Patents

Literature

35results about How to "Improve electrical durability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

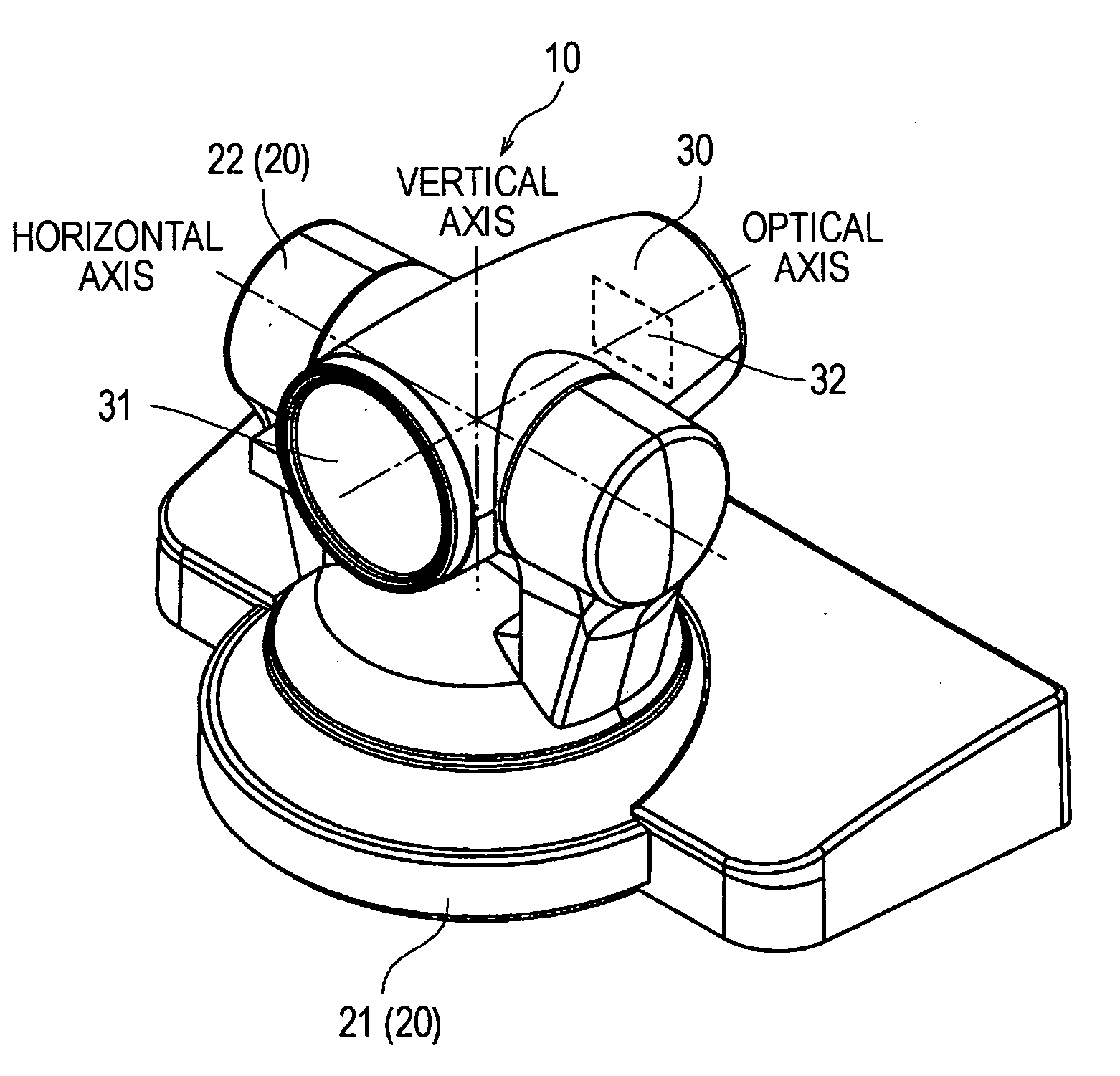

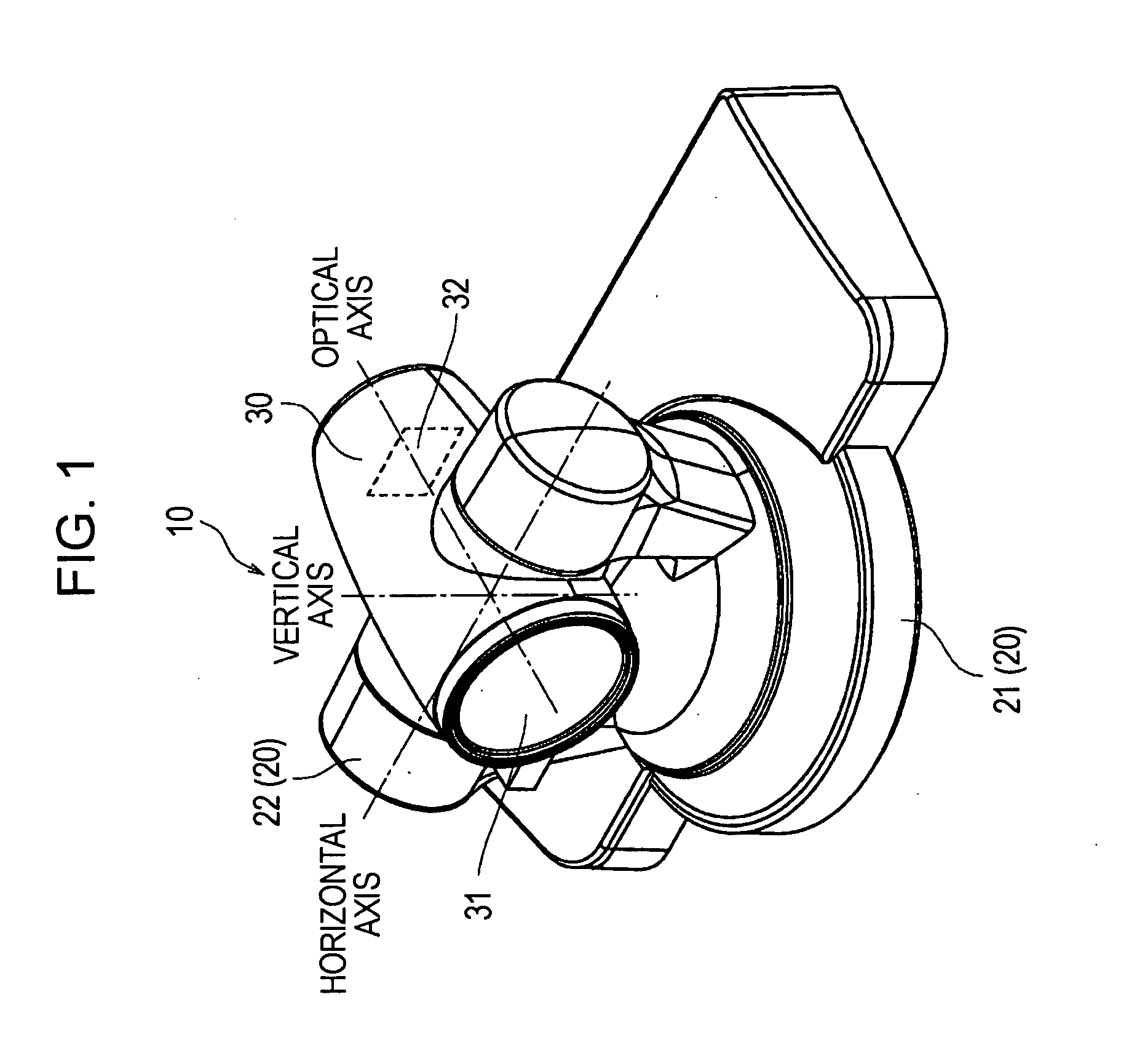

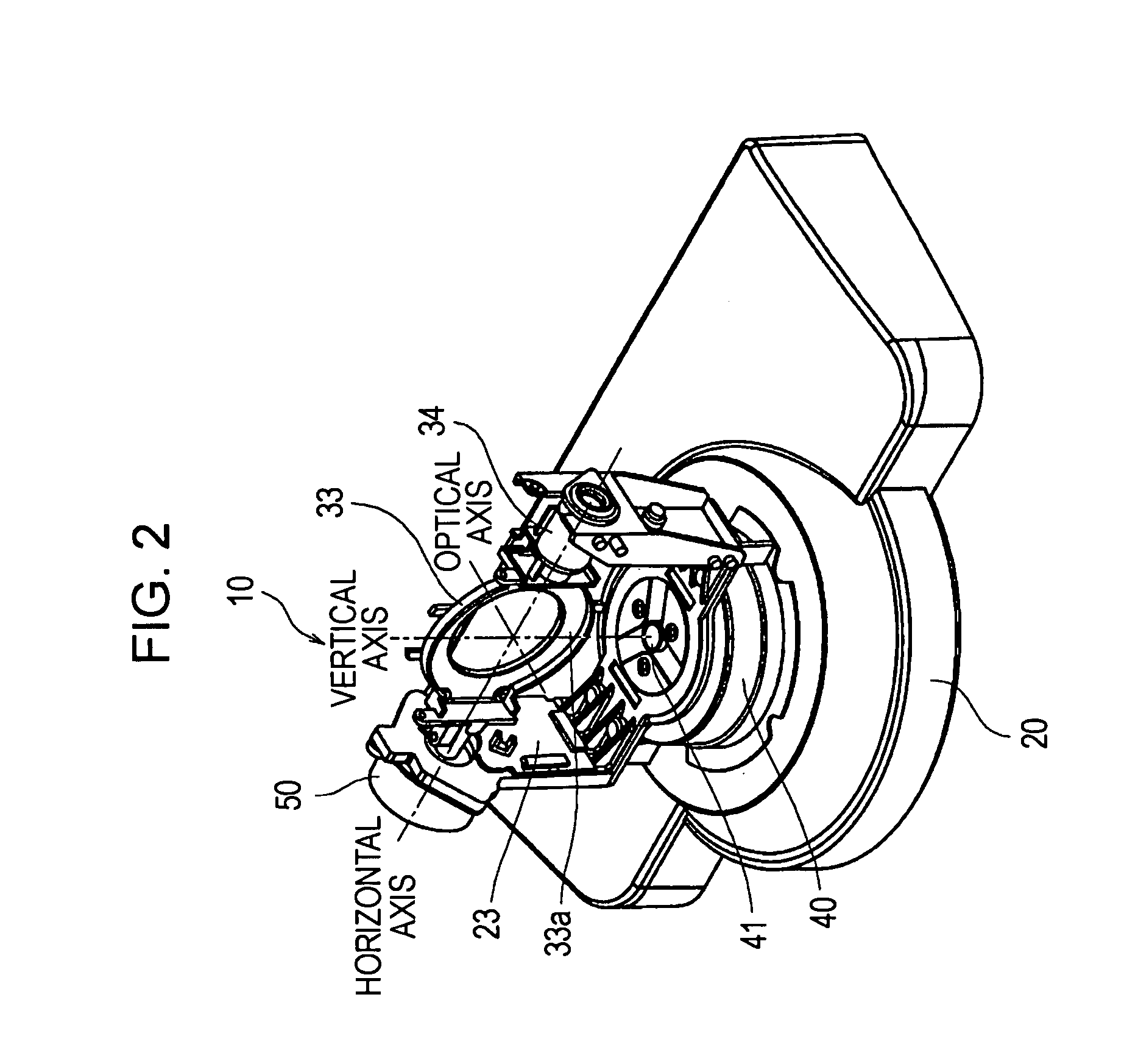

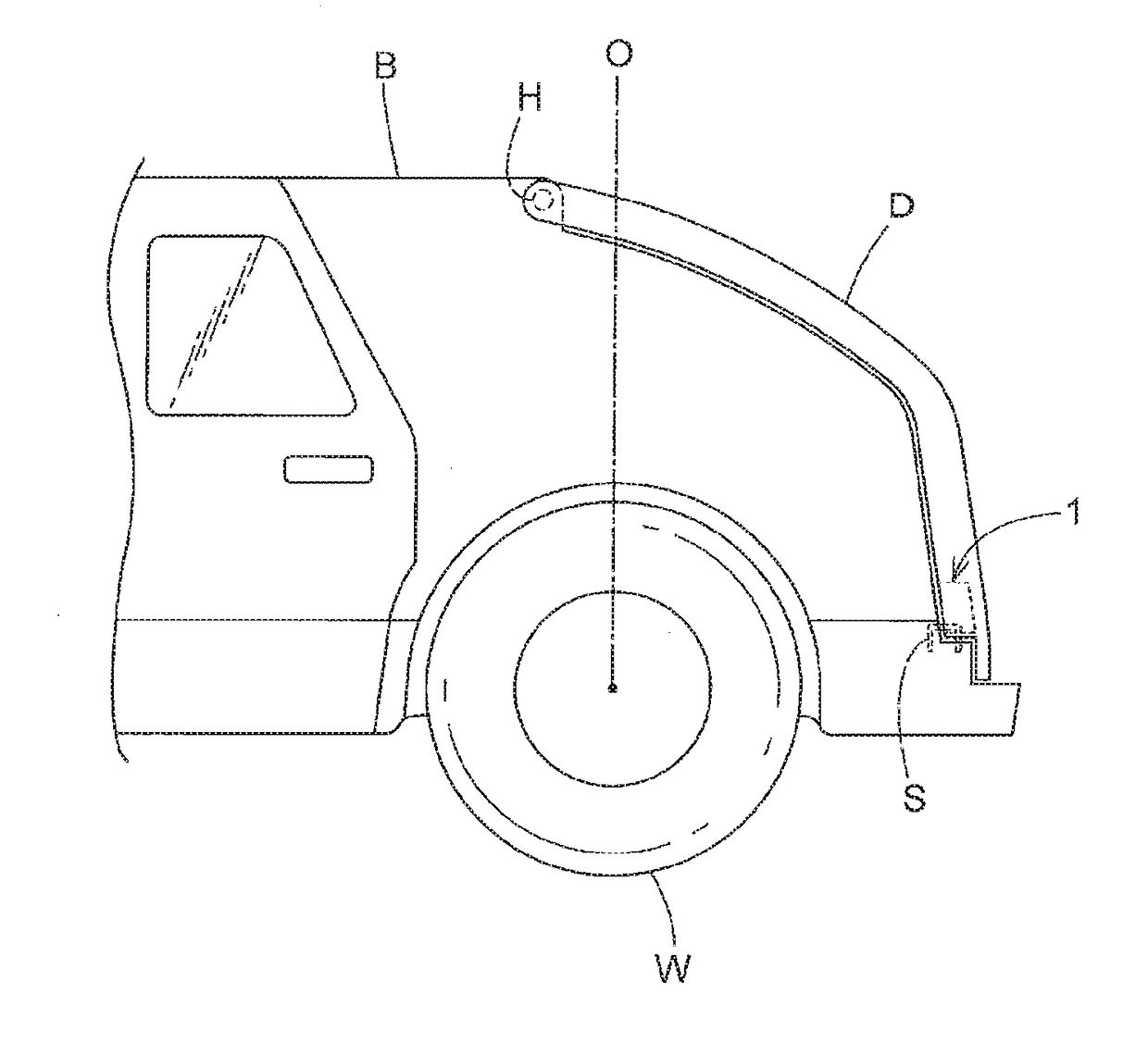

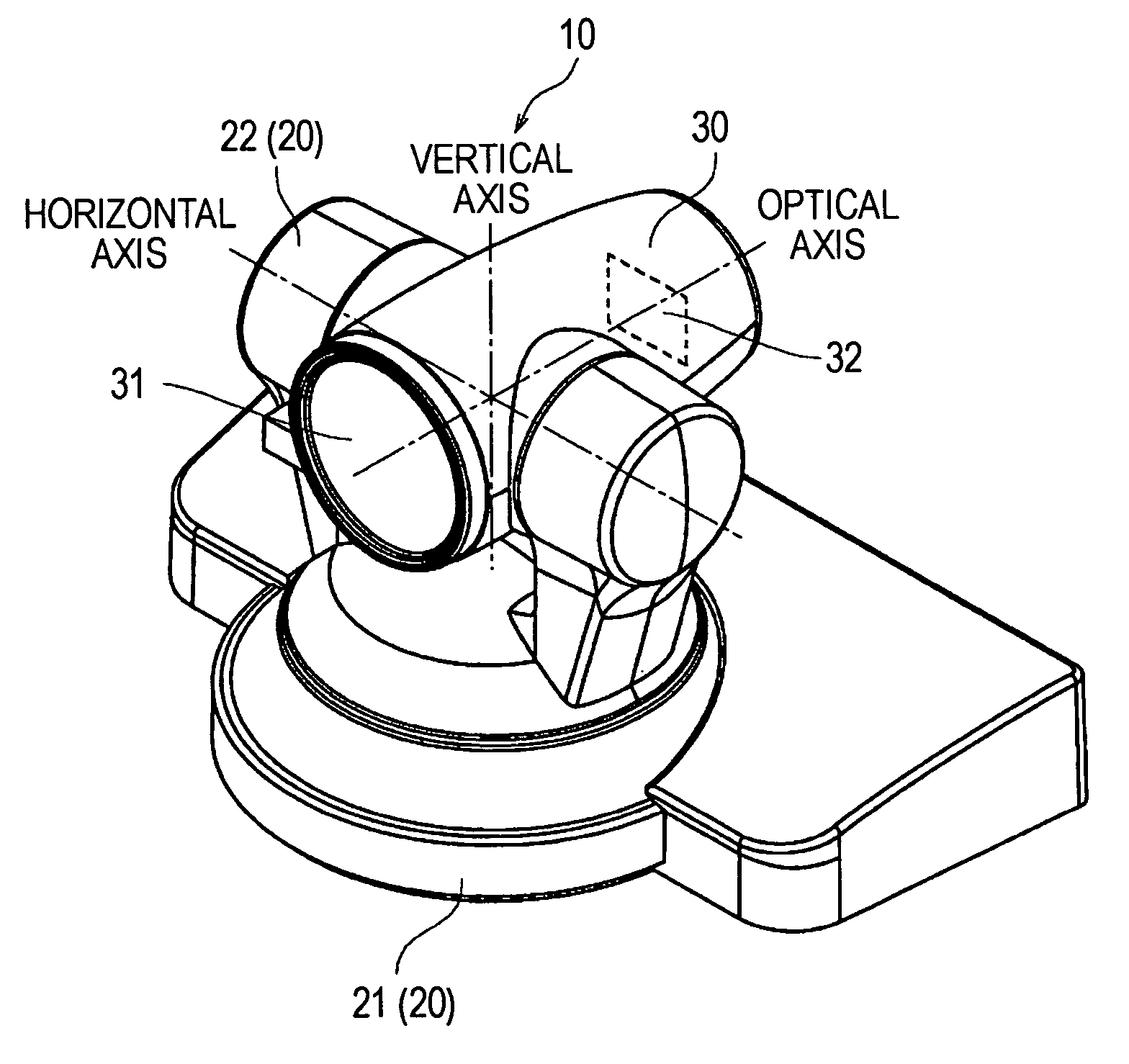

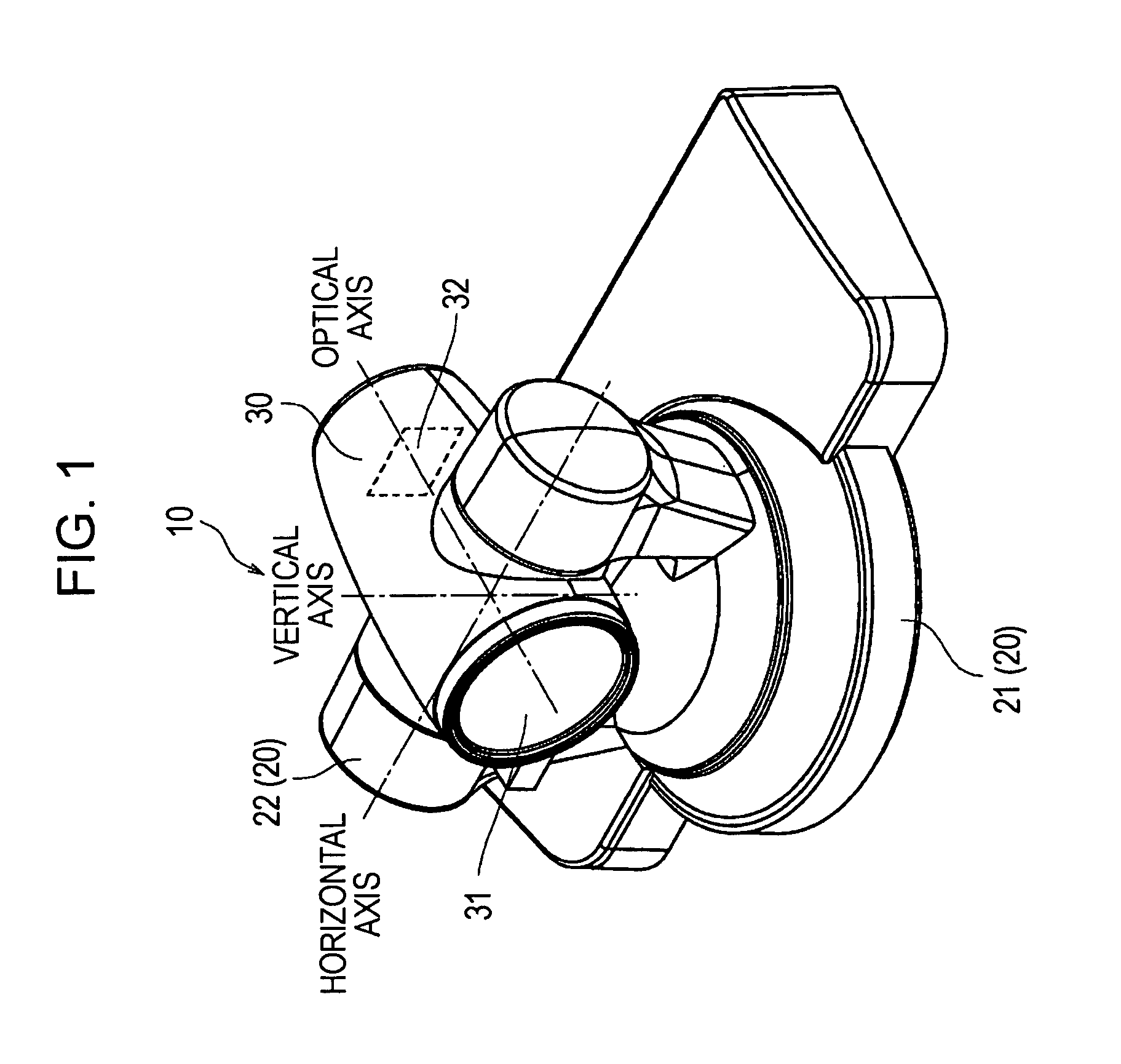

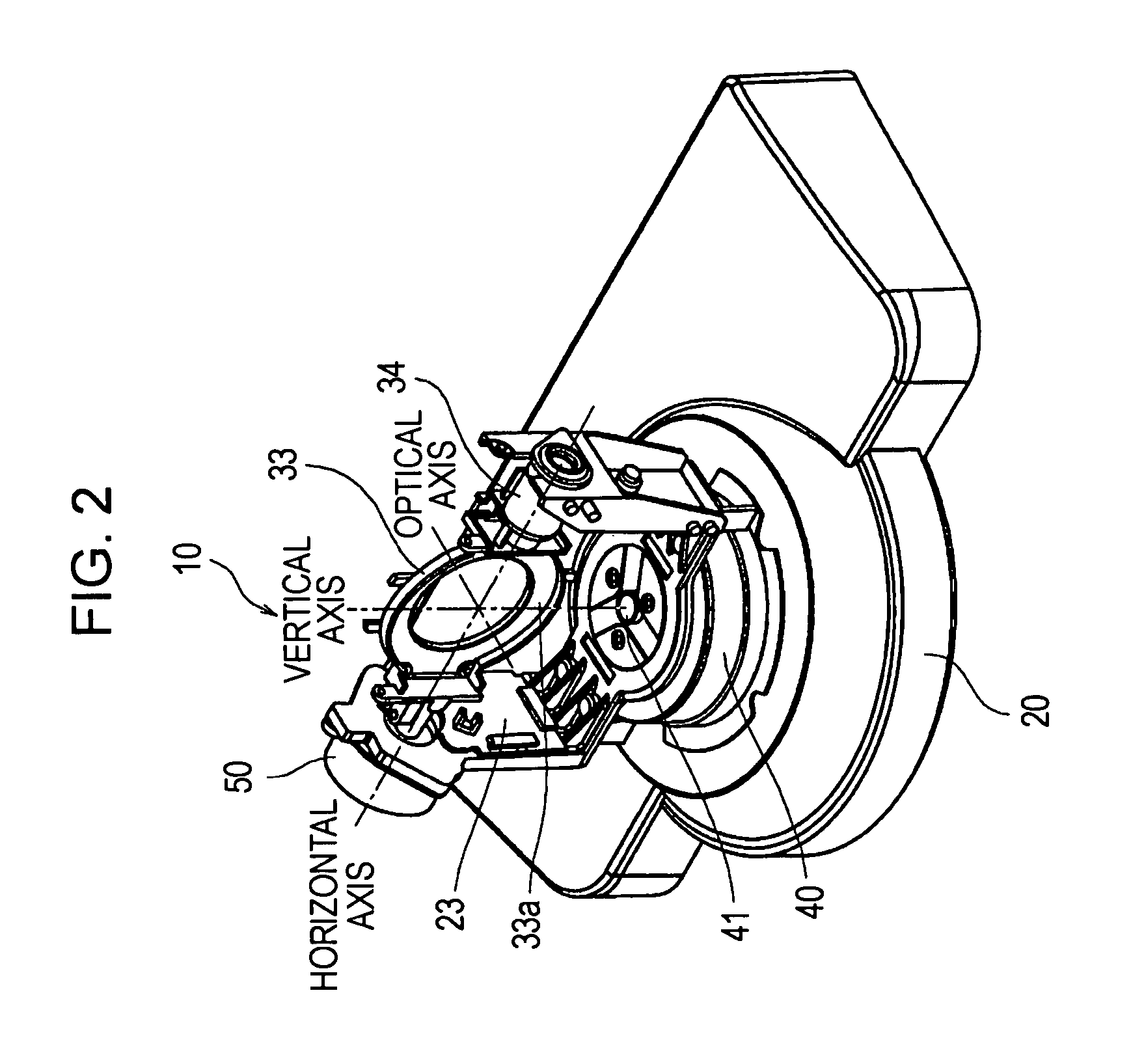

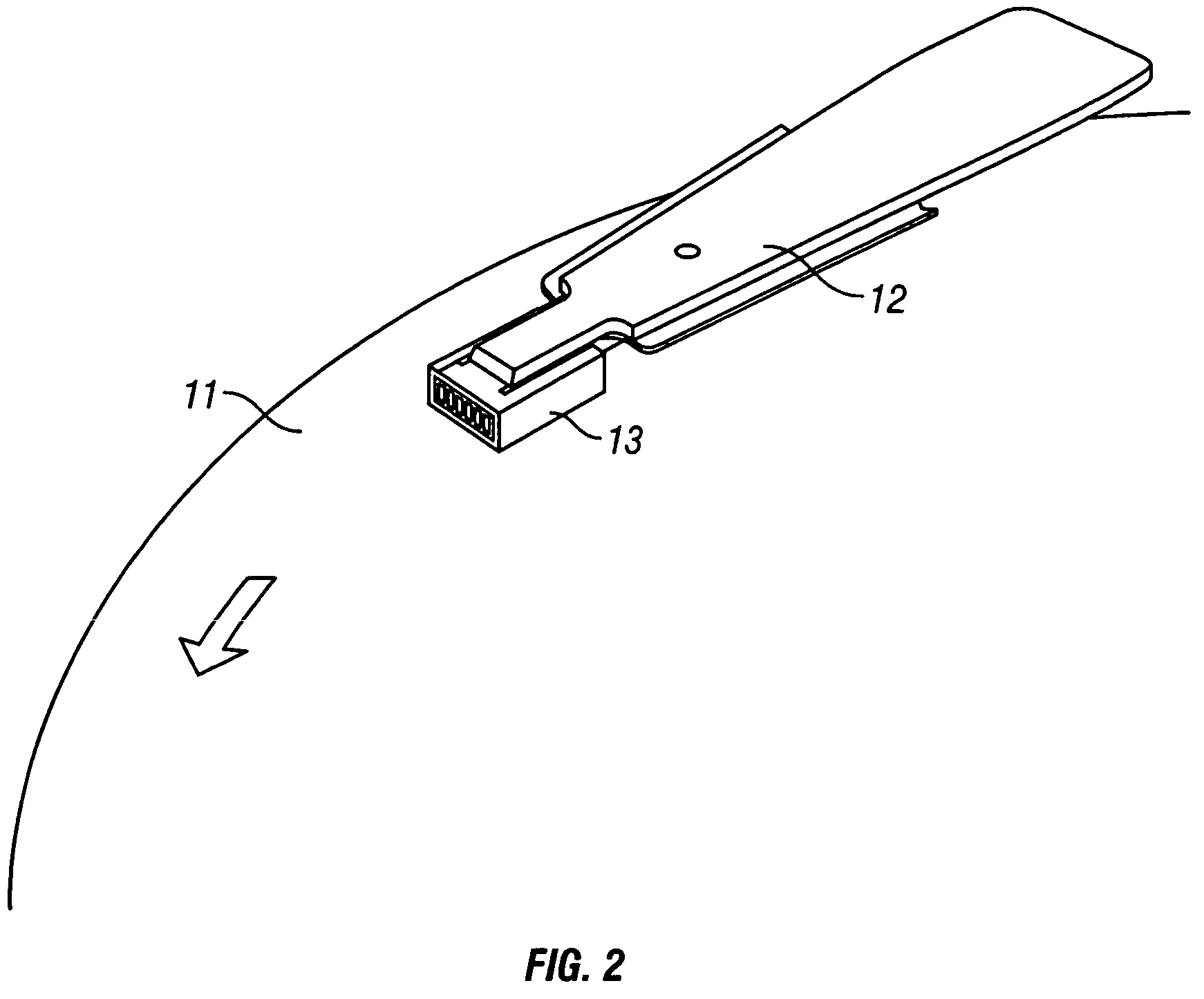

Image pickup apparatus with rotary lens barrel

ActiveUS20080068493A1Easily arrangePrevent be damageTelevision system detailsColor television detailsCamera lensEngineering

An image pickup apparatus includes a lens barrel, a hollow shaft, a base, electric wiring, and a protection member. The lens barrel has a lens and an image pickup device embedded therein. The hollow shaft is rotatable about an axis intersecting with an optical axis of the lens. The axis serves as a central axis of the hollow shaft. The base supports the lens barrel in a rotatable manner by using the hollow shaft. The electric wiring extends through the inside of the hollow shaft to electrically transmit an image pickup signal of the image pickup device. The protection member is provided in the hollow shaft so as to prevent the electric wiring from coming into contact with the hollow shaft.

