Polypyrrole/nanometer platinum composite conductive fiber and preparation method thereof

A technology of composite conductive and conductive fibers, applied in the directions of synthetic fibers, fiber processing, natural fibers, etc., can solve the problems of poor bonding strength of metal conductive layers and high cost of precious metals, so as to compensate for unstable conductivity, simple synthesis methods, and compatibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) In situ synthesis of polypyrrole layer

[0033] After cleaning the cotton fiber, soak it in 1.0mol / L ferric chloride solution for 25min, dry it naturally or dry it at room temperature, then put the treated fiber into a closed container filled with pyrrole vapor to react at 0°C 20 min, and finally washed with ethanol and deionized water respectively, and dried naturally or oven-dried to obtain the conductive fiber A.

[0034] 2) In situ synthesis of nano-platinum-polypyrrole layer

[0035] Soak the conductive fiber A in an aqueous solution of chloroplatinic acid with a concentration of 0.7mol / L for 1 hour, then immerse it in an aqueous solution of pyrrole with a concentration of 0.03mol / L, react at room temperature for 6 hours, and finally wash it with ethanol and deionized water respectively, and let it dry naturally. After drying or drying, the polypyrrole / nano-platinum composite conductive fiber can be obtained.

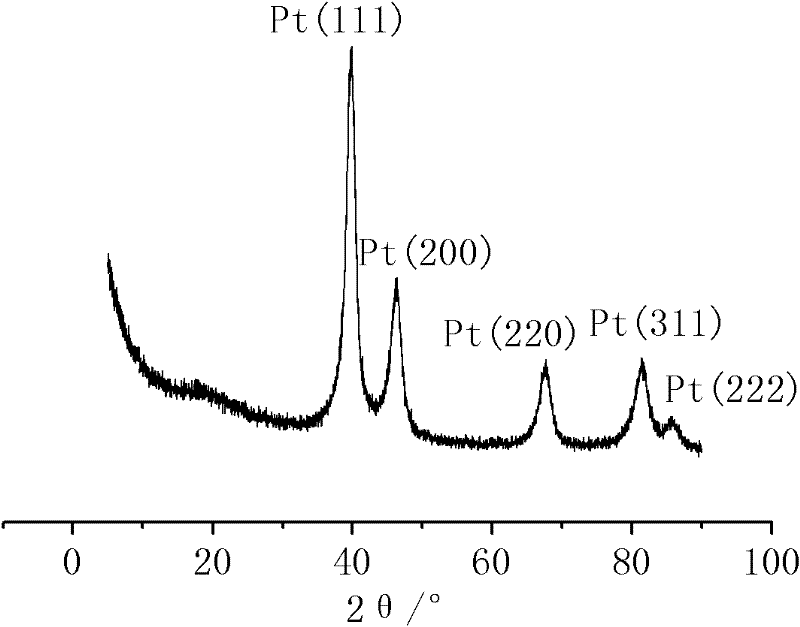

[0036] From figure 1 The scanning electron micro...

Embodiment 2

[0041] 1) In situ synthesis of polypyrrole layer

[0042] After cleaning the viscose fiber, soak it in 0.5mol / L ferric chloride solution for 20min, let it dry naturally or dry at room temperature, then put the treated fiber into a closed container filled with pyrrole steam at 10°C React for 10 minutes, and finally wash with ethanol and deionized water respectively, and dry naturally or dry to obtain the conductive fiber A.

[0043] 2) In situ synthesis of nano-platinum-polypyrrole layer

[0044] Soak conductive fiber A in chloroplatinic acid aqueous solution with a concentration of 1.0mol / L for 1.5h, then immersed in an aqueous solution of pyrrole with a concentration of 0.1mol / L, react at room temperature for 8h, and finally wash with ethanol and deionized water respectively. Drying or drying can obtain the polypyrrole / nano-platinum composite conductive fiber.

[0045] The thickness of the polypyrrole layer in the resulting composite conductive fiber is about 100nm, the thi...

Embodiment 3~5

[0046] Embodiment 3~5: preparation method is the same as embodiment 1~2, changes each processing condition, and the results are shown in Table 1:

[0047] Table 1

[0048] serial number

[0049] Soaking time in chloroplatinic acid solution (h)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com