Microbial fuel cell for treating domestic sewage

A technology for domestic sewage and fuel cells, which is applied in biochemical fuel cells, fuel cells, and components of fuel cells, etc., can solve the problems of a large number of unfavorable microorganisms, narrow application area of catalytic efficiency, small anode surface area, etc., and achieve high power production efficiency. and sewage treatment rate, increase microbial adsorption, good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

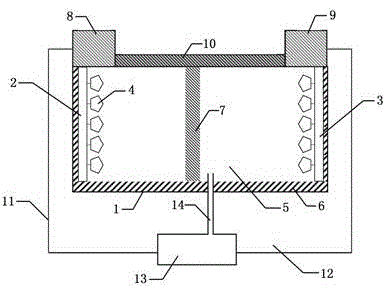

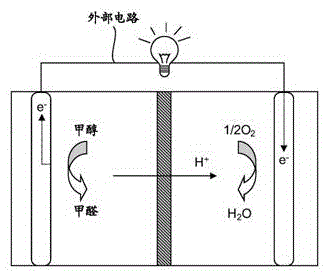

[0038] Such as Figure 1 to Figure 4 As shown, a microbial fuel cell for treating domestic sewage includes a reactor 1 disposed inside the casing 11 and a battery positive electrode 8 and a battery negative electrode 9 arranged outside the casing 11, and the bottom of the battery positive electrode 8 is connected to the reactor 1 One end of the battery negative pole 9 is connected to the other end of the reactor 1; the reactor 1 includes a sealed casing 6 and an anode 2 and a negative electrode 3 arranged in the sealed casing 6, and microorganisms 4 are attached to the surface of the anode 2 and the negative electrode 3, and the anode 2 and the cathode 3 is provided with an ion exchange membrane 7, the anode 2 is connected to the positive electrode 8 of the battery, the cathode 3 is connected to the negative electrode 9 of the battery, and the sealed shell 6 is filled with a medium 5; the medium 5 is domestic sewage; the bottom of the shell 11 is provided with a medium The exc...

Embodiment 2

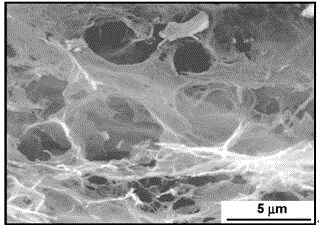

[0045] Anode 2—surface titanium / nitrogen doped mesoporous graphene airgel was prepared by the following steps:

[0046] Step 1: Add graphite powder and sodium nitrate to the concentrated sulfuric acid at the mass ratio of concentrated sulfuric acid: graphite powder: sodium nitrate 65:1:0.6 in an ice bath, stir and dissolve for 30 minutes, and then add graphite powder: potassium permanganate according to the mass ratio of graphite powder: potassium permanganate Ratio 1:5, add potassium permanganate to the mixed solution, stir for 10 hours, add deionized water to the mixed solution according to the volume ratio of concentrated sulfuric acid: deionized water 1:1, and place the mixture under the condition of a vacuum degree of 0.93 Slowly raise the temperature to 52°C at a rate of 1.2°C / h, keep stirring at a constant temperature of 52°C for 22 hours, then add hydrogen peroxide to the mixed solution according to the volume ratio of concentrated sulfuric acid to hydrogen peroxide (1:...

Embodiment 3

[0049] Cathode 3 - VO 2 / S-AC foam nickel air cathode is made by the following steps:

[0050] Step 1: Mix polyvinyl alcohol and polytetrafluoroethylene evenly according to the mass ratio of 1:1 and prepare a catalytic emulsion with a concentration of 10%. Mix VO2 and S-AC evenly according to the mass ratio of 2:1. Weigh the VO2 / S-AC mixture and the catalytic emulsion at a ratio of 1:3, mix the VO2 / S-AC mixture and the catalytic emulsion by ultrasonic waves for 40 minutes, heat the mixed solution to 65°C, and keep stirring for 2 hours to break the emulsion, and obtain Catalyst layer raw material;

[0051] Step 2: Compress the nickel foam into a 0.6mm sheet by a tablet press, scrape-coat the raw materials of the catalytic layer on the upper surface of the nickel foam, and then react with microwaves for 5 minutes under the conditions of a pressure of 70kPa and a power of 100W. The excess powder is gently swept away to obtain foamed nickel covered with a catalytic layer;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com