Owner:SONY CORP

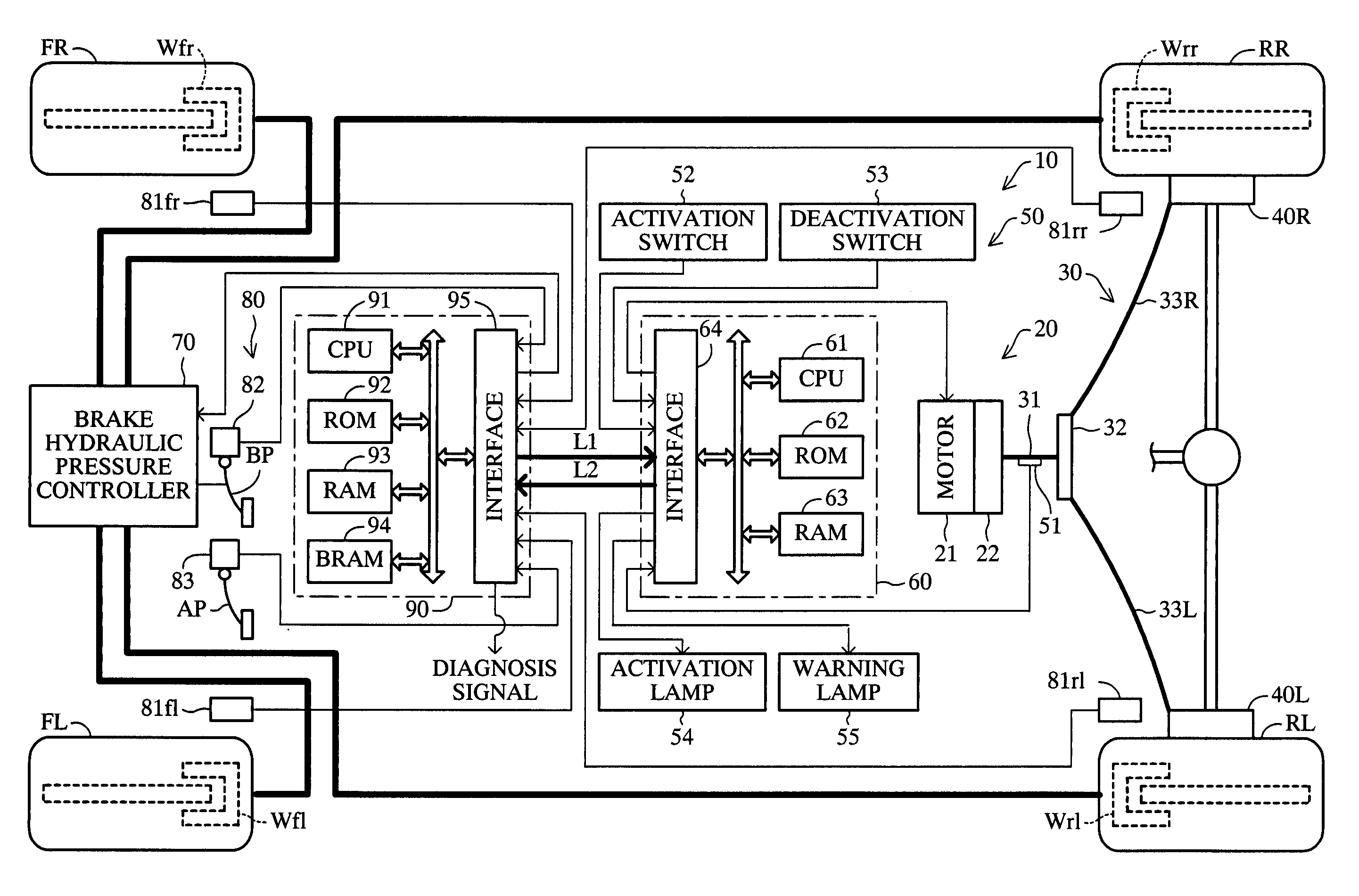

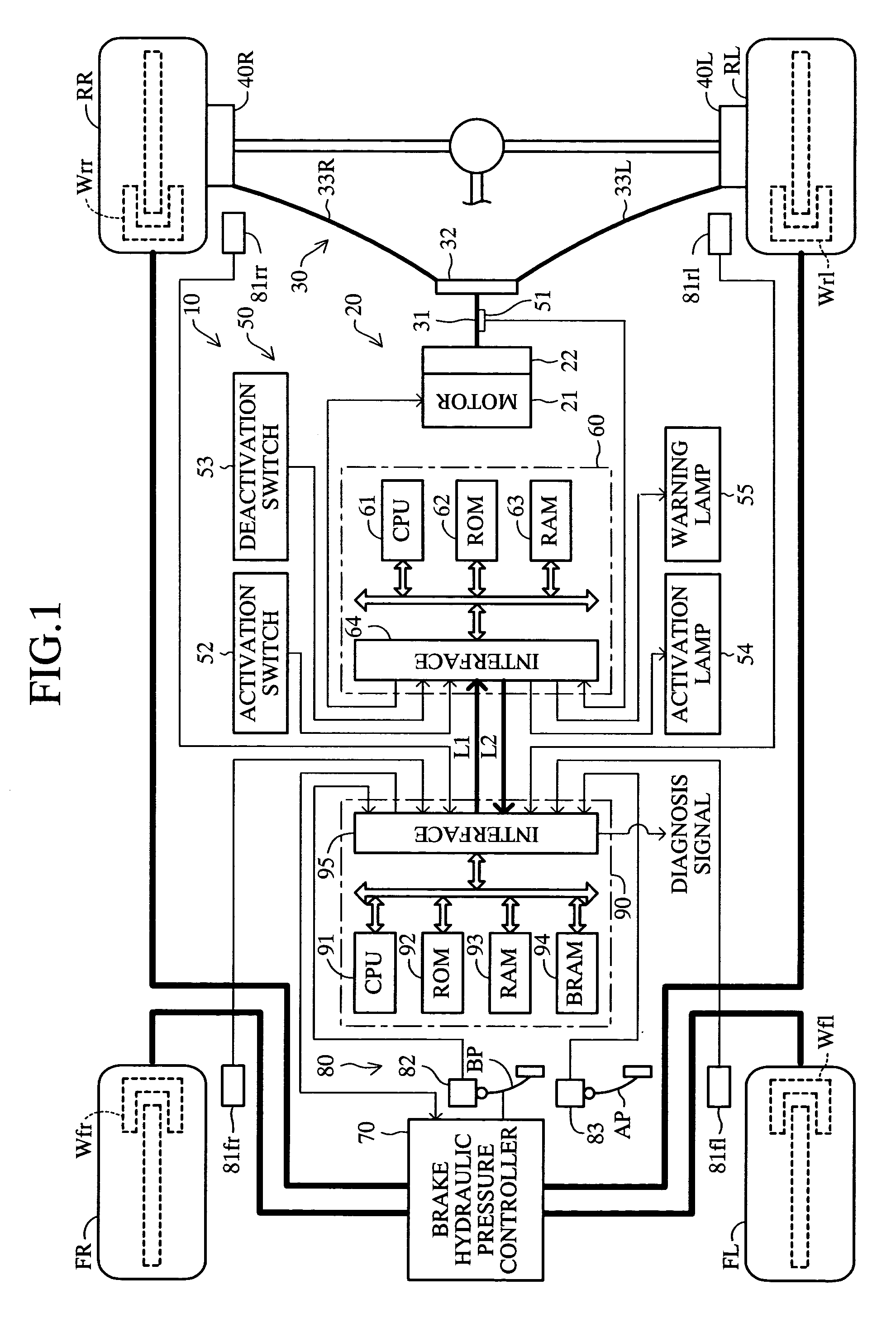

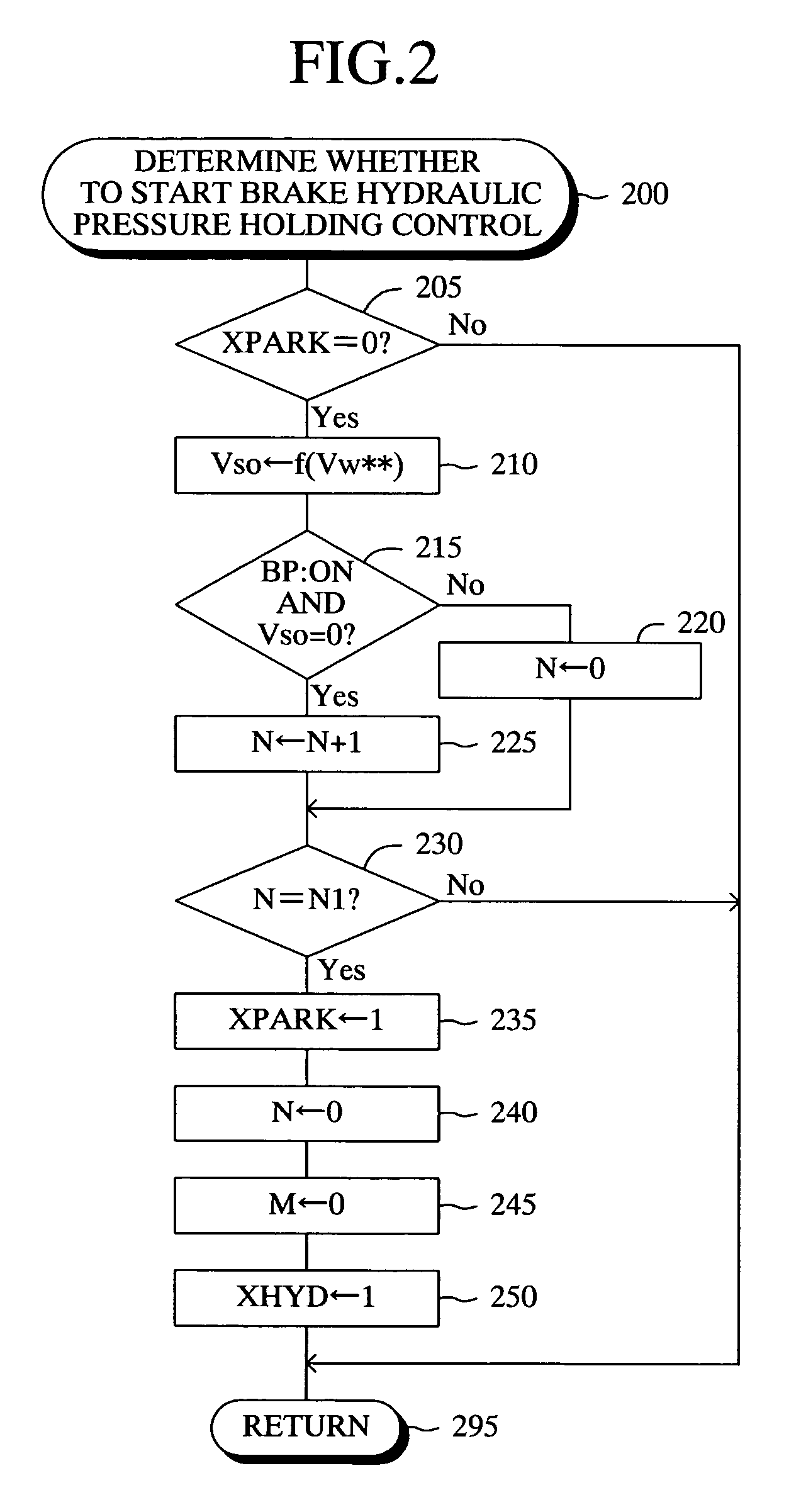

Electric parking brake apparatus

InactiveUS7121633B2Simple configurationSmall sizeBraking action transmissionAutomatic initiationsElectric parking brakeAutomatic control

An electric parking brake control unit of an electric parking brake apparatus has an input section for receiving signals for performing automatic activation and deactivation, but does not have a determination function and a circuit for inputting signals from various sensors, which are necessary to determine whether to start the automatic activation / deactivation control. Therefore, when used in a vehicle which does not require an automatic control function and requires only a manual control function, the electric parking brake control unit can be used solely, with no signal line connected to the input section. When used in a vehicle which requires both the automatic control function and the manual control function, the input section is connected to a second control unit that can output signals for performing automatic activation and deactivation, whereby the electric parking brake control unit operates in cooperation with the second control unit.

