Continuous phosphoric acid method external heating type flat activation furnace

An activation furnace and external heating technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of high temperature resistance and corrosion resistance of activation discs, uneven material temperature, slow heating speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

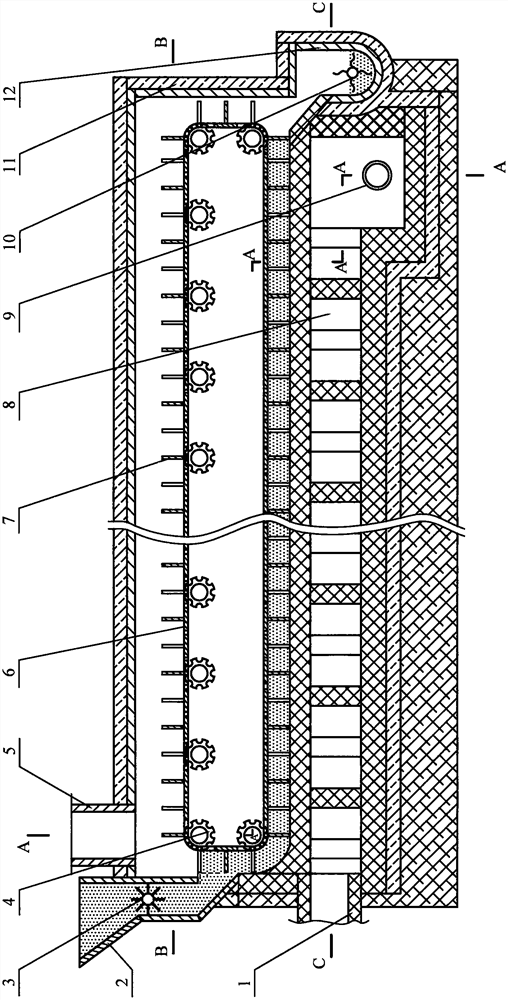

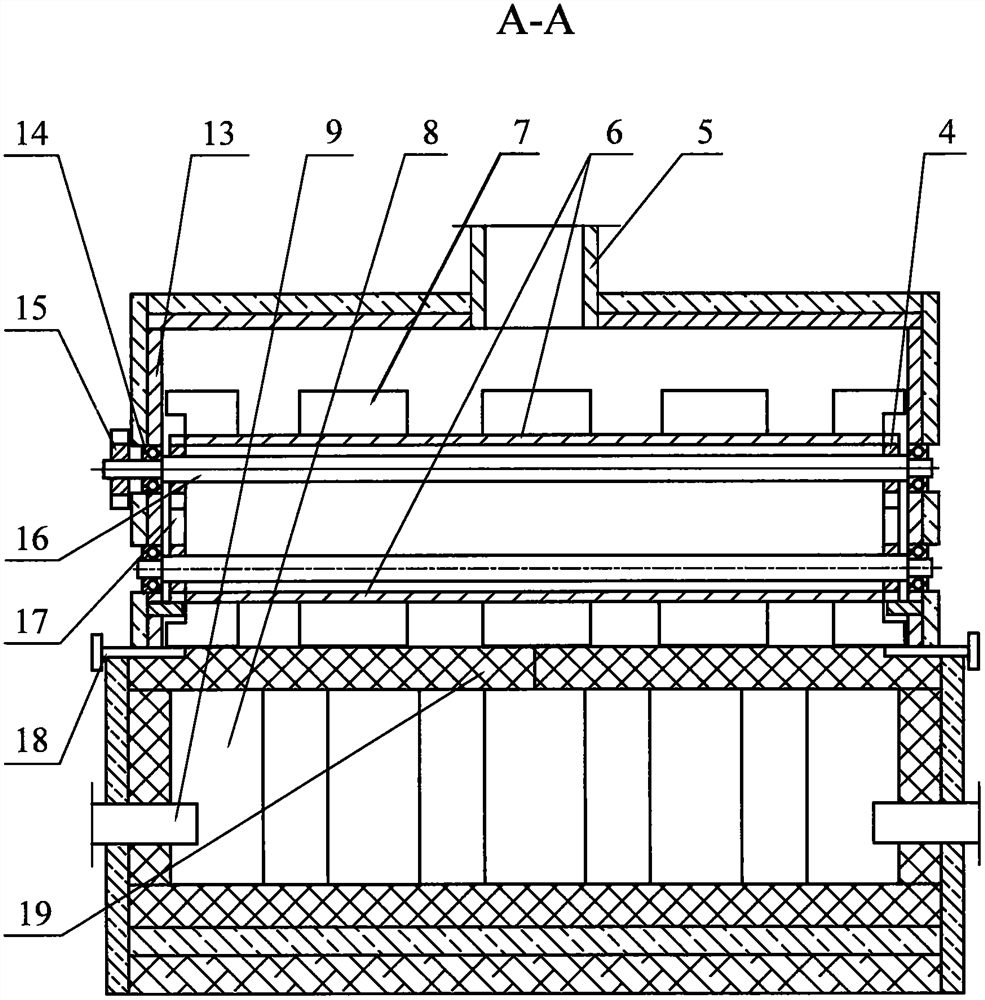

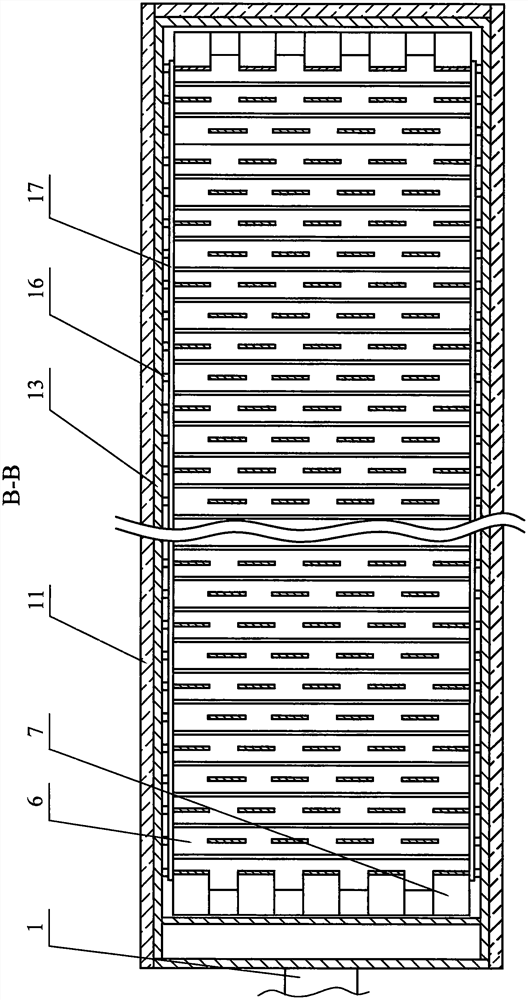

[0005] A kind of continuous phosphoric acid method external heating type plate activation furnace of the present invention is activated in this way, combined with the attached figure 1 The description is as follows: when the activation furnace is heating up, add the material to be activated into the hopper (2), close the activation tail gas outlet (5), and the high-temperature flue gas generated by the combustion of the gas through the gas burner (9) passes through the entire heating chamber to heat the regenerative refractory brick column (20) and the activated material plate (19), and then guide it from the flue gas outlet (1) at the other end of the heating chamber to the waste heat utilization equipment for waste heat utilization and then empty it through the chimney; When the temperature of the temperature measuring point near the discharge port in the activation chamber reaches 500°C, open the exhaust gas discharge port (5) of the activation chamber, start the drive motor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com