater contaminantsWater/sewage treatment by flocculation/precipitationIonActivated carbon

The invention discloses a composite wastewater treatment medicament and a preparation method thereof, and belongs to the technical field of recycled water treatment. The water treatment medicament prepared through the invention modifies an activated carbon system through a carbon-nano tube, the specific area of the medicament is increased, a porosity structure is intensified, and adsorption, electrostatic and other effects are enhanced, so that quick enrichment of pollutants is realized; the loaded persulfate plays a catalytic action through the Co and Fe ions combined by polyoxometalate (POM), the production of the sulfate free radical and hydroxy free radical is further promoted by combining the use of the hydrogen peroxide, and an advanced oxidation effect for activating the persulfateis formed, and the enriched pollutants are efficiently oxidized and degraded. The water treatment medicament prepared through the invention has oxidation and adsorption functions, and can effectivelyremove phosphorous, color and COD.

Owner:江苏环保产业技术研究院股份公司

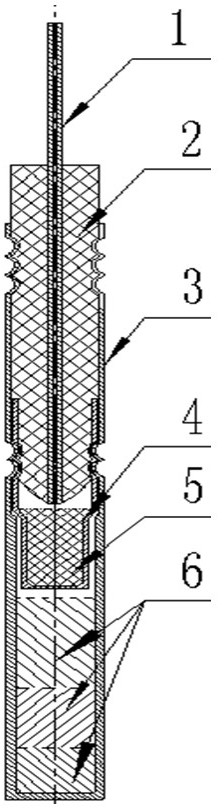

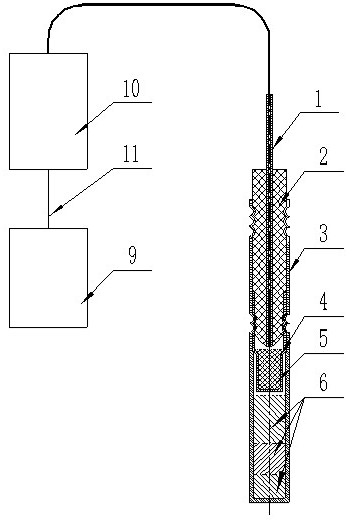

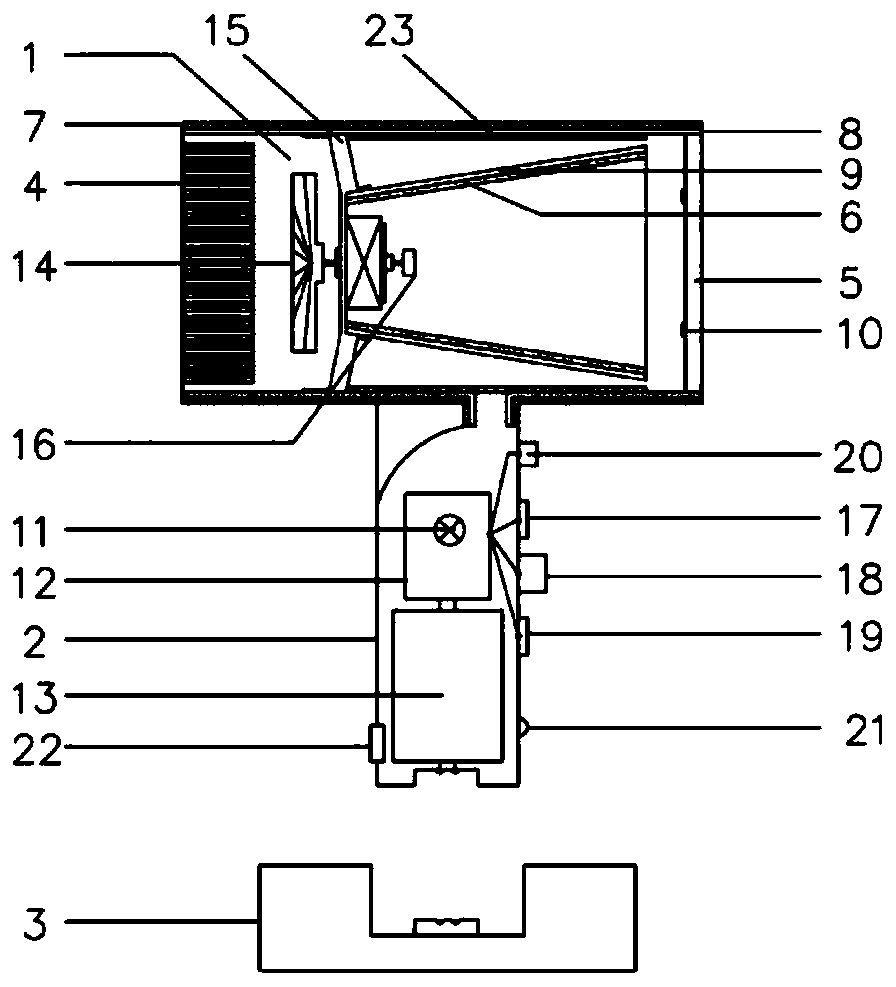

Laser initiation flyer type initiating explosive-free detonator

InactiveCN102435109AImprove energy utilizationGood monochromaticityAmmunition fuzesMulti-mode optical fiberSingle-mode optical fiber

The invention belongs to the field of initiation apparatuses, and discloses a laser initiation flyer type initiating explosive-free detonator. The detonator comprises a detonator matrix filled with three-times high explosive, a detonator exciting device consisting of an inner cap and four-times explosive, and a laser initiation system, wherein the laser initiation system consists of a rubber plug, an optical fiber and a laser generating device connected with the optical fiber; the rubber plug is plugged into the inner cap in a detonator shell, the outer surface of the rubber plug is in tight fit with the inner walls of the detonator shell and the inner cap, the middle of the rubber plug is provided with a through hole, the optical fiber connected with the laser generating device passes through the hole, the end of the optical fiber is flush with the lower port of the rubber plug, and the distance between the lower port and the surface of the four-times explosive in the inner cap is less than 15 millimeters; and the laser wavelength of the laser generating device is in a range of 500 to 1,500 nanometers, the optical fiber is a single mode fiber or a multi-mode fiber, and the energy of the laser output by the optical fiber is more than 0.4W. Through the detonator, initiation of the non-dispersed four-times explosive is realized, and the reliability and the safety of the initiation system are improved; and because the transmission optical fiber has high-temperature and high-pressure resistance, the detonator is suitable for severe environments of deep water, high pressure and the like.