Owner:ADVICS CO LTD

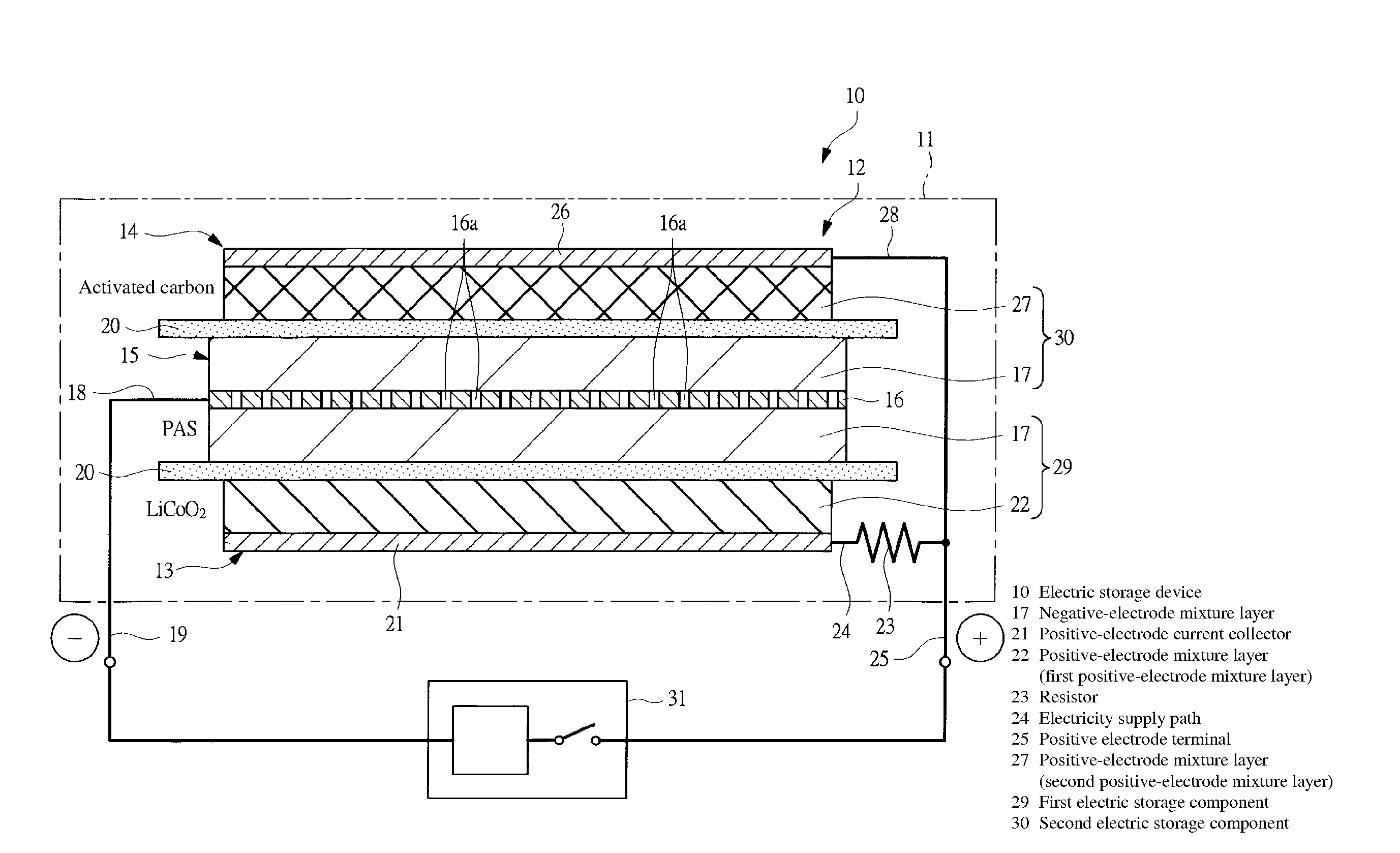

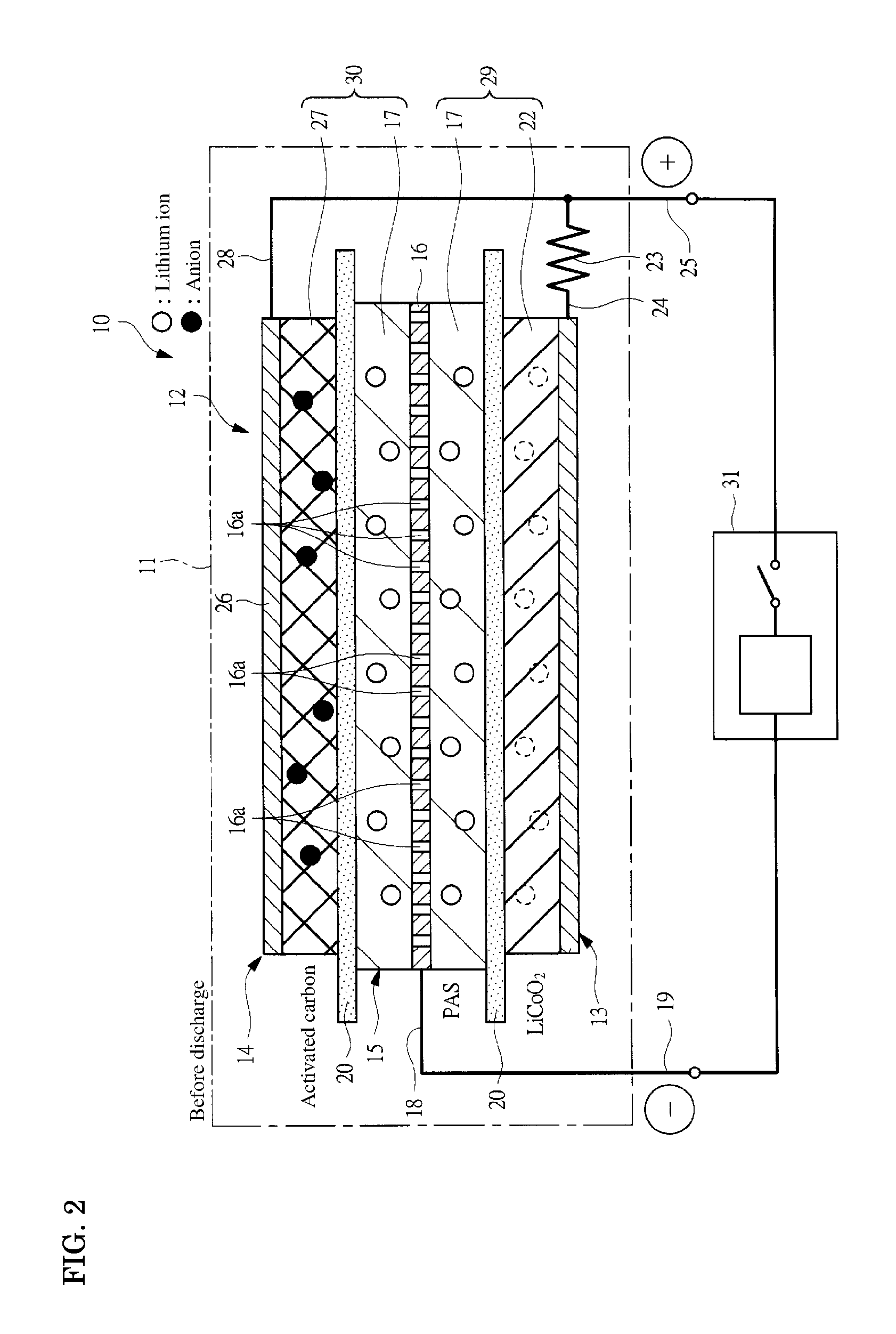

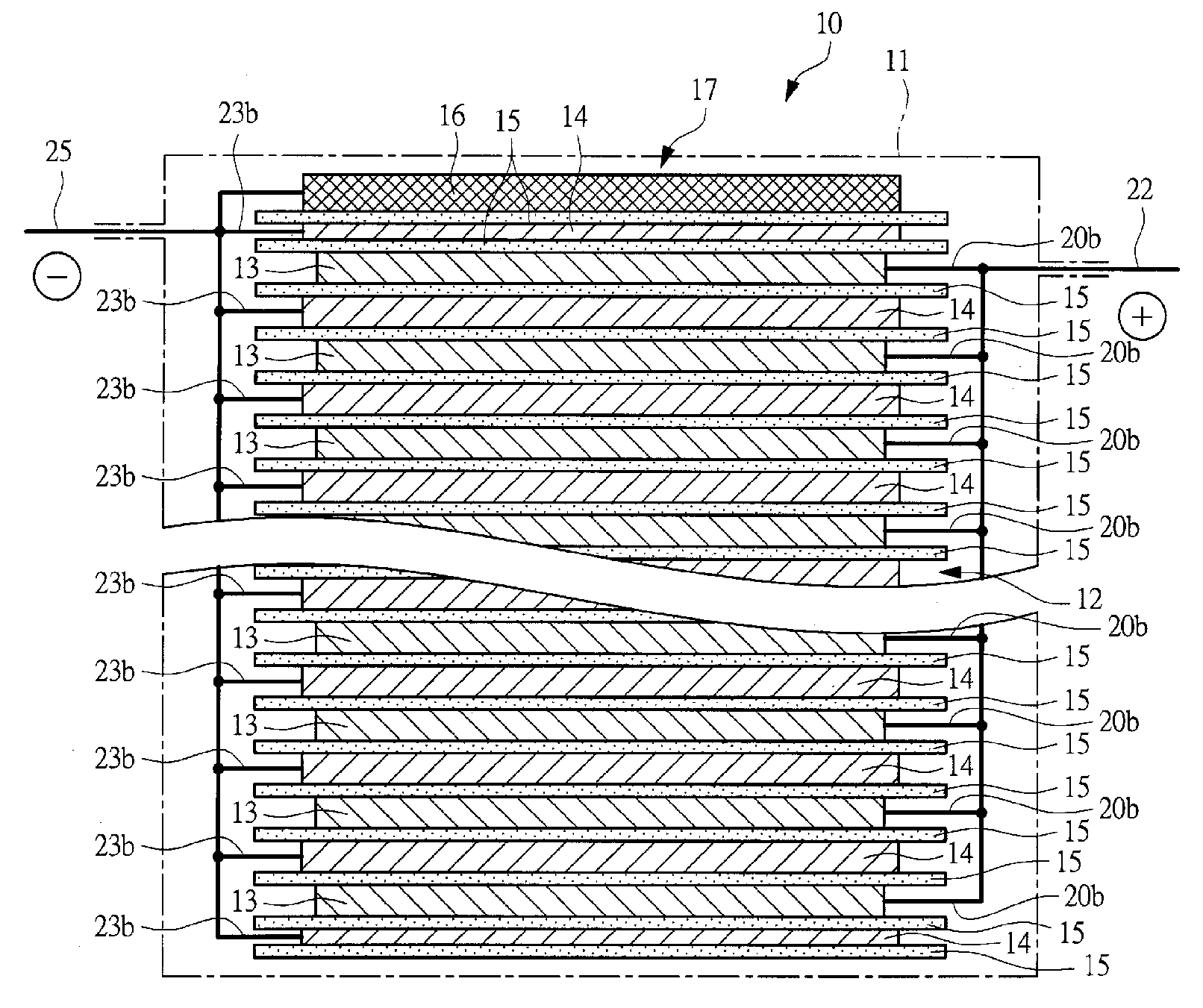

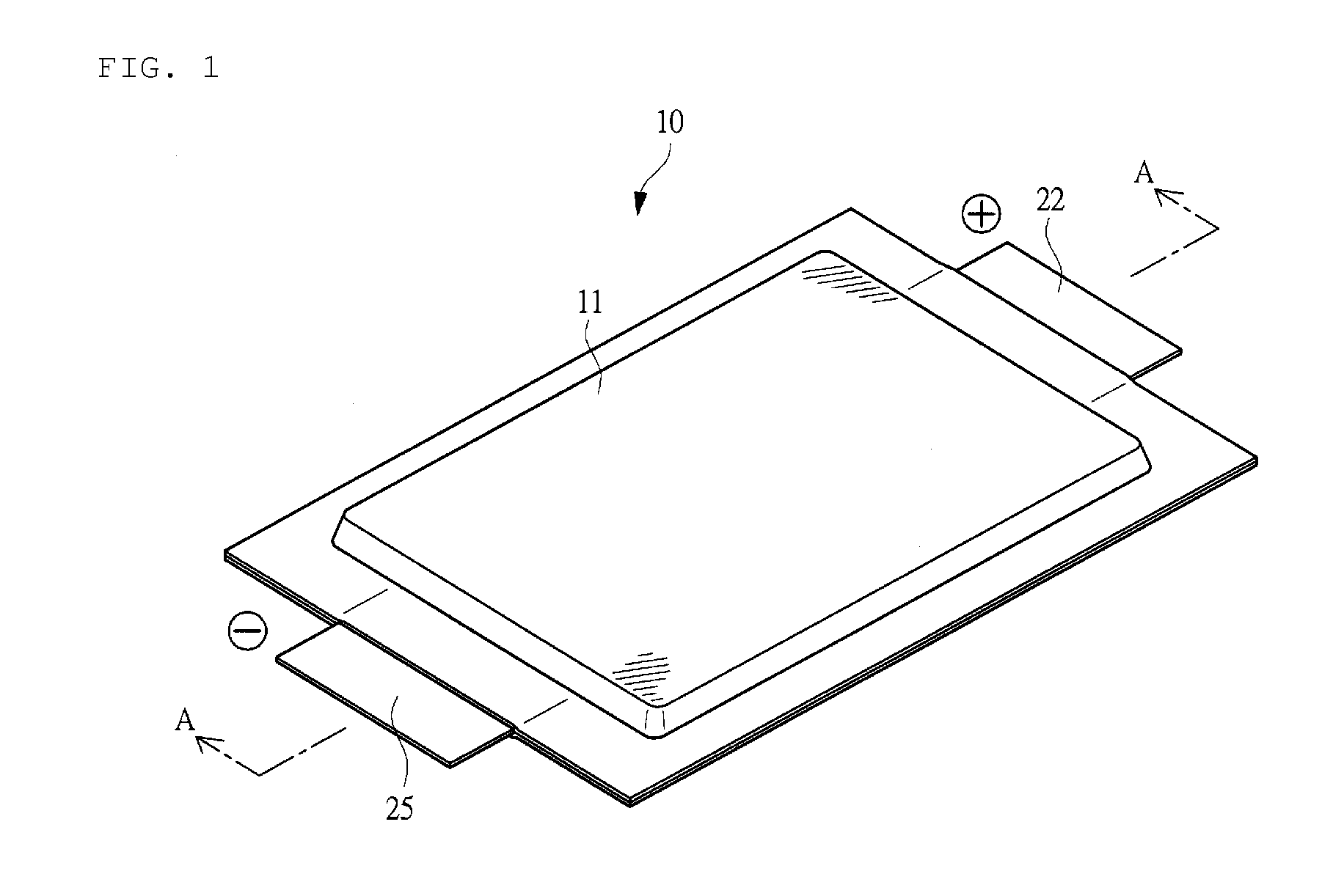

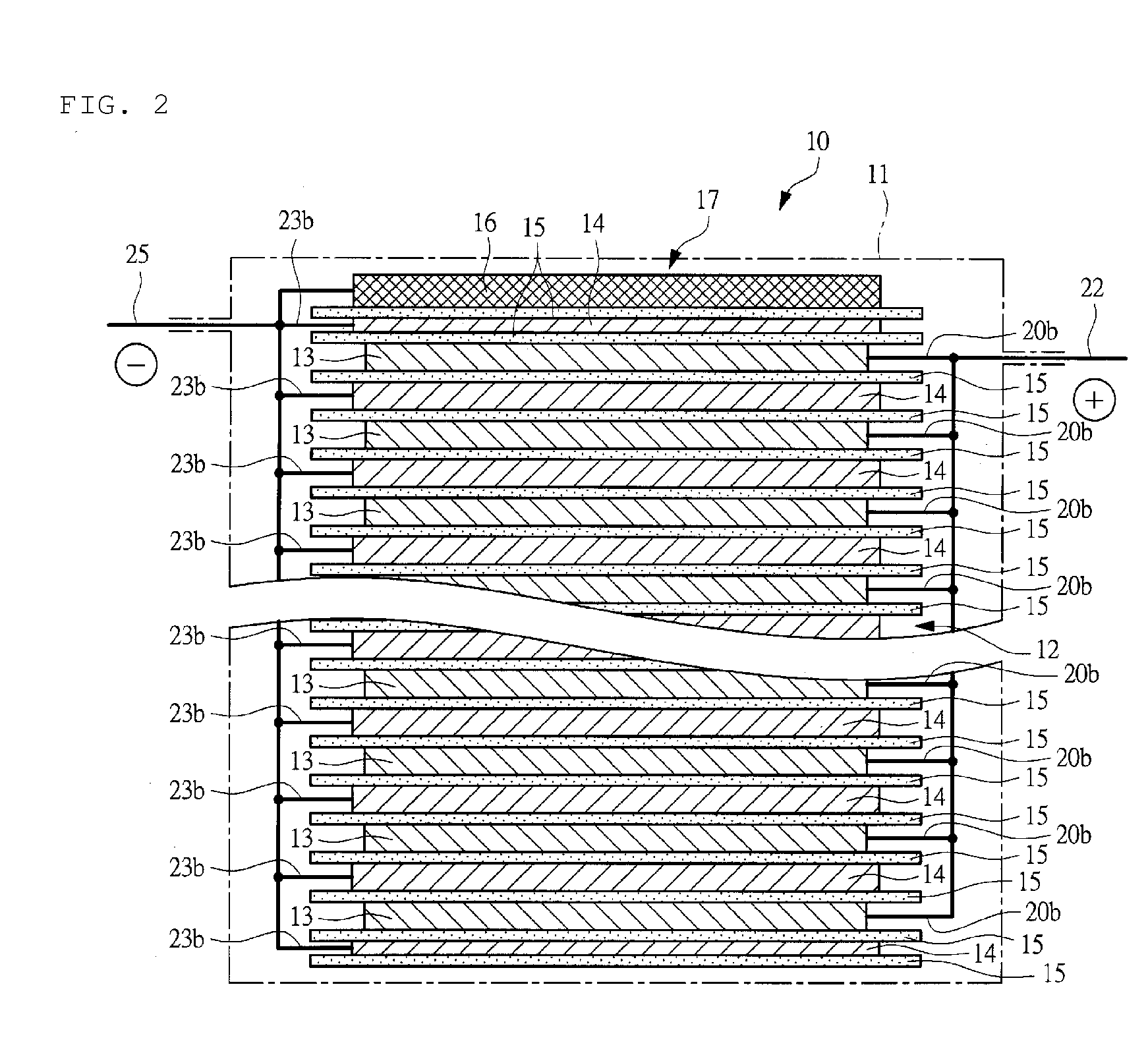

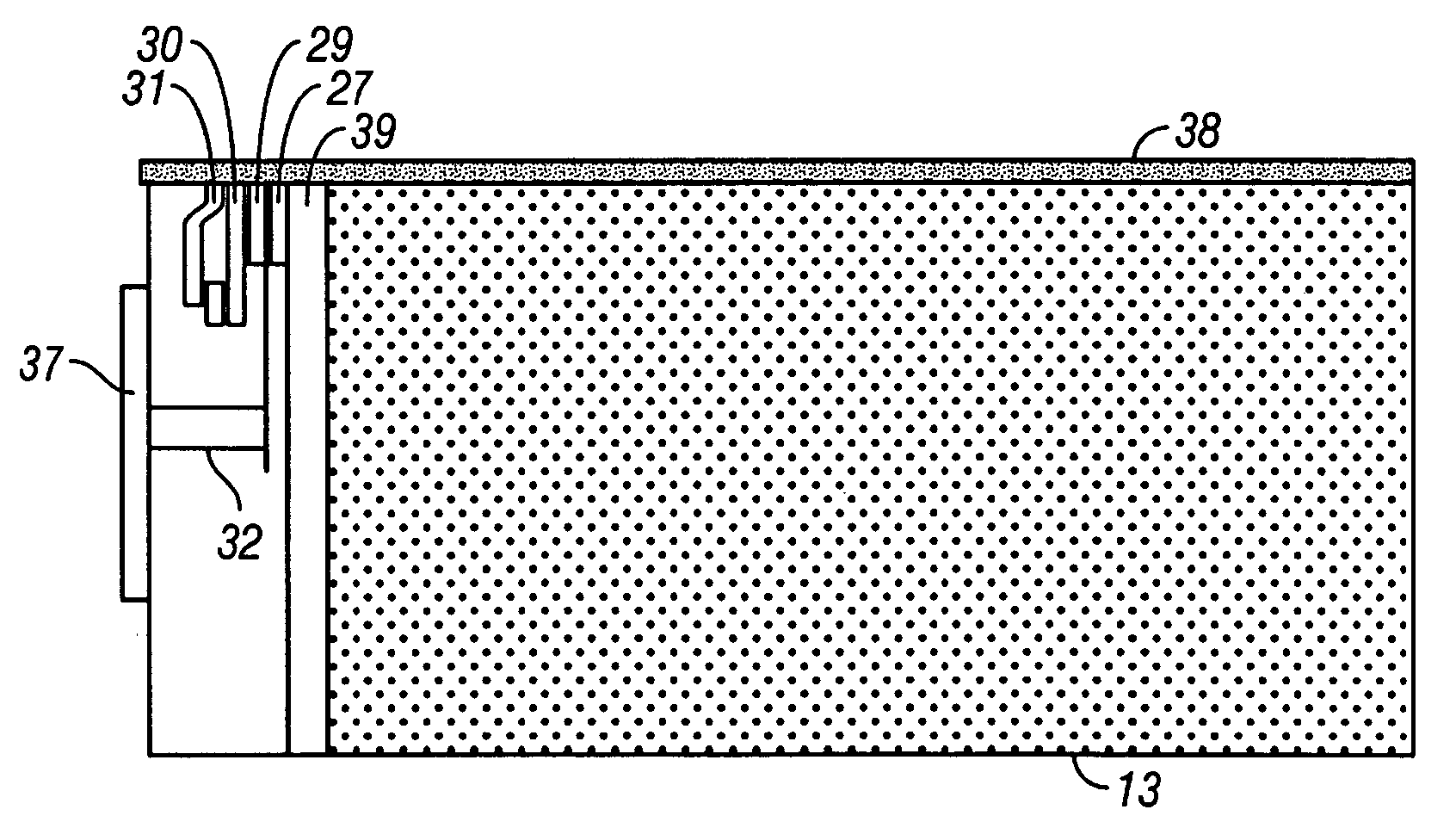

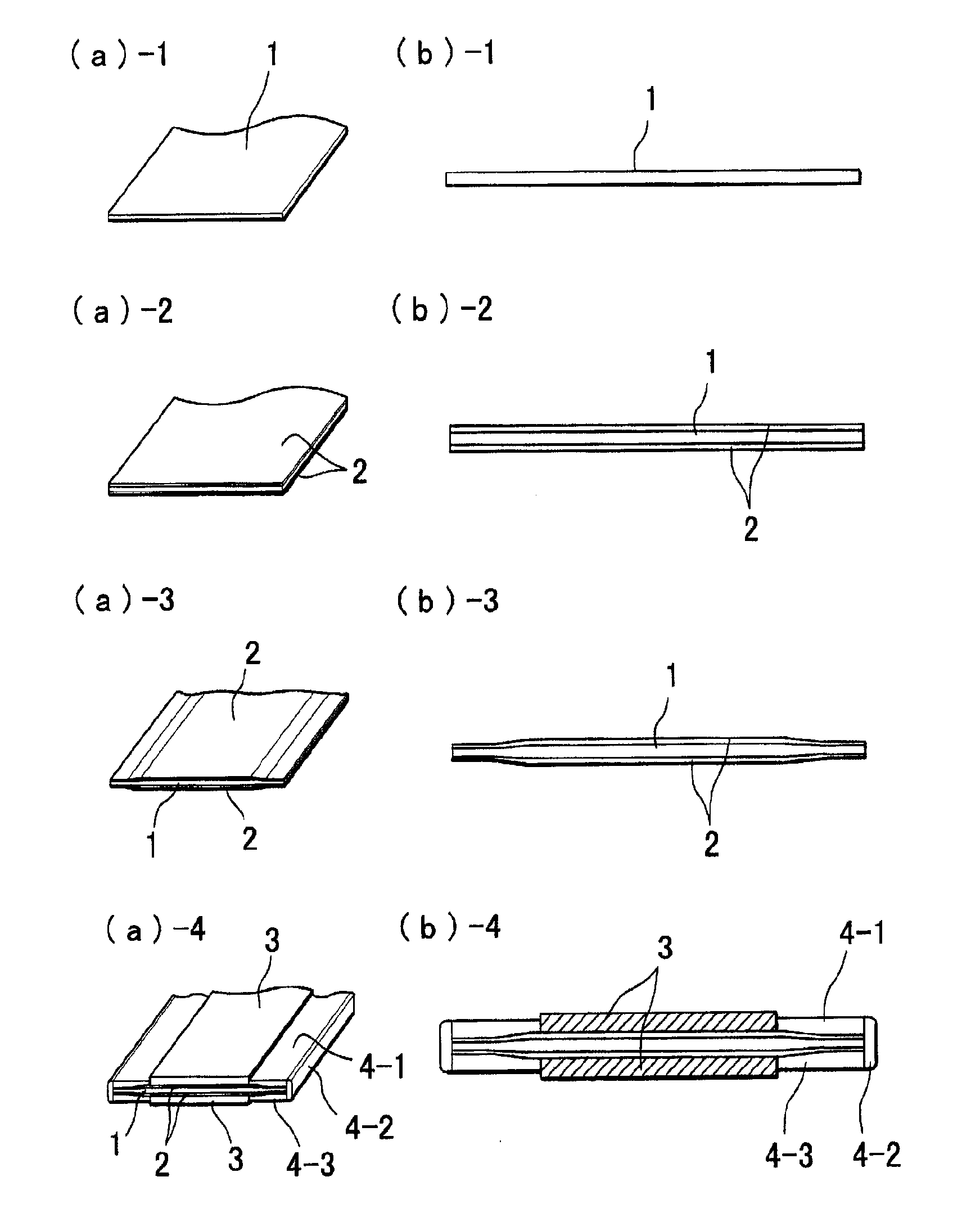

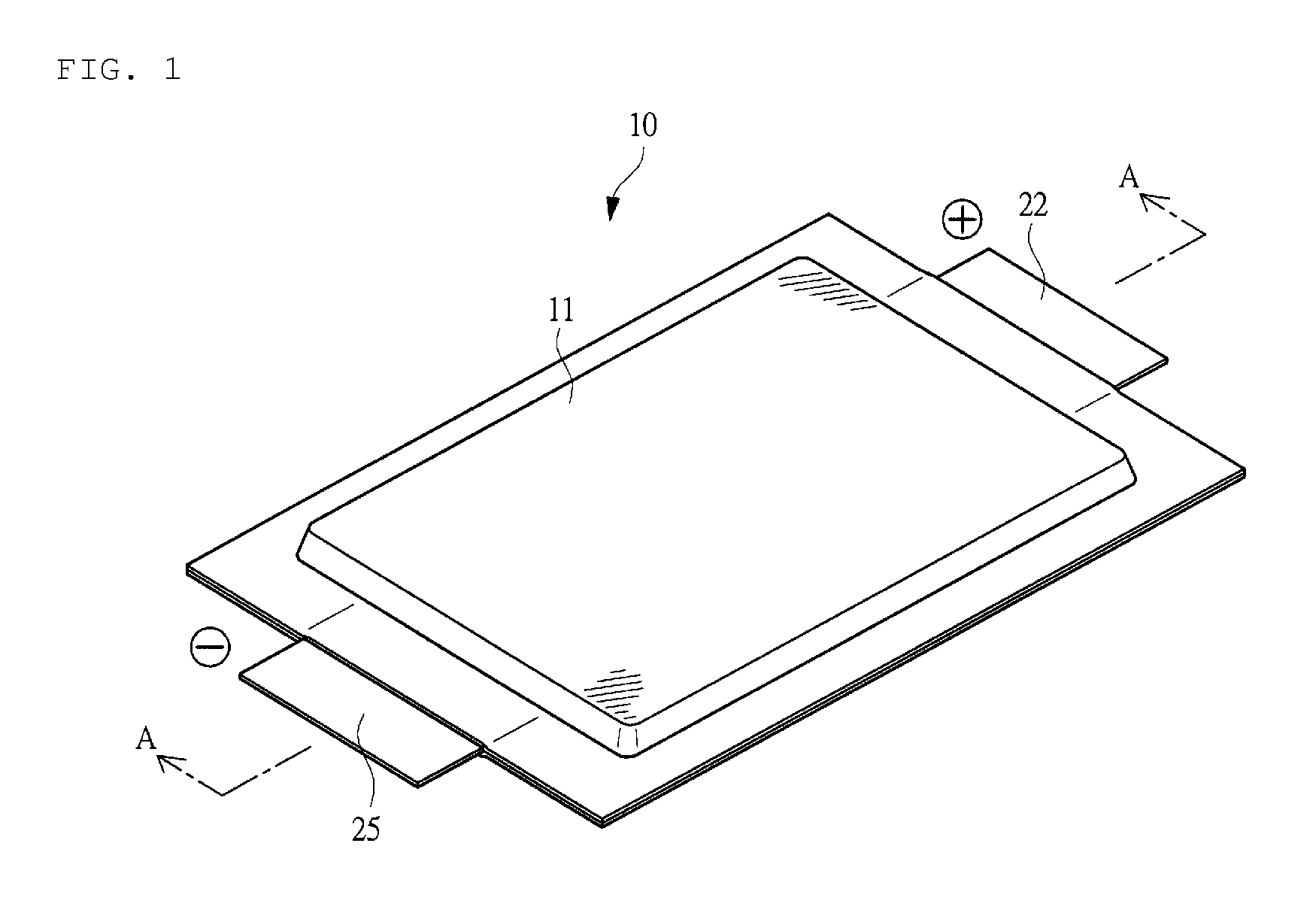

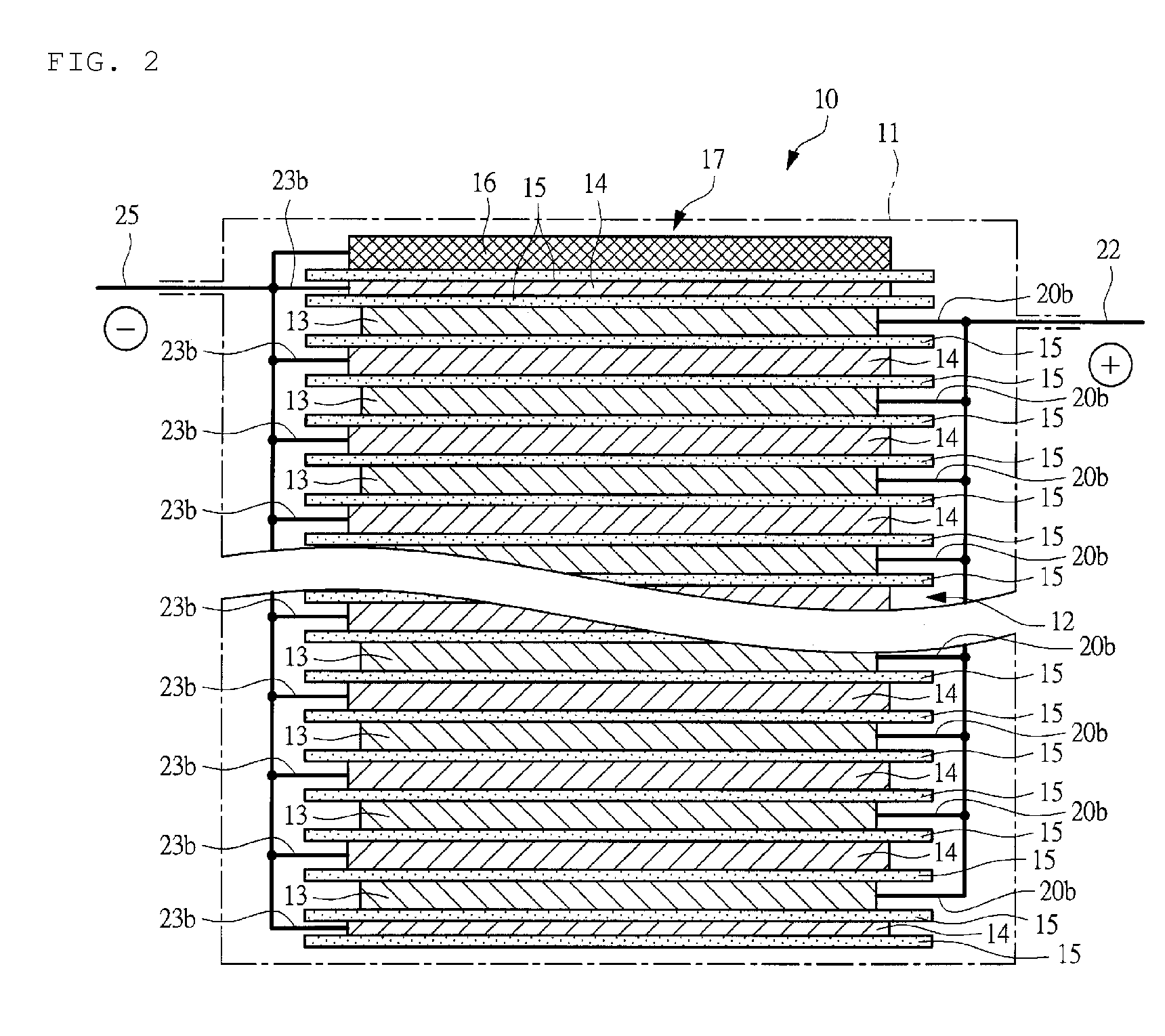

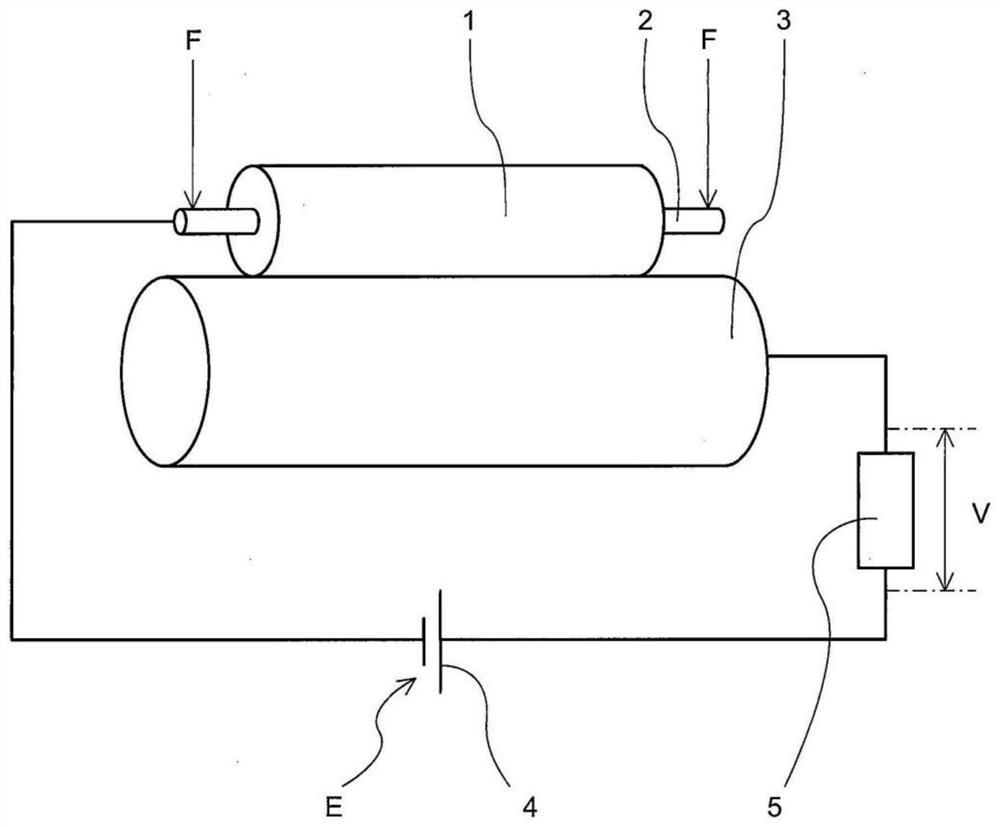

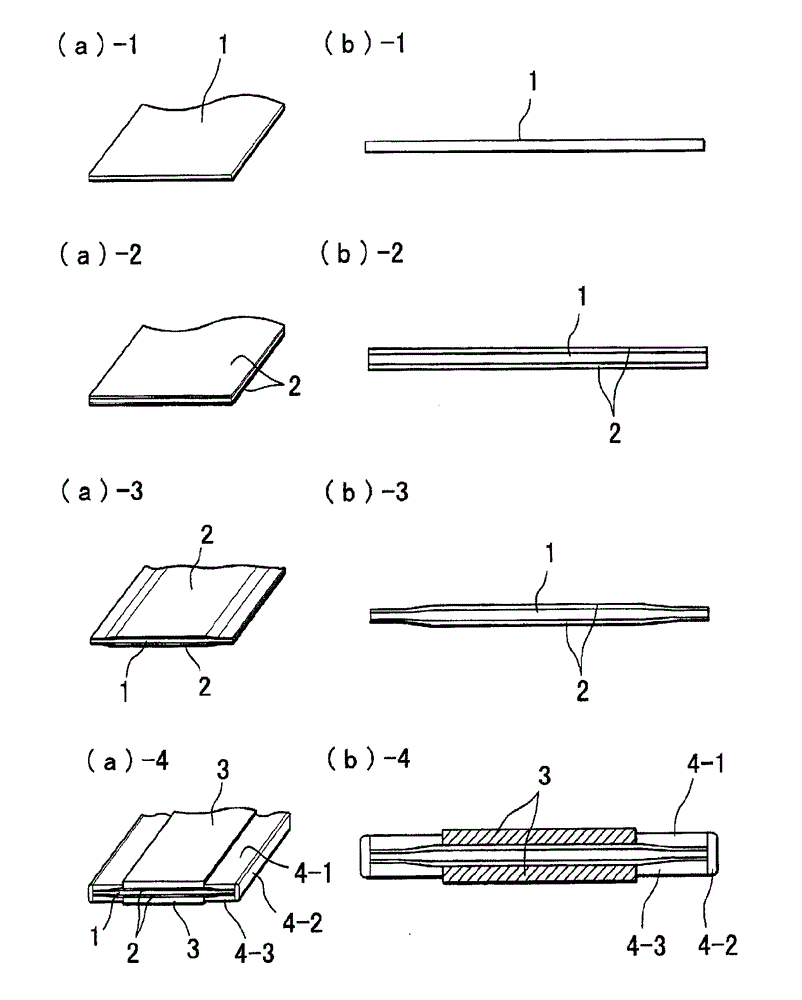

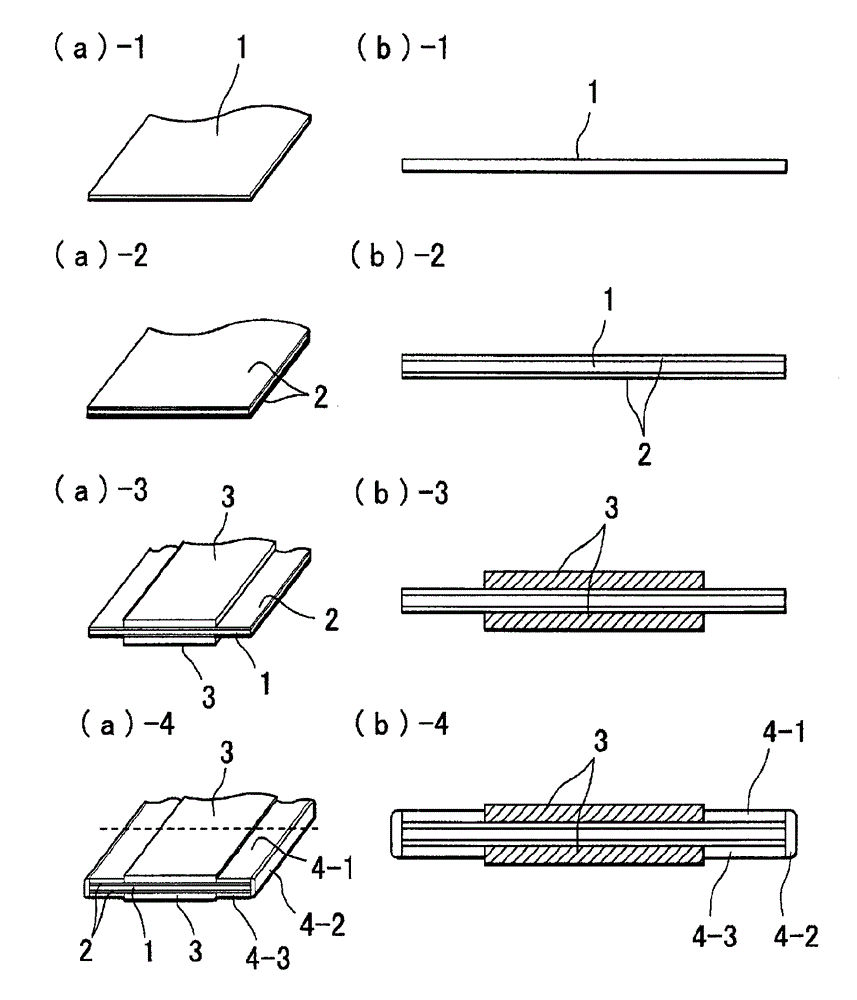

Electric storage device

InactiveUS20090123823A1Increase productionLarge capacityCapacitor and primary/secondary cellsFinal product manufactureLithiumElectricity

An electric storage device 10 has a first electric storage component 29 and a second electric storage component 30. The first component 29 and the second component 30 are connected in parallel. A positive-electrode mixture layer 22 contains a lithium cobaltate to increase a capacity. A positive-electrode mixture layer 27 contains an activated carbon to increase an output. A current collector 16 having through holes 16a is provided between the layers 22 and 27. A positive electrode terminal 25 is connected to a positive-electrode current collector 21 of the first component 29 through an electricity supply path 24 provided with a resistor 23. By this configuration, the electric current flowing through the first electric storage component 29 can be restricted when the device is charged or discharged with high current.

