VO2/S-AC nickel foam air cathode

An air cathode and VO2 technology, applied in the electrode field, can solve the problems of a large number of unfavorable microorganisms attached, narrow catalytic performance, small anode surface area, etc., to achieve the effect of increasing microbial adsorption, improving electronic conductivity, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

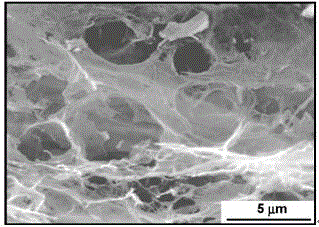

[0037] A kind of VO 2 / S-AC foam nickel air cathode is prepared by the following steps:

[0038] Step 1: According to the mass ratio of 1:1, mix polyvinyl alcohol and polytetrafluoroethylene evenly to prepare a catalytic emulsion with a concentration of 10%, and mix VO 2 Mix evenly with S-AC according to the mass ratio of 2:1, and weigh VO according to the mass ratio of 1:3 2 / S-AC mixture and catalytic emulsion, the VO 2 / S-AC mixture and catalytic emulsion were mixed ultrasonically for 40 minutes, the mixed solution was heated to 65°C, and stirred continuously for 2 hours to break the emulsion to obtain the raw material of the catalytic layer;

[0039] Step 2: Press the nickel foam into a 0.6mm sheet by a tablet press, and evenly scrape the raw material of the catalytic layer on the upper surface of the foam nickel, and then microwave it for 5 minutes under the condition of a pressure of 70kPa and a power of 100W, and the surface of the sheet The excess powder is gently s...

Embodiment 2

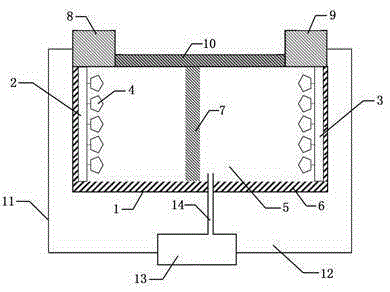

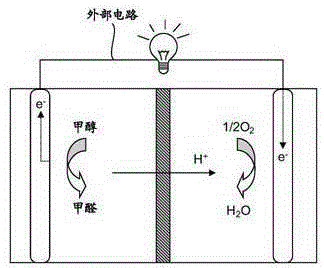

[0043] Such as Figure 1 to Figure 4 As shown, a VO 2 / S-AC foam nickel air cathode, the electrode is applied to the method of microbial fuel cell based on p-trimethylamine oxide medium, a kind of microbial fuel cell based on p-trimethylamine oxide medium, including reactor 1 and The battery positive pole 8 and the battery negative pole 9 are arranged outside the casing 11 , the bottom of the battery positive pole 8 is connected to one end of the reactor 1 ; the bottom of the battery negative pole 9 is connected to the other end of the reactor 1 .

[0044] The reactor 1 includes a sealed shell 6 and an anode 2 and a negative electrode 3 arranged in the sealed shell 6, microorganisms 4 are attached to the surface of the anode 2 and the negative electrode 3, an ion exchange membrane 7 is arranged between the anode 2 and the negative electrode 3, and the anode 2 and the battery The positive pole 8 is connected, the cathode 3 is connected with the negative pole 9 of the battery, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com