Owner:UNIV OF SCI & TECH OF CHINA

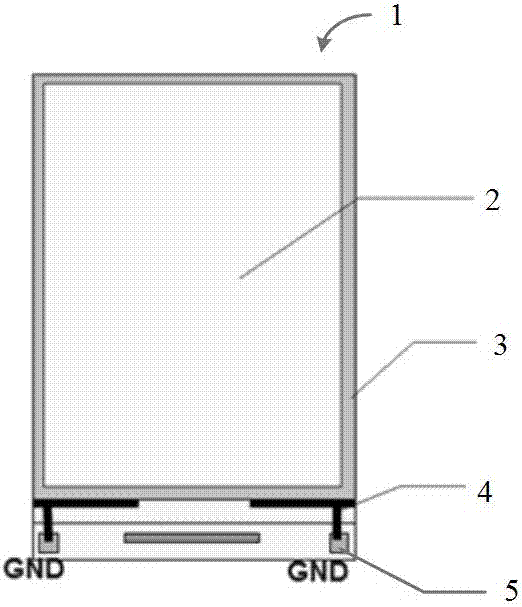

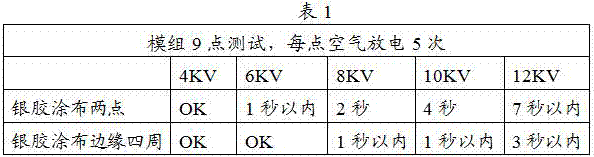

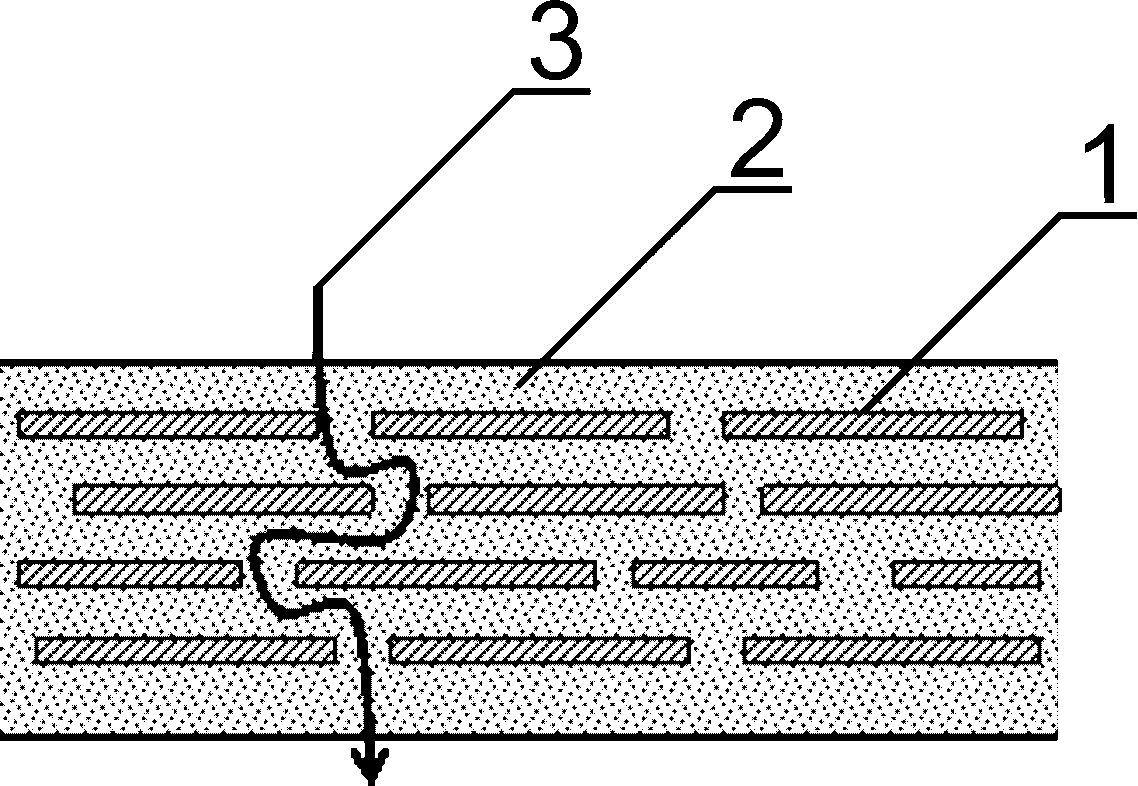

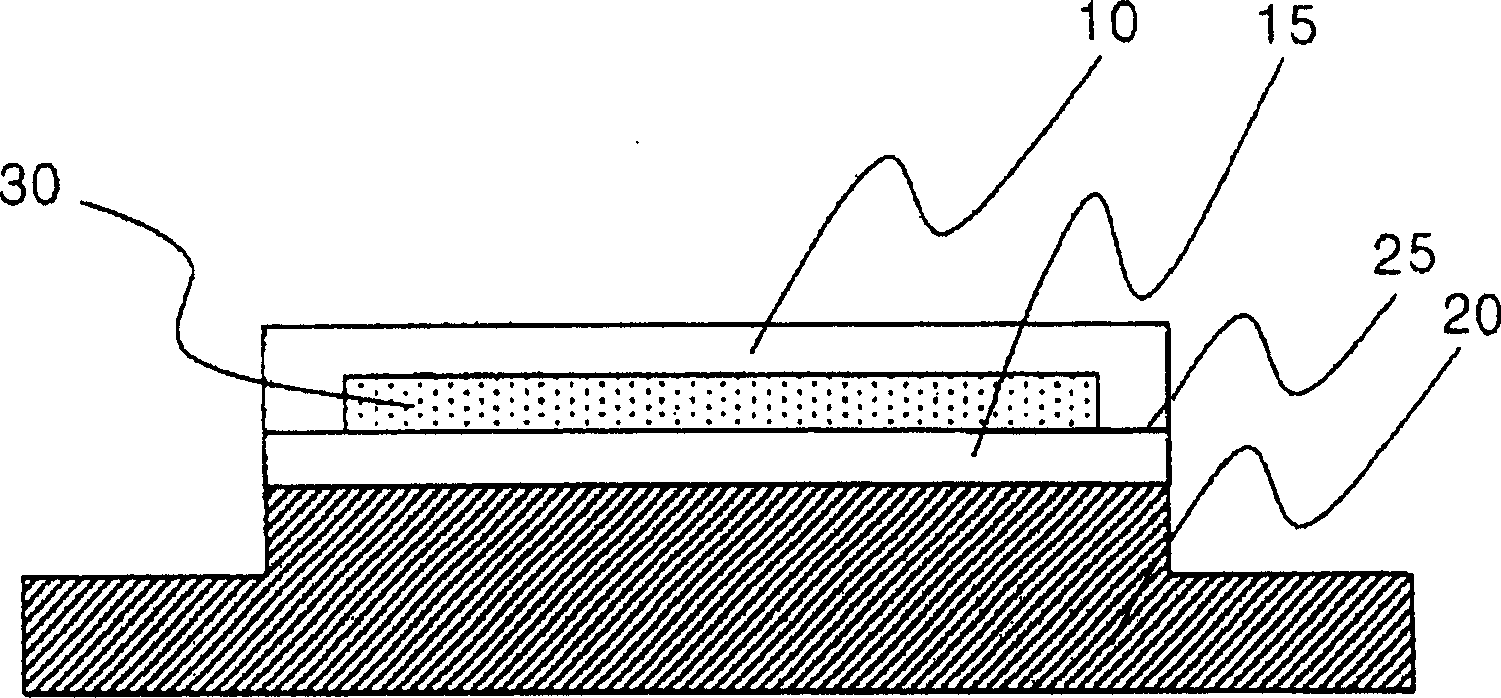

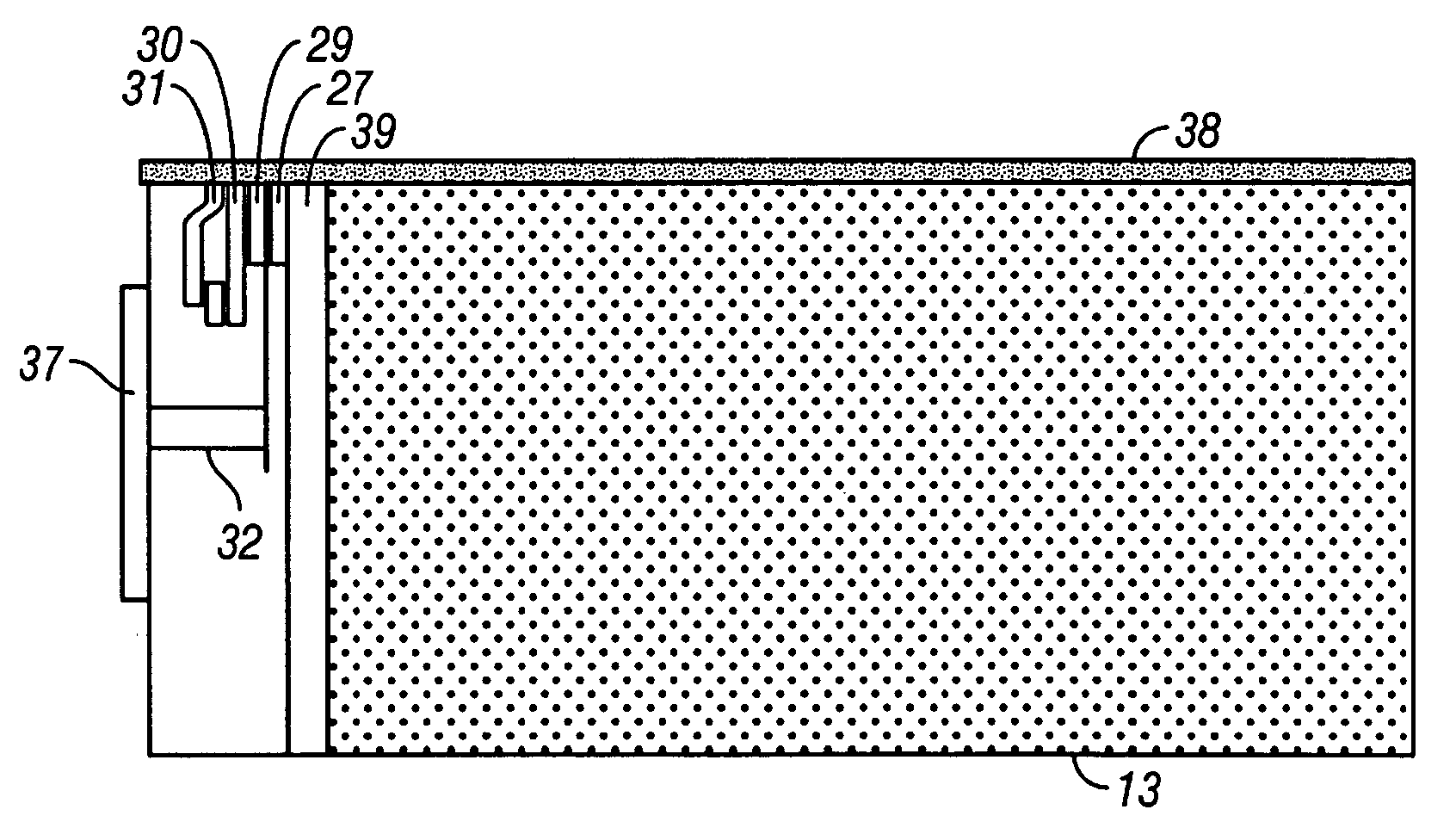

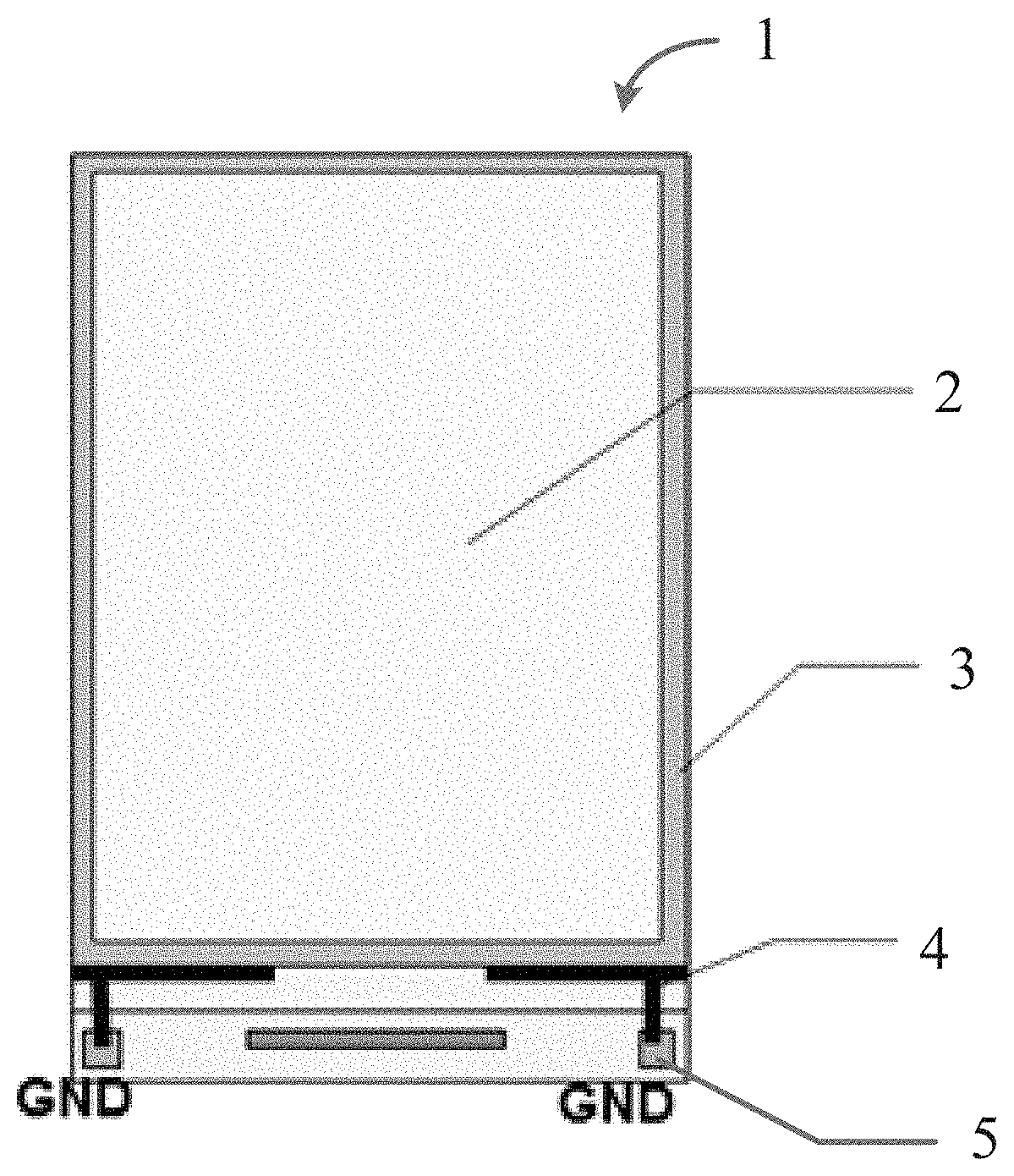

Static electricity release structure for liquid crystal display panels, liquid crystal display panel and liquid crystal display

InactiveCN107367863AIncrease static electricityFacilitated releaseNon-linear opticsHigh resistanceLiquid-crystal display

The embodiment of the invention discloses a static electricity release structure for liquid crystal display panels, which is used on a liquid crystal display panel on which a high-resistance film is attached. The uppermost layer of glass panel of the liquid crystal display panel is covered by a layer of high-resistance film, moreover, an edge is reserved around the high-resistance film, a conductive material layer is arranged on the reserved edge of the glass panel, the conductive material layer is in contact with the circumference of the high-resistance film, and the conductive material layer is connected to GND pins of a TFT (Thin Film Transistor) substrate through conductive silver adhesive. The embodiment of the invention further discloses a corresponding liquid crystal display panel and a corresponding liquid crystal display. According to the embodiment of the invention, the release of static electricity can be accelerated, and the generation of static electricity by film tearing and film attachment is greatly improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

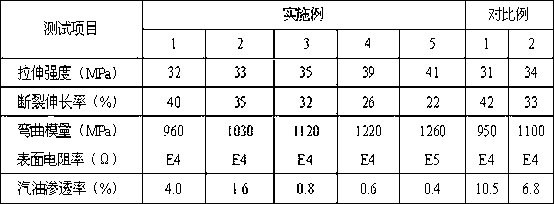

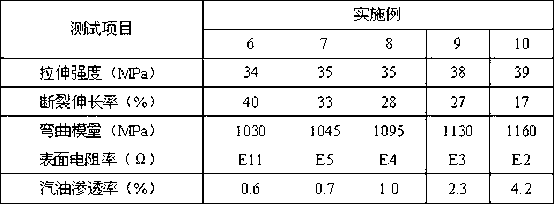

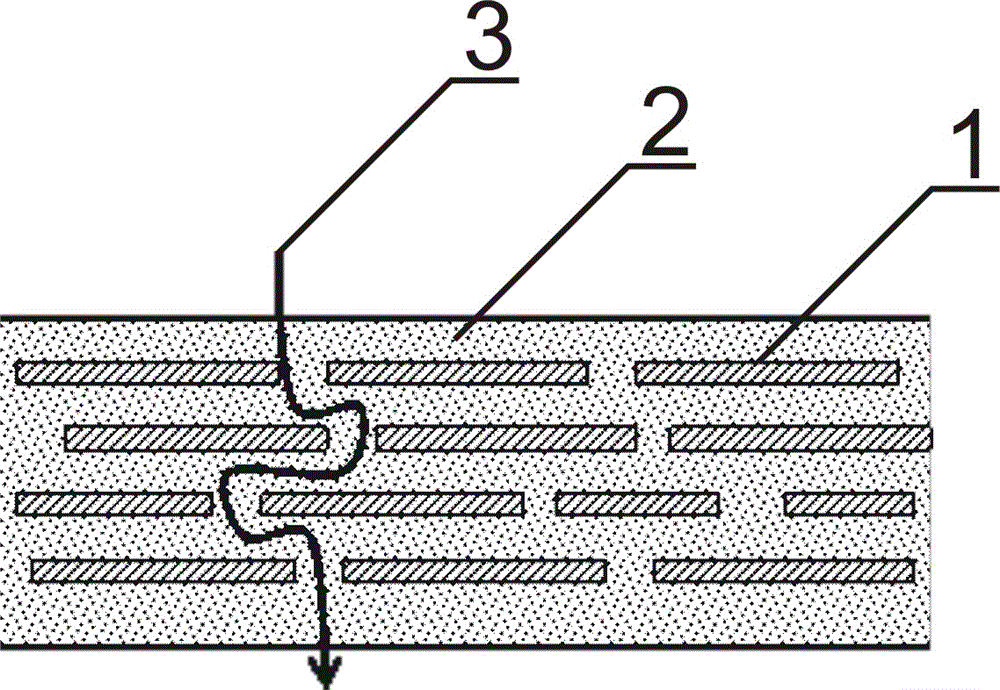

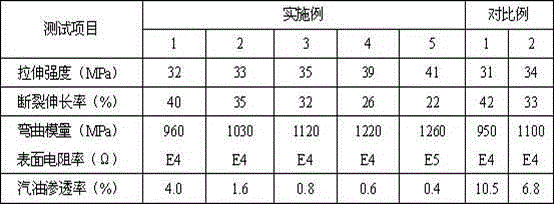

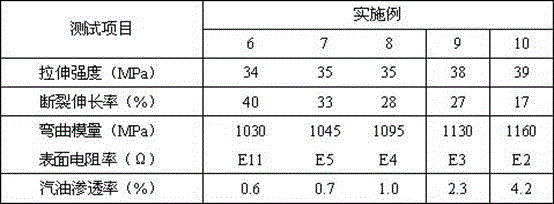

Conductive barrier polyethylene composition, its preparation method and application

The invention discloses a conductive barrier polyethylene composition, its preparation method and application. The composition comprises: (A) 50-90 parts by mass of base resin, which contains (A1) 70-97 mass% of polyethylene resin and (A2) 3-30 mass% of polyamide resin dispersed in the polyethylene resin (A1) in a multilayer overlapping lamellar structure; (B) 0.1-10 parts by mass of a polyolefin grafted copolymer; and (C) 5-25 parts by mass of carbon black. The composition provided in the invention takes polyethylene as the main base resin, fusion and kneading methods are employed to make the polyamide resin form the multilayer overlapping lamellar structure in the polyethylene resin. With excellent barrier property and conductivity, the polyethylene composition is low in cost, increases the material processing window, broadens the application field of materials, and can be used for preparing containers accommodating fuels and organic solvents, and conveying pipelines, etc.

Owner:KINGFA SCI & TECH CO LTD +1

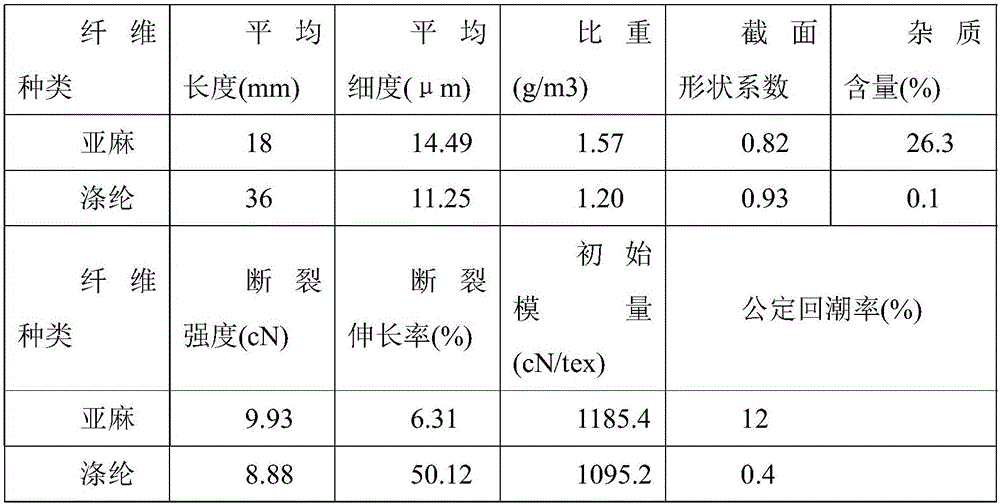

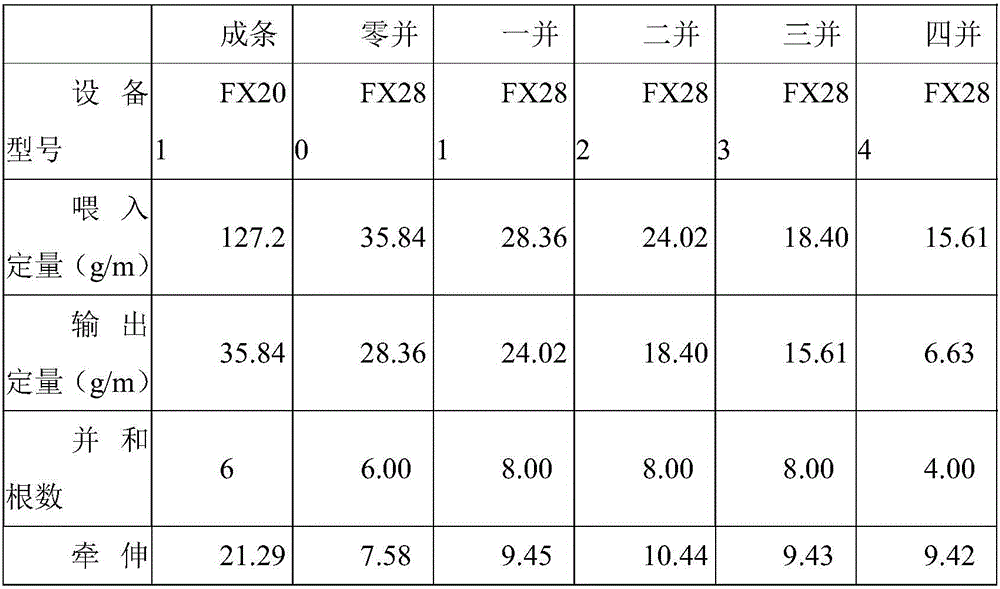

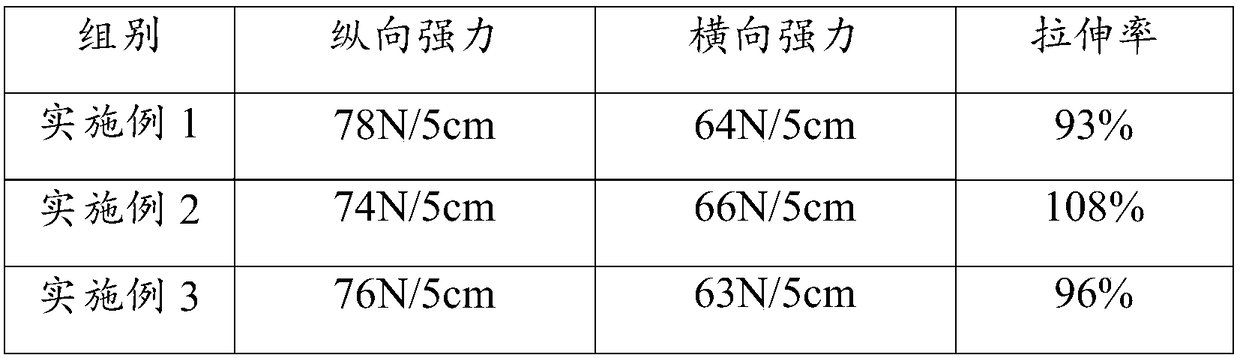

Biological enzymatic production method of breathable polyester fiber and flax fiber blended yarn

ActiveCN106087167AGood moisture absorptionImprove perspirationBiochemical treatment with enzymes/microorganismsYarnPolyesterYarn

The present invention discloses a production method of a breathable polyester fiber and flax fiber blended yarn, flax fiber is 40-80% by weight, and the balance is polyester fiber. The method comprises the steps of pretreating, cleaning, carding, drawing, roving and spinning. The production method provided herein allows for the production of the polyester fiber and flax fiber blended yarn that is hygroscopic, light and thin, glossy, breathable, antibacterial and mite-proof. The flax fiber is degummed by using a composite enzyme solution, with a degumming rate higher than and equal to 98%. In the case where enzyme usage is 15%, enzyme soaking temperature is 50 DEG C, enzyme soaking time is 1 h and stacking time is 16 h, gum residual rate of the flax fiber is only 1.83%. Fission rate of the flax fiber reaches 3.78 / dtex, with strength being 3.97 / CN per tex<-1>.