Owner:SUBARU CORP

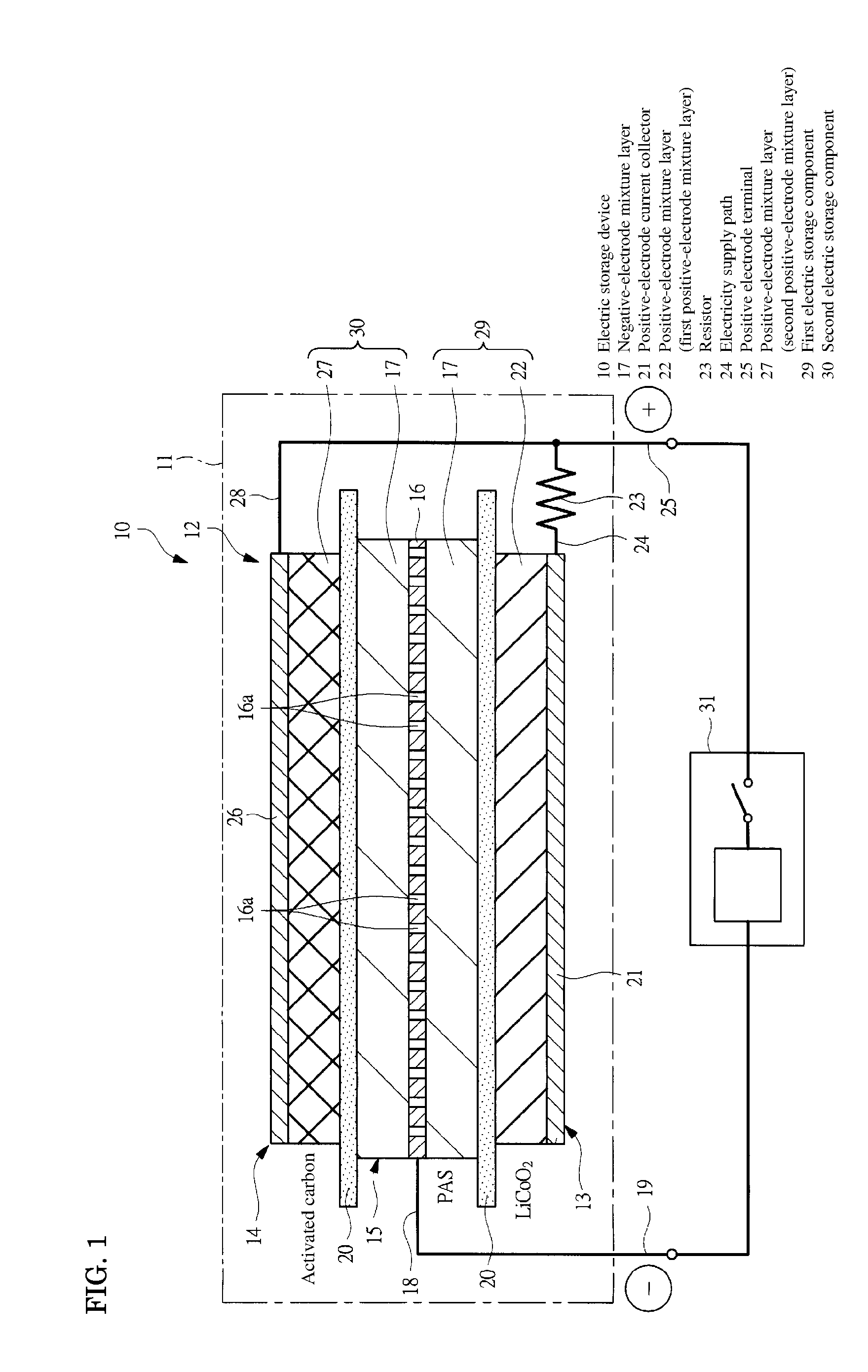

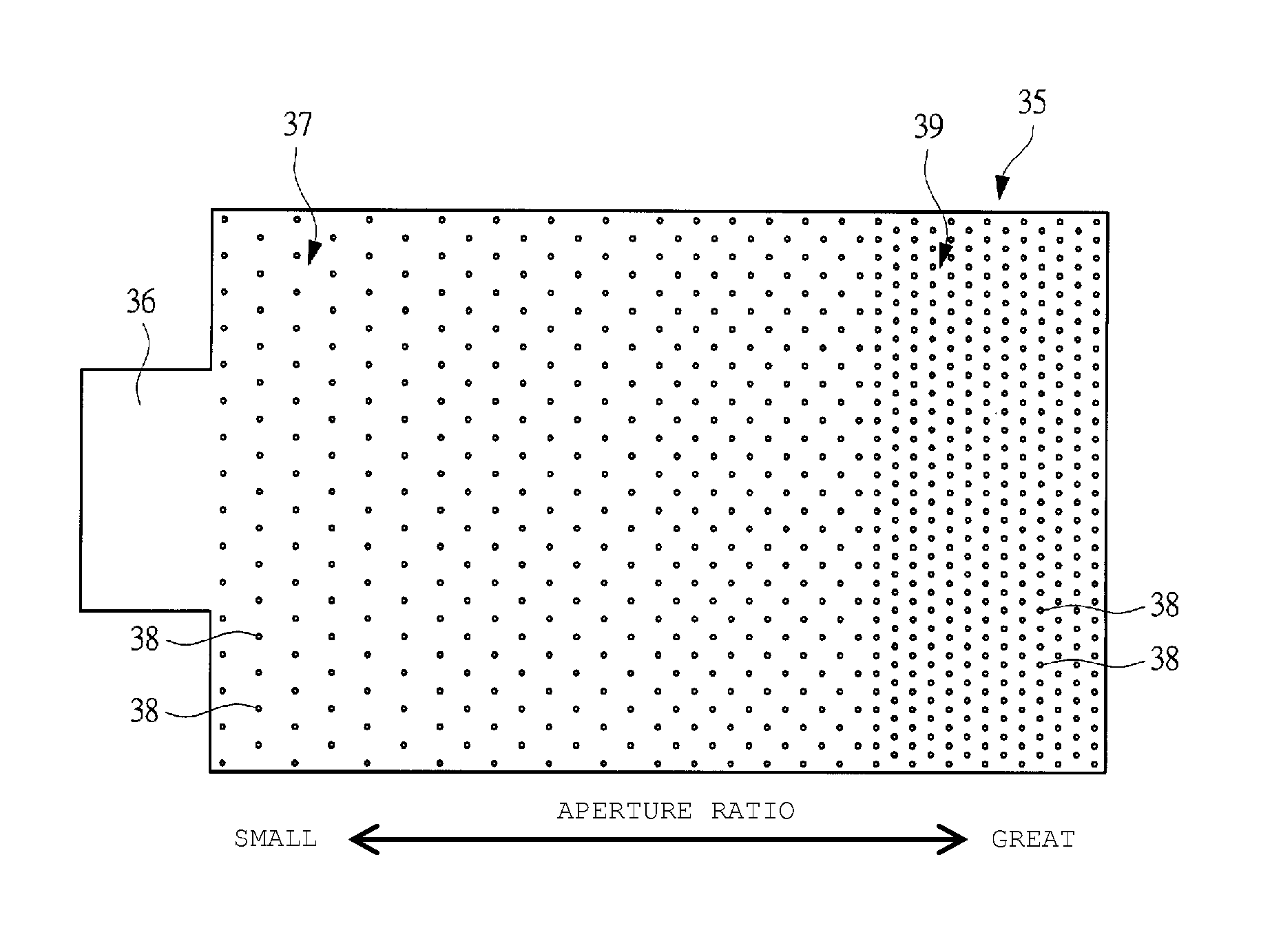

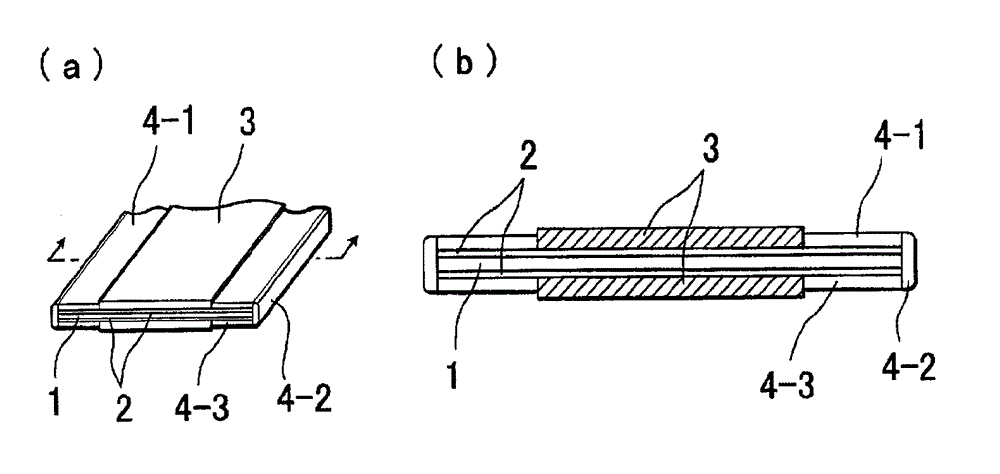

Electric storage device

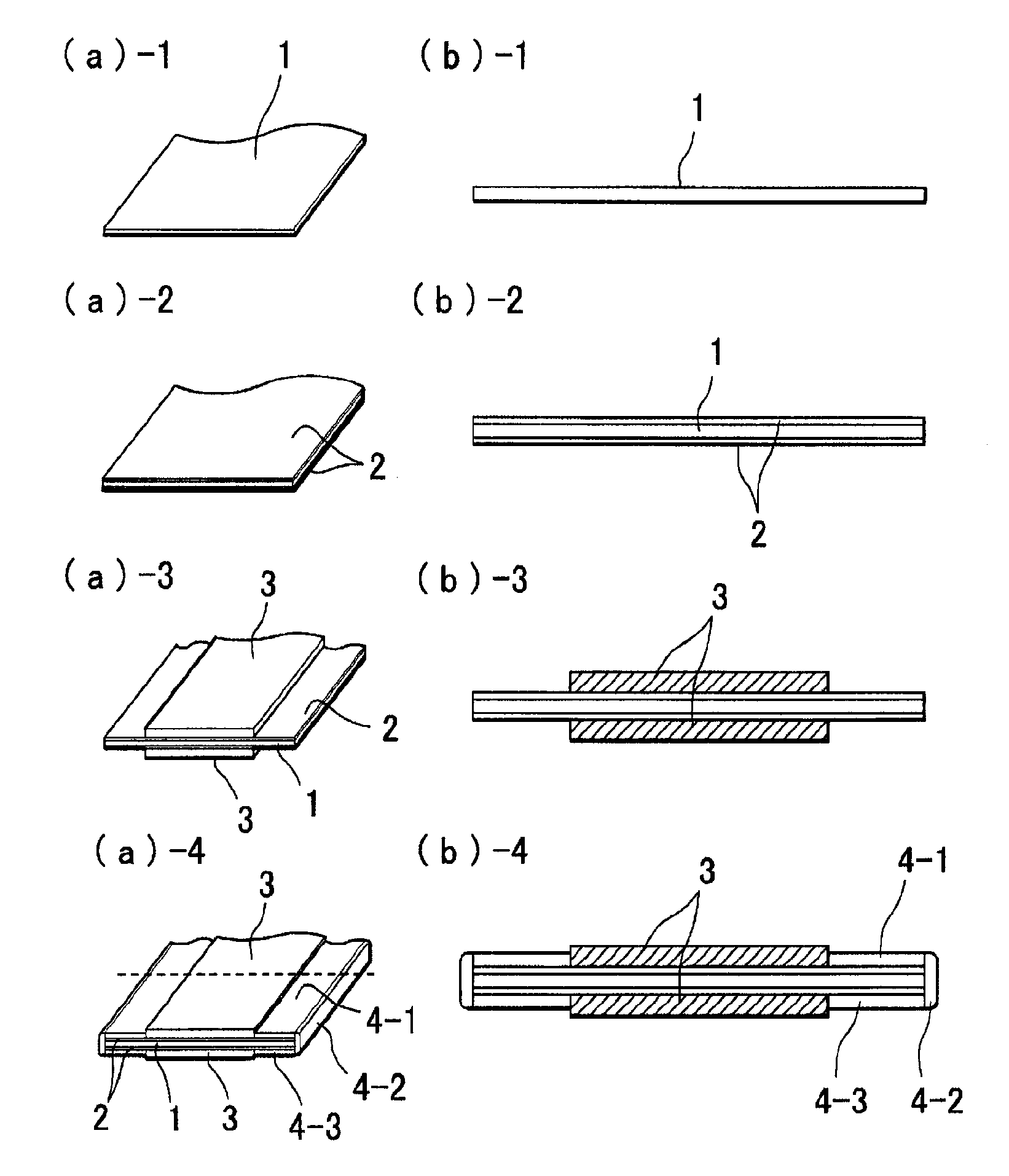

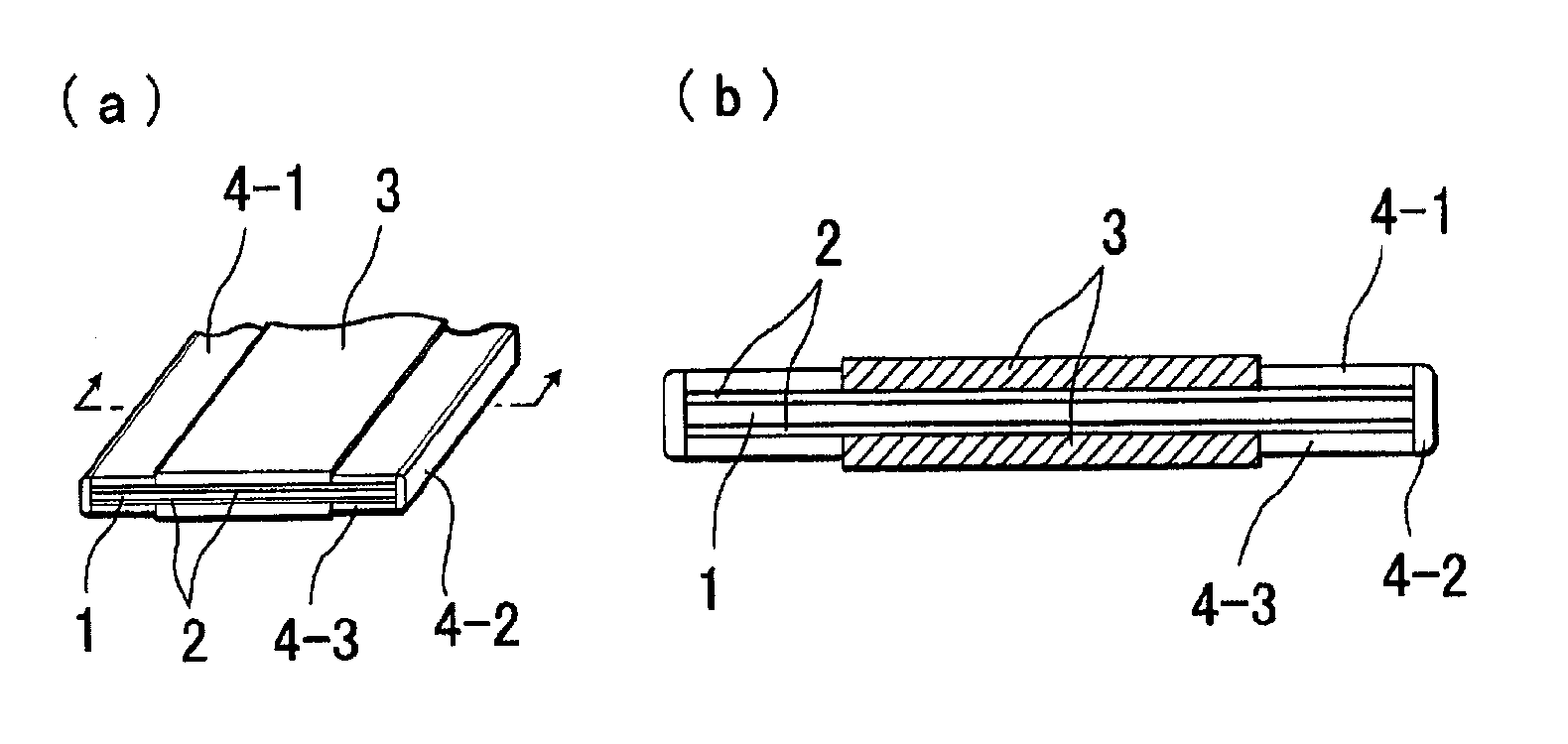

ActiveUS20100035150A1Improve electrical durabilityIncreased durabilityNon-aqueous electrolyte accumulatorsLarge-sized flat cells/batteriesElectricityPermeation

An electrode laminate unit of an electric storage device includes positive electrodes, negative electrodes and a lithium electrode connected to the negative electrode. When an electrolyte solution is injected into the electric storage device, lithium ions are emitted from the lithium electrode to the negative electrode. A positive and a negative electrode current collector have through-holes that guide the lithium ions in the laminating direction. The aperture ratio of the through-holes at the edge parts where the electrolyte solution is easy to be permeated is set to be smaller than the aperture ratio at central parts in order to suppress the permeation. Thus, the distribution of the electrolyte solution is made uniform, whereby the doping amount is made uniform.

Owner:SUBARU CORP

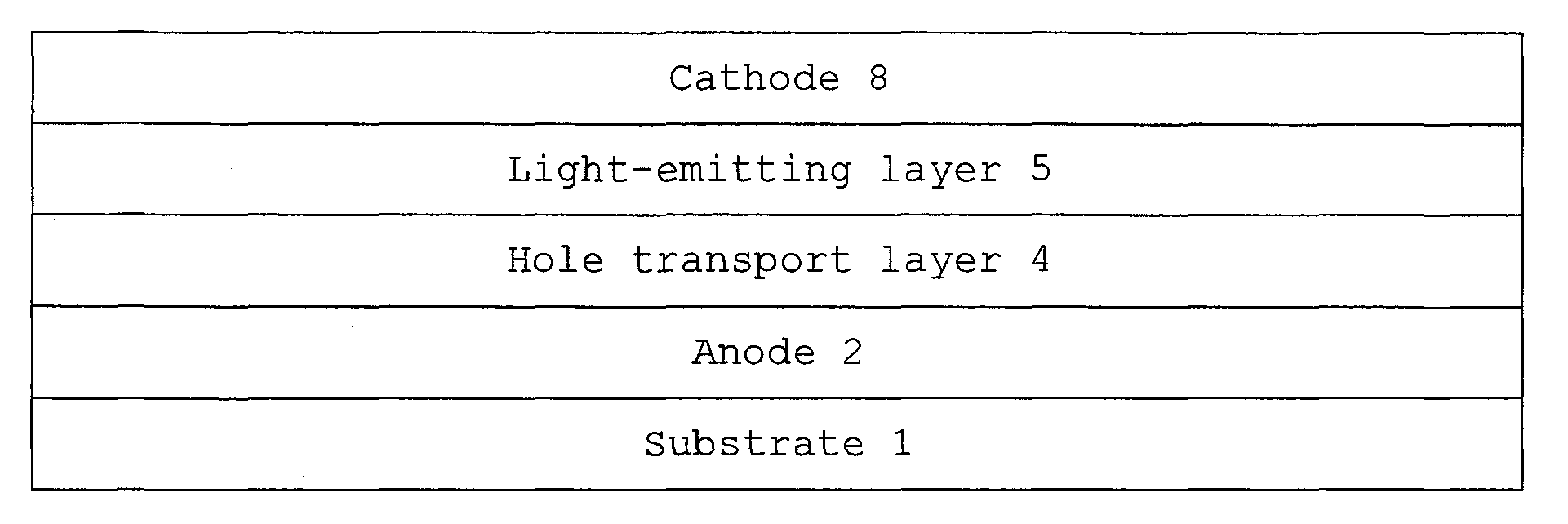

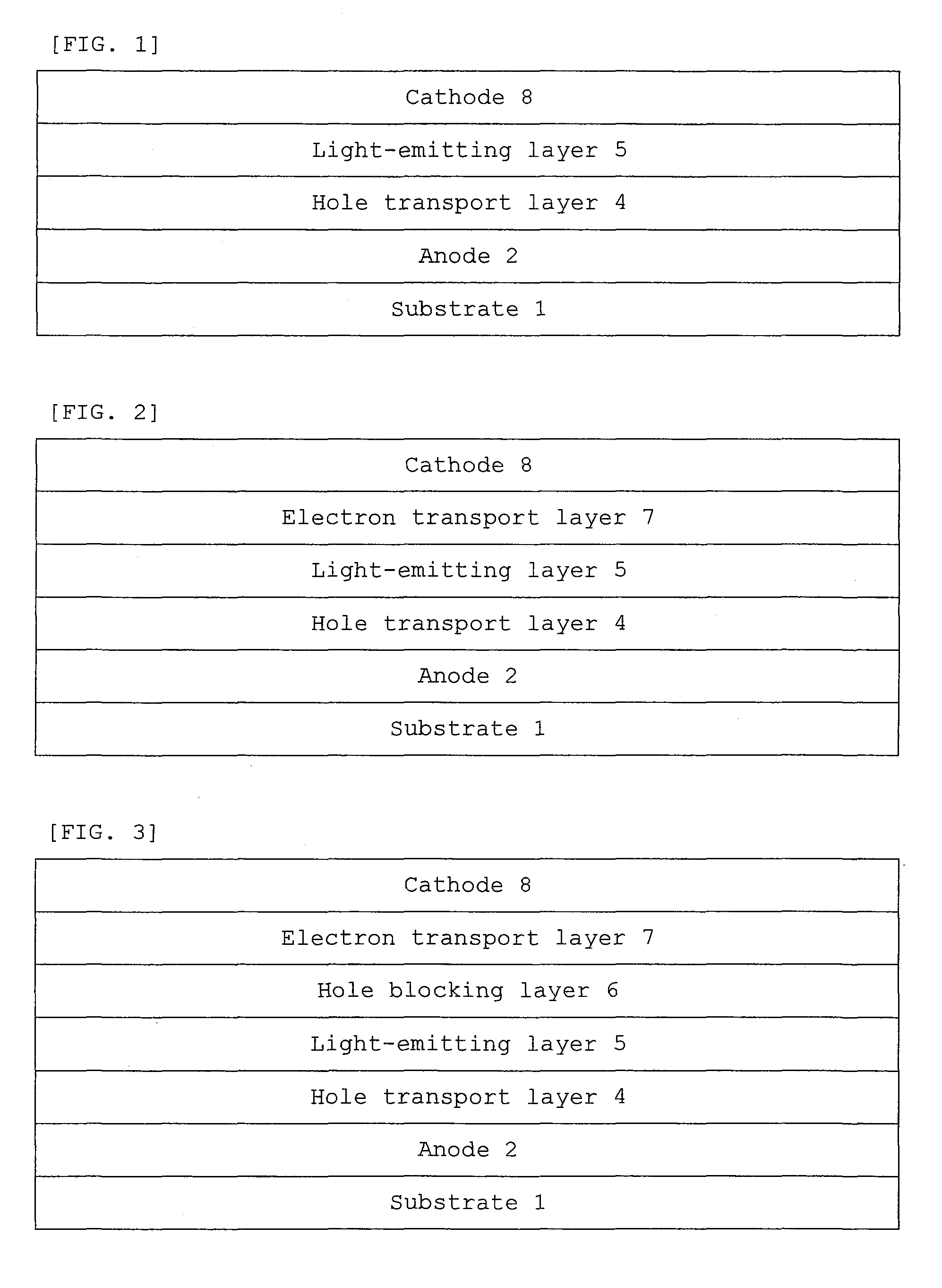

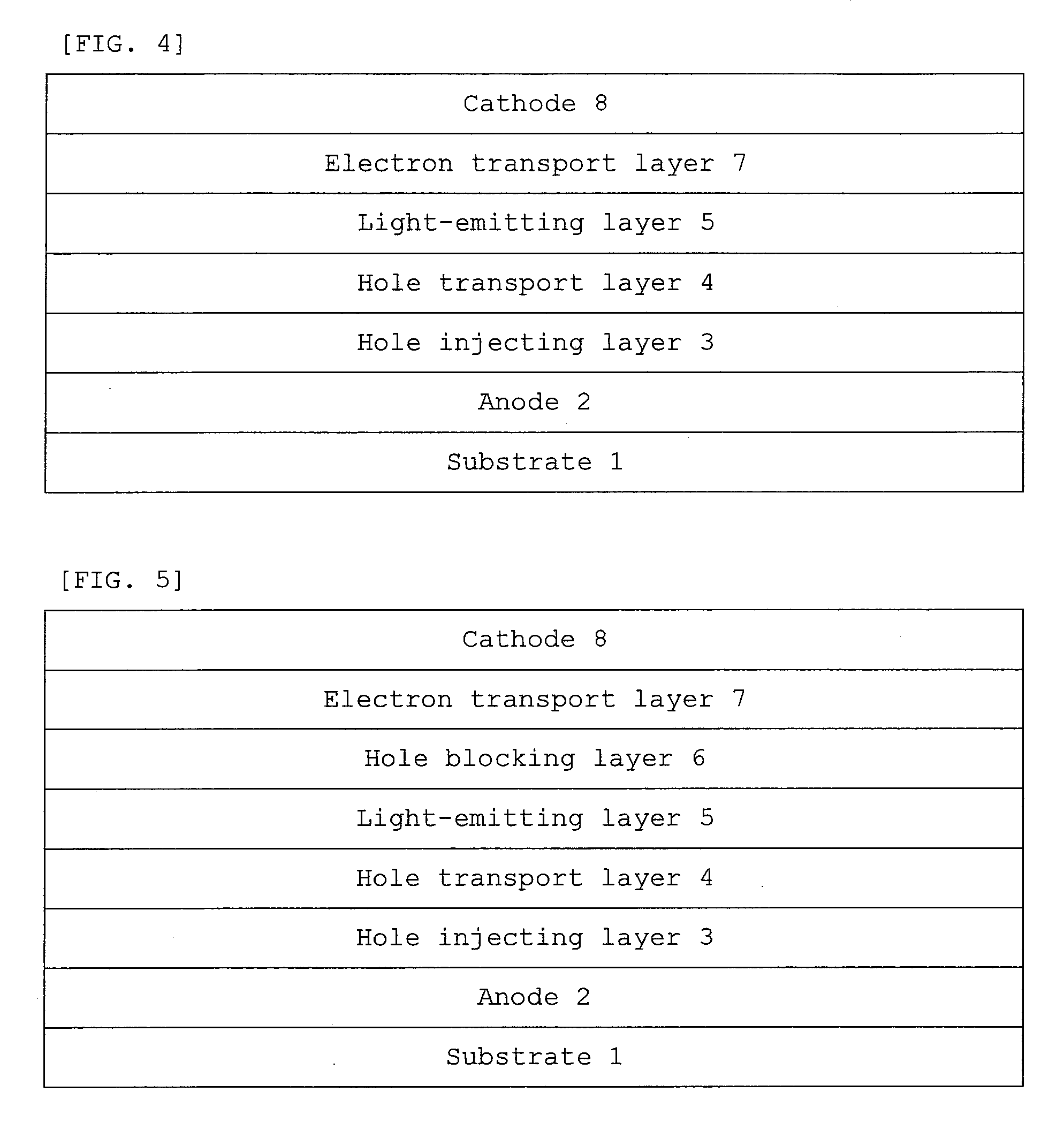

Monoamine compound, charge-transporting material, and organic electroluminescent device

