Conductive rubber composition, conductive rubber roller, and image forming device

A rubber composition and conductivity technology, applied in the fields of electric recording technology using charge pattern, equipment for electric recording technology using charge pattern, and electrography, etc., can solve the problems of suppressing resistance rise, complex mechanism, transfer voltage control, etc. Difficulty and other problems, to achieve the effect of excellent energization durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited by the following examples, and modifications and embodiments within the scope of the present invention are included in the scope of the present invention.

[0105] [Evaluation method]

[0106] (1) Resistance value

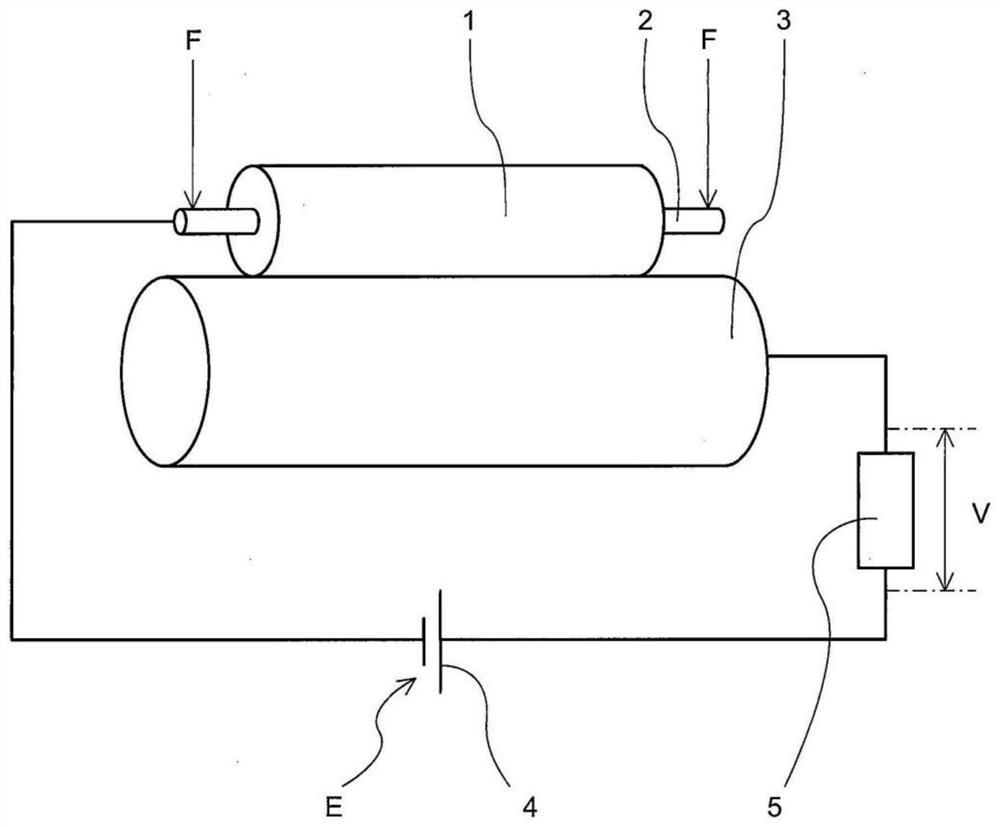

[0107] like image 3 As shown, a conductive rubber roller 1 through which a metal shaft 2 is inserted is supported and disposed above the metal cylinder 3 so that the conductive rubber roller 1 is in contact with the metal cylinder 3 . A DC power supply 4 and a resistor 5 were connected in series between the metal shaft 2 and the metal cylinder 3 to fabricate a resistance value measurement circuit. Furthermore, the DC power supply 4 is connected to the metal shaft 2 on the - side, and connected to the resistor 5 on the + side.

[0108] A load F of 500 gf was applied to both ends of the metal shaft 2, the conductive rubber roller 1 was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com