Owner:JIANGSU HUAXIN LINEN TEXTILE

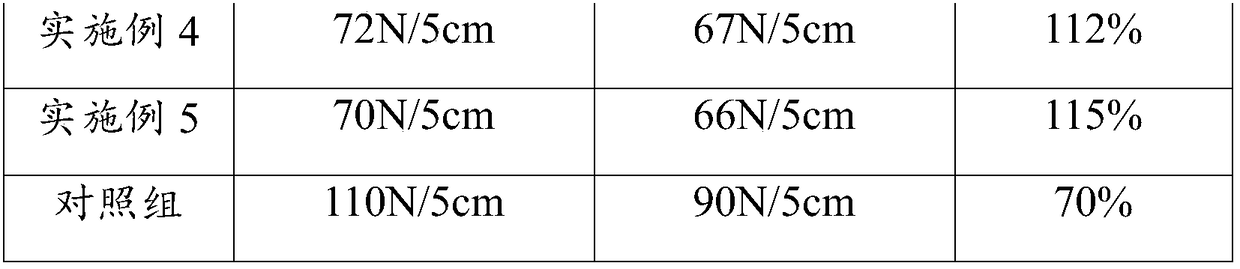

Preparation method of elastic polyester fiber and flax fiber blended yarns by adopting bio-enzyme method

The invention discloses a preparation method of elastic polyester fiber and flax fiber blended yarns by adopting a bio-enzyme method. The weight content of flax fibers is 45 percent to 75 percent and the balance is elastic polyester fibers; the preparation method comprises: pre-treating, blowing, cotton carding, drawing, roving, degumming, bleaching, acid washing, washing and spinning. By adopting the preparation method provided by the invention, the elastic polyester fiber and flax fiber blended yarns with moisture absorption, lightness and thinness, glossiness, air permeability, antibacterial property and mite inhibition property can be prepared. The elastic polyester fiber and flax fiber blended yarns provided by the invention have high spinnability and good elasticity; cloth woven by the elastic polyester fiber and flax fiber blended yarns is light and soft, comfortable and breathable, has sweat-absorbing and antibacterial properties and has elasticity; the cloth has novel and fashionable appearance. The elastic polyester fibers and the flax fibers are blended and the disadvantage of low elasticity of the flax fibers can be made up; a prepared fabric has a comfortable hand feeling and has good elasticity; the style of the blended yarns can be improved and the hand feeling of the blended yarns can be improved.

Owner:JIANGSU HUAXIN LINEN TEXTILE

Preparation method of macroporous pseudo-boehmite

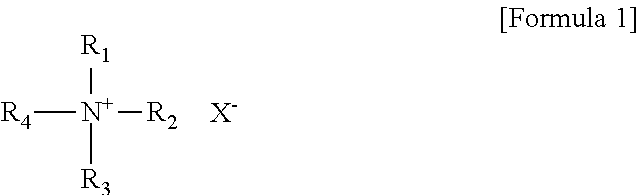

InactiveCN107226477AIncrease static electricityImprove hydrogen bondingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateCarboxylic acid

The invention discloses a preparation method of macroporous pseudo-boehmite. The preparation method comprises adding a surfactant into an acidic aluminum salt solution and then carrying out gelation with a sodium metaaluminate solution. The surfactant comprises one or more of long chain alkyl quaternary ammonium salt CnH2n+1(CH3)3N<+>X<->, polycarboxylic acid and a polycarboxylate. In the presence of the surfactant, through a tubular reactor, the acidic aluminum salt solution and the sodium metaaluminate solution undergo a reaction in a parallel flow way to produce macroporous pseudo-boehmite. The preparation method has simple processes, reduces a cost and improves product quality stability.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Flame-retardant antistatic blended yarn and production method thereof

ActiveCN106048800AGood flame retardant and antistatic effectFunction increaseYarnYarnEconomic benefits

The invention discloses flame-retardant antistatic blended yarn and production method thereof, and the blended yarn has a good antistatic effect, durable functions, good wearability and low production cost. The blended yarn is manufactured by blending the following materials in mass percent: 20% to 70% of flame-retardant viscose, 20% to 70% of flame-retardant acrylic fiber and 5% to 10% of stainless steel fiber. The production method includes raw material pretreatment, an opening picking process, a cotton carding process, a drawing process, a roving process and a spinning process. The flame-retardant antistatic blended yarn produced by the production method is light grey, and a test shows that the quality indexes of the blended yarn reach the first-class yarn level. A flame-retardant antistatic effect is good, and the blended yarn is suitable for industry requirements having special flame-retardant antistatic requirements, and has good economic benefits and market application prospects.

Owner:HENAN INST OF ENG

Display device

ActiveCN103050060AIncrease static electricitySimple processStatic indicating devicesIdentification meansComputer graphics (images)Display device

A display device according to an exemplary embodiment of the present invention includes a display portion including a plurality of display pixels displaying an image and a dummy portion including a plurality of dummy pixels formed in a periphery region of the display portion. An electrostatic test element group (TEG) may be formed in at least one of the dummy pixels.

Owner:SAMSUNG DISPLAY CO LTD

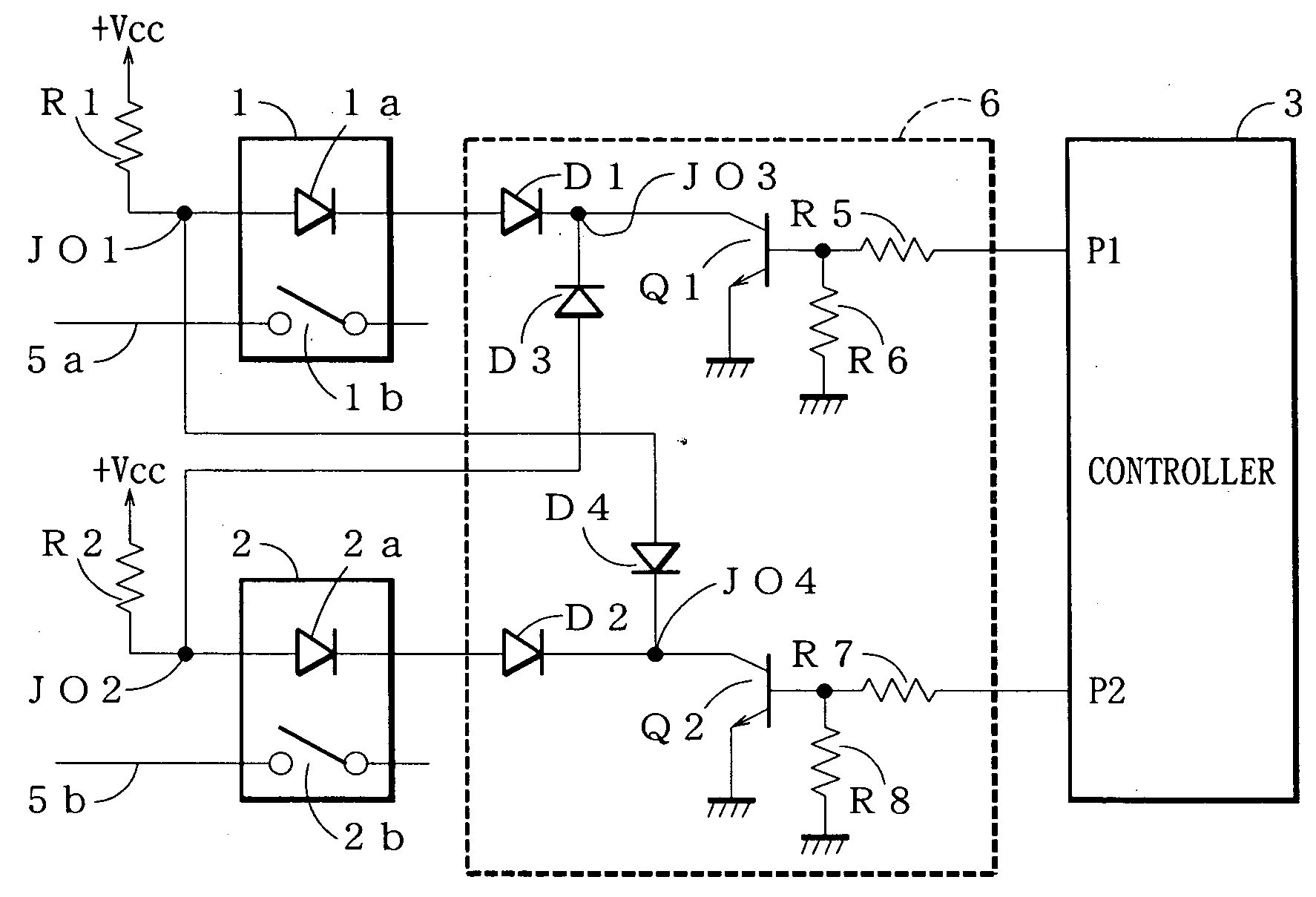

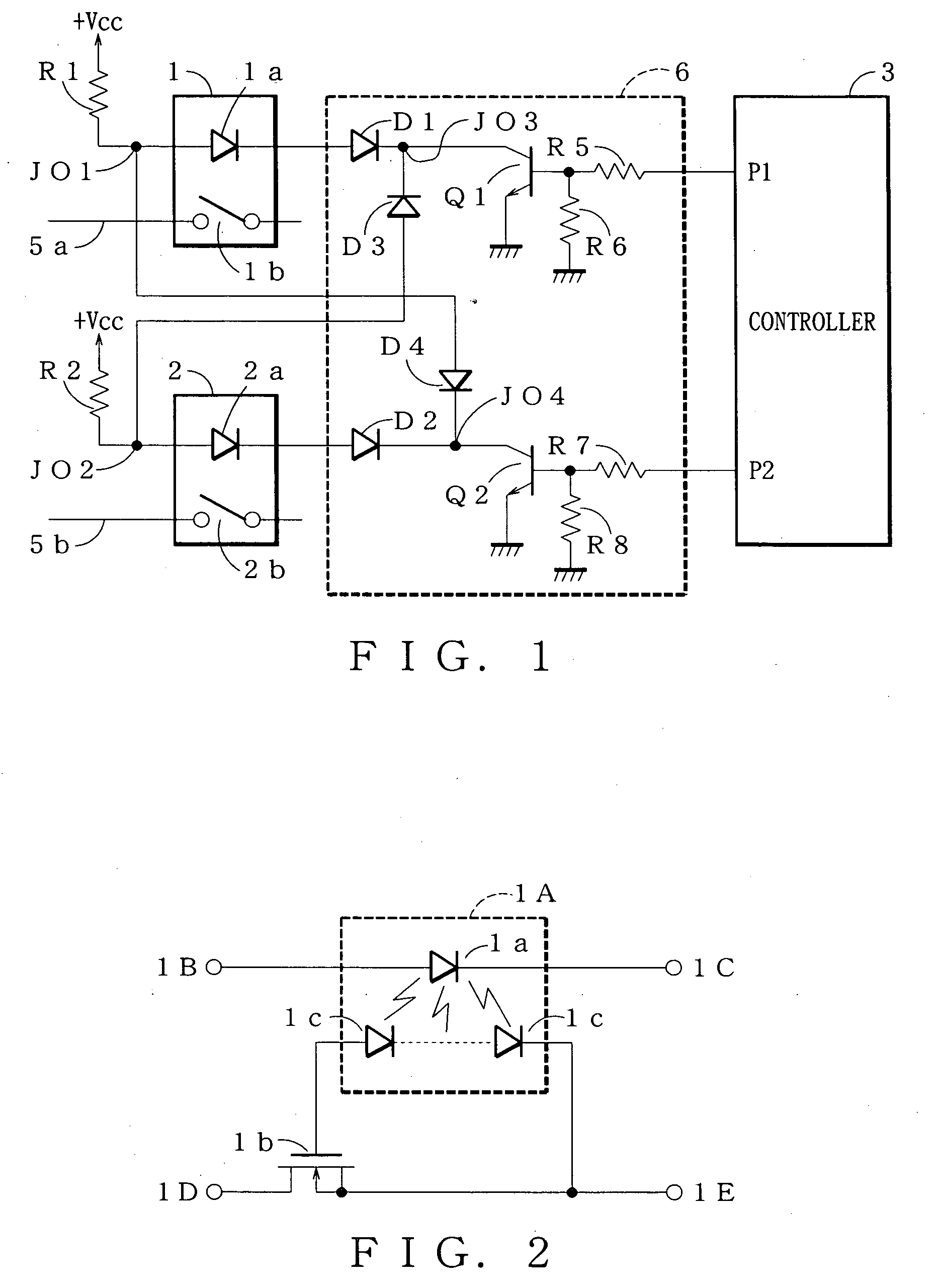

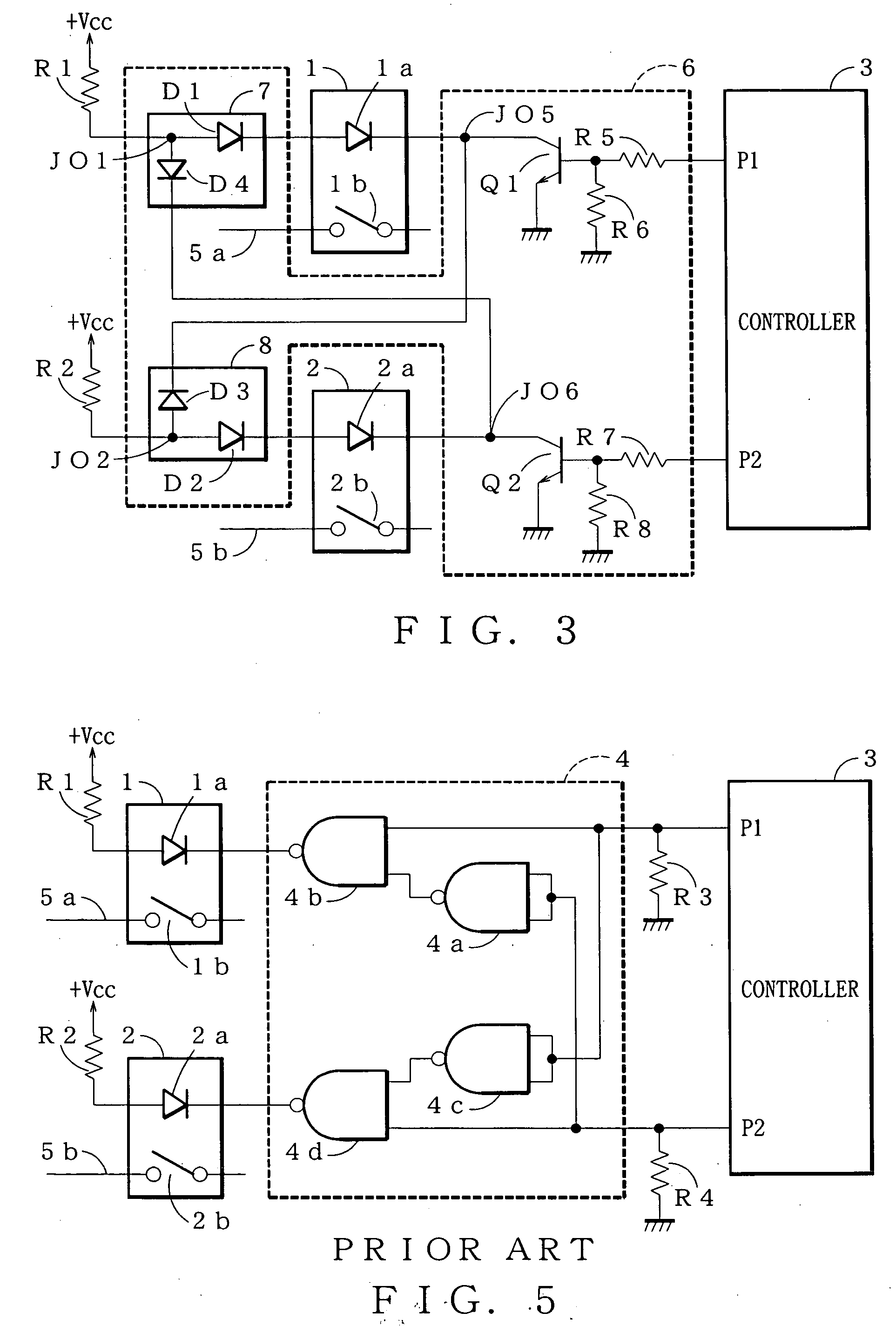

Circuit for preventing simultaneous on operations

ActiveUS20060158039A1Low costIncrease static electricityTransistorBoards/switchyards circuit arrangementsEngineeringJunction point

Providing a circuit for preventing simultaneous ON operations at a relay drive apparatus, which can prevent the simultaneous ON operations securely, the circuit includes a first diode, a second diode, a first transistor connected through the first diode with a first drive unit for controlling ON / OFF operation, a second transistor connected through the second diode with the second drive unit for controlling ON / OFF operation, a first junction point of the first resistor and the first drive unit, a second junction point of the second resistor and the second drive unit, a third junction point of the first diode and the first transistor, a fourth junction point of the second diode and the second transistor, a third diode connected with the second junction point and the third junction point, and a fourth diode connected with the first junction point and the fourth junction point.