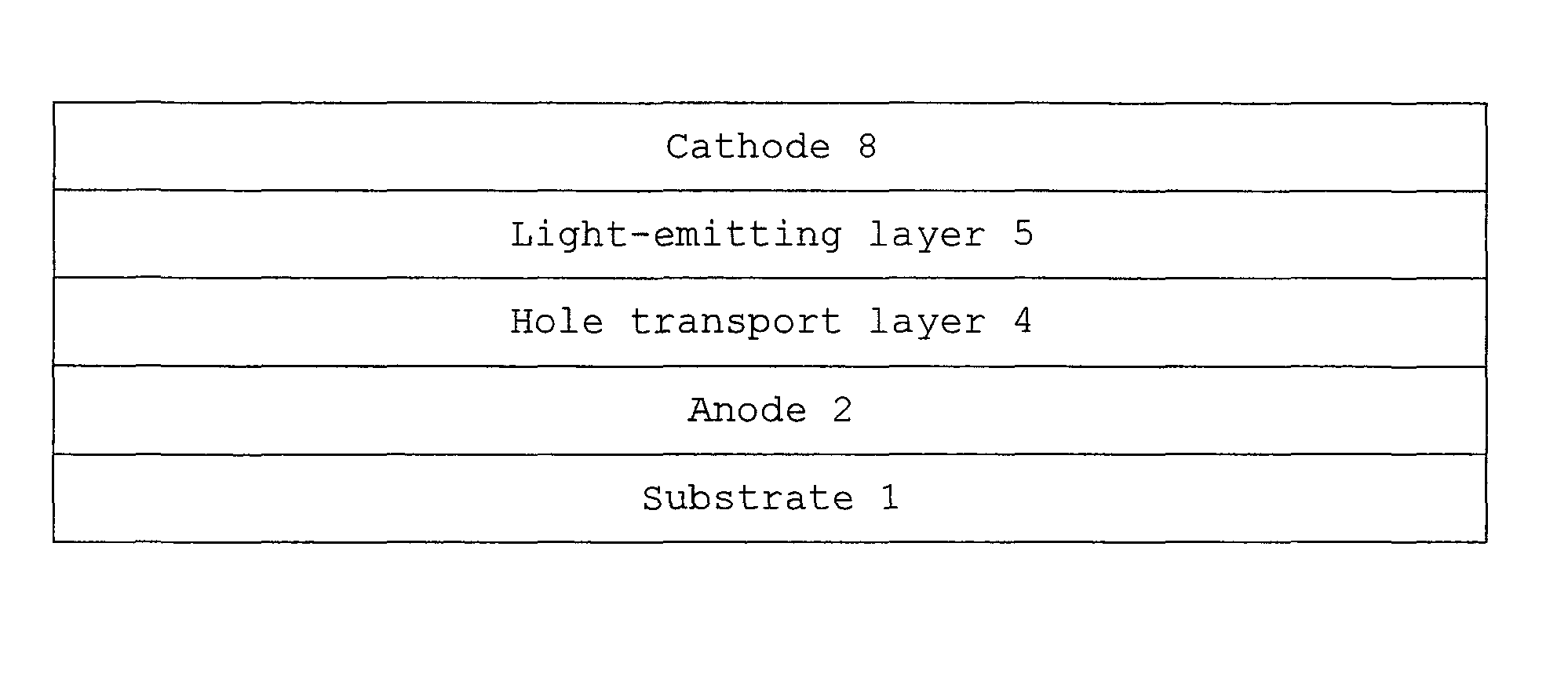

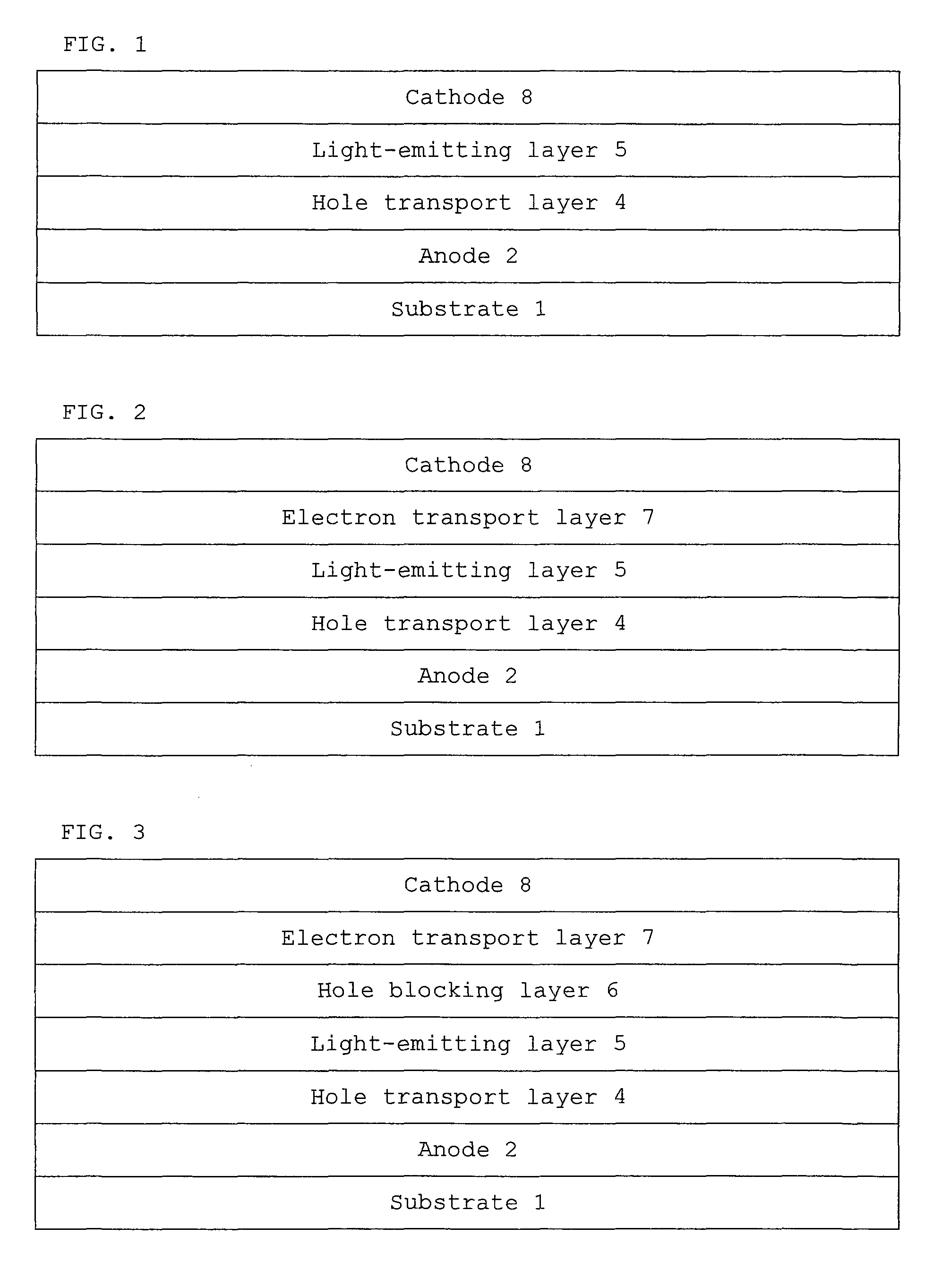

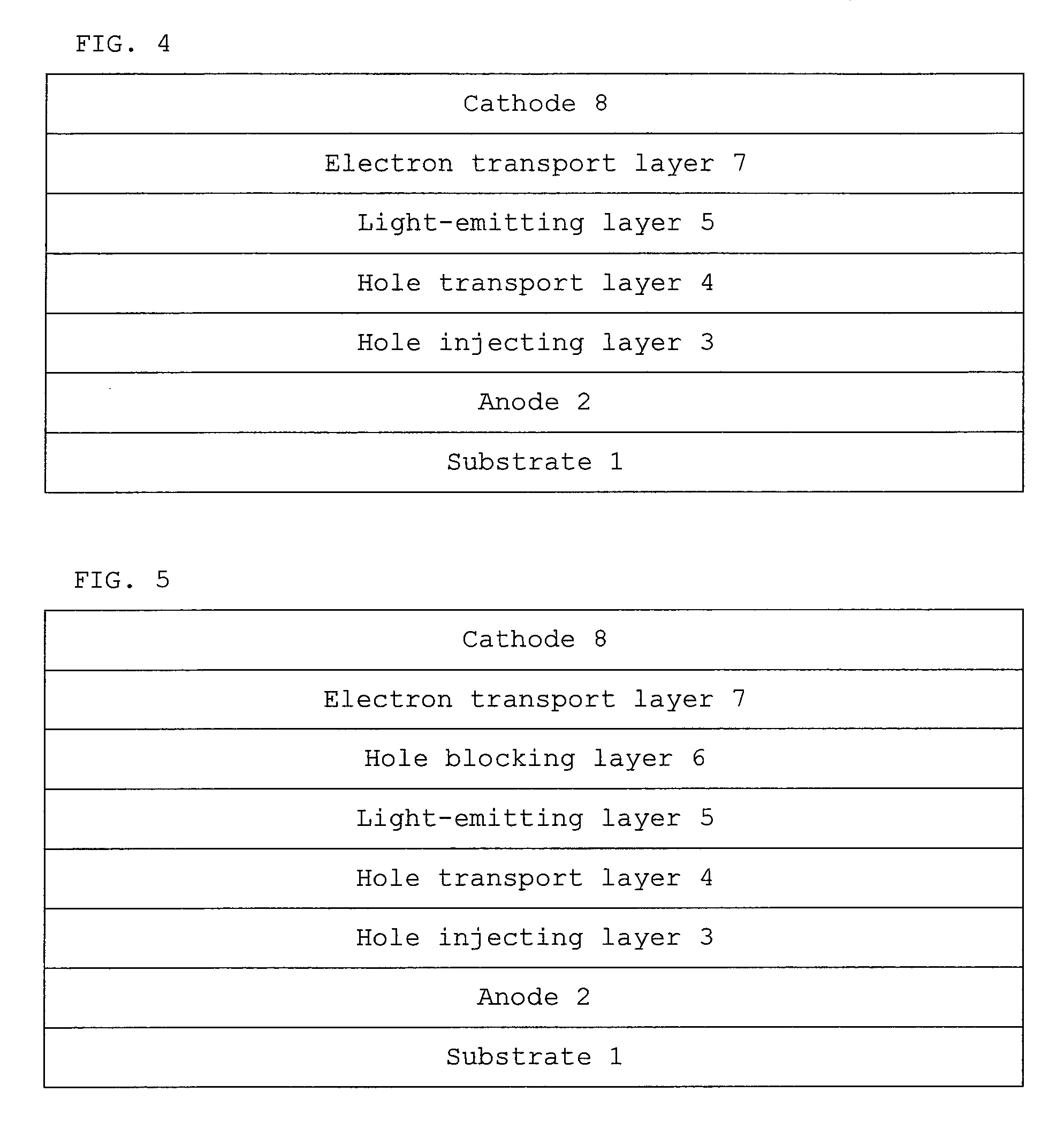

ActiveUS20090230846A1Solution to short lifeIncrease brightnessOrganic chemistryDischarge tube luminescnet screensArylSimple Organic Compounds

The present invention provides an organic electroluminescent device exhibiting a long life, a high luminance, and a high efficiency.An organic electroluminescent device comprising on a substrate an anode, a hole transport layer, an organic light-emitting layer, and a cathode, wherein the organic light-emitting layer contains an organic compound having a pyridine ring, a pyrazine ring, or a triazine ring as a partial structure and the hole transport layer contains a monoamine compound represented by the following formula (I):wherein R1 to R9 represent a hydrogen atom, an aryl group, or an alkyl group; R1 to R9 may be the same or different from each other; and R1 to R9 may further have an aryl group or an alkyl group as a substituent in the case where R1 to R9 are an aryl group or an alkyl group.

Owner:MITSUBISHI CHEM CORP

Method of preparing Ag- based oxide contact materials with directionally arranged reinforcing particles

ActiveUS20130266791A1Easy to processImprove performanceCeramic shaping apparatusAnimal housingHigh energyCompound (substance)

In the present invention, a method of preparing Ag-based oxide contact materials with directionally arranged reinforcing particles is disclosed, comprising steps of: a) preparing evenly dispersed composite powders by chemical co-precipitation method combining with roasting, b) granulating the composite powders by high energy ball milling, and sieving the powders, c) mixing the powders and Ag matrix in a powder mixing machine, d) cold isostatic pressing, e) sintering, f) hot-pressing, g) hot-extruding to obtain Ag-based oxide contact materials with directionally arranged reinforcing particles. This method can obtain particle reinforced Ag-based material with good electrical performance even when the reinforced (oxide) particles are very small. This method is simple, easy to operate, and does not require special equipment. The resistance to welding and arc erosion, electric conductivity and the processability of the material prepared through this present invention can be greatly improved.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

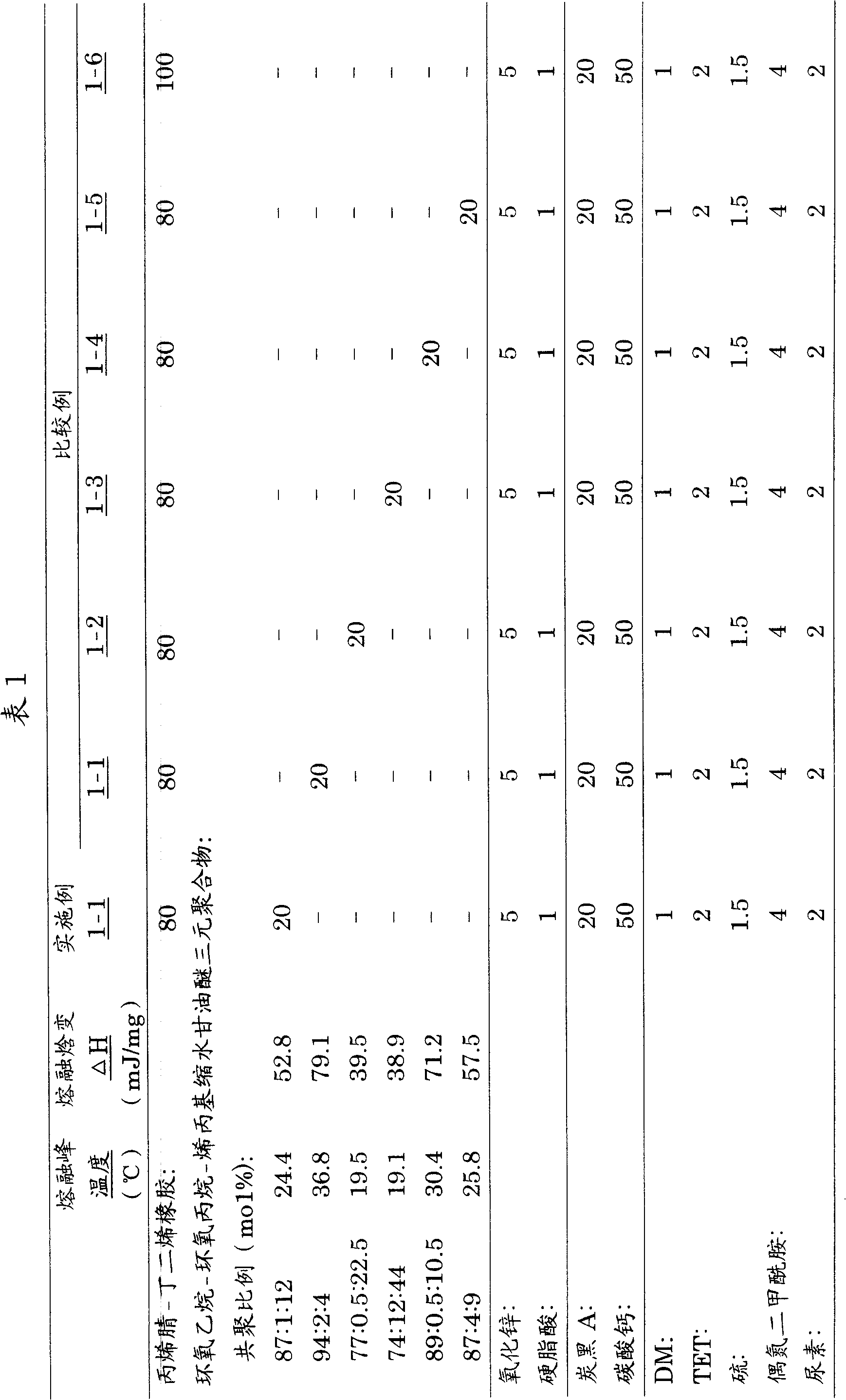

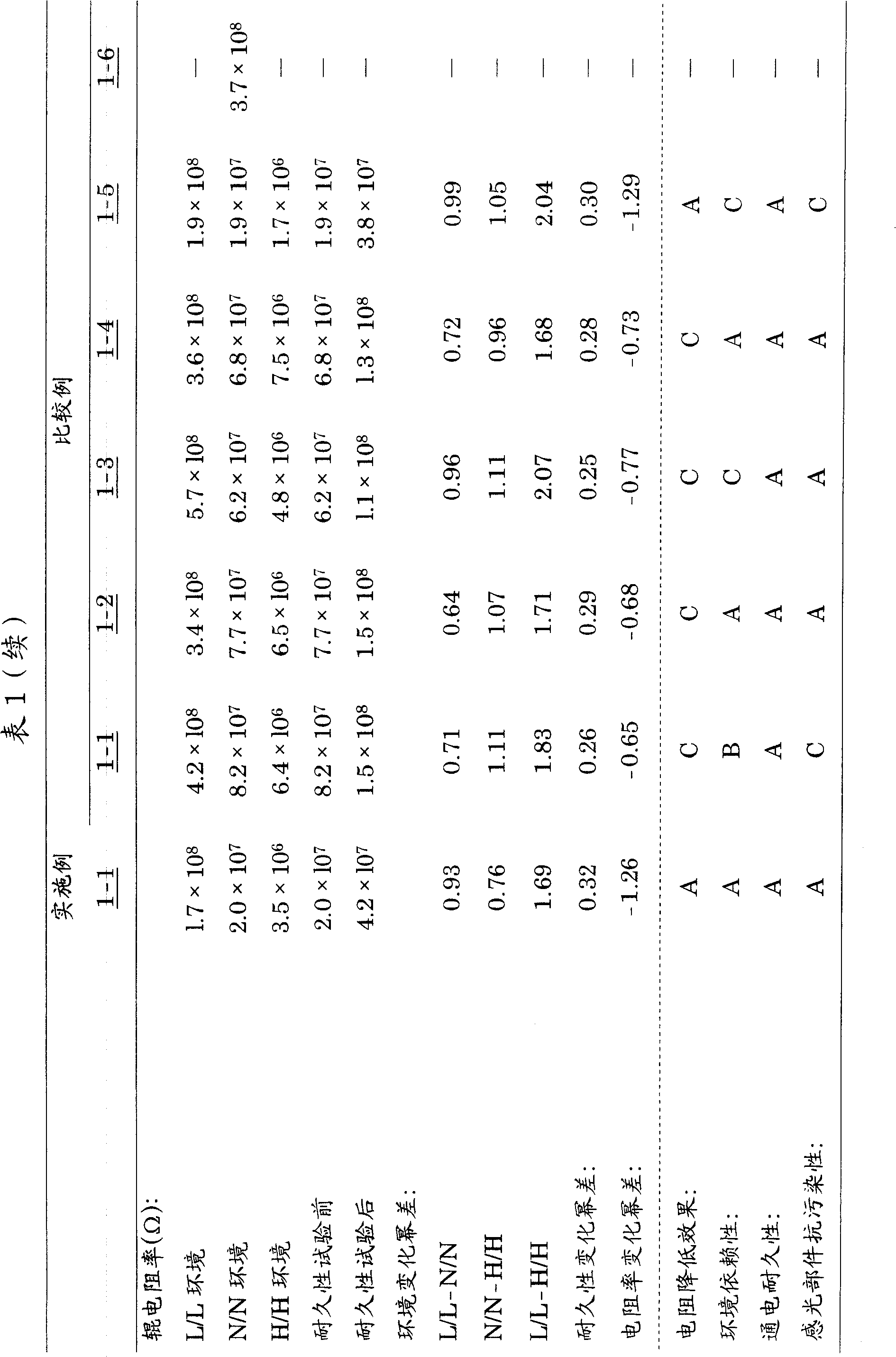

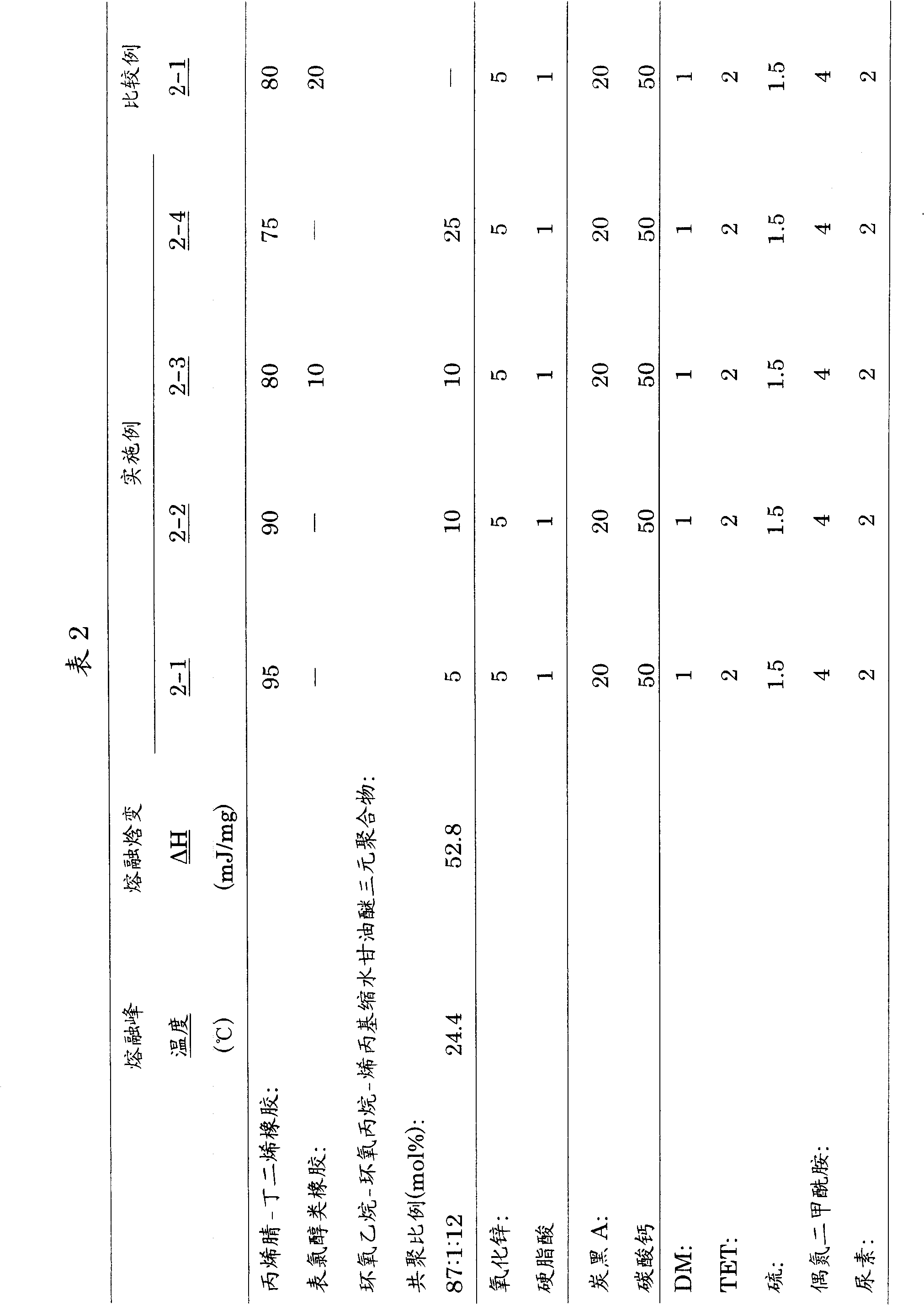

Conductive rubber roller

InactiveCN1862405ANo pollution in the processLow resistivityElectrographic process apparatusCorona dischargePolymer scienceAllyl glycidyl ether

A conductive rubber roller comprising a conductive core material and provided thereon a rubber layer; the rubber layer being formed by using a rubber composition containing as rubber components at least a polar rubber and an ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer; the ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer having a melt peak temperature of from 20 to 30 DEG C. and a melt enthalpy change DeltaH of from 40 to 70 mJ / mg as measured with a differential scanning calorimeter; and the allyl glycidyl ether in the ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer being in a copolymerization ratio of from more than 10 mol % to 20 mol % or less.