Owner:YAZAKI CORP

Method for preparing fiber and flax blended yarn

The invention discloses a preparation method of fiber and flax blended yarn. The weight content of the flax fiber is 45-75%, and the rest is elastic polyester fiber. The preparation includes: pretreatment, cleaning, carding, drawing and roving , degumming, bleaching, pickling, washing and spinning. The production method provided by the invention can prepare the elastic polyester fiber and flax fiber blended yarn with hygroscopicity, lightness, glossiness, air permeability, antibacterial property and anti-mite property. The blended yarn of elastic polyester fiber and flax fiber of the present invention has high spinnability and good elasticity, and the cloth woven with it is soft, comfortable, breathable, sweat-absorbing, antibacterial and elastic, and has a novel and fashionable appearance. The invention blends elastic polyester and flax fiber, which can make up for the low elasticity of the hemp fiber, and makes the fabric feel comfortable and elastic, and can improve the style and feel of the blended yarn.

Owner:江阴市博帆化纺有限公司

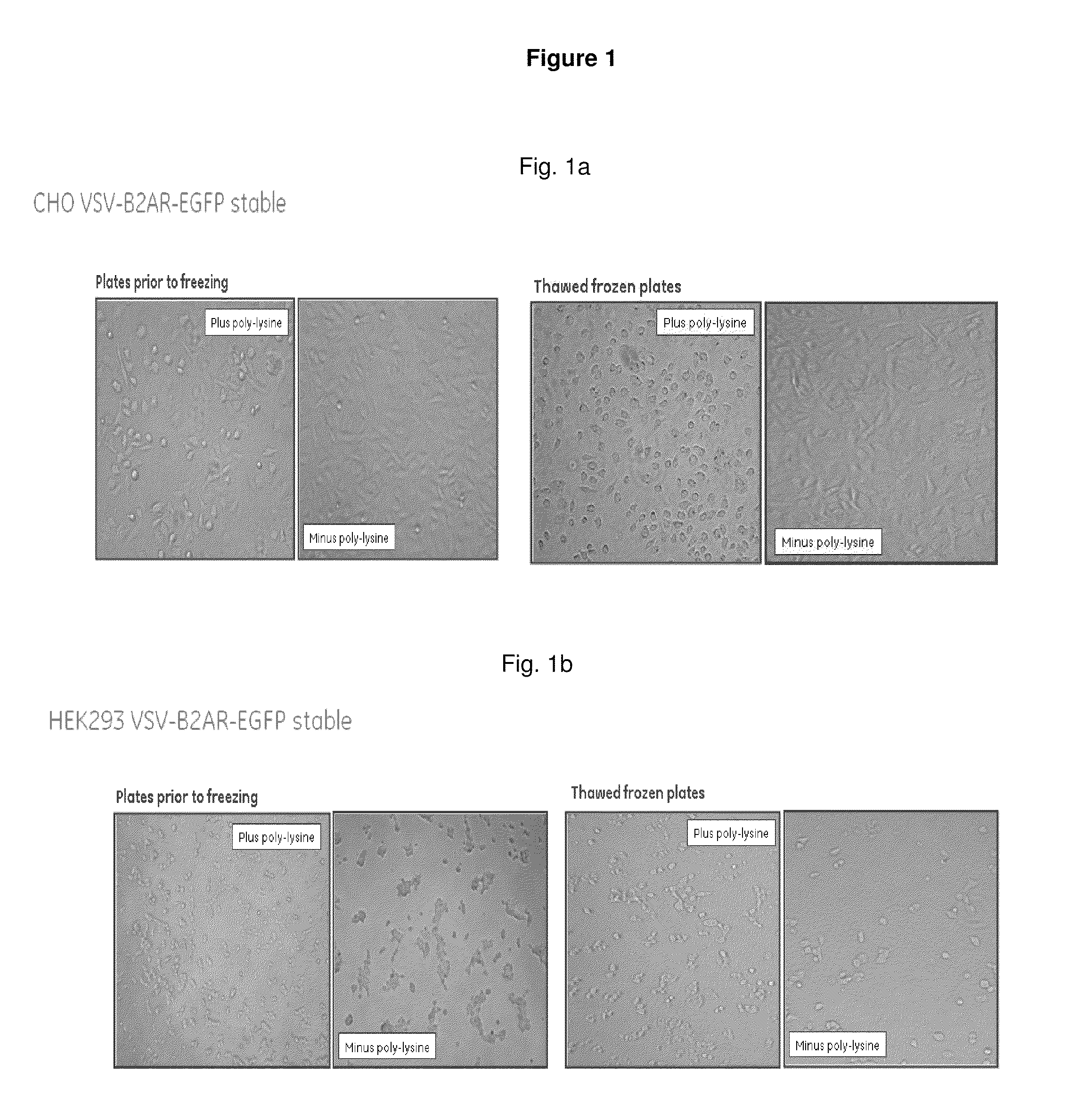

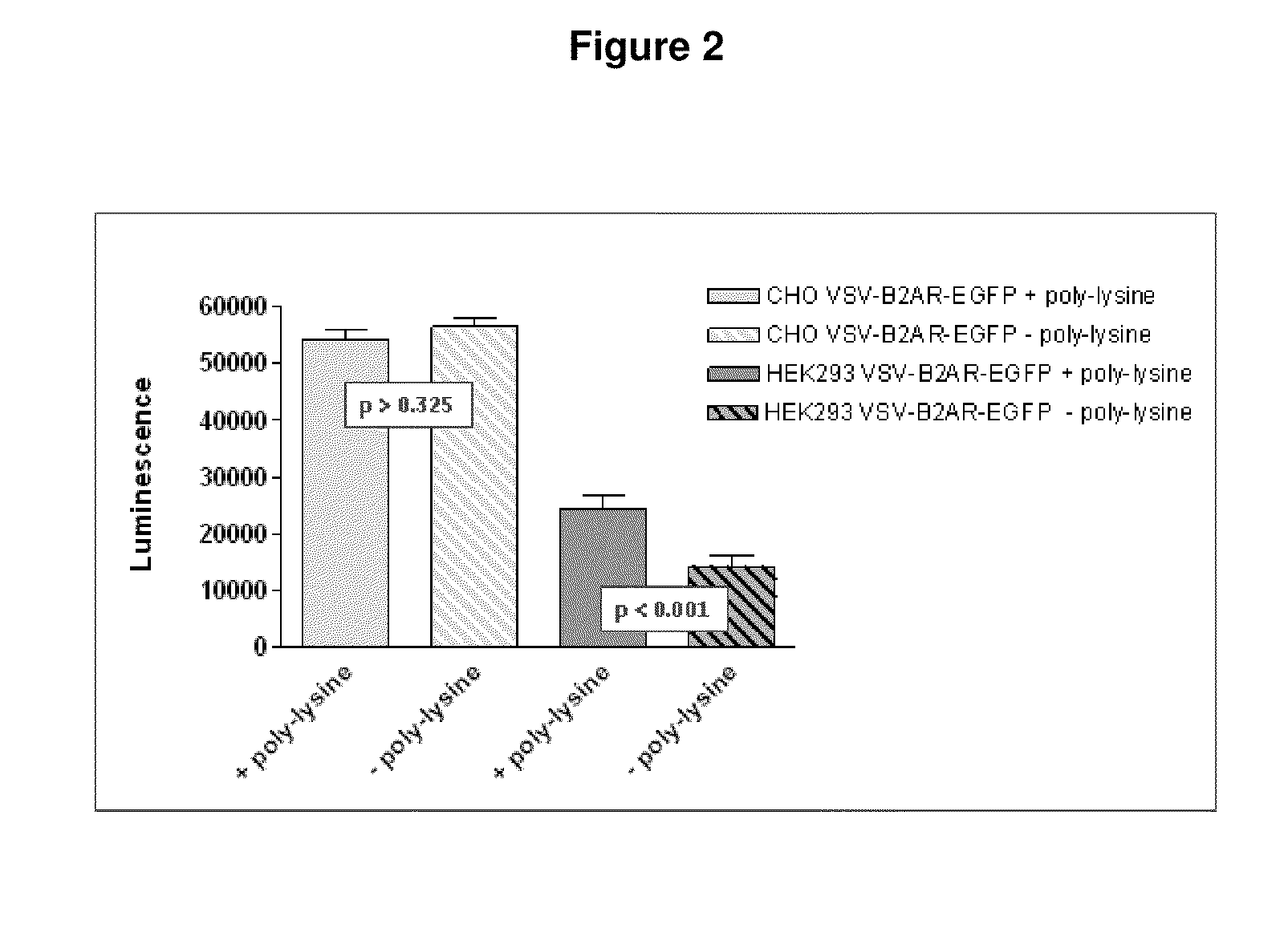

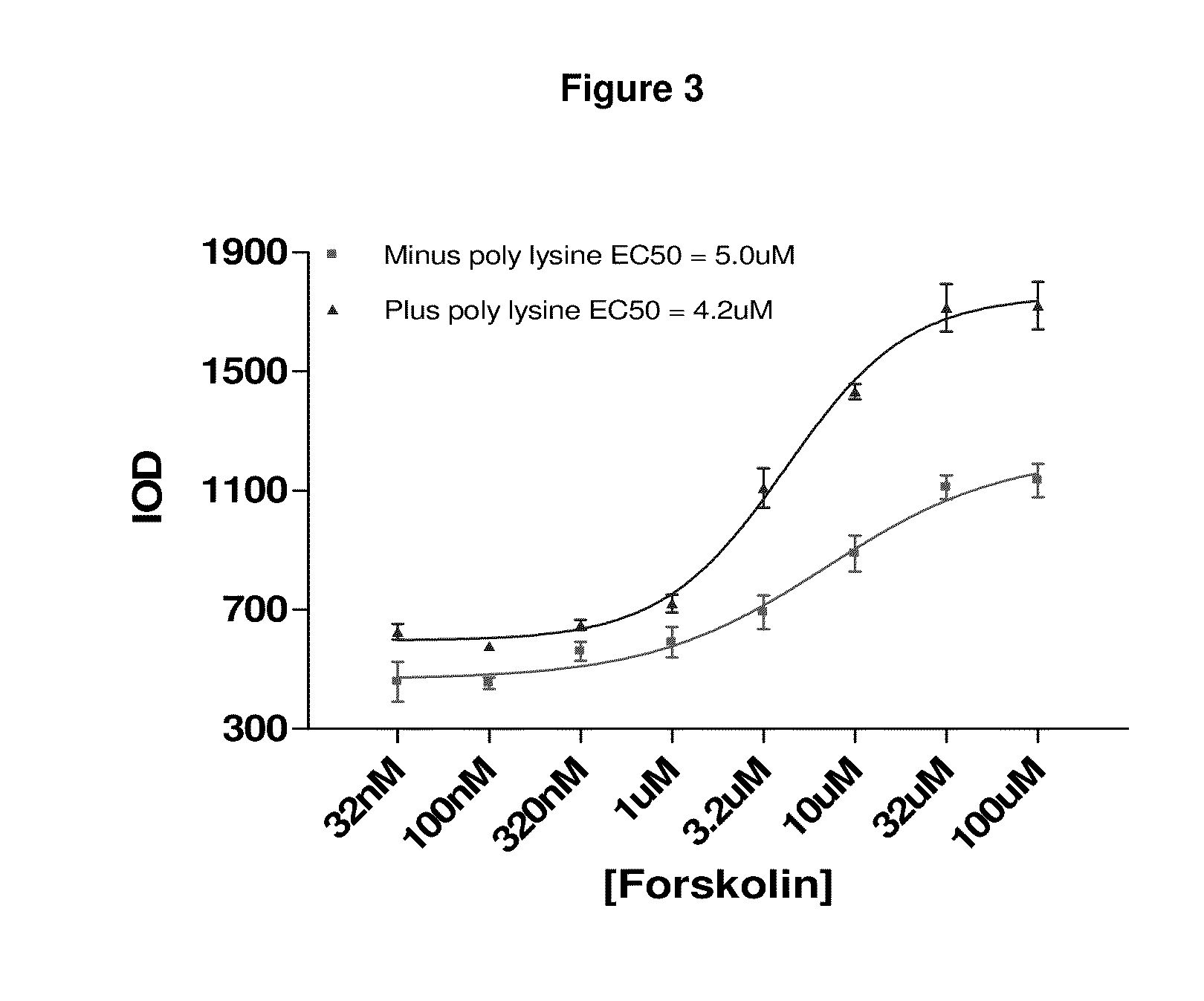

Methods for conducting cellular assays

InactiveUS20110250632A1Reduce cell damageReduce injuriesMicrobiological testing/measurementDead animal preservationCryopreserved CellCellular Assay

The present invention relates to cryopreserved cell cultures, methods for cryopreserving cells and methods for conducting cellular assays on such cells. A cryopreserved cell culture of the invention comprises a container having at least a surface which is coated with poly-lysine and frozen cells supported on the surface.