Owner:CANON KK

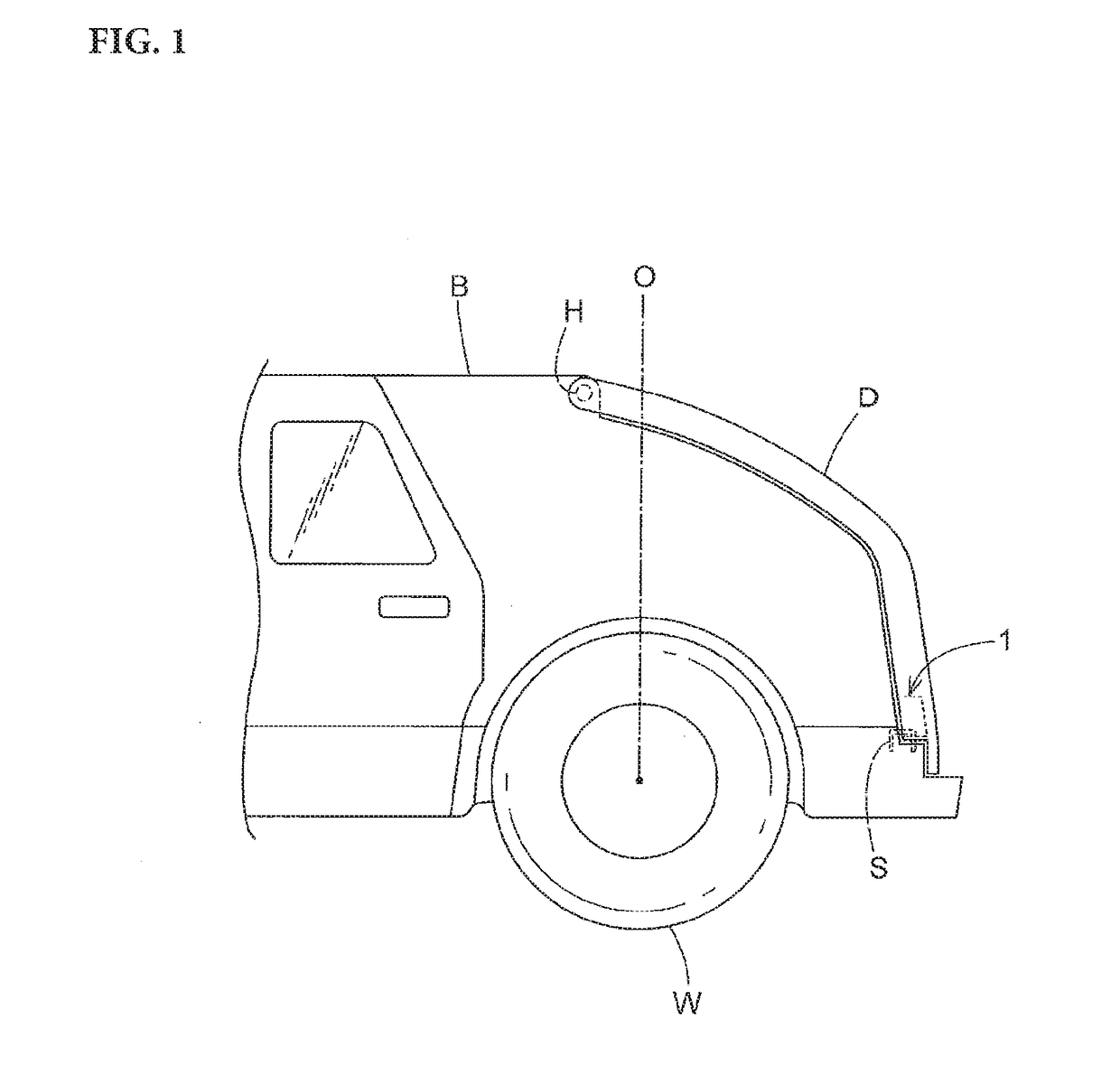

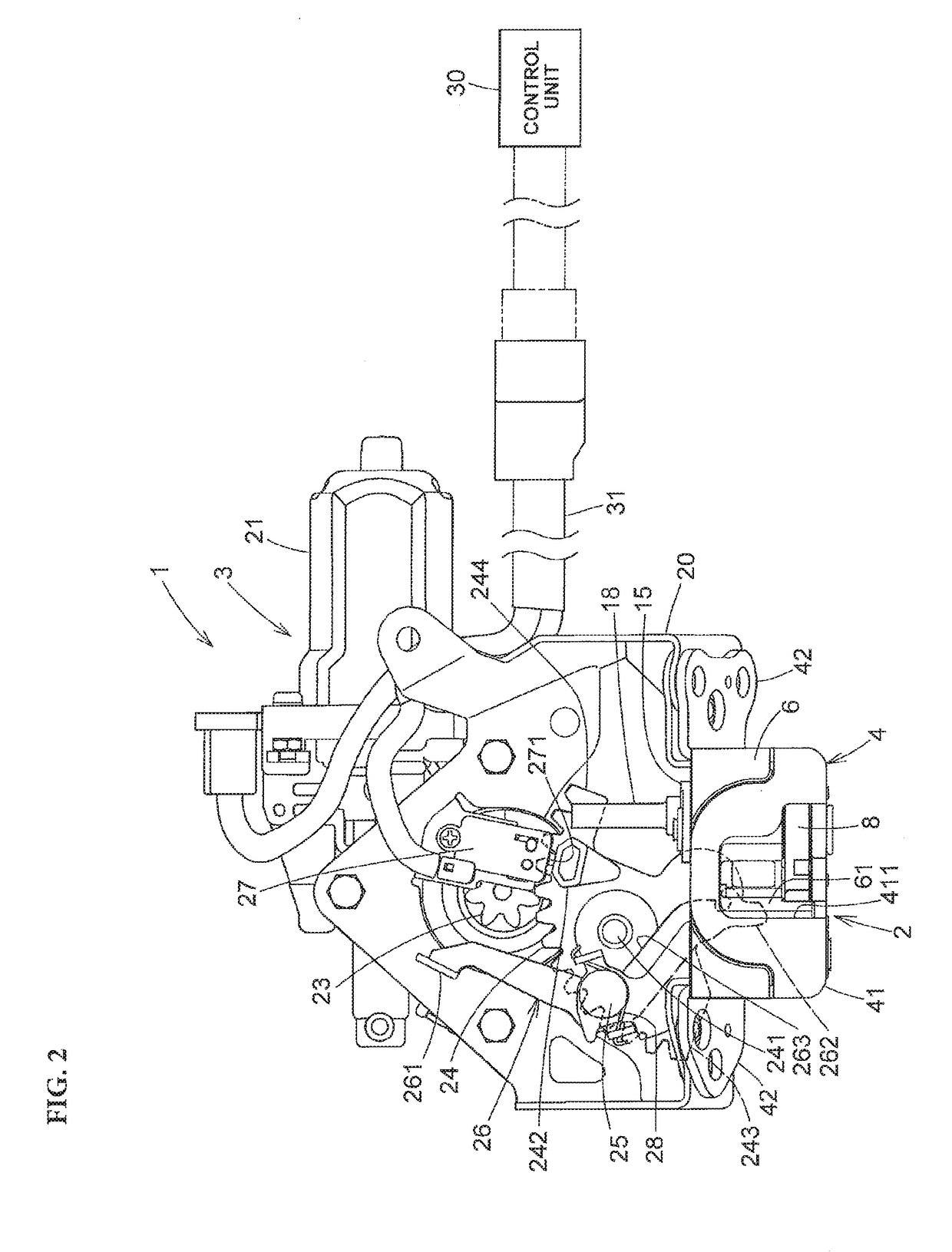

Vehicle door latch device

ActiveUS20180195318A1Improve electrical durabilityShorten the timeElectrical locking circuitsElectrical locking actuatorsEngineeringElectrical drive

Provided is a vehicle door latch device capable of shortening of energization time to an electrical drive source while a moving member is restrained by abutting against a stopper portion and improvement of durability of the electrical drive source. A control unit of the door latch device controls an electric motor for driving a sector gear in a release direction based on a door operation of an operation switch, and controls to stop a power supply to the electric motor when the latch is rotated from the full-latch position to the open position and a full-latch detecting switch is activated while the moving member is brought into abutment with the stopper portion and is stopped.

Owner:MITSUI KINZOKU ACT

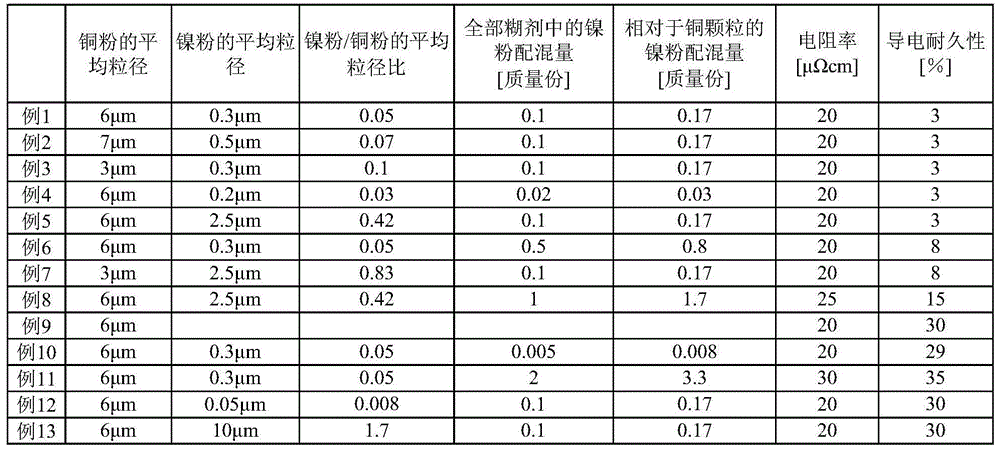

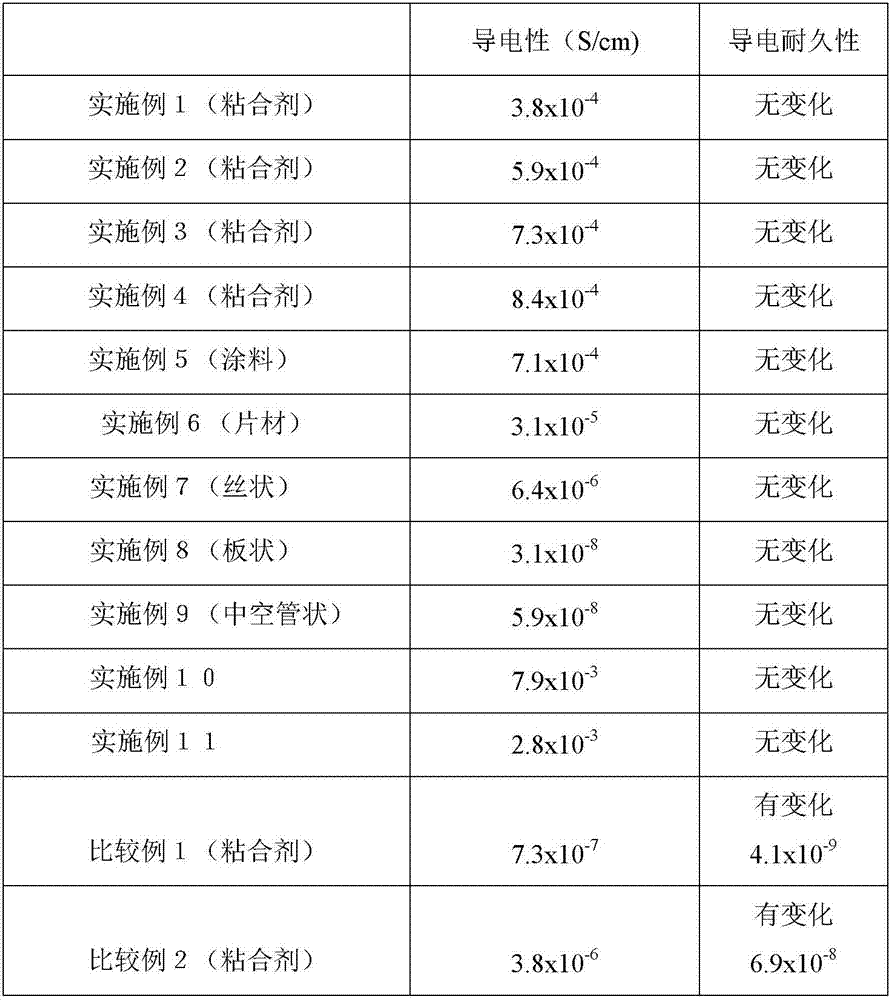

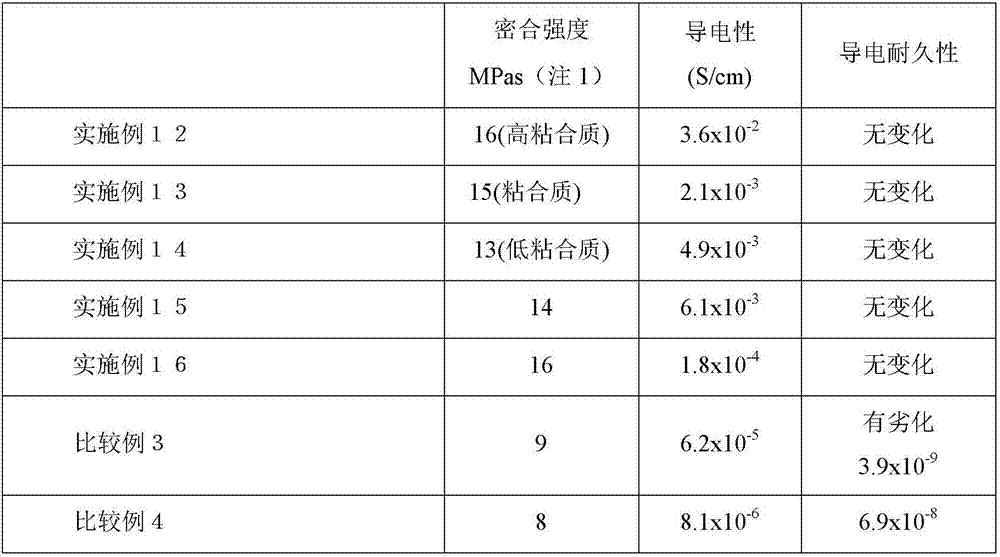

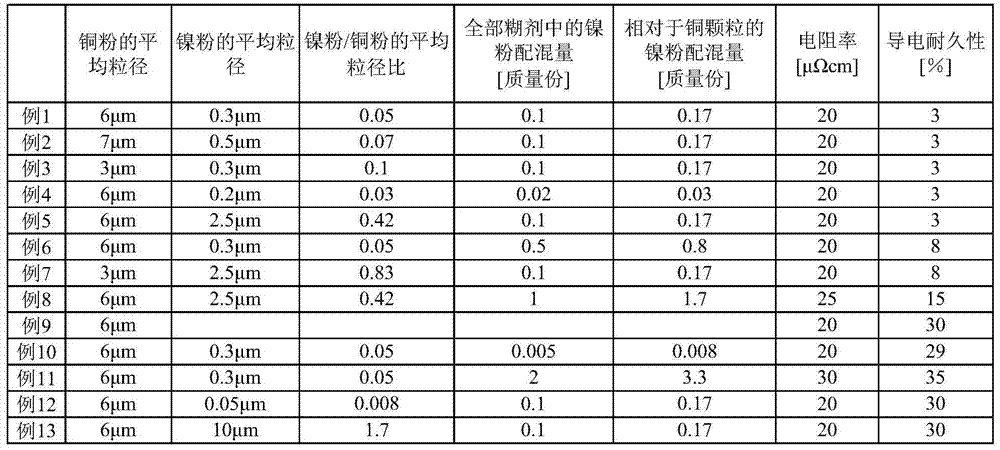

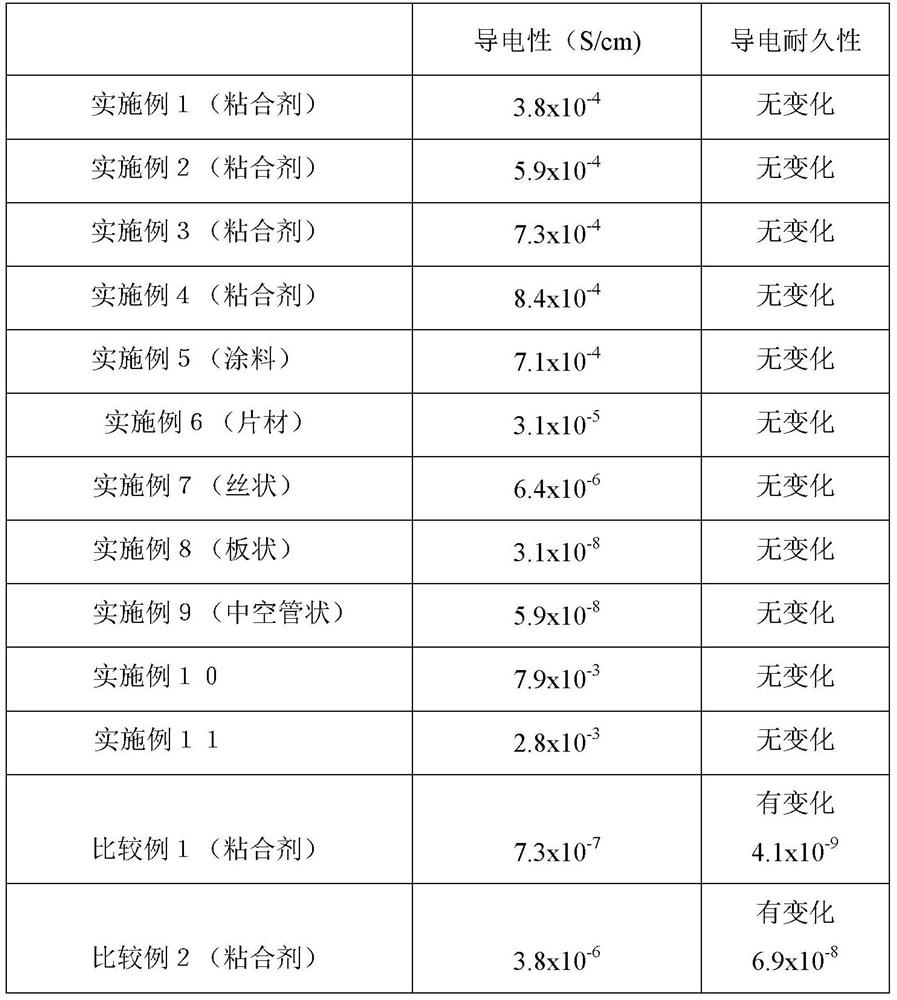

Electrically conductive paste and base material with electrically conductive film

ActiveCN104425054AImprove conductivityImprove electrical durabilityConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialMetal particleOmega

The invention provides electrically conductive paste with excellent electrically conductivity and durability, and a base material which is formed by use of the electrically conductive paste and provided with an electrically conductive film. The electrically conductive paste is characterized in that the electrically conductive paste comprises (A) metal particles whose volume resistivity is less than 10 [mu]omega cm and average diameter is 1-15 [mu]m; (B) base metal particles whose average parameter is 0.1-3 [mu]m and oxidation reduction potential is -440 mV-320 mV (SHE); and (C) binder resin. 0.01-3 parts by mass of above (B) base metal particles are contained relative to 100 parts by mass of above (A) metal particles.

Owner:UNKNOWN +1

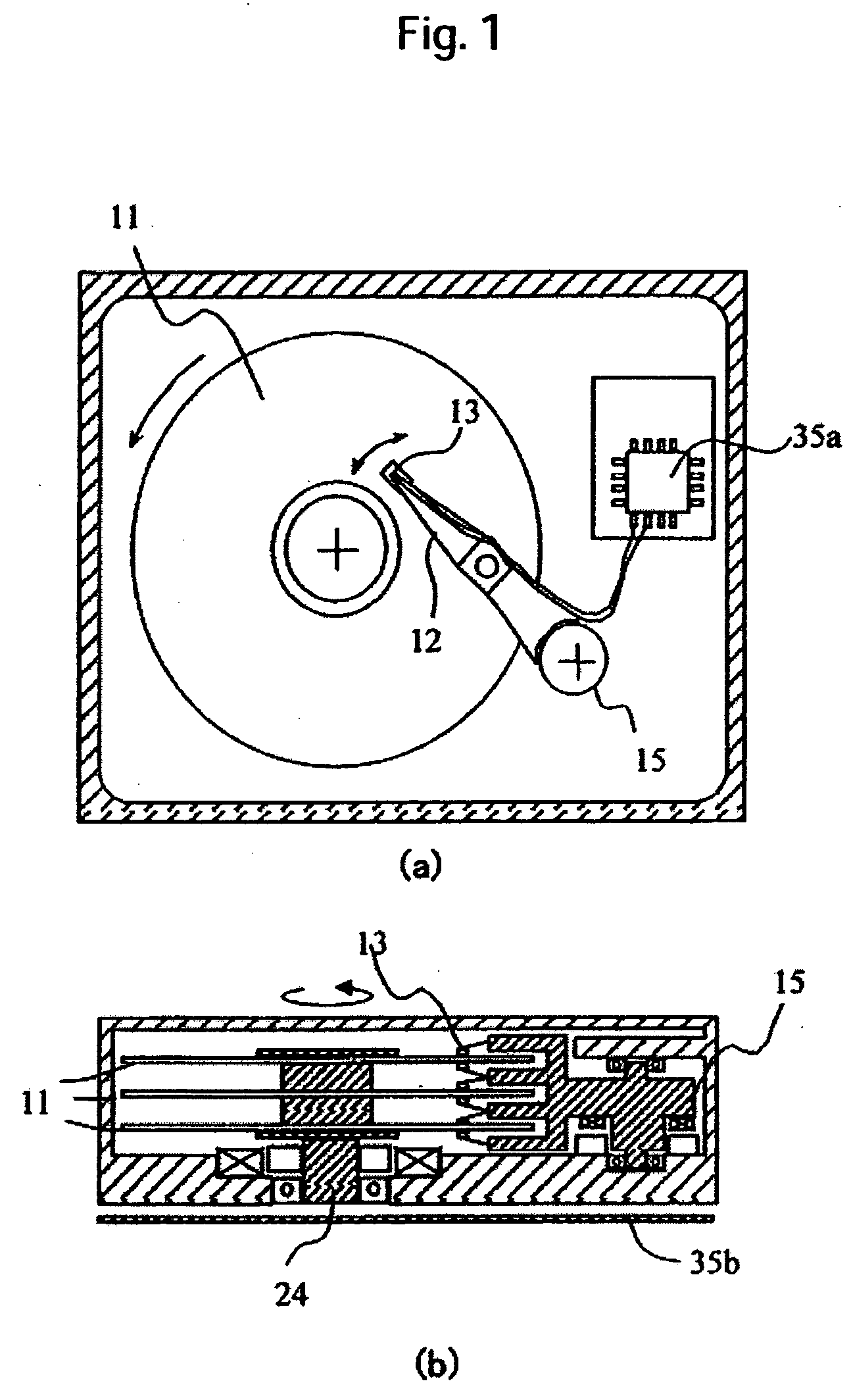

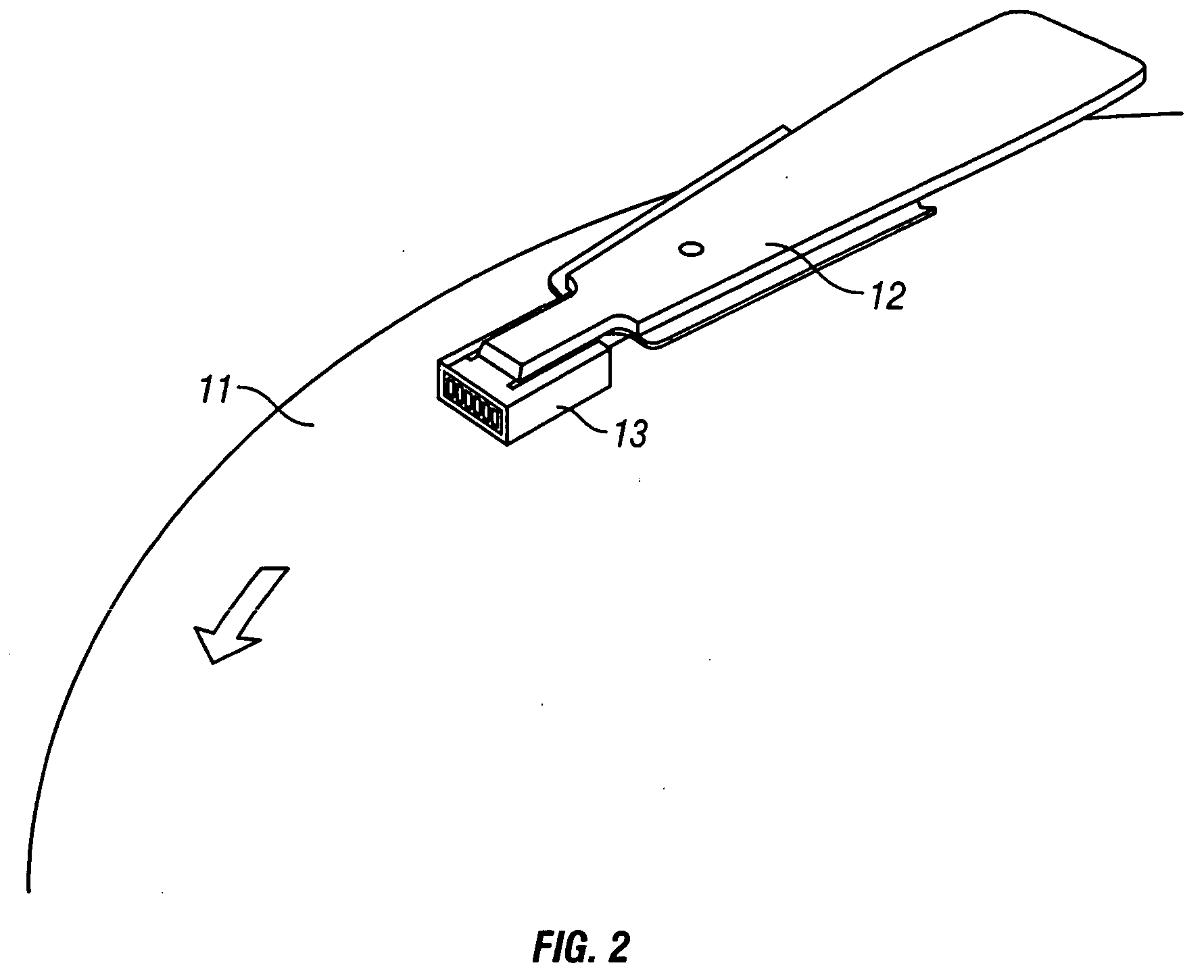

Magnetic head with durability against static electricity

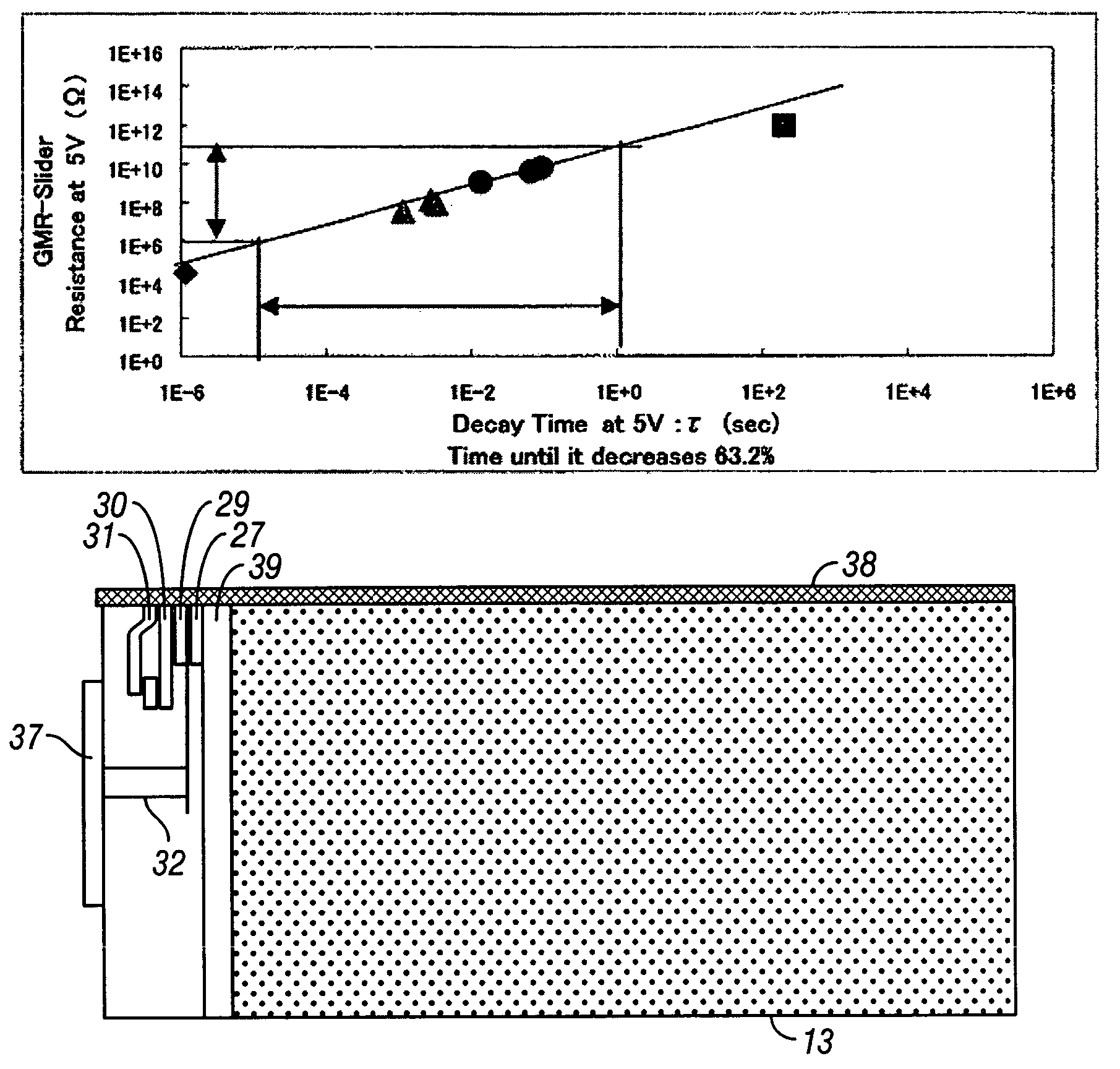

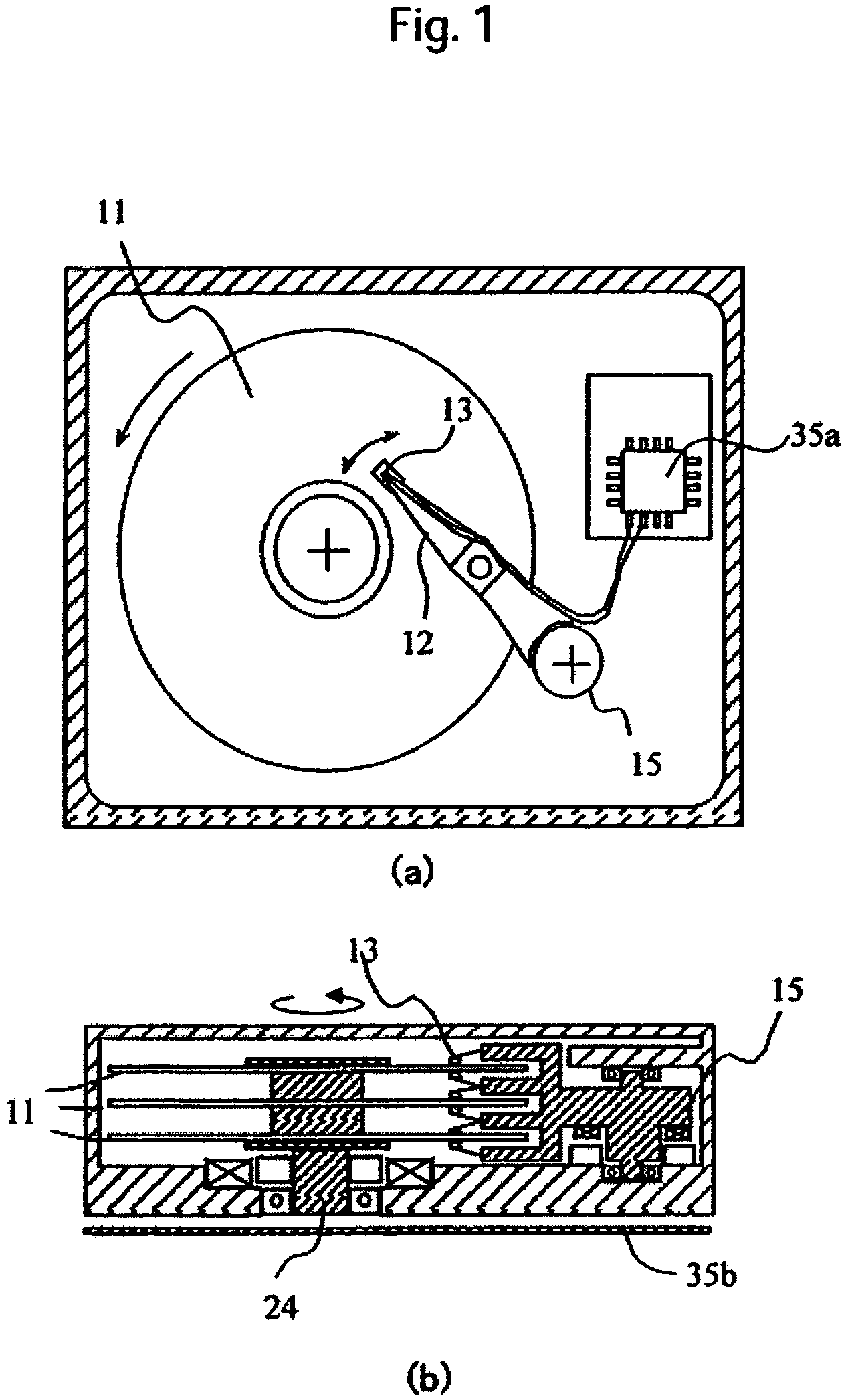

InactiveUS20060132985A1Improve transfer rateImprove electrical durabilityRecord information storageManufacture of flux-sensitive headsRecording densityTime constant

Embodiments of the invention provide a read head which is implemented in a magnetic disk drive that supports a high recording density and a high transfer rate and is excellent in static electricity durability. In one embodiment, a magnetic head wherein a charge diffuses from a read element to a slider at a time constant of about 100 ms or less.