Owner:GE HEALTHCARE LTD

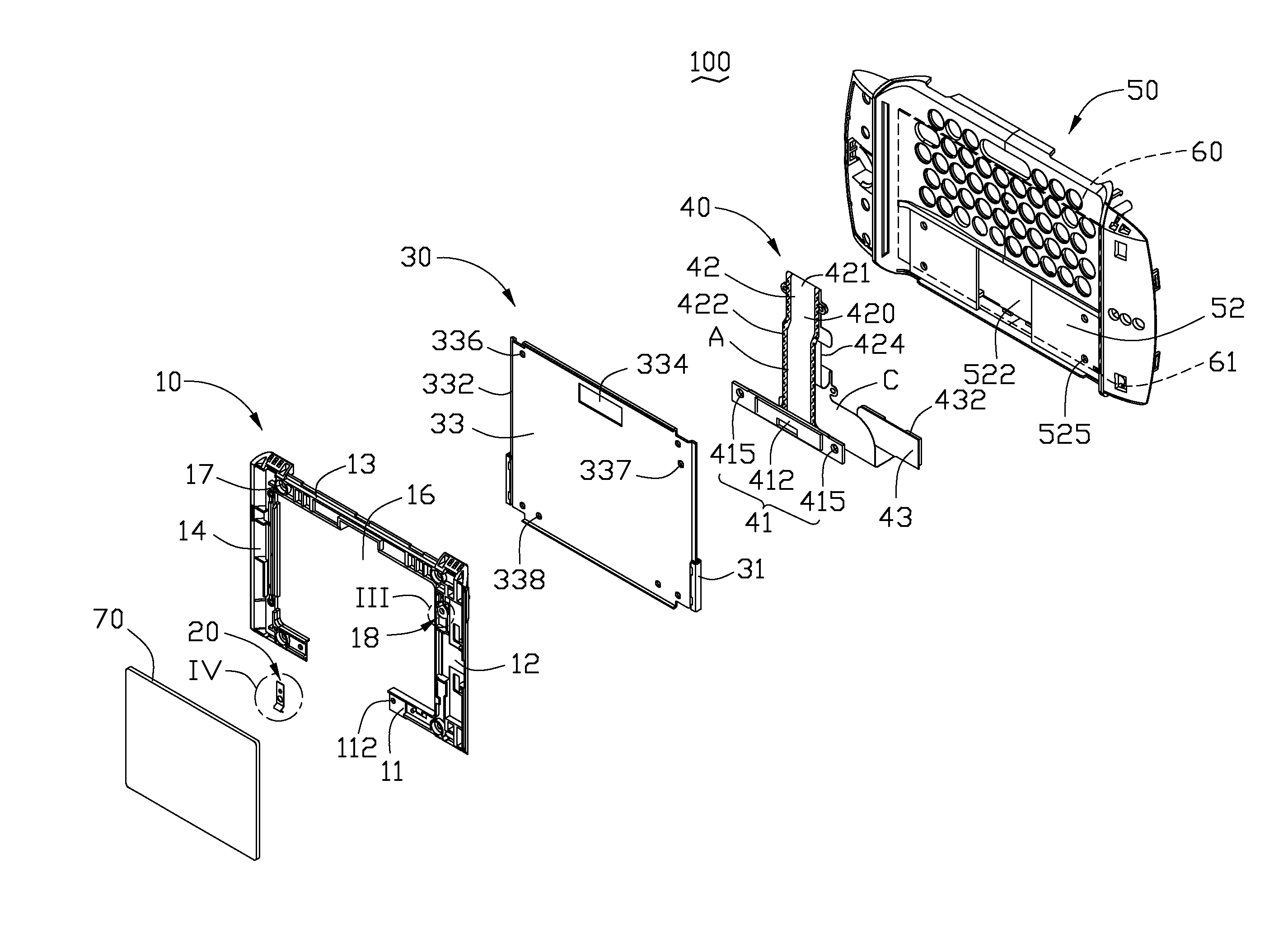

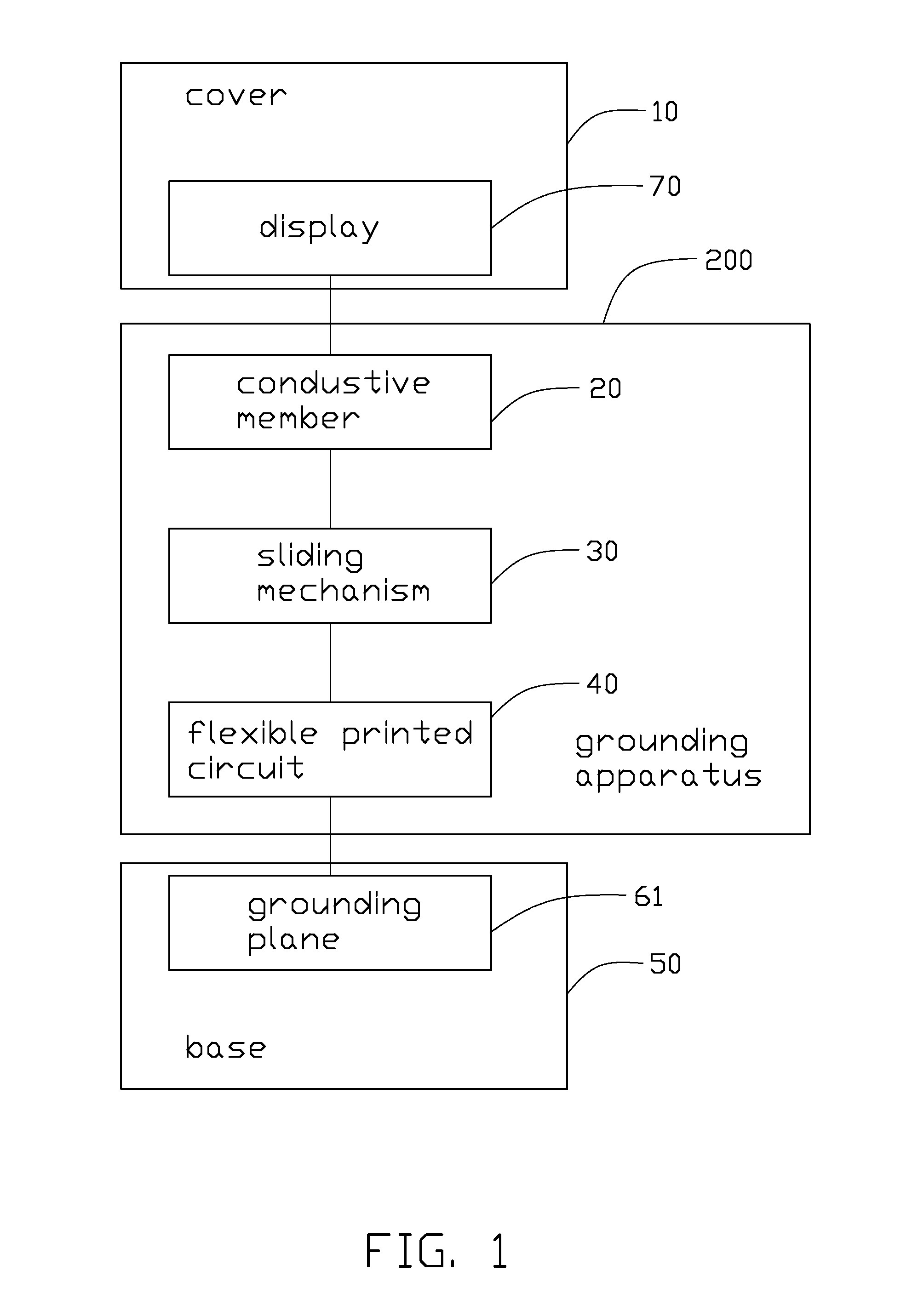

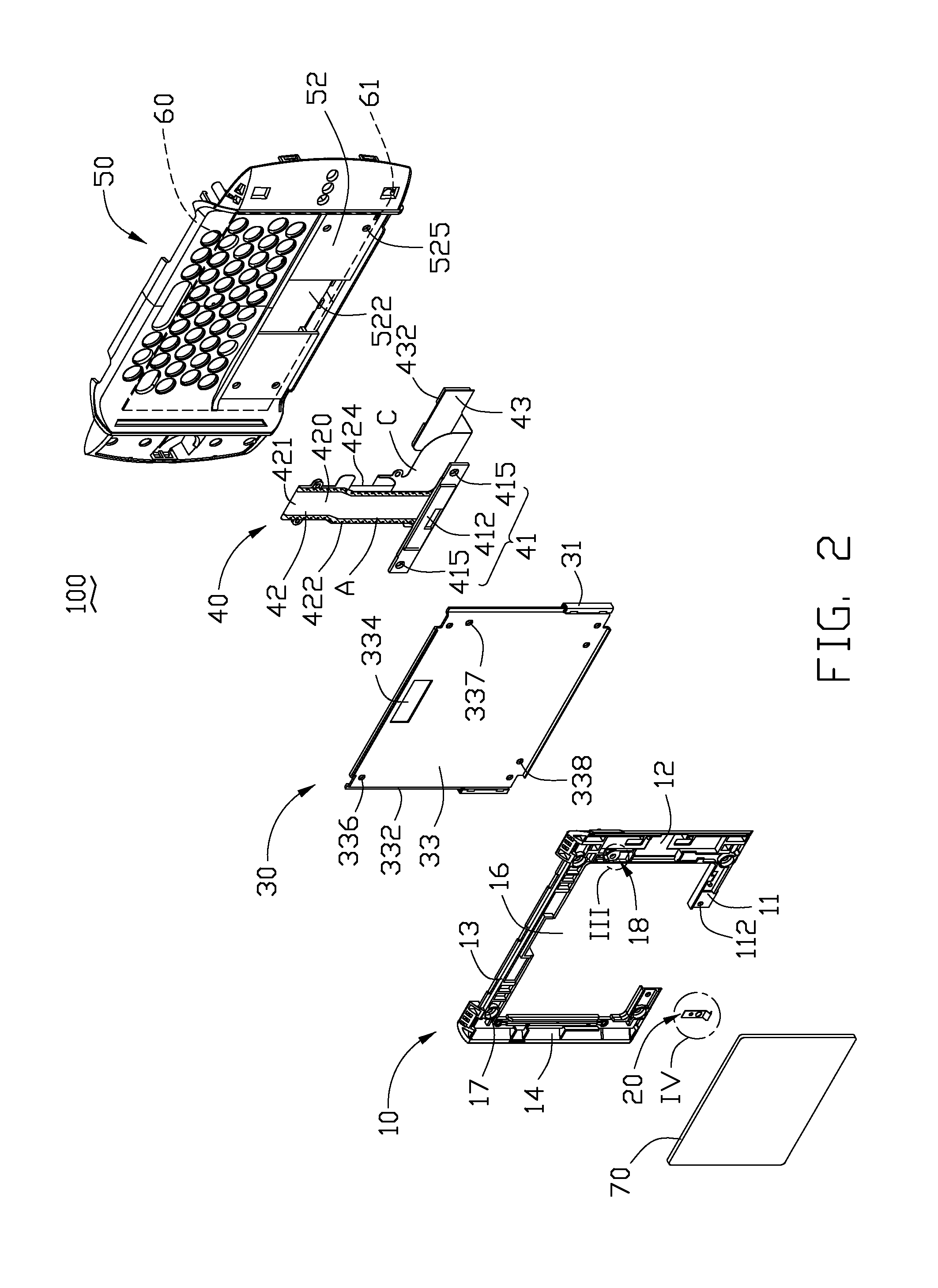

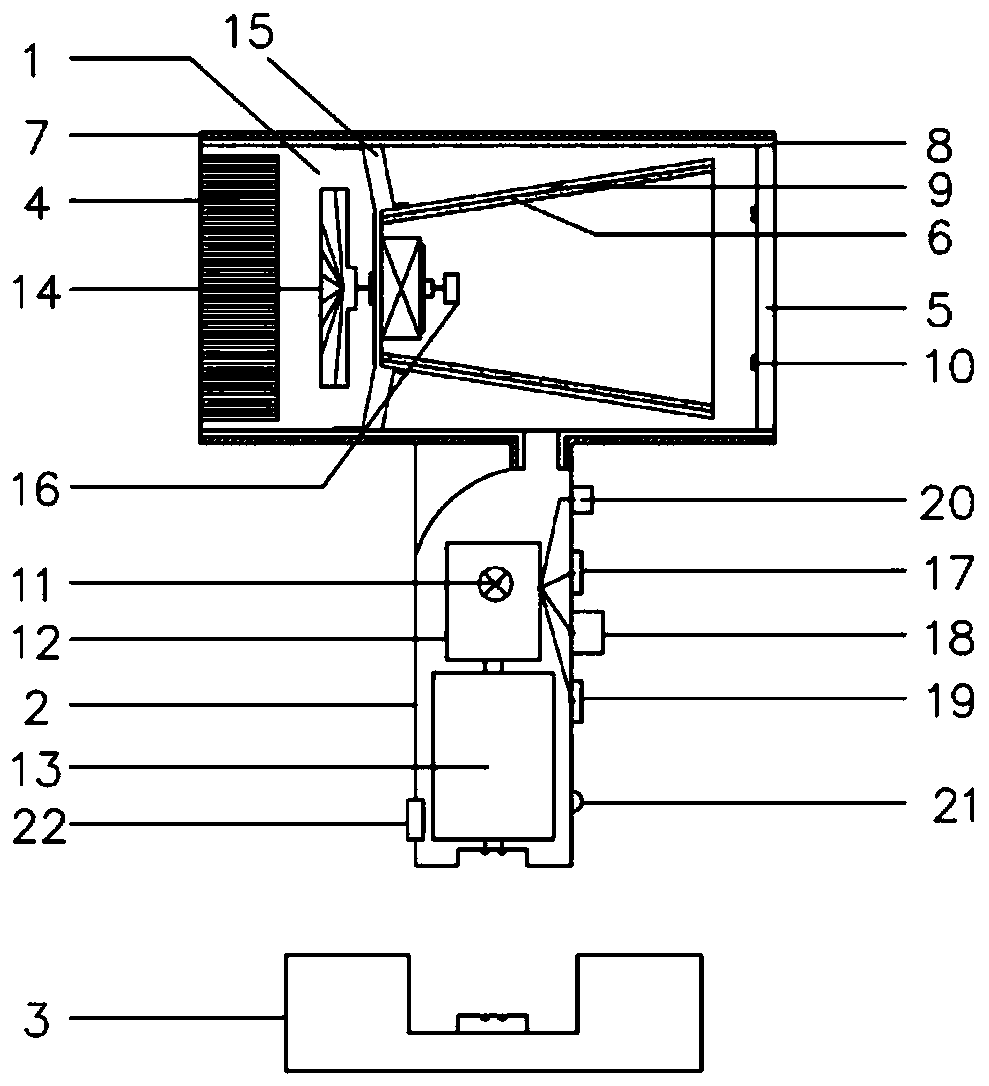

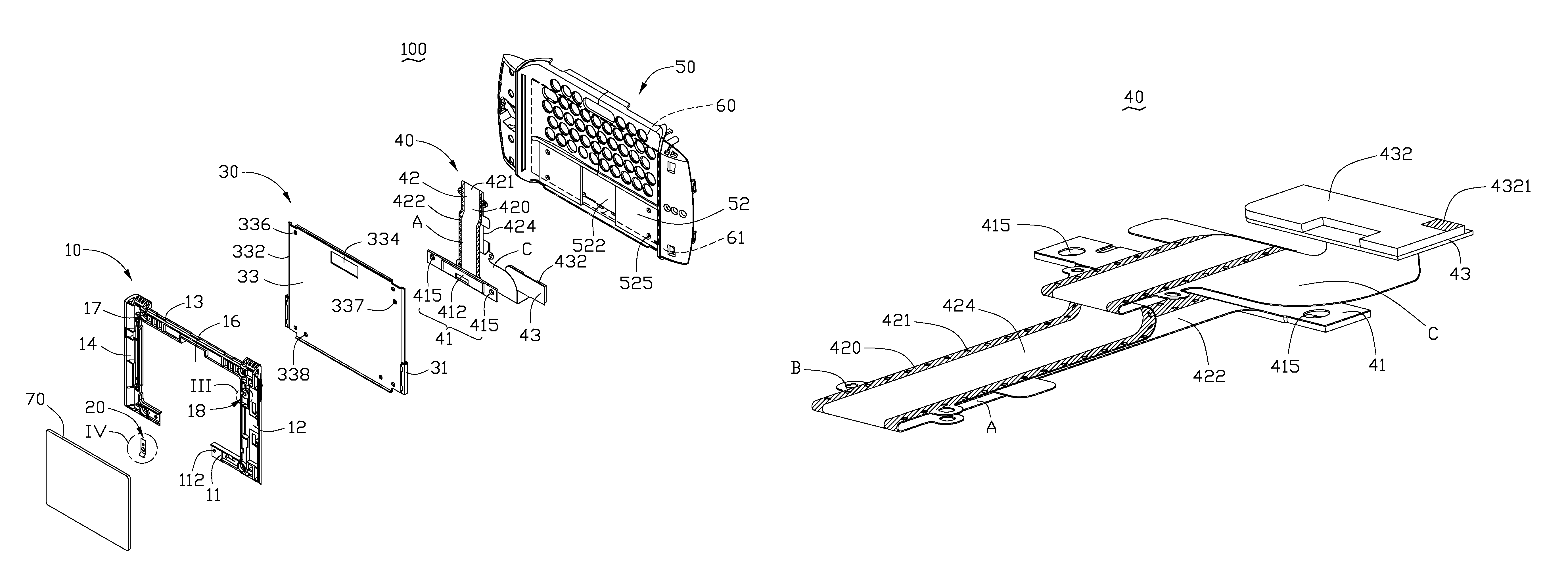

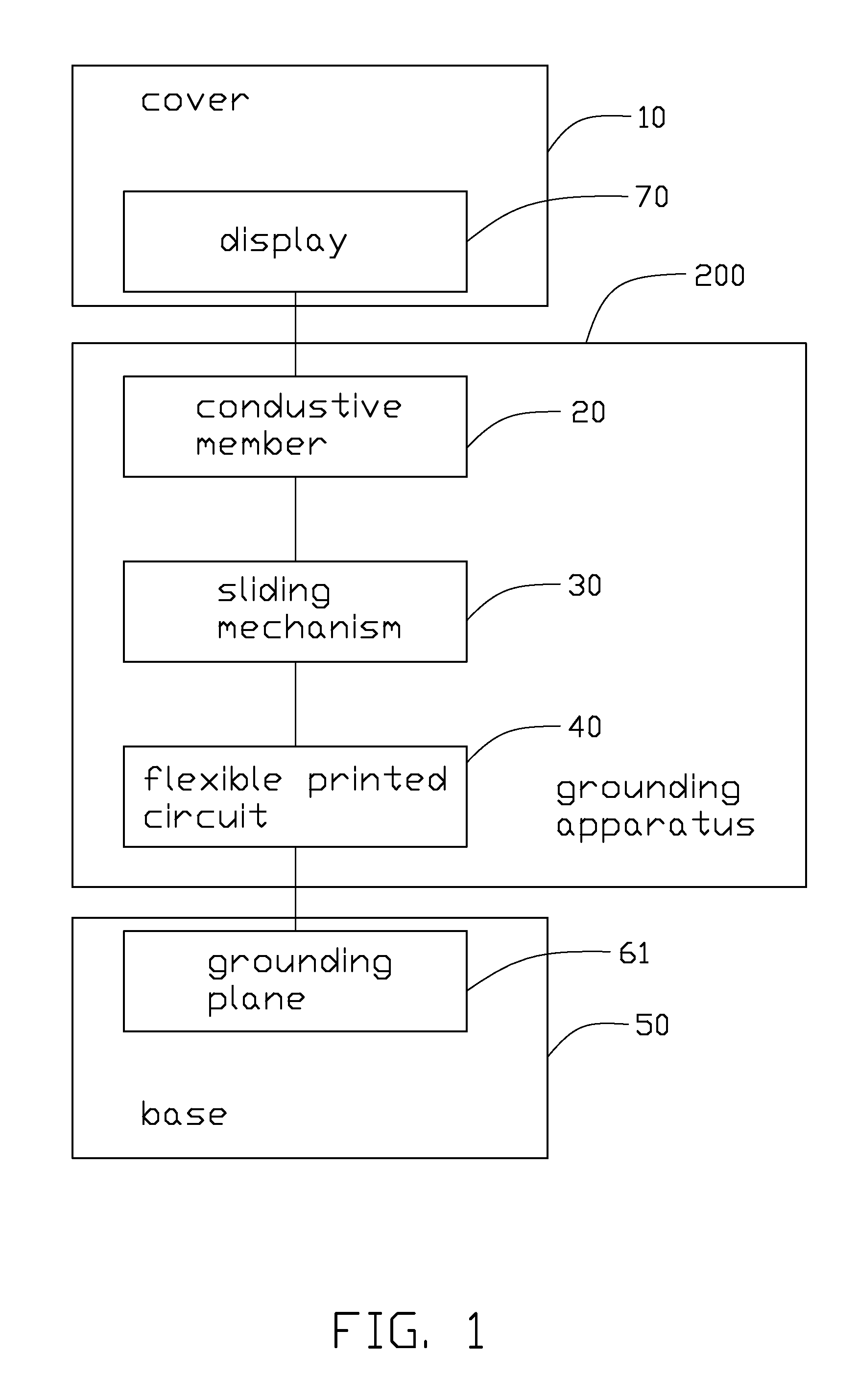

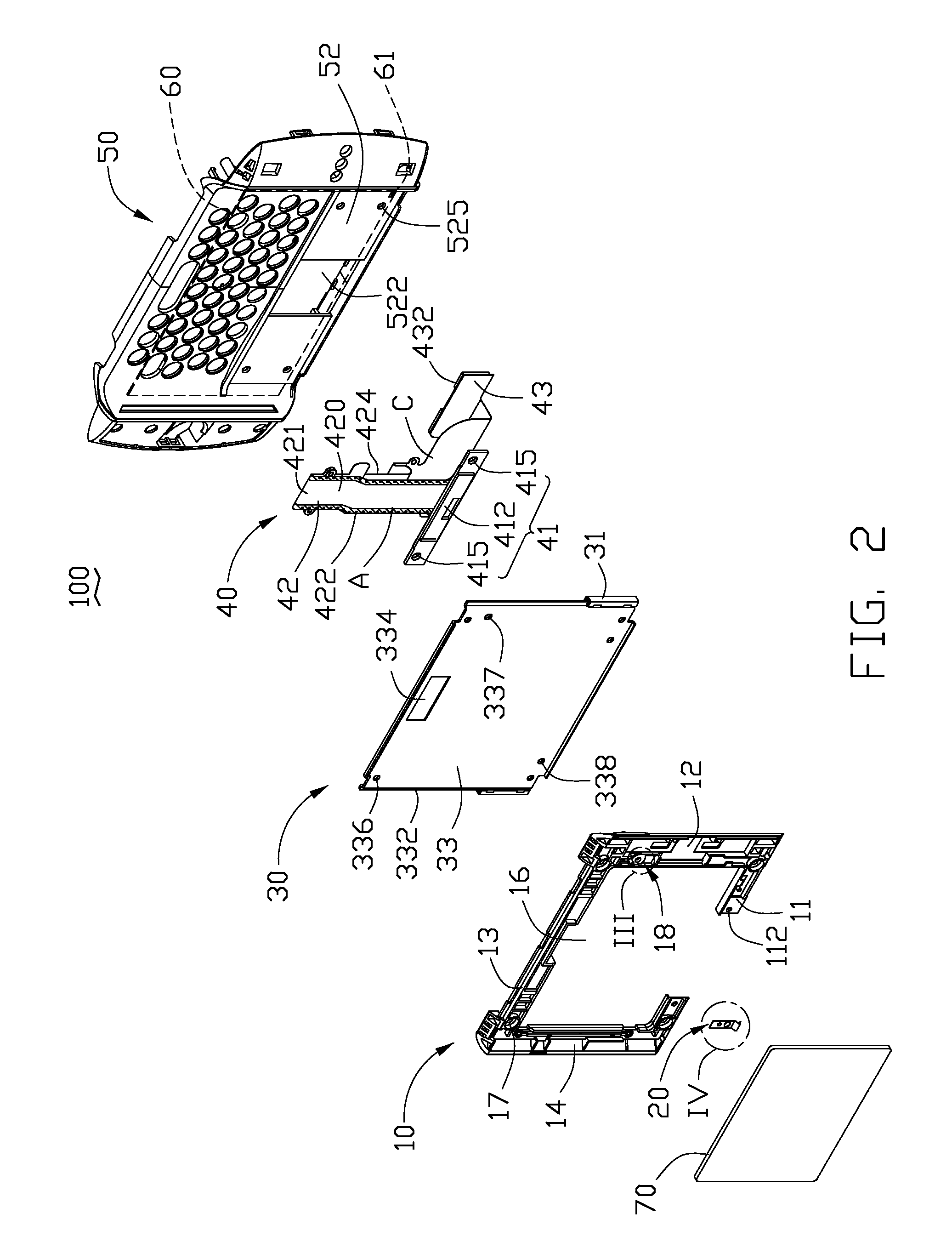

Grounding apparatus of portable electronic devices

InactiveUS20090015993A1Easy to getIncrease static electricityPrinted circuit groundingElectrostatic discharge protectionElectricityEngineering

A grounding apparatus (200) includes at least one conductive member (20), a sliding mechanism (30) and a flexible printed circuit board (40). The sliding mechanism is conductive and electrically connected to the conductive member. The flexible printed circuit board includes a conductive layer (421) and a grounding end (4231), the conductive layer and the grounding end are electrically connected to the sliding mechanism.

Owner:CHI MEI COMM SYST INC

Cross-linkable and re-dispersible polymer powder with high adhesive property

The invention provides cross-linkable and re-dispersible polymer powder with high adhesive property as well as a preparation method and use of the polymer powder. The polymer powder is prepared from a single olefinic bond unsaturated monomer unit with hydroxymethyl or carbonyl, a single olefinic bond unsaturated monomer unit with carboxyl and hydroxyl, an unsaturated monomer unit formed by a (methyl) alkyl acrylate and vinyl aromatic compound of non-branched or branched alcohol with 1-15 carbon atoms, and water-soluble polymer protective colloid. The polymer powder disclosed by the invention has excellent self-adhesive performance and substrate bonding performance; the polymer powder and the aqueous dispersion thereof can be subjected to cross-linking reaction in the constructing and drying processes by virtue of the foundational groups such as hydroxymethyl, carbonyl, carboxyl, hydroxyl and the like, so as to achieve excellent self-adhesive performance and substrate bonding performance.

Owner:TAIYUAN INST OF TECH

Anti-microbial and Anti-static surface treatment agent with quaternary ammonium salt as active ingredient and method for preventing static electricity in polymer fibers using same

ActiveUS20130183456A1Increase blockingIncrease static electricityOrganic chemistryOrganic compound preparationFiberAntistatic agent

Provided are an anti-static and anti-microbial surface treatment agent including a quaternary ammonium salt compound as an active ingredient and a method of preventing a polymer fiber from developing static electricity by using the surface treatment agent. The quaternary ammonium salt compound has excellent anti-static and anti-microbial effects for the prevention or improvement of static electricity in a polymer fiber. Accordingly, the quaternary ammonium salt compound is suitable for use as a fabric softener, or an anti-static agent, and also, provides anti-microbial effects to a polymer fiber.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

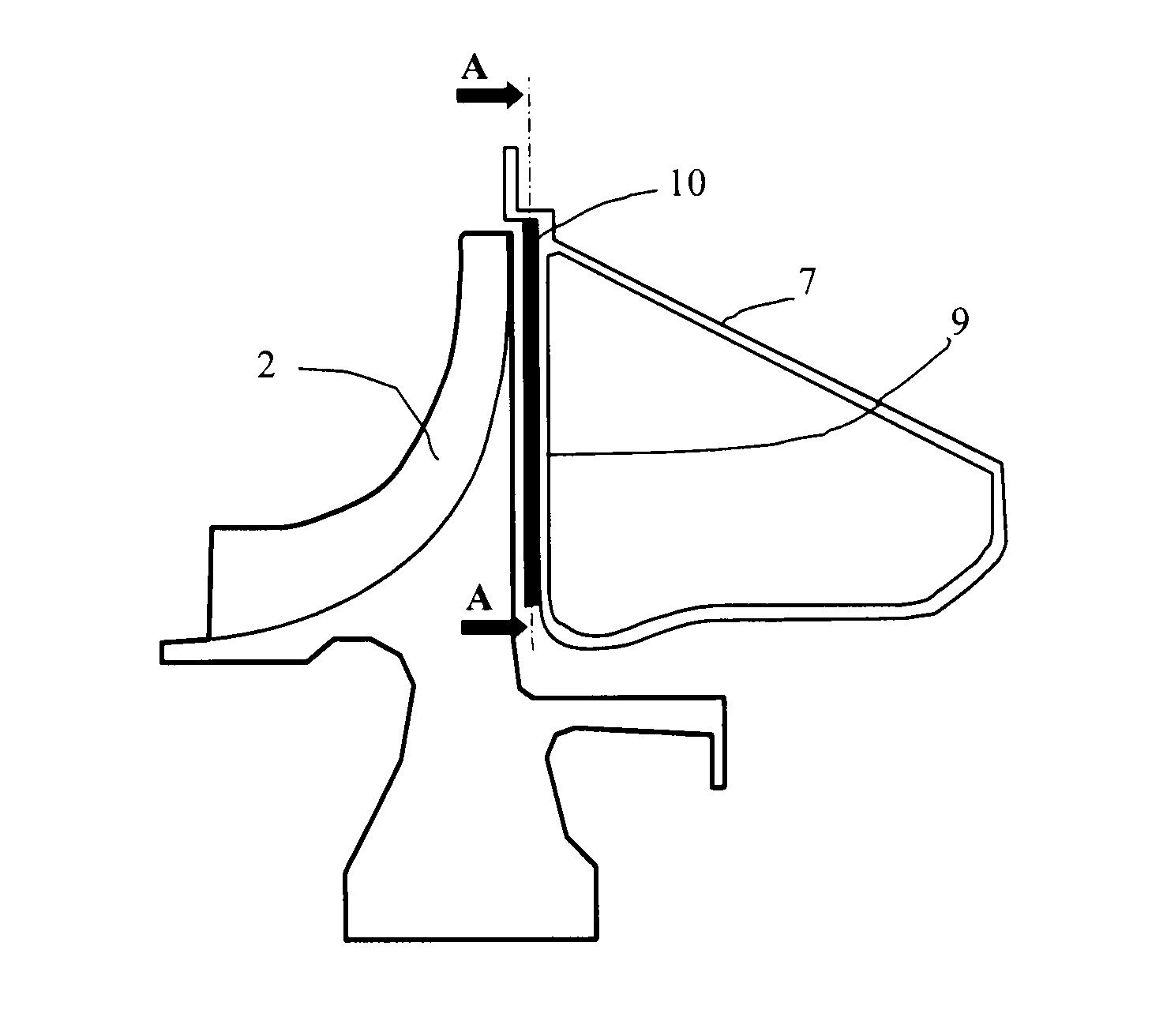

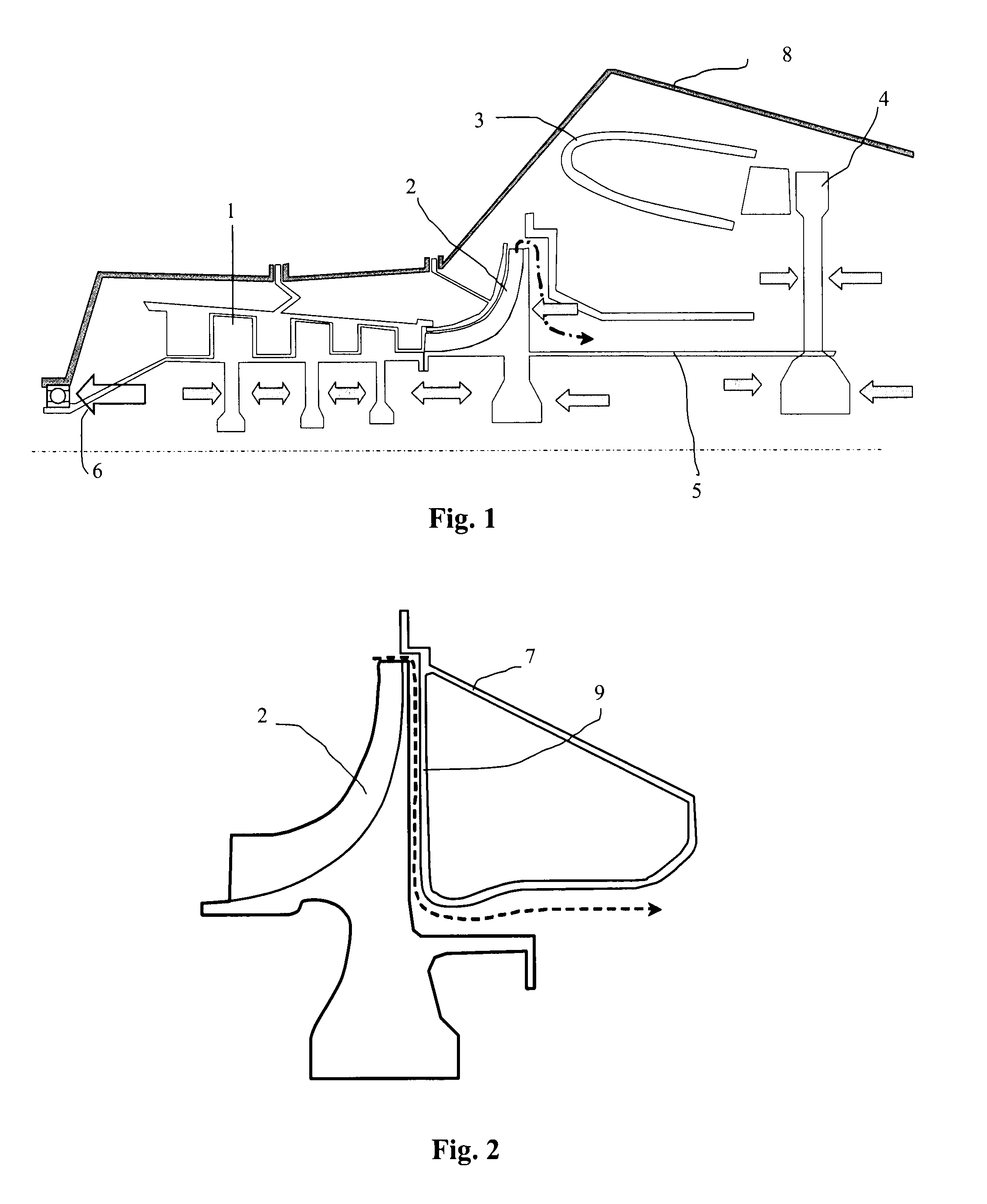

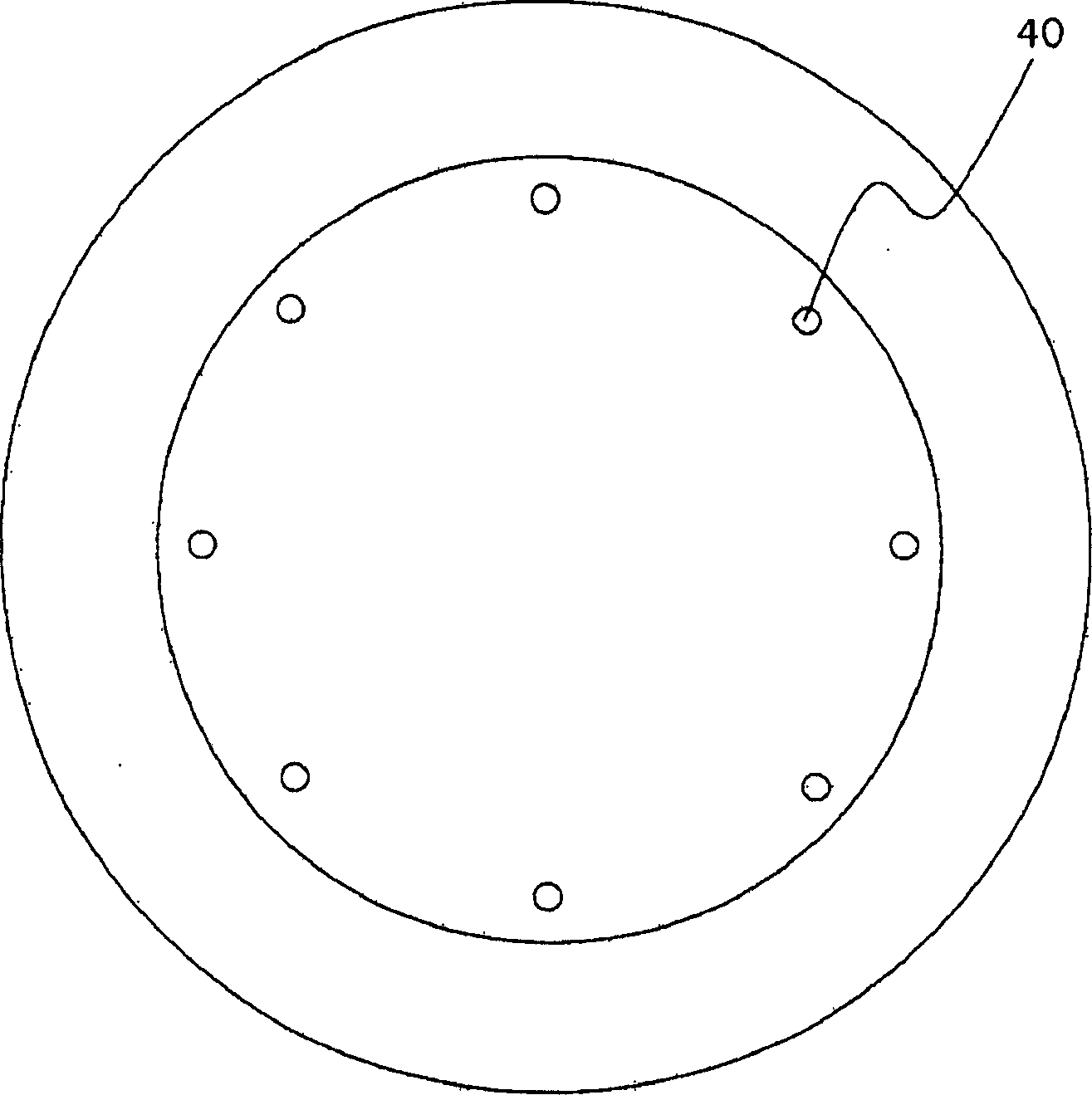

Control of axial thrust by guidance of the air drawn off from a centrifugal compressor

ActiveUS8938975B2Increase static pressureAvoid flowPropellersReaction enginesCircular discCombustion chamber

An inner combustion chamber casing of a turbomachine, which is intended to be placed downstream of a centrifugal compressor, is provided. The casing has the shape of a disc, pierced by a central circle, and includes on its disc at least one guide vane of the drawn-off air. The guide vane extends longitudinally over the disc between the periphery of the disc and the central circle and spreads out axially from the disc so as to form with the downstream face of the centrifugal compressor a guide channel for the air which is drawn off upon exit from the said compressor. The guide vane has a curved shape orienting in a radial direction at the level of its most central end.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

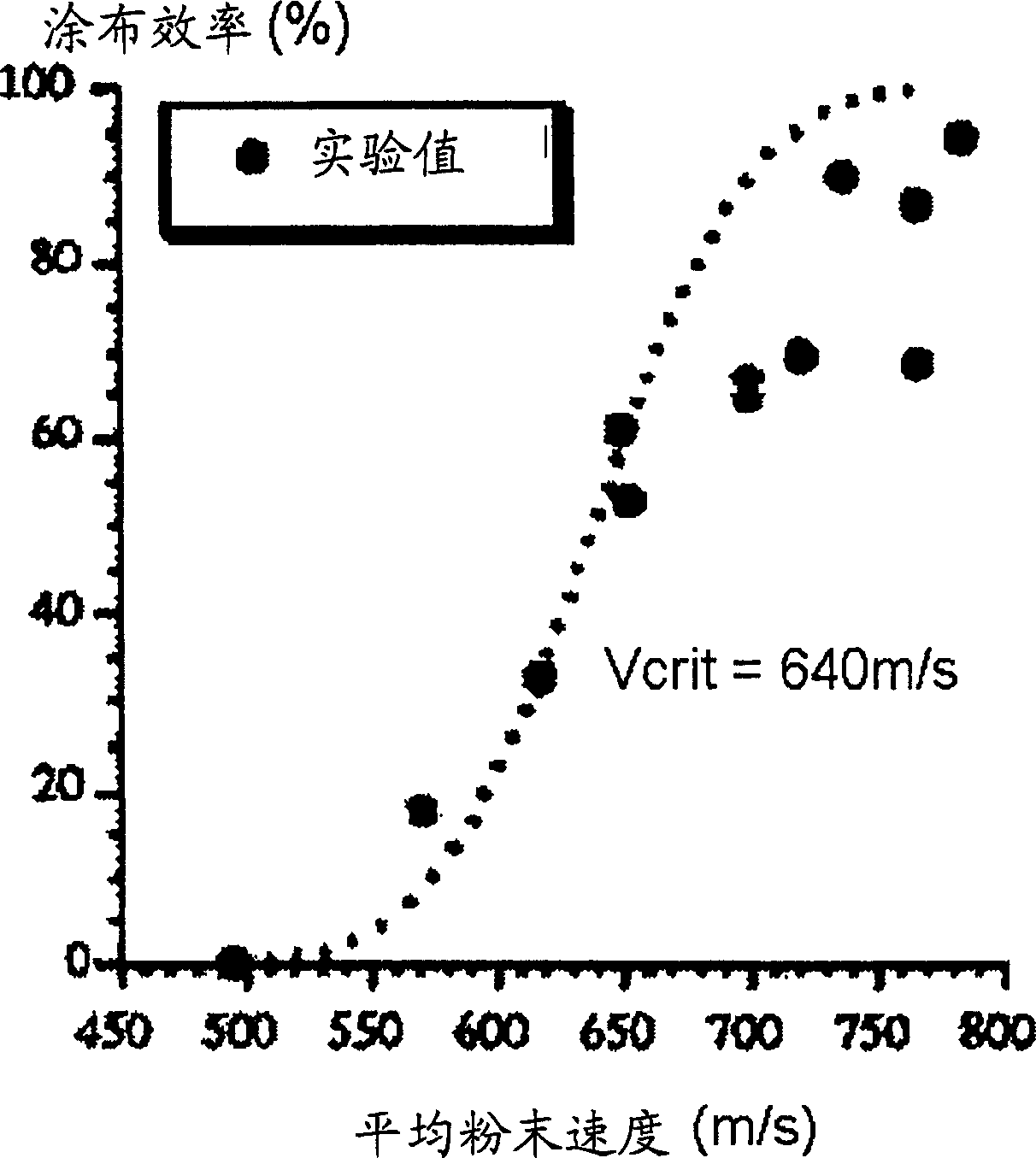

Electro-static chuck with non-sintered aln and a method of preparing the same

InactiveCN1864255AImprove featuresHigh thermal conductivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingBonding processUltimate tensile strength

The present invention relates to an electro-static chuck with non-sintered AlN and a method of preparing the same. Especially, the present invention relates to the electro-static chuck with non-sintered AlN which having coated aluminum nitride (AlN) layer as a dielectric one on the purpose of chucking the wafers in the process of wafers and a method of preparing the same. The electro-static chuck of the present invention has excellent dielectric characteristics, bonding strength and thermal conductivity by forming an AlN layer as a dielectric one without sintering process or bonding process with binders.

Owner:SNT CO LTD

Low-pressure wireless hair dryer

The invention relates to a low-pressure wireless hair dryer. The low-pressure wireless hair dryer comprises an air cylinder and a handle, wherein the air cylinder is communicated with an inner cavityof the handle, the air cylinder is internally provided with a heating part, the heating part comprises a heating element, the heating element is made from a flexible material, and electro-thermal conversion can be achieved under a low voltage condition; the handle is internally provided with a circuit control board and a battery, the heating element and the battery are connected with the circuit control board separately, and the battery supplies power to the heating element through the circuit control board. The low-pressure wireless hair dryer can work under low voltage, has high safety performance, is not restricted by the use environment, and is convenient to store and use.

Owner:TANWENG BEIJING TECH CO LTD

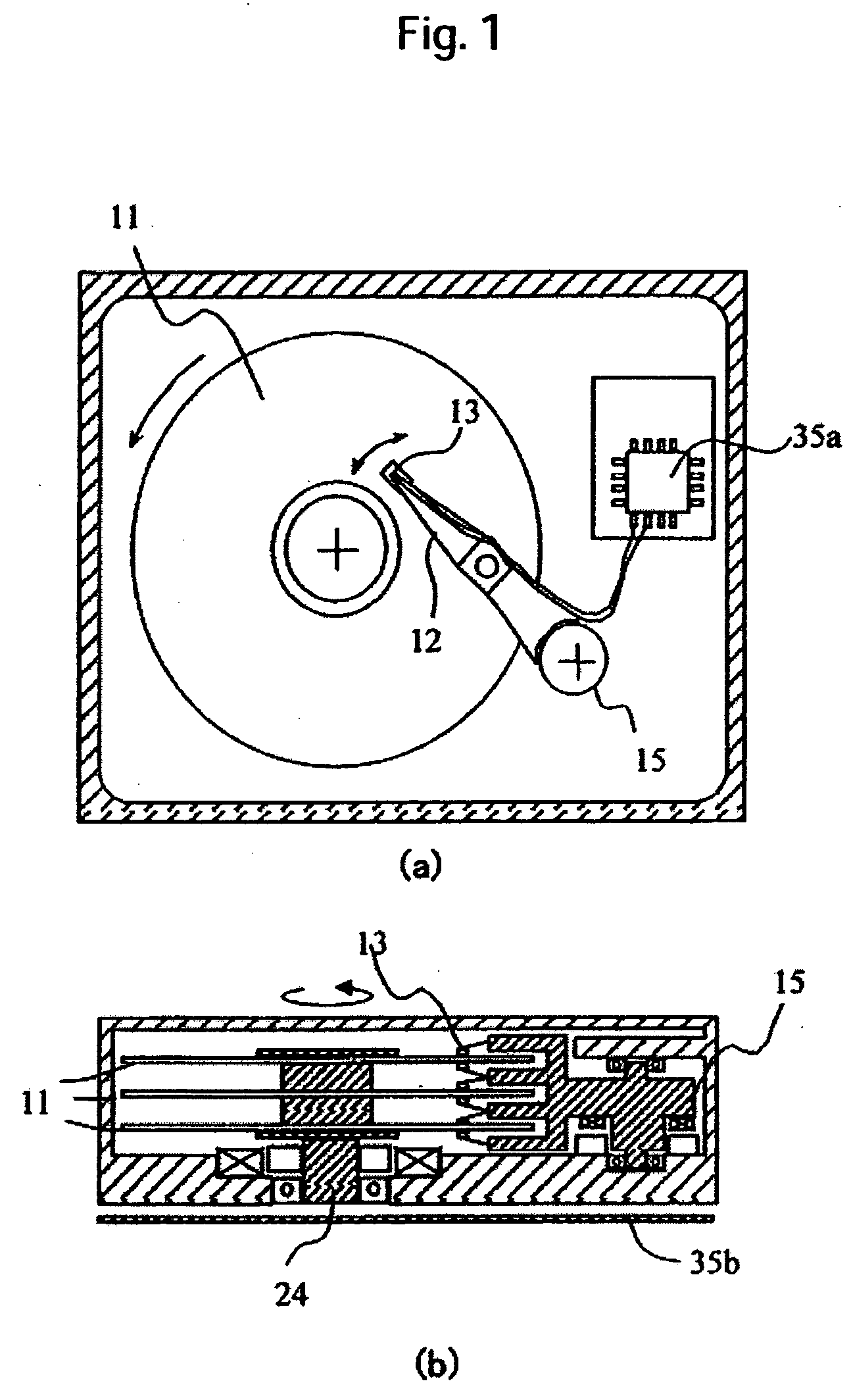

Magnetic head with durability against static electricity

InactiveUS20060132985A1Improve transfer rateImprove electrical durabilityRecord information storageManufacture of flux-sensitive headsRecording densityTime constant

Embodiments of the invention provide a read head which is implemented in a magnetic disk drive that supports a high recording density and a high transfer rate and is excellent in static electricity durability. In one embodiment, a magnetic head wherein a charge diffuses from a read element to a slider at a time constant of about 100 ms or less.