Owner:WESTERN DIGITAL TECH INC

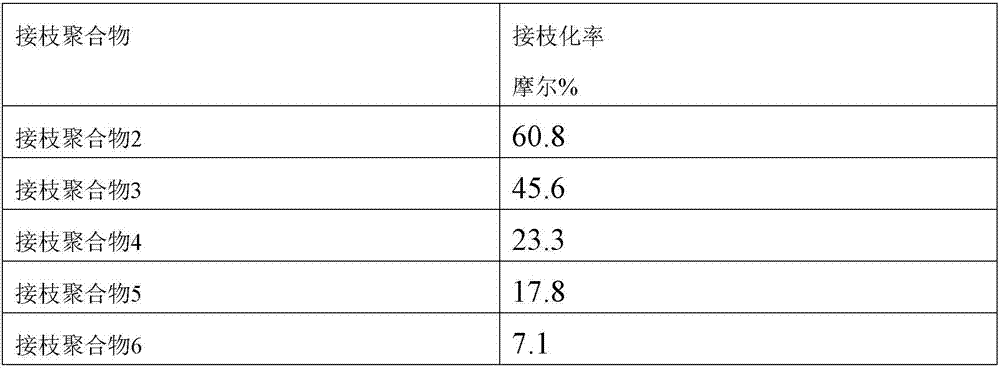

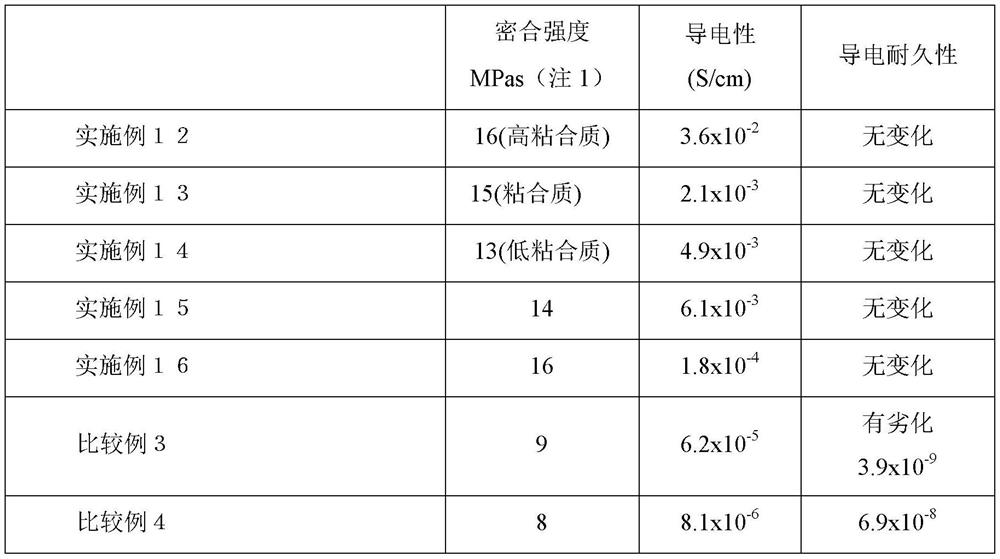

Electrically conductive material and laminate

ActiveCN107207816AImprove electrical durabilityHigh strengthOptical articlesWood layered productsMolten saltUltimate tensile strength

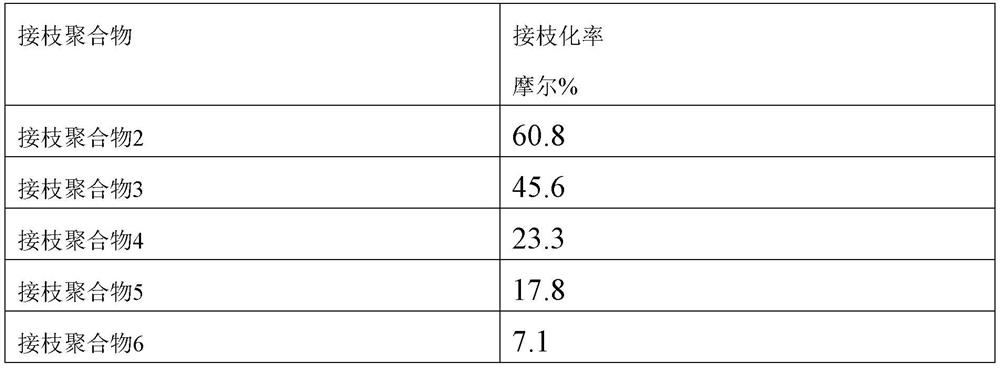

The present invention addresses the problem of obtaining: an electrically conductive material with excellent strength, electrical conductivity, and electrical conduction durability; and a laminate or a molding wherein a laminate with a non-conducting resin layer on one or both surfaces exhibits excellent electrical conductivity and electrical conduction durability as well as having excellent adhesive strength. The problem is solved by providing an electrically conductive material comprising a composition containing 0.1-95 weight% of a polymeric electrically conductive composition (X1) in a fluorine polymer (X2), the polymeric electrically conductive composition being obtained by graft polymerizing 2-90 mole% of a molten salt monomer, which has a salt structure obtained from an onium cation and a fluorine-containing anion and has polymerizable functional groups, with a fluorine polymer.

Owner:派尔查克株式会社

Image pickup apparatus with rotary lens barrel

InactiveUS8035732B2Improve image qualityHigh definitionTelevision system detailsColor television detailsCamera lensOptical axis

An image pickup apparatus including a lens barrel, a hollow shaft, a base, electric wiring, and a protection member. The lens barrel has a lens and an image pickup device embedded therein. The hollow shaft is rotatable about an axis intersecting with an optical axis of the lens. The axis serves as a central axis of the hollow shaft. The base supports the lens barrel in a rotatable manner by using the hollow shaft. The electric wiring extends through the inside of the hollow shaft to electrically transmit an image pickup signal of the image pickup device. The protection member is provided in the hollow shaft so as to prevent the electric wiring from coming into contact with the hollow shaft.

Owner:SONY CORP

Monoamine compound, charge-transporting material, and organic electroluminescent device

ActiveUS8427046B2Increase brightnessImprove electrical durabilityOrganic chemistryDischarge tube luminescnet screensArylSimple Organic Compounds

The present invention provides an organic electroluminescent device exhibiting a long life, a high luminance, and a high efficiency.An organic electroluminescent device comprising on a substrate an anode, a hole transport layer, an organic light-emitting layer, and a cathode, wherein the organic light-emitting layer contains an organic compound having a pyridine ring, a pyrazine ring, or a triazine ring as a partial structure and the hole transport layer contains a monoamine compound represented by the following formula (I):wherein R1 to R9 represent a hydrogen atom, an aryl group, or an alkyl group; R1 to R9 may be the same or different from each other; and R1 to R9 may further have an aryl group or an alkyl group as a substituent in the case where R1 to R9 are an aryl group or an alkyl group.

Owner:MITSUBISHI CHEM CORP

High-durability copper-bearing phenolic resin conducting ink

The invention discloses high-durability copper-bearing phenolic resin conducting ink. The high-durability copper-bearing phenolic resin conducting ink is characterized by being prepared from the following raw materials in parts by weight: 20-50 parts of copper powder, 15-20 parts of phenol, 10-30 parts of a formaldehyde solution, 45-60 parts of sodium hydroxide, 5-15 parts of zinc powder and 2-5 parts of an assistant. The zinc powder is added on the basis of a traditional conductive agent employing copper as a conductive paint; and after the paint is sprayed, the zinc powder material of which the conductivity is inferior to that of the copper powder is consumed in advance in loss due to the fact that a zinc-copper electrode is to be formed on the surface of the paint, so that oxidation or loss of the copper powder for environmental reasons is prevented and the overall conductivity durability is improved.

Owner:欧振云

Low-resistance chip resistor and method of manufacturing same

ActiveCN102473494AHigh mechanical strengthAvoid reduction in electrical durabilityResistor chip manufacturePrinted resistor incorporationPhysicsSurface electrode

Provided are a low-resistance chip resistor having a simple structure in which self-independence is given and the mechanical strength is increased for durability, and an easier and faster method of manufacturing same. A low-resistance chip resistor characterized in that resistive layers are formed on both the front and back surfaces of an insulating substrate, or insulating substrates are formed on both the front and back surfaces of a resistive layer, that in the former, protective films are formed on the central portions of the resistive layers in the longitudinal direction and surface and back electrodes are formed on the resistive layers on both sides of the protective films, and in the latter, surface and back electrodes are formed on the resistive layers on both sides of the substrates, and that in both the former and latter, end surface electrodes are provided at both ends in the width direction.

Owner:KAMAYA ELECTRIC

Magnetic head having durability against static electricity with modified time constant

InactiveUS7558188B2Improve transfer rateImprove electrical durabilityRecord information storageManufacture of flux-sensitive headsRC time constantRecording density

Embodiments of the invention provide a read head which is implemented in a magnetic disk drive that supports a high recording density and a high transfer rate and is excellent in static electricity durability. In one embodiment, a magnetic head wherein a charge diffuses from a read element to a slider at a time constant of about 100 ms or less.

Owner:WESTERN DIGITAL TECH INC

Conductive paste and substrate with conductive film

ActiveCN104425054BImprove conductivityImprove electrical durabilityConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialConductive pasteConductive polymer

PROBLEM TO BE SOLVED: To provide a conductive paste capable of forming a conductive film having good conductivity and excellent durability, and to provide a substrate with a conductive film formed by using such a conductive paste.SOLUTION: The conductive paste contains (A) metal particles having a volume resistivity of 10 μ&OHgr; cm or less and an average particle diameter of 1-15 μm, (B) base metal particles having an average particle diameter of 0.1-3 μm and an oxidation-reduction potential of -440 to 320 mV (SHE), and (C) a binder resin. The base metal particles as the component (B) are contained in an amount of 0.01-3 pts.mass based on 100 pts.mass of the metal particles as the component (A).

Owner:UNKNOWN +1

Electric storage device

ActiveUS8232009B2Suppress mutationImprove electrical durabilityNon-aqueous electrolyte accumulatorsHybrid capacitor electrodesPermeationAperture ratio

Owner:SUBARU CORP

Conductive raw materials and laminates

ActiveCN107207816BImprove electrical durabilityHigh strengthOptical articlesWood layered productsPolymer scienceFluoropolymer

A conductive raw material with excellent strength, conductivity, and conductive durability is obtained, and a laminate having a non-conductive resin layer on one or both surfaces is obtained and exhibits excellent conductivity, excellent conductive durability, and has excellent Laminated bodies and molded bodies with high adhesion strength. This is achieved by providing a conductive raw material which has a fluorine-based polymer (X 2 ) contains 0.1 to 95% by weight of the polymer conductive composition (X 1 ) composition, the polymer conductive composition (X 1 ) is obtained by graft-polymerizing 2 to 90 mol% of a molten salt monomer having a salt structure containing an onium cation and a fluorine-containing anion and having a polymerizable functional group on a fluorine-based polymer.

Owner:派尔查克株式会社

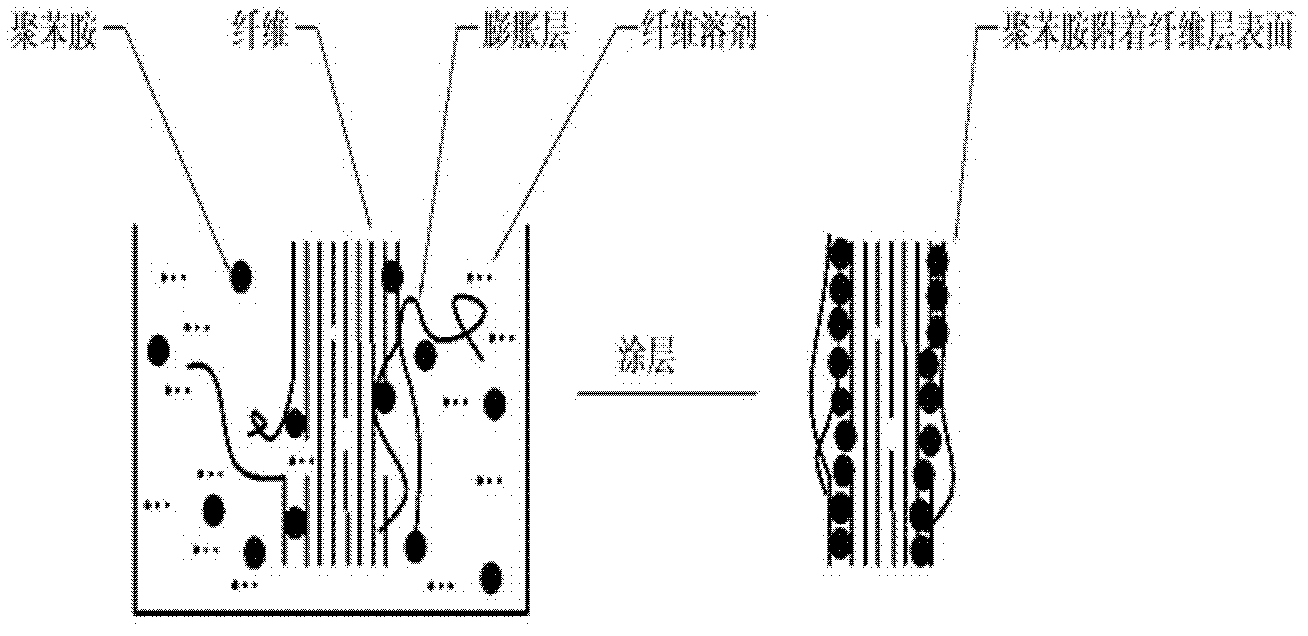

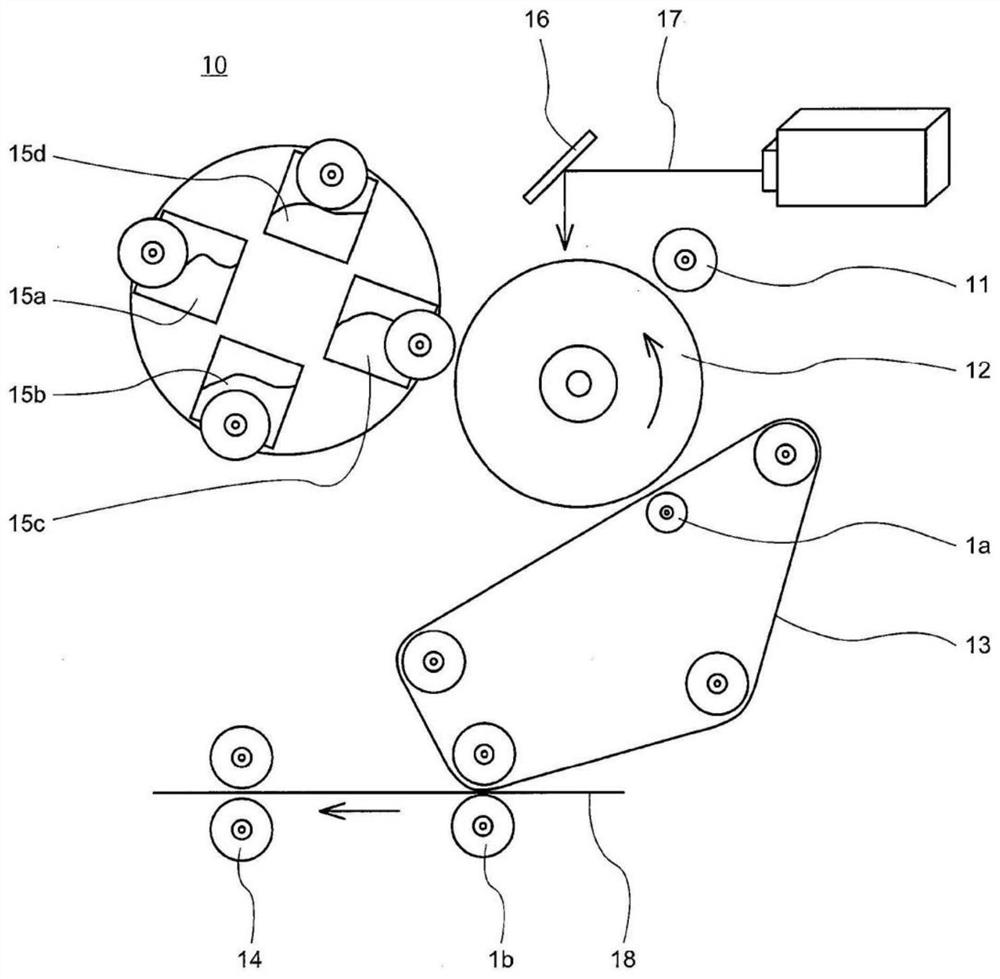

Method for preparing polyaniline composite nano silver conductive fibers

InactiveCN102444023BImprove conductivityMeet different conductivity requirementsFibre typesConductive coatingRoom temperature

The invention discloses a method for preparing polyaniline composite nano silver conductive fibers. The method comprises the following steps of: 1) preparation of a conductive coating solution, preparing polyaniline particles ground by a mortar and formic acid solutions of different mass fractions into the conductive coating solution, wherein the mass fractions of the formic acid solutions are 60 to 80 percent; 2) preparation of coated conductive fibers: coating the conductive coating solution on the surface of fibers by adopting a roller type fiber coating machine to prepare the coated conductive fibers, and washing and drying the coated conductive fibers to obtain conductive fibers; and 3) in-situ synthesis of a nano silver-polyaniline layer: soaking the conductive fibers A into 0.1 to 1.0mol / L aqueous solution of silver nitrate (AgNO3) for 0.5 to 2 hours, soaking the conductive fibers A into 0.2 to 2 mol / L aqueous solution of NaBH4, reacting for 6 to 10 hours at room temperature, washing by using ethanol and deionized water respectively, performing natural airing or drying, and thus obtaining the polyaniline / nano silver composite conductive fibers. The conductive fibers have high electric conductivity, the electric conductivity of the fibers can be regulated by controlling the process conditions, and different electric conductivity requirements are met.