Owner:WESTERN DIGITAL TECH INC

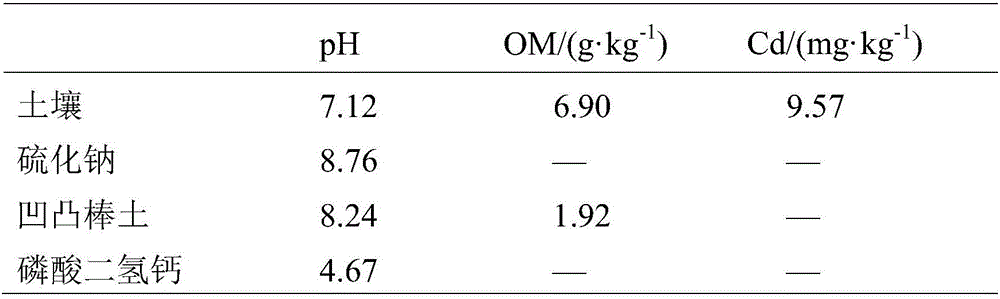

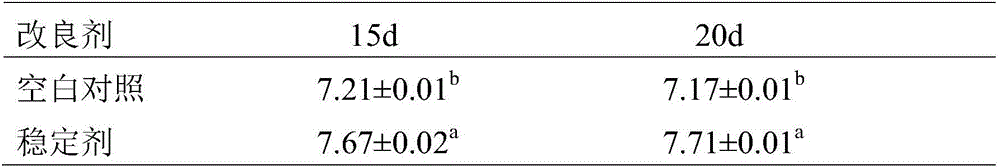

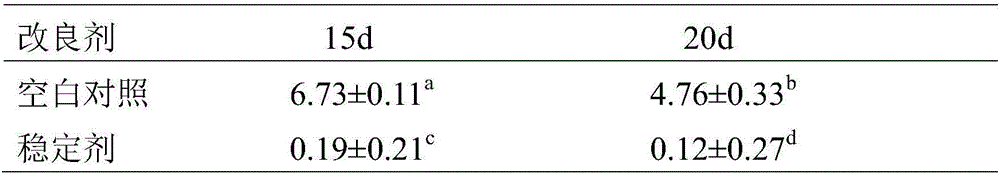

A stabilizing agent used for restoration of cadmium-polluted soil

InactiveCN106520128ALarge specific surface areaIncrease static electricityOrganic fertilisersSoil conditioning compositionsPollution soilRoom temperature

A stabilizing agent used for restoration of cadmium-polluted soil is disclosed. The stabilizing agent includes, based on the mass of the polluted soil, 1-2% of modified attapulgite, 2-3% of sodium sulfide and 1-3% of calcium dihydrogen phosphate. The stabilizing agent is added into the cadmium-polluted soil firstly and stirred to fully mix the stabilizing agent with the soil, water is added, stirring is performed continuously, the water content of fields with the soil is kept and maintenance is performed at room temperature. The stabilizing agent is cheap, easily available and good in effects and free of secondary pollution, does not greatly change the pH value of the polluted soil, can increase water retention and aeration properties of the soil and facilitates subsequent utilization of the soil.

Owner:北京德瑞科森环保科技有限公司

Grounding apparatus of portable electronic devices

InactiveUS7787255B2Easy to getIncrease static electricityElectrostatic discharge protectionPrinted circuit groundingEngineeringFlexible electronics

A grounding apparatus (200) includes at least one conductive member (20), a sliding mechanism (30) and a flexible printed circuit board (40). The sliding mechanism is conductive and electrically connected to the conductive member. The flexible printed circuit board includes a conductive layer (421) and a grounding end (4231), the conductive layer and the grounding end are electrically connected to the sliding mechanism.

Owner:CHI MEI COMM SYST INC

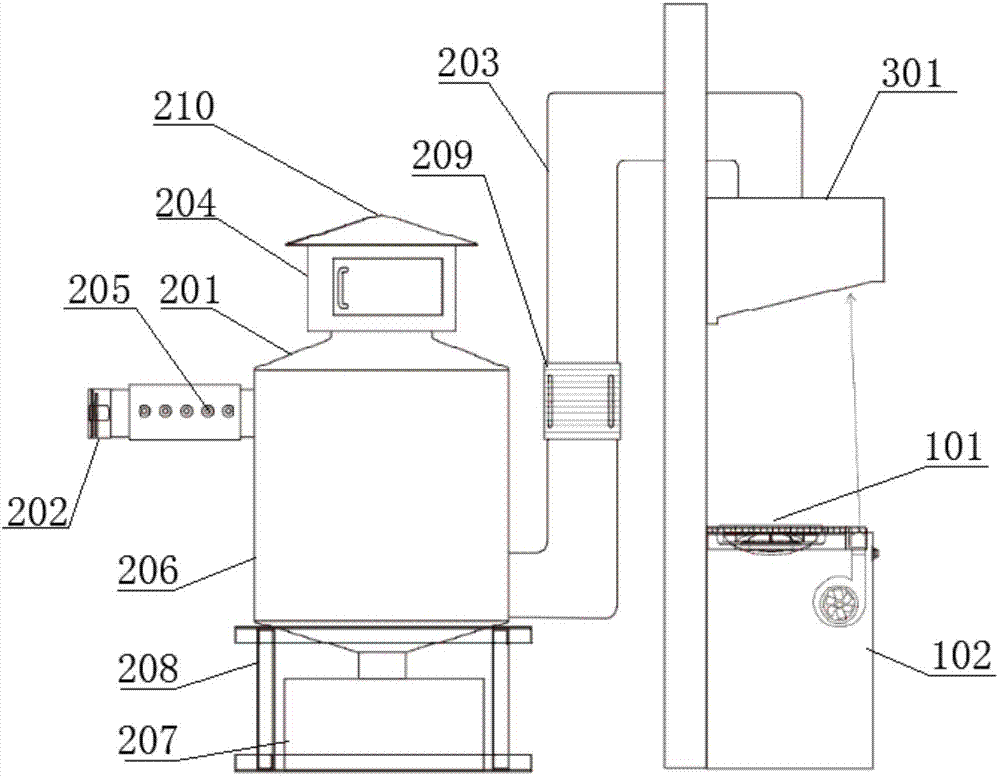

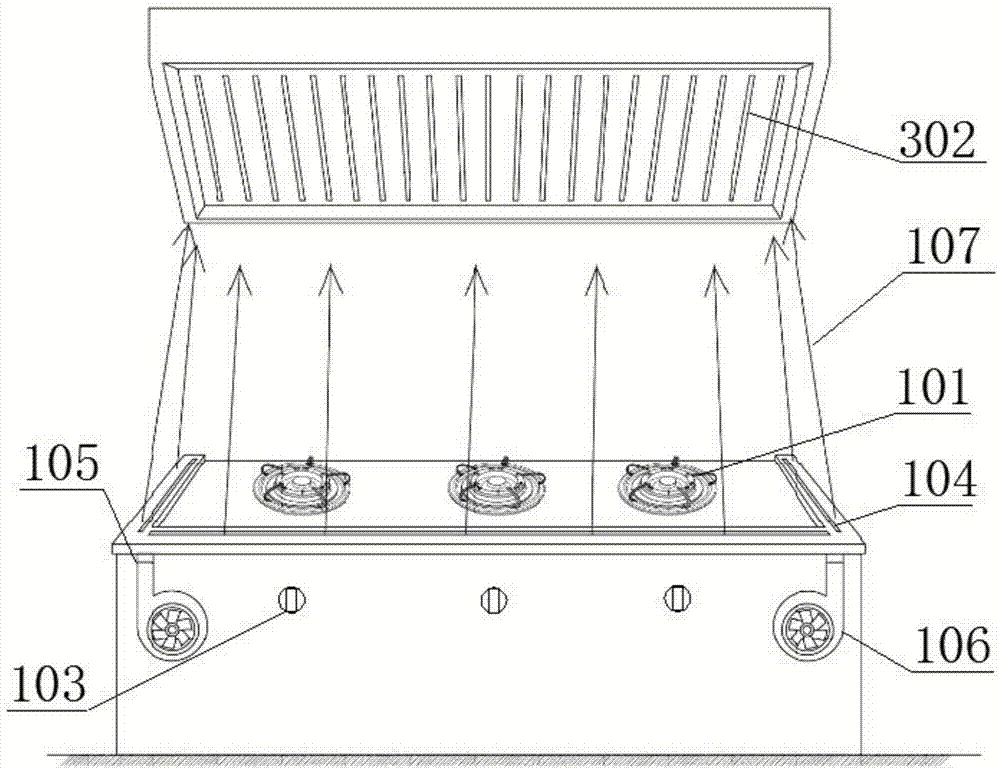

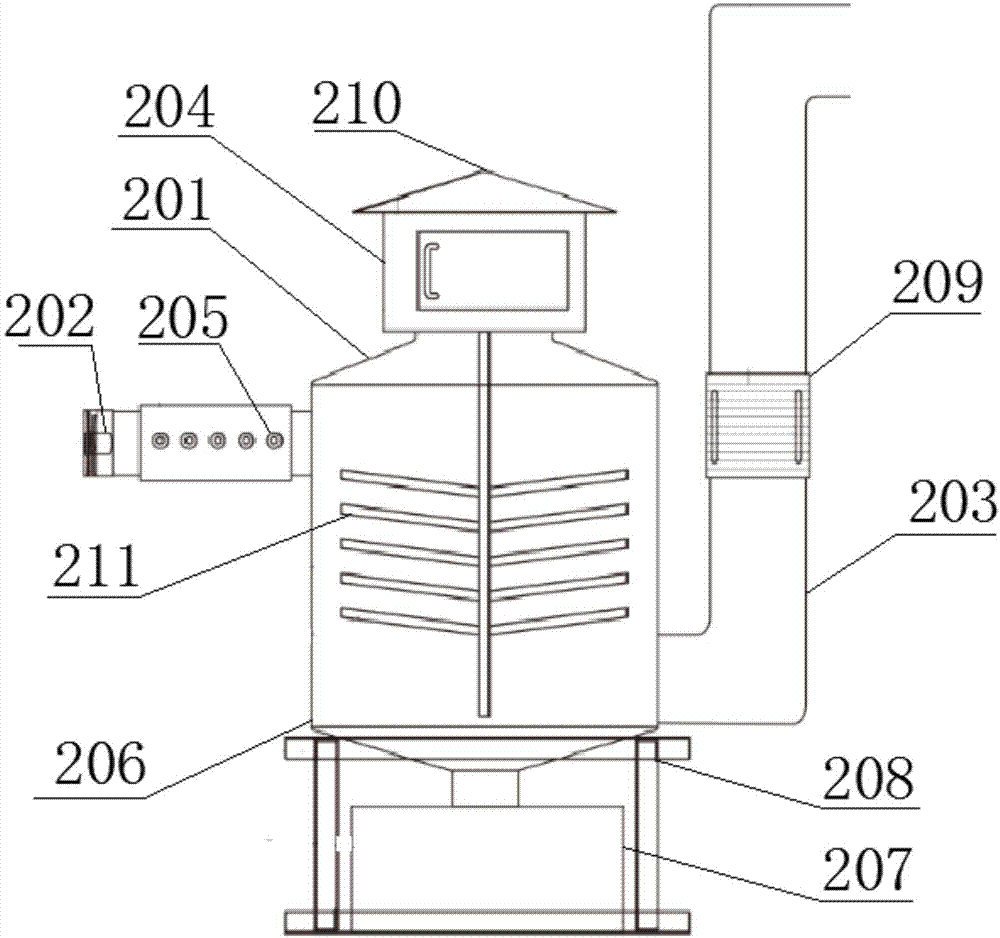

Comprehensive treatment device capable of controlling cooking oil fume, reducing consumption and purifying exhaust installed indoors and outdoors

InactiveCN103791538ASync isolationIncrease static electricityDomestic stoves or rangesLighting and heating apparatusHearthCooking oil

The invention relates to a comprehensive treatment device capable of controlling cooking oil fume, reducing consumption and purifying exhaust installed indoors and outdoors. The comprehensive treatment device comprises a cooking oil fume isolation air curtain stove, a cooking oil fume purifier and a range hood, wherein the range hood is arranged at the upper end of the cooking oil fume isolation air curtain stove and the cooking oil fume purifier is arranged at one end of the cooking oil fume isolation air curtain stove. Compared with the prior art, the comprehensive treatment device is environmentally friendly, good in cooking oil fume purification and exhaustion effects, low in cost and easy to wash.

Owner:广西华信恒基科技发展有限公司

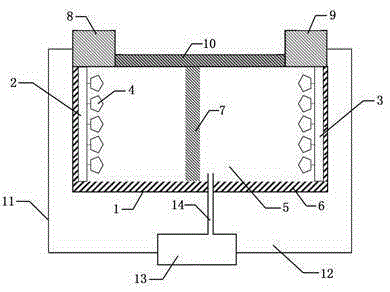

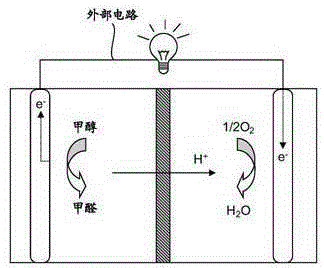

VO2/S-AC nickel foam air cathode

InactiveCN105355927ALarge activation areaIncrease static electricityCell electrodesFinal product manufactureNickelRaw material

The invention discloses a VO2 / S-AC nickel foam air cathode and belongs to the field of electrodes. The preparation method of the VO2 / S-AC nickel foam air cathode includes the three steps of preparing a catalytic layer raw material, preparing nickel foam coated with a catalytic layer and preparing the VO2 / S-AC nickel foam air cathode. The VO2 / S-AC nickel foam air cathode has the advantages that the VO2 / S-AC nickel foam air cathode is larger in electrode surface activation area, the electrostatic effect between microbes and the electrode surface is improved, the microbial adsorptivity is improved, the catalytic performance is good, accordingly the power output is improved, and the production cost is reduced.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

Electrostatic discharge structure of liquid crystal display panel, liquid crystal display panel and liquid crystal display device

ActiveUS10613398B2Easy dischargeIncrease static electricityNon-linear opticsSilver pasteLiquid-crystal display

The present disclosure discloses an electrostatic discharge structure of a LCD panel for mounting on a LCD panel with a high-resistance film, wherein the LCD panel includes a glass layer on an uppermost layer of the LCD panel covered with a high-resistance film, an edge reserved around the high-resistance film, and a conductive material layer arranged on the edge reserved on the glass panel, wherein the conductive material layer is in contact with a periphery of the high-resistance film, and the conductive material layer is connected to a GND pin of the TFT substrate through a conductive silver paste. The present disclosure also discloses a LCD panel and a LCD device. According to the embodiments of the present disclosure which can speed up the discharge of static electricity and greatly improve the static electricity generated by the tearing film and the coating film.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A kind of conductive, barrier polyethylene composition and its preparation method and application

Owner:KINGFA SCI & TECH CO LTD +1

Jacquard non-woven fabric and preparation method thereof

The invention provides a jacquard non-woven fabric and a preparation method of the jacquard non-woven fabric, and relates to the technical field of production of non-woven fabrics. The jacquard non-woven fabric is mainly prepared from a three-dimensional crimp hollow fiber, a polypropylene fiber and a common polyester staple fiber, the three-dimensional crimp hollow fiber has a crimping arc, the radius of curvature is relatively large, the jacquard non-woven fabric has the characteristic that the jacquard non-woven fabric does not cause fatigue yield easily after deforming because of compression for multiple times; the common polyester staple fiber increases the entanglement degree of the non-woven fabric; the polypropylene fiber improves the strength of the non-woven fabric, and the jacquard non-woven fabric does not deform easily. Therefore, the jacquard non-woven fabric has the advantages that the pattern is clear, the hand feeling is soft, the stereoscopic impression is strong, thestatic electricity is high, the elasticity of compression is good, the surface is fluffy, and the dust collection effect is good.

Owner:高长水

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com