Owner:翔瑞(泉州)纳米科技有限公司

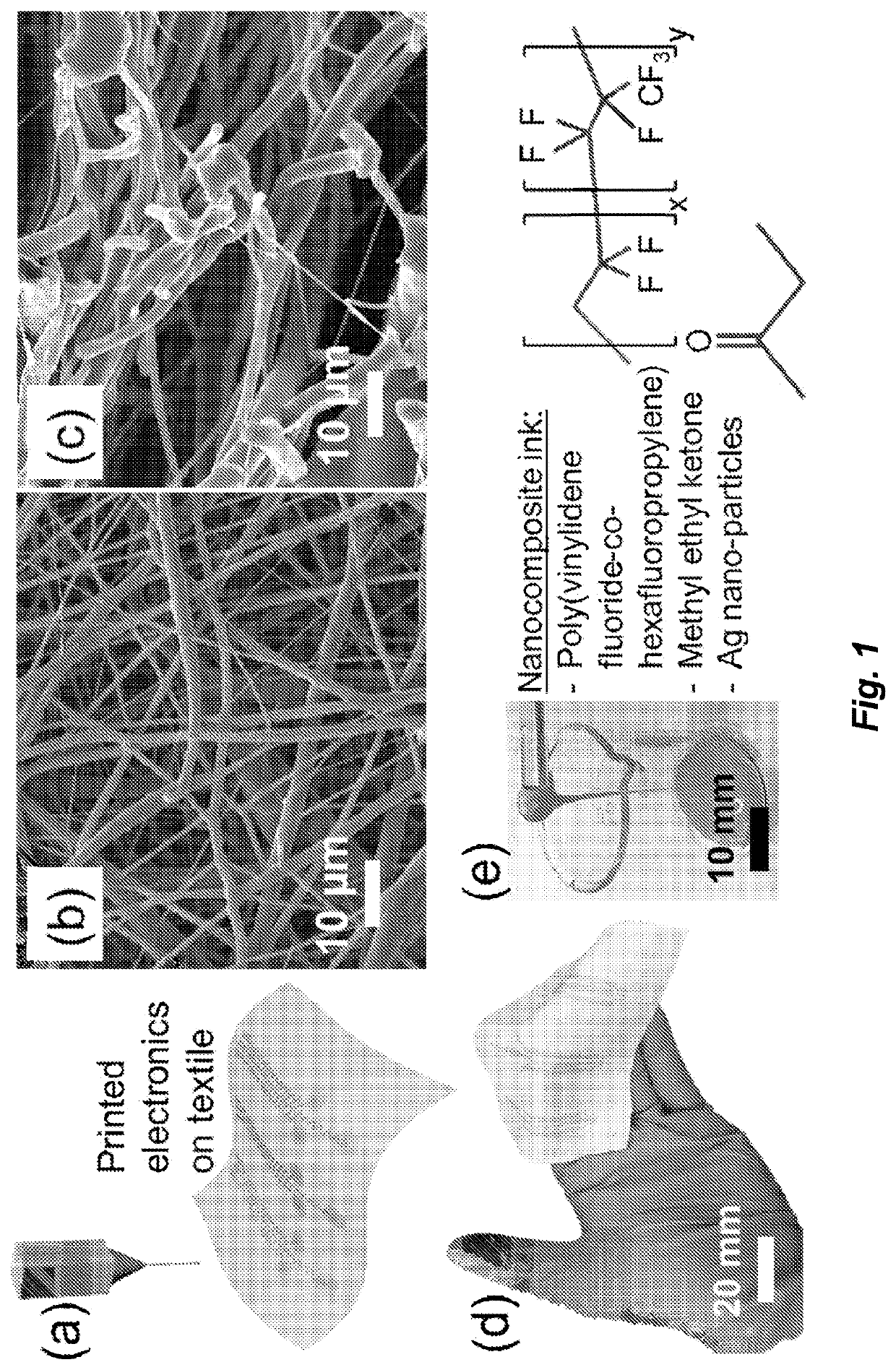

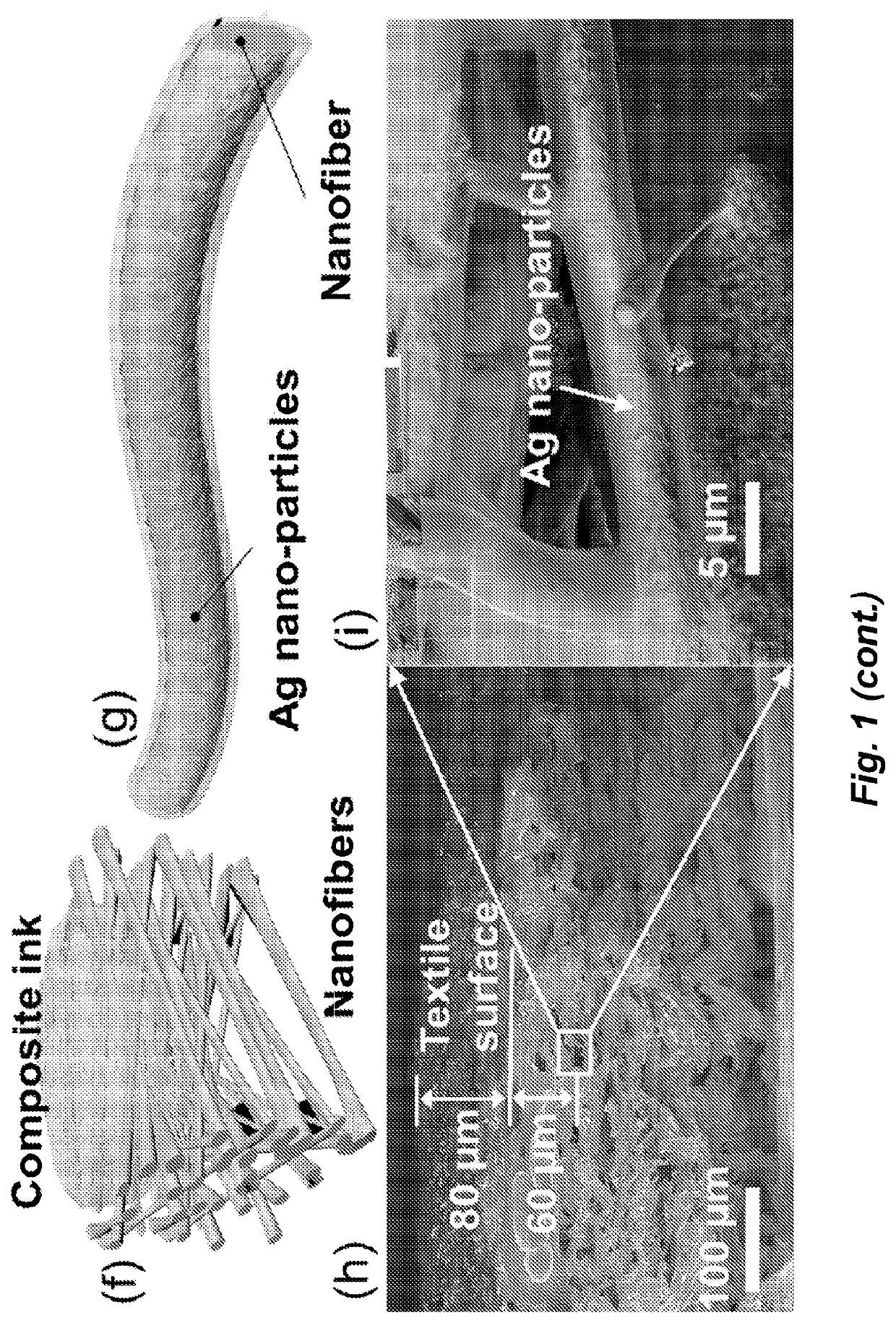

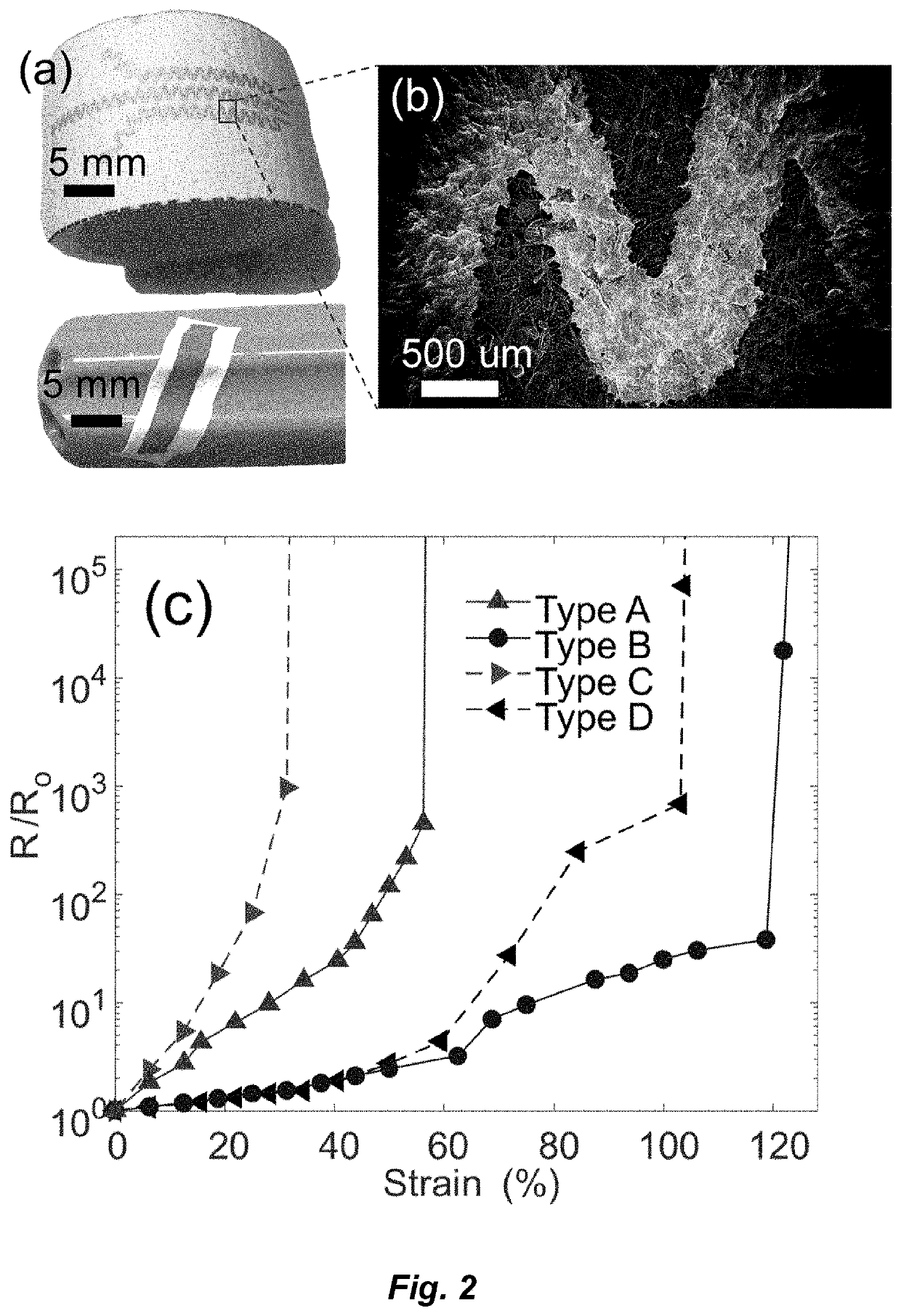

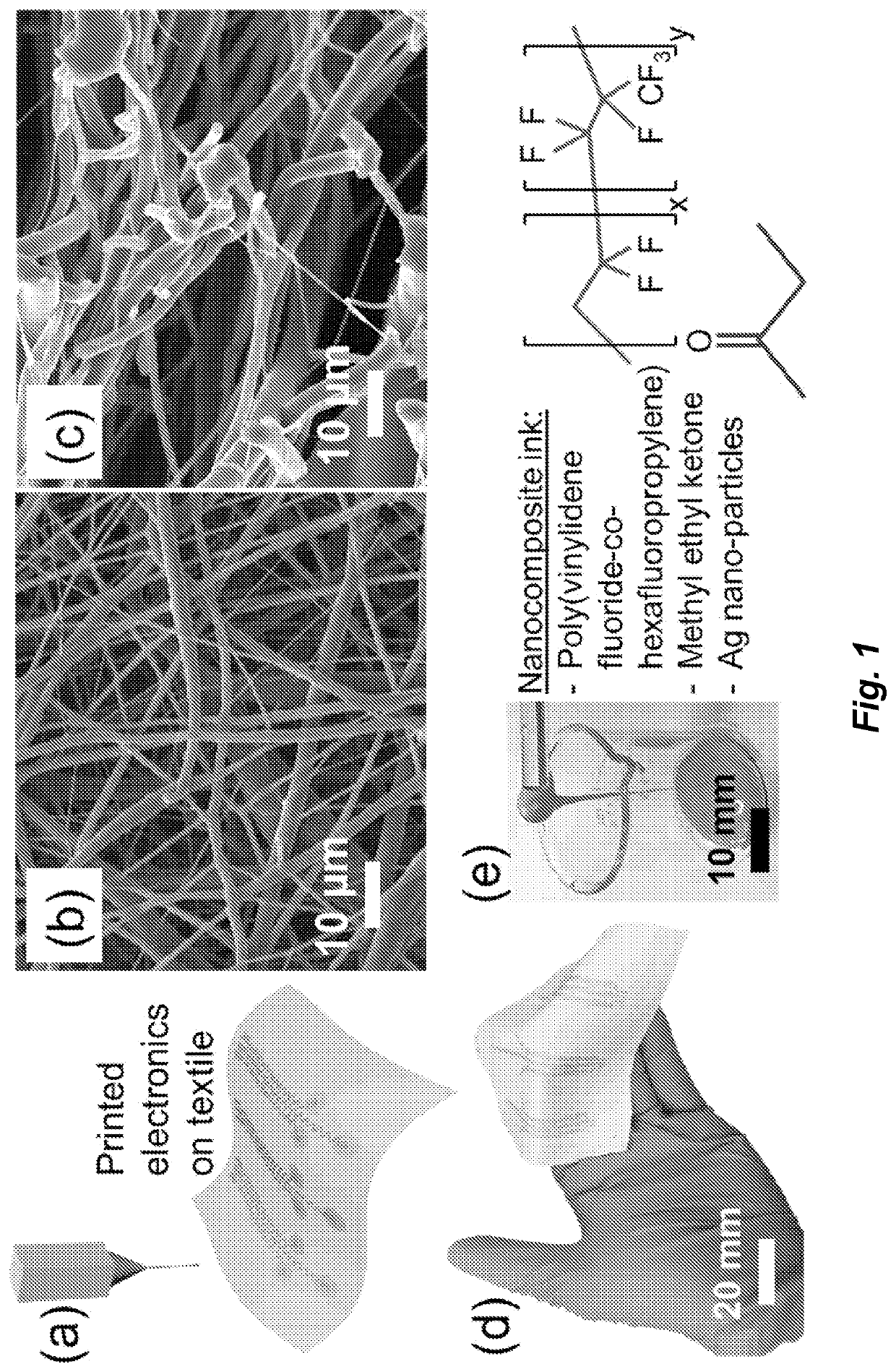

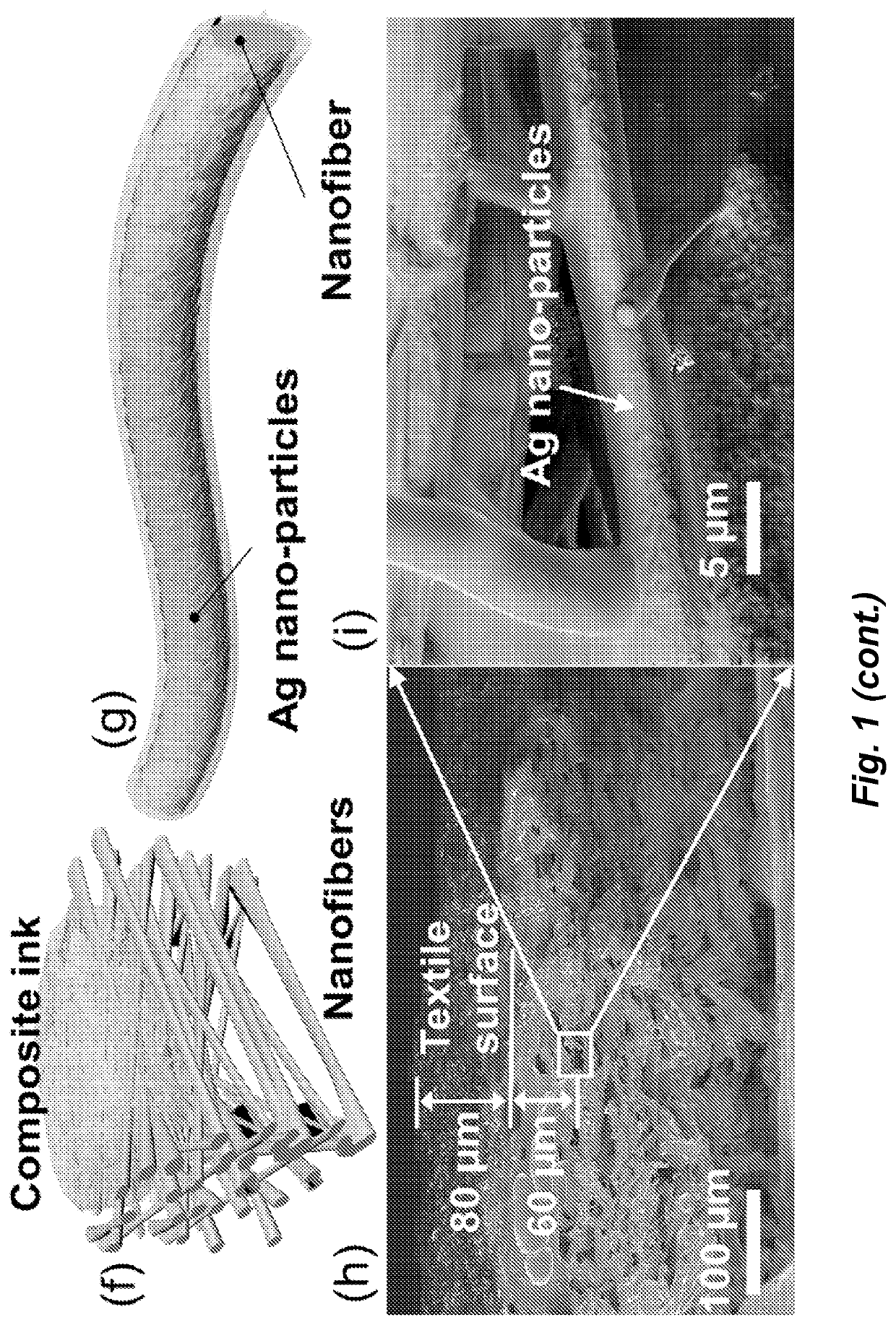

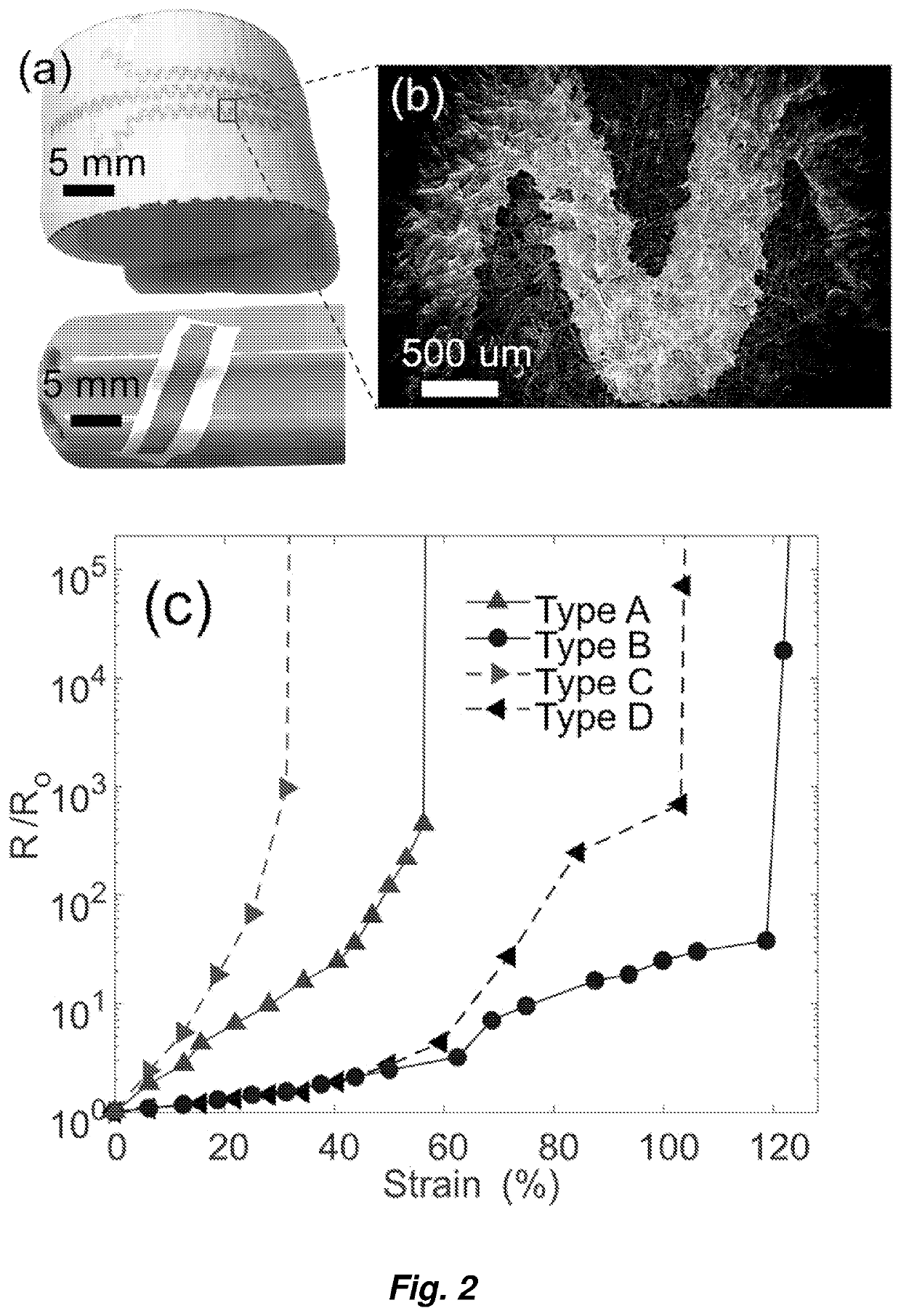

Elastic printed conductors

ActiveUS20220256693A1Improve conductivityImprove electrical durabilityPorous dielectricsCircuit bendability/stretchabilityTextile fiberElectrical conductor

The development of stretchable, mechanically and electrically robust interconnects by printing an elastic, silver-based composite ink onto stretchable fabric. Such interconnects can have conductivity of 3000-4000 S / cm and are durable under cyclic stretching. In serpentine shape, the fabric-based conductor is enhanced in electrical durability. Resistance increases only ˜5 times when cyclically stretched over a thousand times from zero to 30% strain at a rate of 4% strain per second due to the ink permeating the textile structure. The textile fibers are ‘wetted’ with composite ink to form a conductive, stretchable cladding of the silver particles. The e-textile can realize a fully printed, double-sided electronic system of sensor-textile-interconnect integration. The double-sided e-textile can be used for a surface electromyography (sEMG) system to monitor muscles activities, an electroencephalography (EEG) system to record brain waves, and the like.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

A kind of preparation method of long-acting conductive polyester fiber

ActiveCN106351000BEasy to processImprove compactnessFibre typesBiochemical treatment with enzymes/microorganismsPolyesterFiber

The invention discloses a preparing method of a long-acting and conductive polyester fiber and belongs to the technical field for preparing polyester fiber. The mussel meat provided in the invention is in enzymolysis into polypeptide by alkaline protease; polypeptide matter is taken as complexing agent which reacts with zinc chloride solution to form complex for standby; the polyester fiber is taken and soaked in alkali, so that a pit is formed on the fiber surface; the fiber is soaked by beef extract-peptone medium nutrient solution, and then the fiber is absorbed and grown in the fiber surface and pitby saccharomycetes to modify the fibers; the modified fiber is mixed with the standby complex; the zinc ion can be relieved by the polypeptide in the saccharomycetes consumption complex on the surface of the fiber to be absorbed on the saccharomycetes surface; and then the potassium dihydrogen phosphate solution is taken as the reducing agent to reduce the fiber; the metal zinc can grow in the fiber surface and pit, and then the metal zinc is dried to obtain the long-acting and conductive polyester fiber. The problems of poor density and reduced conductive durability are effectively solved. The preparation steps in the invention are simple, the obtained polyester fiber is easy to be processed and formed with high conductive durability.

Owner:SHANGHAI MINGGUAN PURIFICATION MATERIALS

Preparation method of conductive polyester fiber

InactiveCN105970635ASolve the problem that is not easy to evenly distributeSimple preparation stepsFibre typesFiberPolyester

The invention discloses a preparation method of conductive polyester fiber, which belongs to the technical field of conductive fiber preparation. The invention uses waste rubber to prepare conductive carbon black powder, carries out dispersive composite modification on it through garcinia cambogia juice rich in hydroxyl and Pichia submembraneus, and mixes it with polyester fiber to prepare conductive carbon black powder. The coating solution is applied to the surface of the polyester fiber by a dissolution coating method to obtain a conductive polyester fiber. The beneficial effects of the present invention are: the preparation steps of the present invention are simple, and the dispersive composite modification of the carbon black is carried out by fully utilizing the garcinia cambogia juice rich in hydroxyl groups and Pichia submembranesis, which effectively solves the problem that the carbon black is not easy to be uniform on the fiber surface The problem of distribution, the obtained product feels good, the carbon black on the surface of the fiber does not fall off, and the conductive durability is improved by 28-29%.

Owner:郭舒洋

Conductive rubber composition, conductive rubber roller, and image forming device

PendingCN113024909AImprove electrical durabilityElectrographic process apparatusPolymer scienceImage formation

The invention provides a rubber composition capable of forming a conductive rubber roller with excellent electrification durability, a conductive rubber roller and an image forming device. The conductive rubber composition contains (A) a base rubber, (B) an alkylene oxide-phenyl glycidyl ether copolymer, and (C) an ion conductive agent.

Owner:SUMITOMO RUBBER IND LTD

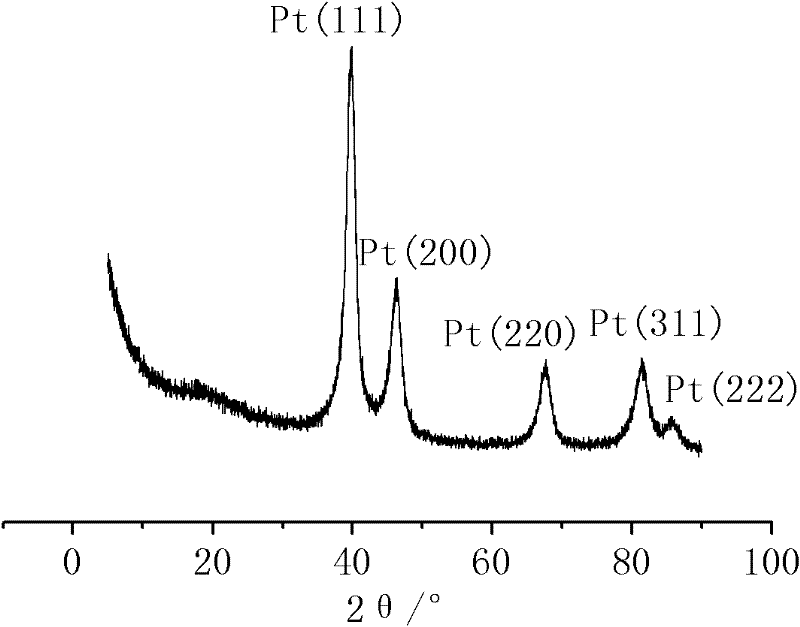

Polypyrrole/nanometer platinum composite conductive fiber and preparation method thereof

InactiveCN102011313BImprove conductivityMeet different conductivity requirementsSynthetic fibresNatural fibresFiberPolypyrrole

The invention discloses a polypyrrole / nanometer platinum composite conductive fiber and a preparation method thereof. The method comprises the following steps of: performing treatment such as proper cleaning and the like on a fiber, soaking in an oxidant solution for 10 to 30 minutes, air-drying at room temperature or drying, putting the treated fiber into a sealed container filled with pyrrole steam, reacting at the temperature of between 0 and 30 DEG C for 5 to 30 minutes, respectively washing by using ethanol and deionized water, and air-drying or drying to obtain a conductive fiber A; and soaking the conductive fiber A in a chloroplatinic acid (H2PtCl6.6H2O) aqueous solution at the concentration of 0.1 to 1.0mol / L for 0.5 to 2 hours, dipping in pyrrole aqueous solution at the concentration of 0.01 to 0.1mol / L, reacting at room temperature for 6 to 10 hours, respectively washing by using ethanol and deionized water, and air-drying or drying to obtain the polypyrrole / nanometer platinum composite conductive fiber. The conductive fiber can be directly used for weaving and also can be blended with a common fiber in a ratio of 1:10-100 to prepare a fabric with an antistatic function and an electromagnetic screen function. The specific resistance of the polypyrrole / nanometer platinum composite conductive fiber is 103 to 107 omega.cm; and the polypyrrole / nanometer platinum composite conductive fiber has the antistatic function and the electromagnetic screen function.

Owner:泉州红瑞兴纺织有限公司

Method of preparing Ag-based oxide contact materials with directionally arranged reinforcing particles

ActiveUS9293270B2Improve electrical performanceEasy to operateAnimal housingCeramic shaping apparatusHigh energyElectrical performance

In the present invention, a method of preparing Ag-based oxide contact materials with directionally arranged reinforcing particles is disclosed, comprising steps of: a) preparing evenly dispersed composite powders by chemical co-precipitation method combining with roasting, b) granulating the composite powders by high energy ball milling, and sieving the powders, c) mixing the powders and Ag matrix in a powder mixing machine, d) cold isostatic pressing, e) sintering, f) hot-pressing, g) hot-extruding to obtain Ag-based oxide contact materials with directionally arranged reinforcing particles. This method can obtain particle reinforced Ag-based material with good electrical performance even when the reinforced (oxide) particles are very small. This method is simple, easy to operate, and does not require special equipment. The resistance to welding and arc erosion, electric conductivity and the processability of the material prepared through this present invention can be greatly improved.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Conductive rubber roller

InactiveCN100430834CNo pollution in the processLow resistivityElectrographic process apparatusCorona dischargePolymer scienceAllyl glycidyl ether

A conductive rubber roller comprising a conductive core material and provided thereon a rubber layer; the rubber layer being formed by using a rubber composition containing as rubber components at least a polar rubber and an ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer; the ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer having a melt peak temperature of from 20 to 30 DEG C. and a melt enthalpy change DeltaH of from 40 to 70 mJ / mg as measured with a differential scanning calorimeter; and the allyl glycidyl ether in the ethylene oxide-propylene oxide-allyl glycidyl ether terpolymer being in a copolymerization ratio of from more than 10 mol % to 20 mol % or less.

Owner:CANON KK

Elastic printed conductors

ActiveUS11343910B2High conductivityImprove electrical durabilityPorous dielectricsCircuit bendability/stretchabilityElectro conductivityWoven fabric

The development of stretchable, mechanically and electrically robust interconnects by printing an elastic, silver-based composite ink onto stretchable fabric. Such interconnects can have conductivity of 3000-4000 S / cm and are durable under cyclic stretching. In serpentine shape, the fabric-based conductor is enhanced in electrical durability. Resistance increases only ˜5 times when cyclically stretched over a thousand times from zero to 30% strain at a rate of 4% strain per second due to the ink permeating the textile structure. The textile fibers are wetted with composite ink to form a conductive, stretchable cladding of the silver particles. The e-textile can realize a fully printed, double-sided electronic system of sensor-textile-interconnect integration. The double-sided e-textile can be used for a surface electromyography (sEMG) system to monitor muscles activities, an electroencephalography (EEG) system to record brain waves, and the like.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

A kind of preparation method of polyacrylonitrile-based high-strength conductive fiber

ActiveCN105401247BHigh strengthImprove conductivityFibre typesMonocomponent synthetic polymer artificial filamentAcrylonitrileAqueous solution

The invention relates to high-strength conductive fibers and particularly relates to a preparing method of a polyacrylonitrile-based high-strength conductive fiber. The method includes 1) preparing a polyacrylonitrile fiber by adopting acrylonitrile and vinyl acetate as raw materials, 2) subjecting the prepared fiber to high-temperature drafting, 3) processing the fiber subjected to high-temperature drafting in saturated low-pressure vapor, 4) putting the fiber processed in the saturated low-pressure vapor to a sodium hydroxide solution, washing and drying, 5) putting the dried fiber into an aqueous solution of a copper salt, heating to 50-60 DEG C, adding a sodium thiosulfate solution, heating to 70-80 DEG C, maintaining the temperature for 30-40 min, adding a sodium thiosulfate solution again, heating to 100-105 DEG C, and maintaining the temperature for 1-1.5 h, and 6) after the temperature maintaining is finished, washing, oiling, dehydrating and drying. The polyacrylonitrile-based high-strength conductive fiber prepared by the method is stable in conductivity, good in conductive durability and high in strength.

Owner:JILIN ACRYLIC FIBERS CO LTD

Low-resistance chip resistor and manufacturing method thereof

ActiveCN102473494BReduce surface temperatureImprove electrical durabilityResistor chip manufacturePrinted resistor incorporationElectrical resistance and conductanceMaterials science

Provided are a low-resistance chip resistor having a simple structure in which self-independence is given and the mechanical strength is increased for durability, and an easier and faster method of manufacturing same. A low-resistance chip resistor characterized in that resistive layers are formed on both the front and back surfaces of an insulating substrate, or insulating substrates are formed on both the front and back surfaces of a resistive layer, that in the former, protective films are formed on the central portions of the resistive layers in the longitudinal direction and surface and back electrodes are formed on the resistive layers on both sides of the protective films, and in the latter, surface and back electrodes are formed on the resistive layers on both sides of the substrates, and that in both the former and latter, end surface electrodes are provided at both ends in the width direction.

Owner:KAMAYA ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com